A kind of active material granulation method for zinc electrode

A technology of active material and zinc electrode, which is applied in the field of zinc-silver batteries, can solve the problems of uneven particle size distribution of active material, poor uniformity of zinc electrode, low production efficiency, etc., achieve good fluidity, uniform particle size, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

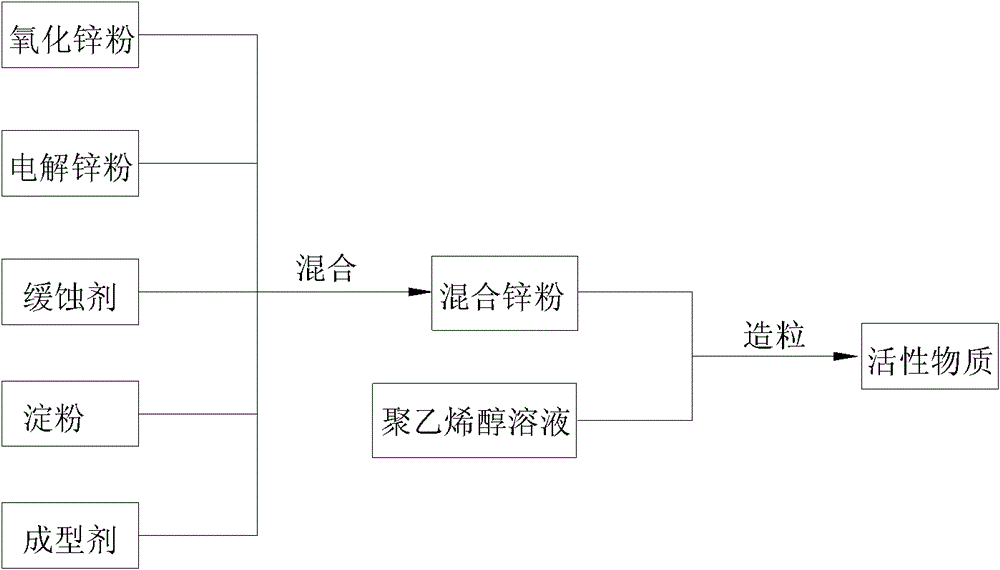

[0020] Embodiment: refer to attached figure 1 : Include the following steps:

[0021] (1) According to the weight ratio of zinc oxide powder: electrolytic zinc powder: corrosion inhibitor: starch: forming agent = 75: 25: 2: 2-4: 1-3, weigh 15 kg of zinc oxide powder, 5 kg of electrolytic zinc powder, and Mercury 0.4kg, cornstarch 0.4kg-0.8kg, plant cellulose 0.2kg-0.6kg, poured into a single-shaft powder mixer and mixed for 2 hours to form mixed zinc powder;

[0022] (2) Sieve the mixed zinc powder formed in step (1) with a 40-mesh sieve, and then mix 1kg of the sieved mixed zinc powder with 150ml - 200ml of 2% polyvinyl alcohol aqueous solution is directly poured into the three-cylinder powder mixer and mixed and granulated for 1h to 2h to form active substance granules;

[0023] (3) Use a 40-mesh sieve to sieve the active material particles in step (2) to produce the active material for the zinc electrode of the present invention.

[0024] by attaching figure 2 The zinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com