Freeze-dry process preparation method of bulk vegetable egg flower soup base

A technology of egg drop soup and vegetables, applied in food preparation, application, food science, etc., can solve problems such as increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of freeze-drying process preparation method of bulk vegetable egg drop soup stock, its steps are:

[0023] 1. Spinach processing: select spinach that is disease-free and non-rotten, and remove impurities by cutting the root, cleaning, cutting into sections, blanching and sterilization, cooling, draining, spreading, putting on shelves, quick-freezing, freeze-drying, and leaving the warehouse for later use.

[0024] 1.1 Arrangement of spinach: select spinach that is disease-free and non-rotten, remove impurities by cutting the roots, wash, cut into sections, blanching and sterilization, cooling, draining, and set aside;

[0025] 1.2 Spreading the tray: Evenly spread the spinach processed in step 1.1 in the material tray and then put it on the material shelf cart;

[0026] 1.3 Quick-freezing: push the material shelf cart into the quick-freezing warehouse for quick-freezing, keep the warehouse temperature at -25°C, and quick-freeze for 200 minutes;

[0027] 1.4 Free...

Embodiment 2

[0048] The preparation method of bulk freeze-dried tomato egg drop soup, the steps are:

[0049] 1. Tomato processing: select tomatoes without disease, rot and deterioration, remove impurities by cutting the roots, wash, slice, cook and sterilize, cool, plate, put on shelves, quick-freeze, freeze-dry, and leave the warehouse for later use;

[0050] 1.1 Tomato sorting: select tomatoes without disease and rot, remove impurities by cutting the roots, wash, cut, cook and sterilize, cool, and prepare tomatoes for use;

[0051] 1.2 Spreading the tray: spread the processed tomatoes evenly in the material tray and then put it on the material shelf cart;

[0052] 1.3 Quick-freezing: push the material shelf cart into the quick-freezing warehouse for quick-freezing, keep the warehouse temperature at -28°C, and quick-freeze for 220 minutes;

[0053] 1.4 Freeze-drying: Push the material shelf cart into the freeze-drying warehouse from the quick-freezing warehouse, start the condensation s...

Embodiment 3

[0065] 1. the making of freeze-dried parsley section is with embodiment 1;

[0066] 2. the making of freeze-dried carrot slices is with embodiment 1;

[0067] 3. Egg flower production is the same as in Example 1;

