Method for producing hydrated solidified body, and hydrated solidified body

A manufacturing method and a technology for a solidified body, which are applied in the directions of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as processing difficulties, and achieve the effect of high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

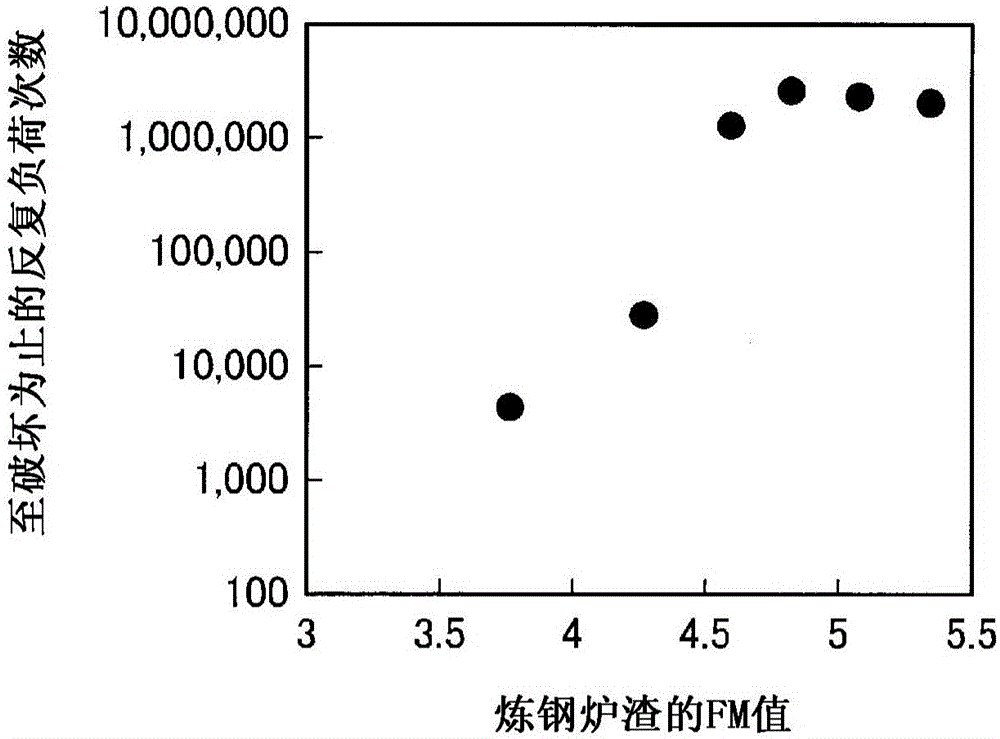

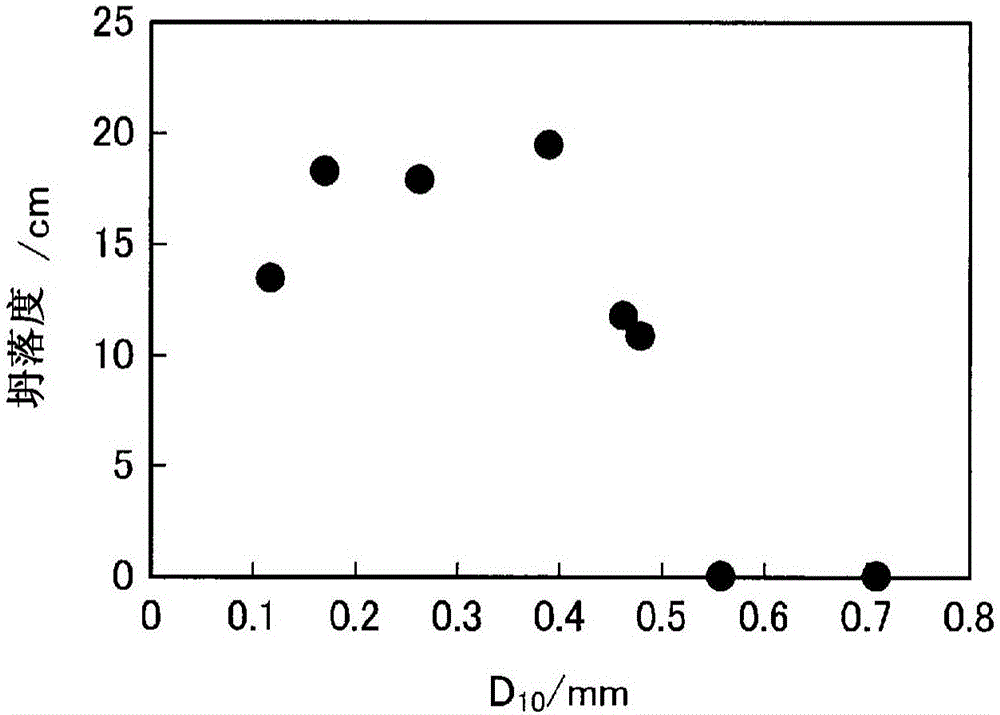

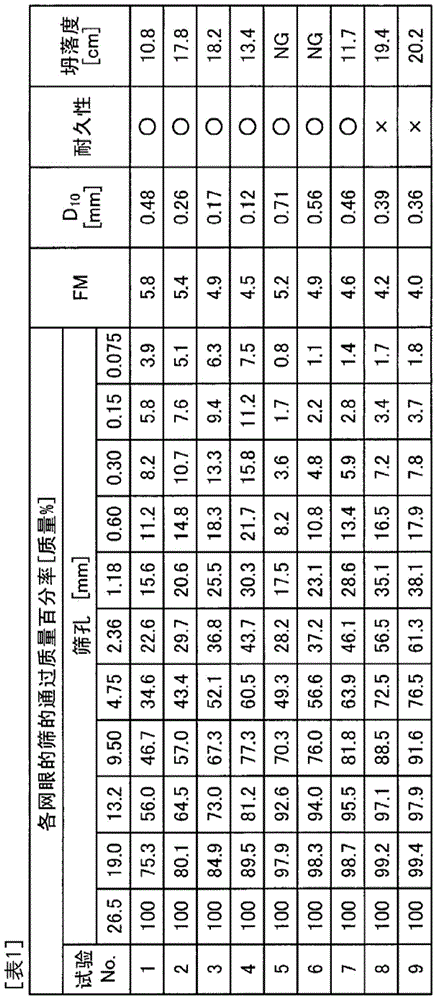

[0051] In this example, the hydrated solidified body was produced using the powdery steelmaking slag whose particle size was adjusted. As the granular steelmaking slag, molten iron pretreatment slag generated when dephosphorizing blast furnace molten iron tapped from a blast furnace is used. In addition, blast furnace granulated slag fine powder and fly ash were used as a binding material, and ordinary Portland cement was used as an alkali stimulating material. The particle size, FM value and D of the steelmaking slag used in the test 10 It is selected as the scope of the present invention and the conditions for comparison. The granularity, FM value, and D at this time 10 are shown in Table 1.

[0052] The powdery steelmaking slag, caking material, alkaline stimulating material and water were kneaded using a mixer in the combination shown in Table 2. In order to evaluate the workability, after the slump of the kneaded product was measured by the slump test method of the Ja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com