Freeze drying preparation method of fruit and vegetable crisp slices

A technology of vacuum freeze-drying and crispy vegetables, which is applied in the fields of fruit and vegetable preservation, food preservation, food science, etc., to achieve the effects of broadening the market, accelerating water sublimation, and avoiding uneven appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

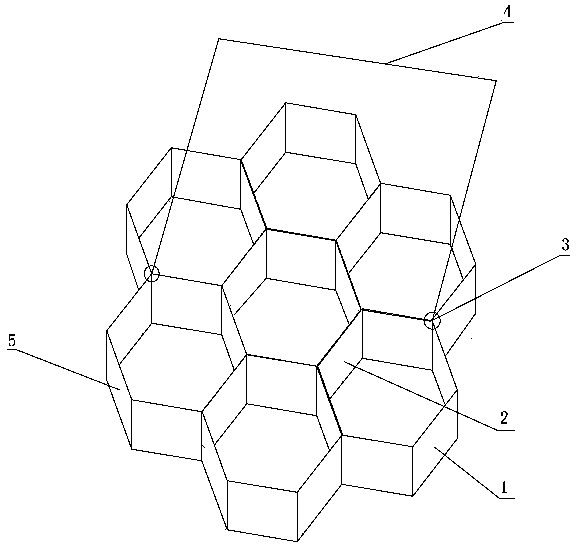

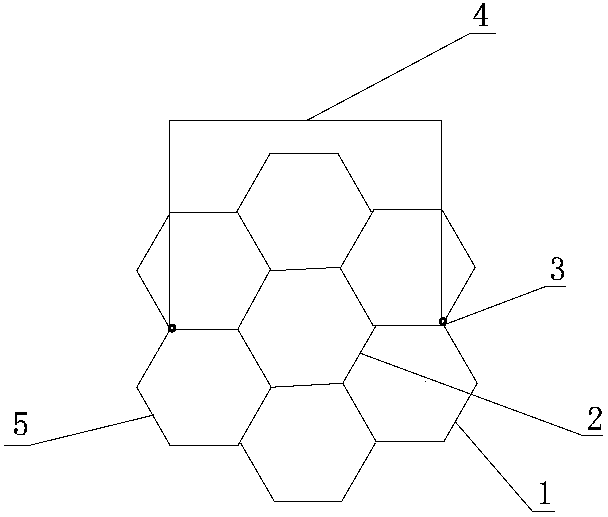

Image

Examples

Embodiment 1

[0024] Banana crisp slices, peel fully ripe bananas, take 50 kg of flesh, cut into 5mm thick pulp slices, and quickly put them into a constant temperature heating blanching pool at 85°C. After blanching for 2 minutes, transfer to a 4°C precooling The color pool and color protection solution use 0.03% cysteine hydrochloride, 0.5% citric acid, 0.2% sodium erythorbate, 0.1% sodium phytate, 30% maltodextrin and 5% β-cyclodextrin. After the pulp slices are cooled in the color protection pool for 5 minutes, take 15 liters of the color protection solution and 50 kg of pulp into a beater to mix and beat. Insert an integrated grid metal mold that has been soaked in 1% sodium alginate aqueous solution and dried into a film, and arrange it tightly and compact it as much as possible. Freeze slowly at -30°C for 5 hours. Vacuum freeze-drying conditions are: vacuum degree 30Pa, shelf temperature is set to rise at 3°C per hour, when the temperature reaches 10°C, keep the temperature for ...

Embodiment 2

[0026] Mango crisp slices, fully mature mangoes, peeled, pitted, 50 kg of pulp, and 20 kg of 4 ℃ pre-cooled color protection solution, using 0.5% sodium erythorbate and 0.2% sodium phytate , 20% maltodextrin and 2% β-cyclodextrin, after fully mixing and homogenizing, pour it into a freeze-drying tray with a thickness of 10mm, insert the integrated, soaked in 0.5% aqueous solution of konjac glucomannan and Form a dry grid metal mold, and arrange it tightly and compact it as much as possible. Freeze slowly at -30°C for 5 hours. Vacuum freeze-drying conditions are: vacuum degree 30Pa, shelf temperature set at 5°C per hour, when the temperature reaches 10°C, keep the temperature for 1 hour, continue to heat up at 5°C per hour, when it reaches 40°C, keep the temperature for 2 hours , drying ends. In an operating room with a temperature of 20°C and a humidity of 35%, small packages of 2-5 pieces per bag are used for sealing, and each large package contains a portion of deoxidizing...

Embodiment 3

[0028] Pitaya crisp slices, take 50 kg of pitaya pulp, beat with 15 kg of 4 ℃ pre-cooled color protection solution, use 0.5% sodium erythorbate, 0.1% citric acid, 10% maltodextrin and 3% β-cyclodextrin, fully mixed and homogeneous, poured into a freeze-drying tray with a thickness of 8mm, inserted into an integrated grid metal mold soaked in 1.5% sodium carboxymethylcellulose aqueous solution and dried to form a film , slow freezing at -30°C for 5 hours. Vacuum freeze-drying conditions are: vacuum degree 30Pa, shelf temperature is set to rise at 4°C per hour, when the temperature reaches 10°C, keep the temperature for 1 hour, continue to heat up at 6°C per hour, when it reaches 40°C, keep the temperature for 2 hours , drying ends. In the operating room with a temperature of 20°C and a humidity of 30%, 2-5 small packages per bag are used to seal, and each large package contains a deoxidizing dehumidifier, which is flushed with nitrogen and sealed, and leaves the factory after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com