Disintegrating magnesium-containing granular fertilizer and preparation method thereof

A technology for magnesium granules and fertilizers, which is applied in the field of disintegrating magnesium-containing granular fertilizers and their preparation, and can solve the problems of unspecified disintegration performance of magnesium-containing granular fertilizers, unspecified disintegration time limits of granular fertilizers, and reduced content of active ingredients in fertilizers, etc. , to achieve the effect of convenient mechanical fertilization, smooth particles and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

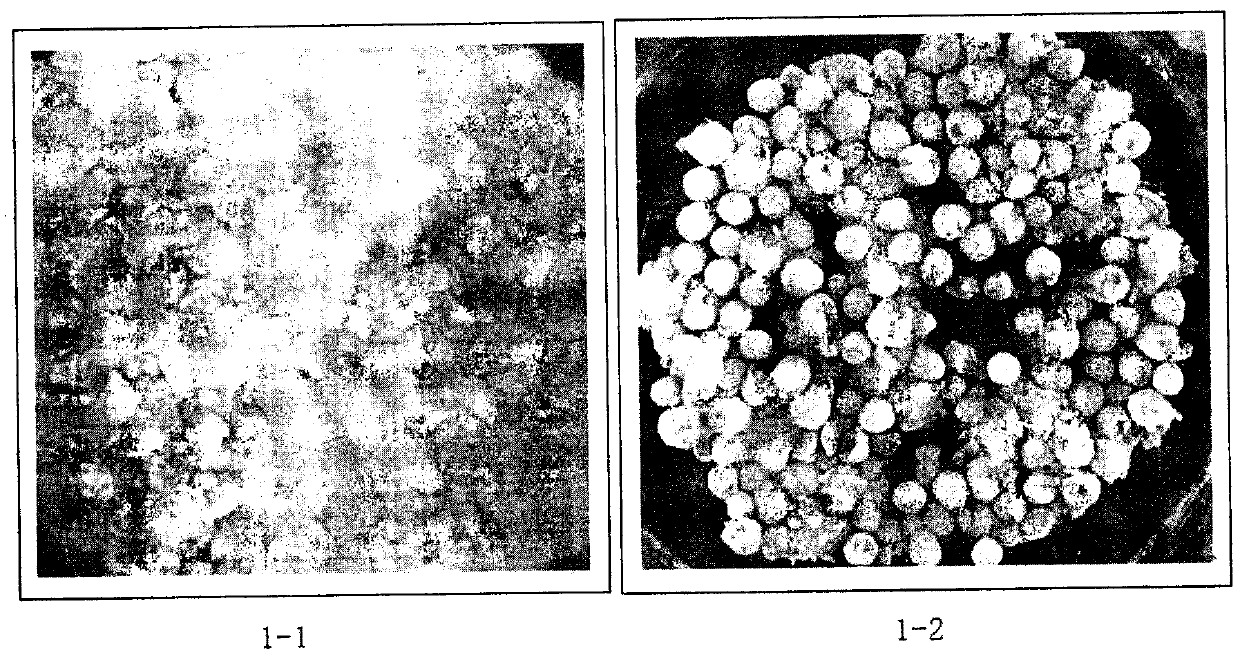

Embodiment 1

[0027] A disintegrating magnesium-containing granular fertilizer is provided in this example, which is prepared according to the following proportions and methods: (1) Prepare raw materials: take 80 kg of magnesium-containing raw materials (among them: brucite powder 65 kg, dolomite powder 15 kg) and mix evenly 20kg (wherein: magnesium sulfate monohydrate powder 17kg, magnesium carbonate powder 3kg) of balling aid is taken and mixed uniformly; Get oxalic acid and be dissolved in water, be mixed with the oxalic acid solution that 12kg mass concentration is 20%;

[0028] (2) Wetting treatment: put the magnesium-containing raw material mixed uniformly in the step (1) into the granulator, spray the organic acid solution prepared in the step (1) in the form of spray during operation, and perform wetting Wet acidification treatment;

[0029] (3) Balling and granulation: on the basis of step (2), alternately add the balling aid prepared in step (1) and spray organic acid solution to ...

