Biodegradable material and preparation method and application thereof

A degradable material and biological technology, applied in medical science, prosthesis, etc., can solve the problems of self-healing effect and poor tensile strength, and achieve good healing effect, simple and easy reaction process, and good stretching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

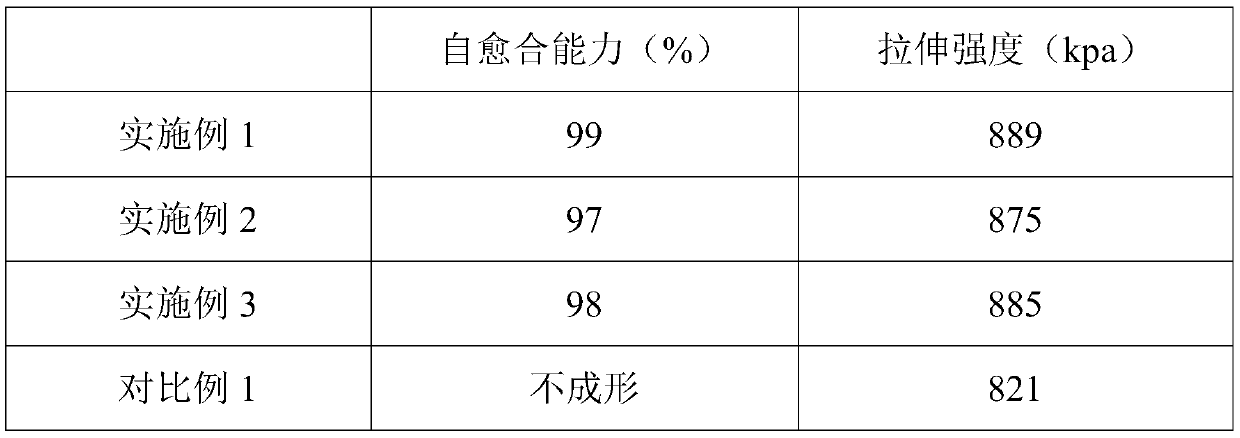

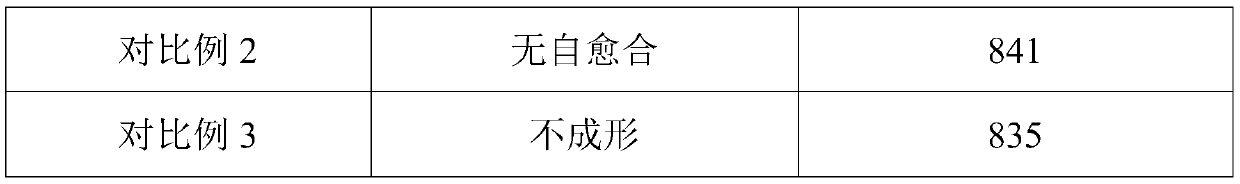

Examples

preparation example Construction

[0024] The embodiment of the present invention also provides the preparation method of the above-mentioned biodegradable material, the method comprising the following steps:

[0025] Step 1, adding α-hydroxy acid to sodium polyphosphate, fully stirring and reacting to obtain a mixed solution;

[0026] Step 2, adding RAPA and malic acid to the mixed solution obtained in step 1, fully stirring and reacting to obtain a mixed fluid;

[0027] In step 3, the mixed fluid obtained in step 2 is washed with absolute ethanol and freeze-dried to obtain a biodegradable material.

[0028] Further, in step 1, the reaction temperature is 20-40°C, and the reaction time is 6-8d.

[0029] Further, in step 2, the reaction temperature is 20-40°C, and the reaction time is 2-3d.

[0030] The present invention prepares a fully degradable polymer with good healing effect and good stretching effect by blending α-hydroxy acid, sodium polyphosphate malate and rigid polymer RAPA in a certain proportion ...

