Preparation method for coarse cereal food

A technology for food and miscellaneous grains, applied in food preparation, food science, application, etc., can solve the problems of unsanitary, human health hazards, nutrient destruction, etc., and achieve the effect of fast rehydration and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

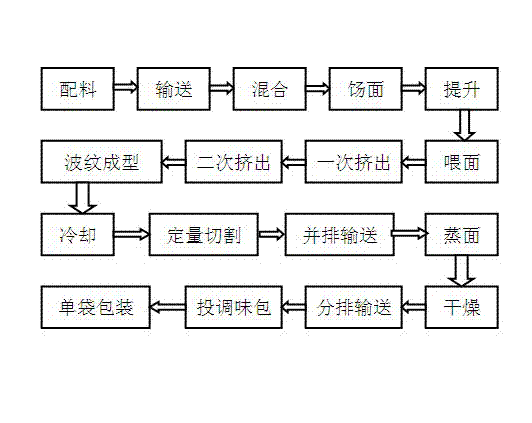

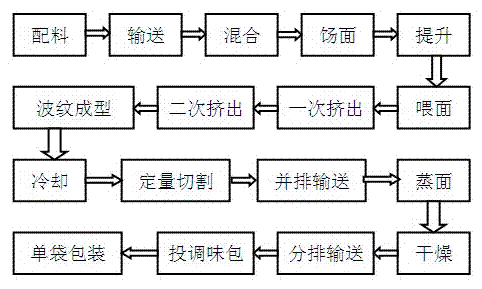

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of preparation method of multigrain food, comprises the following steps:

[0028] Step 1. Ingredients: Potato starch, buckwheat flour, corn flour, wheat flour and sweet potato flour are the main ingredients. The weight ratio is: potato starch 28%, buckwheat flour 22%, corn flour 18%, wheat flour 20%, sweet potato flour 12% %; then add an appropriate amount of compound additives, the best ratio between the additives is: modified starch: 65.8%; compound phosphate: 5.7%; gluten enhancer: 21.9%; emulsifier: 6.6%;

[0029] Step 2. Conveying: Send the ingredients into the mixer;

[0030] Step 3. Mixing: Add pure water into the mixer according to the material-to-water ratio of 4:1, start the mixer, and fully mix the material and water for 10 minutes to form a dough;

[0031] Step 4, noodles: let the dough rest for 50 minutes;

[0032] Step 5. Elevation: Use the elevator to elevate the dough to the noodle feeding machine;

[0033] Step 6. Noodle feeding:...

Embodiment 2

[0045] Embodiment 2: a kind of preparation method of multigrain food, comprises the following steps:

[0046] Step 1. Ingredients: Mung bean flour, potato starch, buckwheat flour, corn flour, wheat flour and sweet potato flour are the main ingredients. The weight ratio is: mung bean flour 7%, potato starch 26%, buckwheat flour 21%, corn flour 16% , wheat flour 19%, sweet potato flour 11%, and then add appropriate amount of compound additives, the best ratio between the additives is: modified starch: 65.8%; compound phosphate: 5.7%; gluten enhancer: 21.9%; emulsifier: 6.6 %;

[0047] Step 2. Conveying: Send the ingredients into the mixer;

[0048] Step 3. Mixing: Add pure water into the mixer according to the material-to-water ratio of 4:1, start the mixer, and fully mix the material and water for 10 minutes to form a dough;

[0049] Step 4, noodles: let the dough rest for 60 minutes;

[0050] Step 5. Elevation: Use the elevator to elevate the dough to the noodle feeding mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com