Embodiment 2

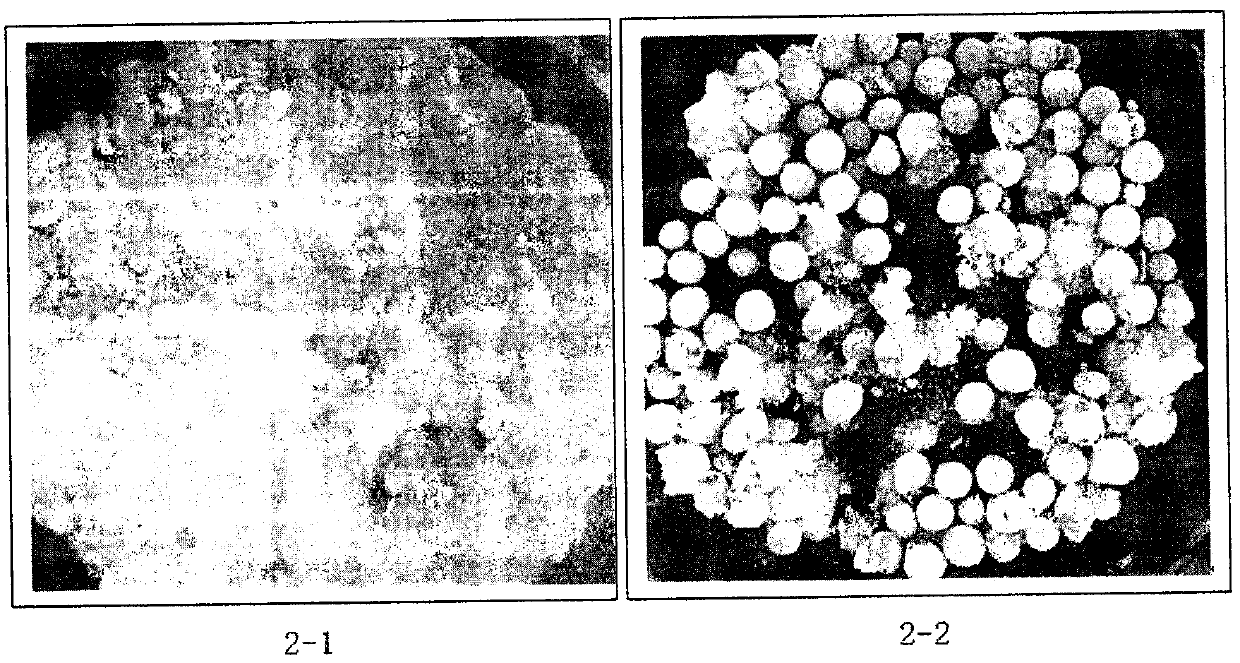

[0036] This example provides a disintegrating magnesium-containing granular fertilizer, which is prepared according to the following ratio and method:

[0037] (1) Prepare raw materials: take 85kg of magnesium-containing raw materials (including 70kg of brucite powder and 15kg of dolomite powder) and mix them evenly; The acid is dissolved in water, and 15kg of oxalic acid solution with a mass concentration of 15% is prepared;

[0038] (2) Wetting treatment: put the magnesium-containing raw material mixed uniformly in the step (1) into the granulator, spray the organic acid solution prepared in the step (1) in the form of spray during operation, and perform wetting Wet acidification treatment;

[0039] (3) Balling and granulation: on the basis of step (2), alternately add the balling aid prepared in step (1) and spray organic acid solution to carry out balling and granulation to obtain round granular materials; The disc inclination angle is 30°, and the rotation speed is 35-40r...

Embodiment 3

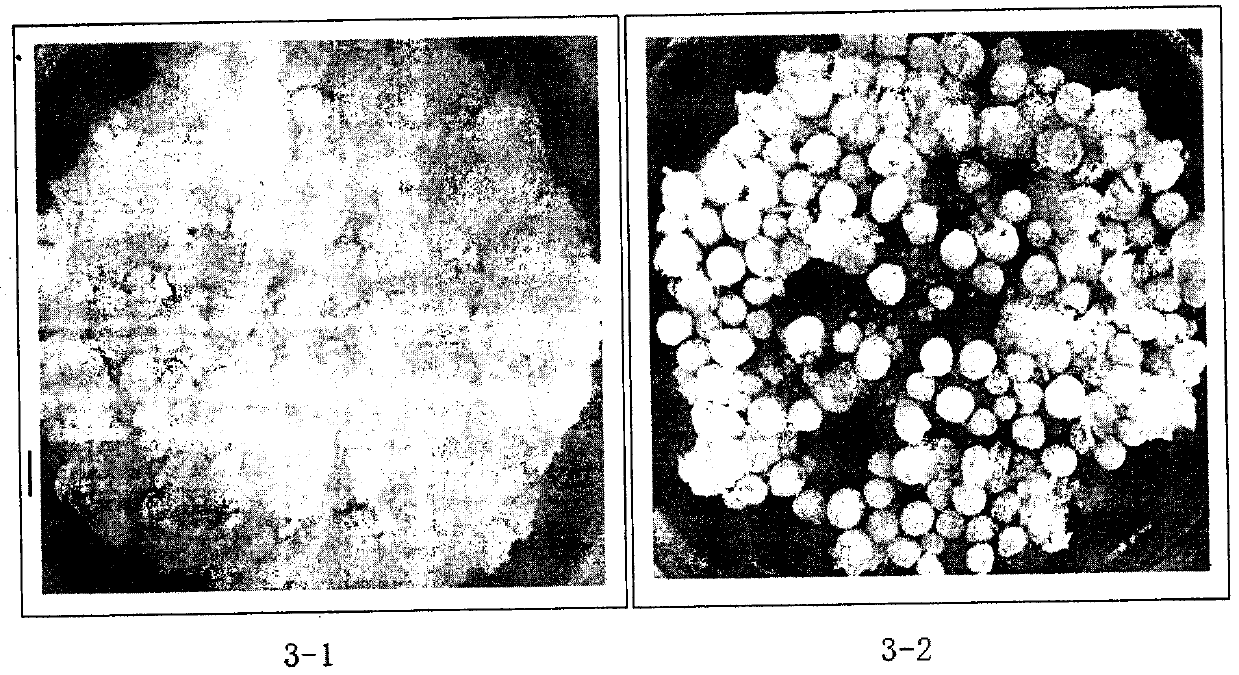

[0046] This example provides a disintegrating magnesium-containing granular fertilizer, which is prepared according to the following ratio and method:

[0047] (1) Prepare raw materials: take 90kg of magnesium-containing raw materials (including 75kg of brucite powder and 15kg of dolomite powder) and mix them evenly; Dissolve the acid in water, and prepare 16kg of oxalic acid solution with a mass concentration of 10%;

[0048] (2) Wetting treatment: put the magnesium-containing raw material mixed uniformly in the step (1) into the granulator, spray the organic acid solution prepared in the step (1) in the form of spray during operation, and perform wetting Wet acidification treatment;

[0049] (3) Balling and granulation: on the basis of step (2), alternately add the balling aid prepared in step (1) and spray organic acid solution to carry out balling and granulation to obtain round granular materials; The disc inclination angle is 30°, and the rotation speed is 35-40r / min; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com