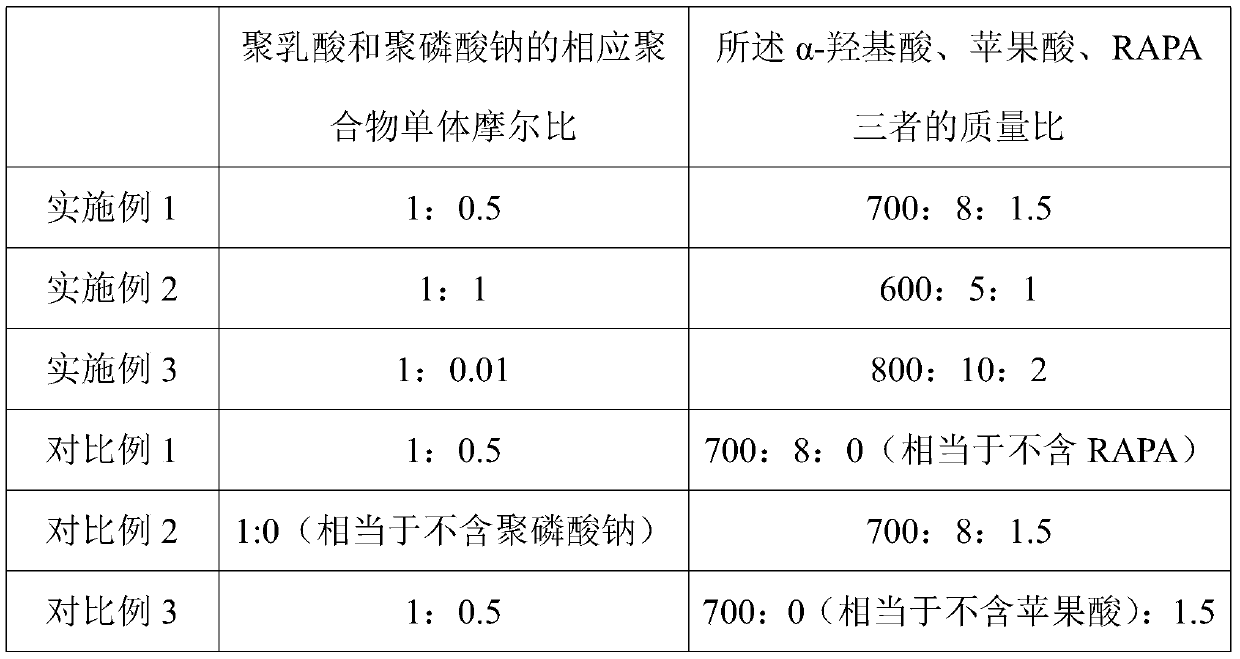

Embodiment 1

[0032] This embodiment provides a biodegradable material, including polylactic acid, malic acid, sodium polyphosphate, and RAPA;

[0033] Among them, the corresponding polymer monomer molar ratio of polylactic acid and sodium polyphosphate is 1:0.5; the mass ratio of polylactic acid, malic acid, and RAPA is 700:8:1.5;

[0034] The above-mentioned biodegradable materials are specifically prepared by the following method:

[0035] Step 1, adding polylactic acid to sodium polyphosphate, fully stirring and reacting at 20-40°C for 6-8 hours to obtain a mixed solution;

[0036] Step 2, adding RAPA and malic acid to the mixed solution obtained in step 1, adding to the reaction solution obtained in step 1, fully stirring and reacting at 20-40°C for 2-3 hours to obtain a mixed fluid;

[0037] In step 3, the mixed fluid obtained in step 2 is washed with absolute ethanol and freeze-dried to obtain a biodegradable material.

Embodiment 2

[0039] This embodiment provides a biodegradable material prepared from polylactic acid, malic acid, sodium polyphosphate, and RAPA;

[0040] Among them, the corresponding polymer monomer molar ratio of polylactic acid and sodium polyphosphate is 1:1; the mass ratio of polylactic acid, malic acid, and RAPA is 600:5:1;

[0041] The above-mentioned biodegradable materials are specifically prepared by the following method:

[0042] Step 1, adding polylactic acid to sodium polyphosphate, fully stirring and reacting at 20-40°C for 6-8 hours to obtain a mixed solution;

[0043] Step 2, adding RAPA and malic acid to the mixed solution obtained in step 1, adding to the reaction solution obtained in step 1, fully stirring and reacting at 20-40°C for 2-3 hours to obtain a mixed fluid;

[0044] In step 3, the mixed fluid obtained in step 2 is washed with absolute ethanol and freeze-dried to obtain a biodegradable material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com