A method for preparing layered lithium manganate cathode material by doping with low lithium-manganese ratio

A layered lithium manganate, cathode material technology, applied in the direction of positive electrode, battery electrode, active material electrode, etc., can solve the problems of low utilization rate of raw materials, uneven distribution, irregular morphology, etc. Uniform and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

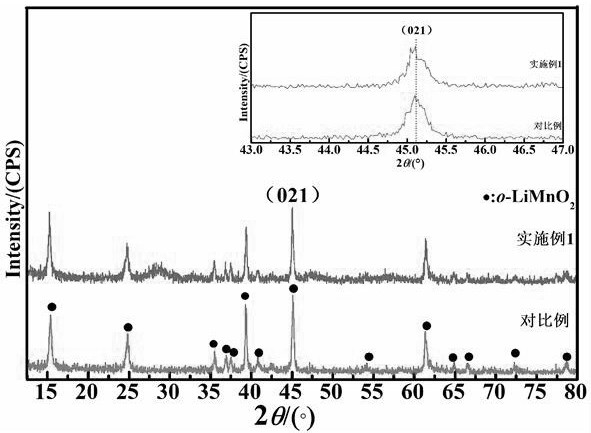

Embodiment 1

[0036] The present embodiment provides a low lithium-manganese ratio doped lithium battery cathode material layered lithium manganate preparation method, doped elements are Ce, comprising the following steps:

[0037] (a) The LiOH · H 2 O、Mn 2 O 3 and Ce(SO 4 ) 2 ·4H 2 O According to the molar ratio of 1:0.9:0.1, the ball ratio of 6:1, and the speed of 120 rpm / min ball grinding mixture are used to obtain the product containing Ce element;

[0038] (b) The product containing Ce element is mixed with KOH with deionized water to form a mixture of pH = 13.91, and then the mixture is put into a homogeneous reactor, and the catalyst liquid ammonia is added to do a homogeneous catalytic reaction, the homogeneous catalytic reaction temperature is 180 °C, the reaction time is 10h, and the uniform-phase reactor speed is 5 rpm;

[0039] (c) The product after the homogeneous catalytic reaction is washed, dried, and finally the target product is obtained o -LiCe 0.1 Mn 0.9 O 2 。

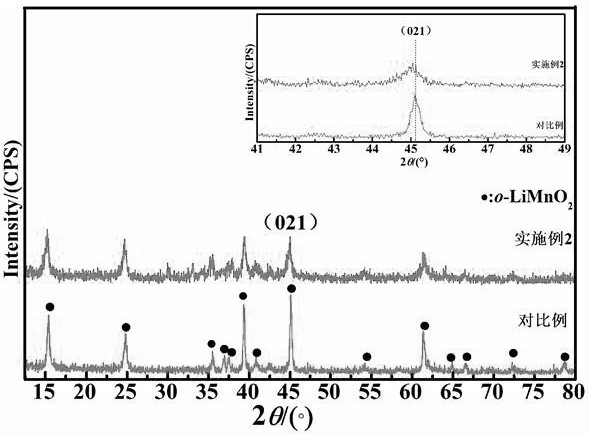

Embodiment 2

[0041] The present embodiment provides a low lithium-manganese ratio doped lithium battery cathode material layered lithium manganate preparation method, doped elements are Fe, comprising the following steps:

[0042] (a) The LiOH · H 2 O、Mn 2 O 3 and Fe 2 O 3 According to the molar ratio of 1:0.9:0.1, the ball ratio of 6:1, and the speed of 120 rpm / min ball grinding mixture are obtained to obtain the product containing Fe element;

[0043] (b) The product containing Fe element is mixed with NaOH with deionized water to form a mixture of pH = 13.93, and then the mixture is put into a homogeneous reactor, and the catalyst liquid ammonia is added to do a homogeneous catalytic reaction, the homogeneous catalytic reaction temperature is 180 °C, the reaction time is 10h, and the homogeneous reactor speed is 5 rpm;

[0044] (c) The product after the homogeneous catalytic reaction is washed, dried, and finally the target product is obtained o -LiFe 0.1 Mn 0.9 O 2 。

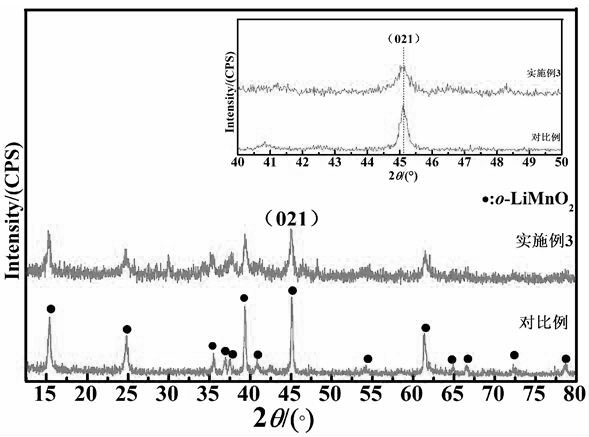

Embodiment 3

[0046] The present embodiment provides a low lithium-manganese ratio doped lithium battery cathode material layered lithium manganate preparation method, doped elements are Sr, comprising the following steps:

[0047] (a) The LiOH · H 2 O、Mn 2 O 3 and SrCO 3 According to the molar ratio of 1:0.9:0.1, the ball ratio of 6:1, the speed of 120 rpm / min ball grinding mixture to obtain products containing Sr element;

[0048] (b) The product containing Sr element is mixed with NaOH with deionized water to form a mixture of pH = 13.97, and then the mixture is put into a homogeneous reactor, and the catalyst liquid ammonia is added to do a homogeneous catalytic reaction, the homogeneous catalytic reaction temperature is 180 °C, the reaction time is 10h, and the homogeneous reactor speed is 5 rpm;

[0049] (c) The product after the homogeneous catalytic reaction is washed, dried, and finally the target product is obtained o -LiSr 0.1 Mn 0.9 O 2 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com