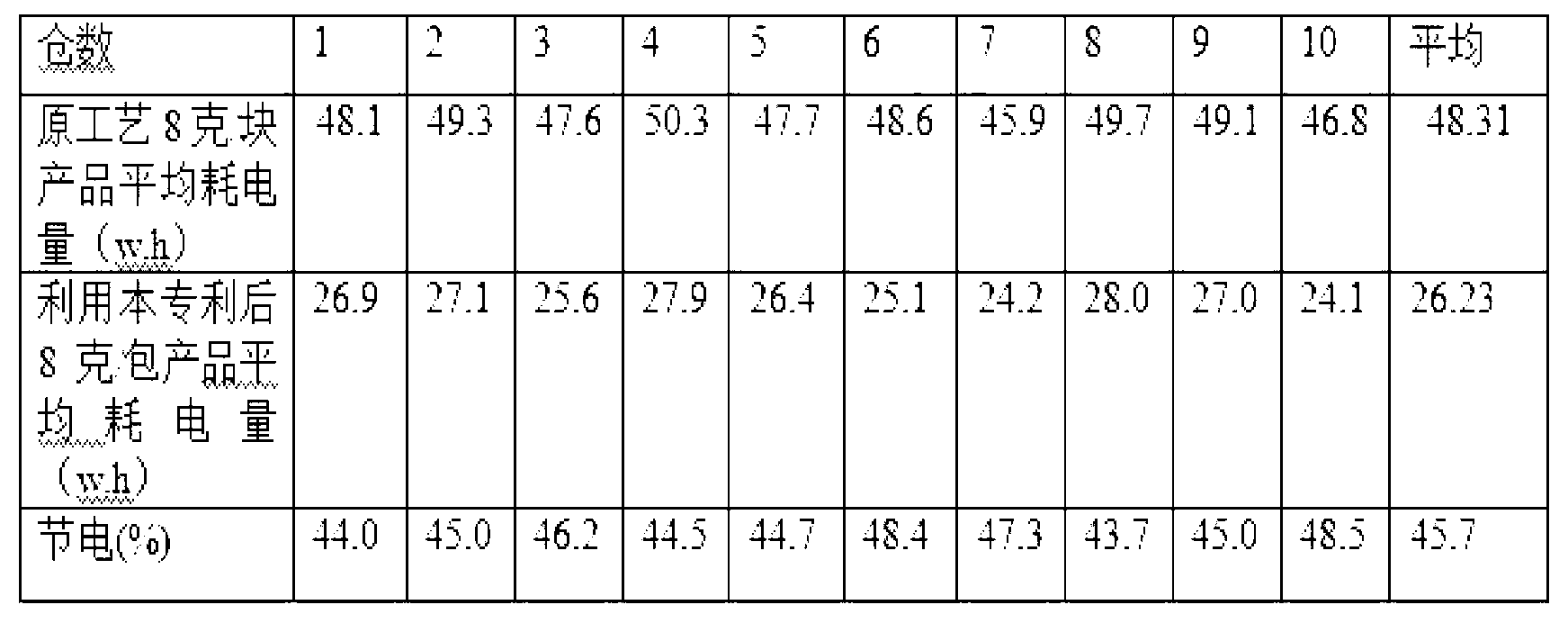

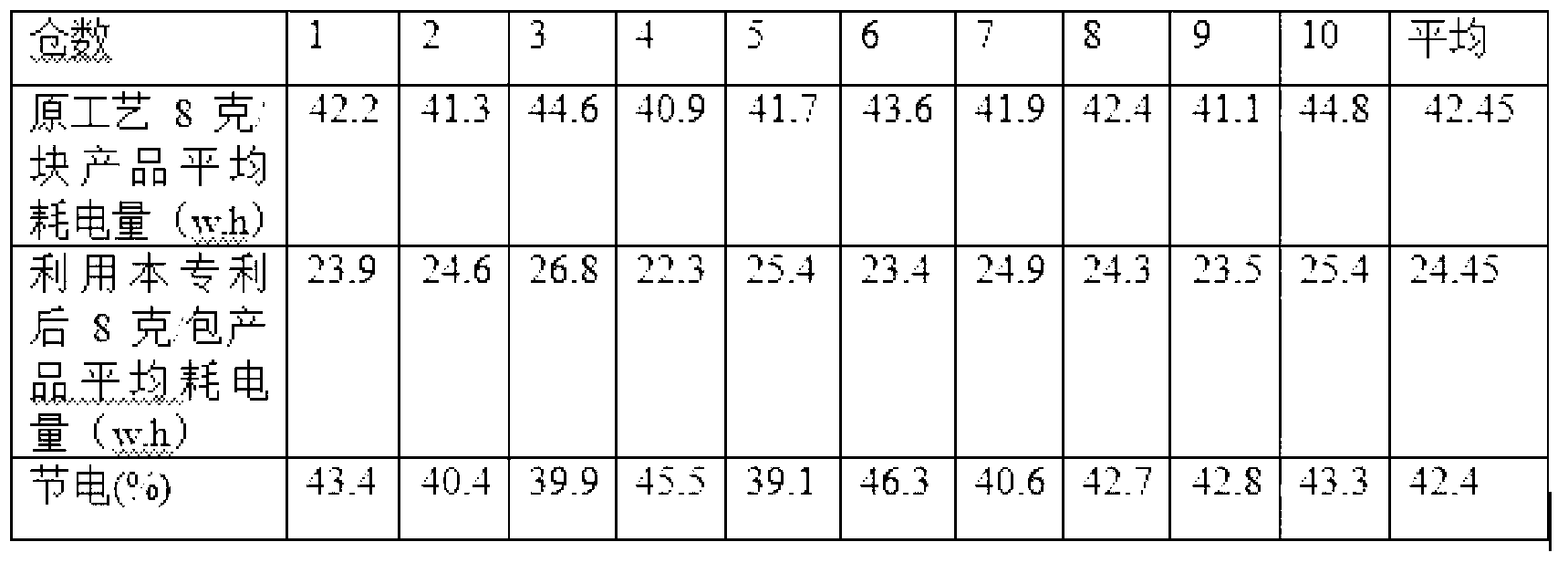

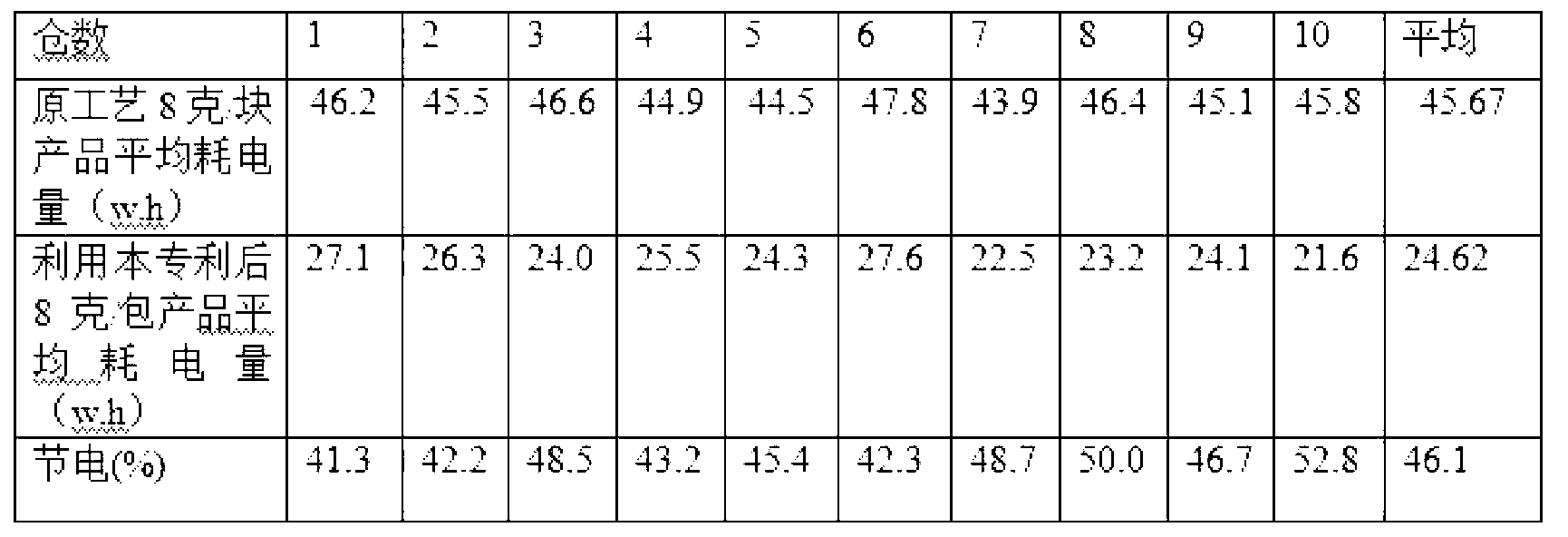

[0068] 4. Freeze-dried coriander, carrot slices, egg flower and seaweed, chicken essence, maltodextrin, white sugar, refined edible salt, I+G (taste nucleotide disodium) seasoning obtained in steps 1, 2, and 3 , by mass percentage laver 27%, freeze-dried carrot slices 5%, freeze-dried coriander 3%, freeze-dried egg flower 35%, maltodextrin 11.1%, chicken essence 3.5%, refined edible salt 11.1%, white sugar 3.5%, I +G (flavored nucleotide disodium) 0.8% is weighed and packaged to obtain the finished product after the bulk freeze-dried seaweed egg flower soup package. After detailed tracking and calculation, the same weight of 8 grams made by this embodiment The energy cost of the freeze-dried laver bulk egg drop soup was 46.1% lower than that of the traditional fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com