Production method of straight rice noodle made of broken rice

A technology of straight rice noodles and production methods, which is applied in the fields of application, food preparation, food science, etc., can solve the problems of restricting the development of the rice noodle industry, adding too much broken rice, and the large amount of rice noodle spit out, so as to achieve good development prospects and improve Utilization rate, fast rehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

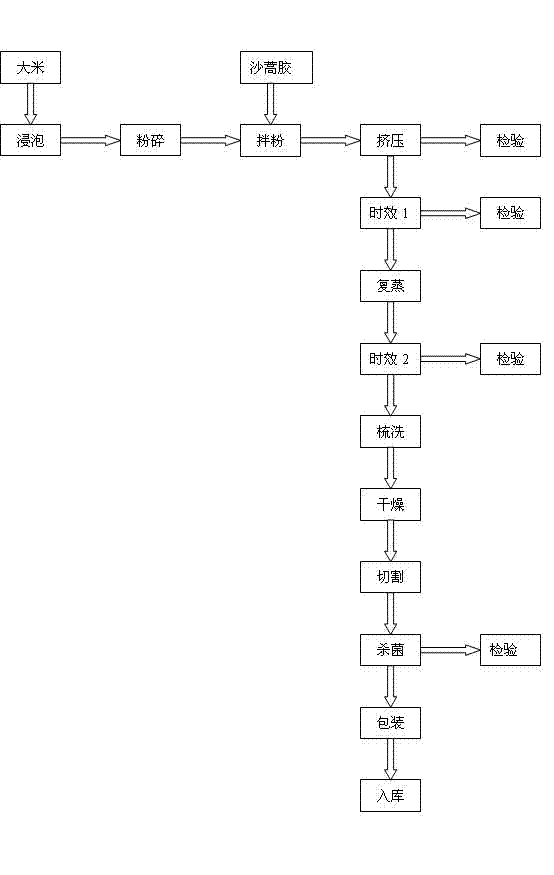

Method used

Image

Examples

Embodiment 1

[0042] (1) Raw materials: 37.5kg of early indica rice, 12.5kg of early indica broken rice and 12.5kg of late indica rice were mixed, sanded and washed;

[0043] (2) Soaking: Soak the cleaned raw materials in water, the ratio of water to rice is required to be 1.5:1, and the soaking time is 3 hours;

[0044] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill (0.6mm mesh screen);

[0045] (4) Powder mixing: use a powder mixing machine to mix the pulverized material and 0.125kg of Artemisia gum evenly, and make the water content 30%;

[0046] (5) Extrusion: The mixed materials are squeezed through a twin-screw extruder, and the freshly squeezed rice noodles are preliminarily evacuated and cut under the action of a fan;

[0047] (6) Aging 1: Send the extruded rice vermicelli into an environment with a certain temperature (35±1°C) and a certain humidity (90%) for aging for 20 hours;

[0048] (7) Re-steaming: Send the rice noodles wit...

Embodiment 2

[0056] (1) Raw material: mix 20kg of early indica rice, 10kg of early indica broken rice and 10kg of late indica broken rice, sand and wash;

[0057] (2) Soaking: Soak the cleaned raw materials in water, the ratio of water to rice is required to be 1.5:1, and the soaking time is 4 hours;

[0058] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill (0.6mm mesh screen);

[0059] (4) Powder mixing: use a powder mixing machine to mix the pulverized material and 0.1kg of Artemisia gum evenly, and make the water content 30%;

[0060] (5) Extrusion: Extrude the mixed materials through a twin-screw extruder, and the freshly extruded rice noodles are preliminarily evacuated and cut under the action of the fan;

[0061] (6) Aging 1: Send the extruded rice vermicelli into an environment with a certain temperature (35°C) and a certain humidity (85%) for 19 hours;

[0062] (7) Re-steaming: Send the rice noodles with aging 1 into the steaming ...

Embodiment 3

[0070] (1) Raw material: mix 25kg early indica rice, 25kg early indica broken rice, 5kg late indica rice and 5kg late indica broken rice, sand and wash;

[0071] (2) Soaking: Soak the cleaned raw materials in water, the ratio of water to rice is required to be 1.5:1, and the soaking time is 2.5 hours;

[0072] (3) Crushing: After the raw rice is fully soaked and drained, it is pulverized with a hammer mill (0.6mm mesh screen);

[0073] (4) Powder mixing: use a powder mixing machine to mix the pulverized material and 0.12kg of gluten enhancer evenly, and make the water content 30%;

[0074] (5) Extrusion: Extrude the mixed materials through a twin-screw extruder, and the freshly extruded rice noodles are preliminarily evacuated and cut under the action of the fan;

[0075] (6) Aging 1: Send the extruded rice vermicelli into an environment with a certain temperature (36°C) and a certain humidity (80%) for aging for 20 hours;

[0076] (7) Re-steaming: Send the rice noodles with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com