Ferrite rubber-plastic magnetic powder and preparation method thereof

A technology of rubber-plastic magnetic powder and ferrite, which is applied in the direction of chemical instruments and methods, magnetic materials, iron compounds, etc., can solve the problems of unsuitable for industrial production, complex process, high energy consumption, etc., and reduce labor costs and energy consumption costs , The preparation process is simple and the effect of less powder impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

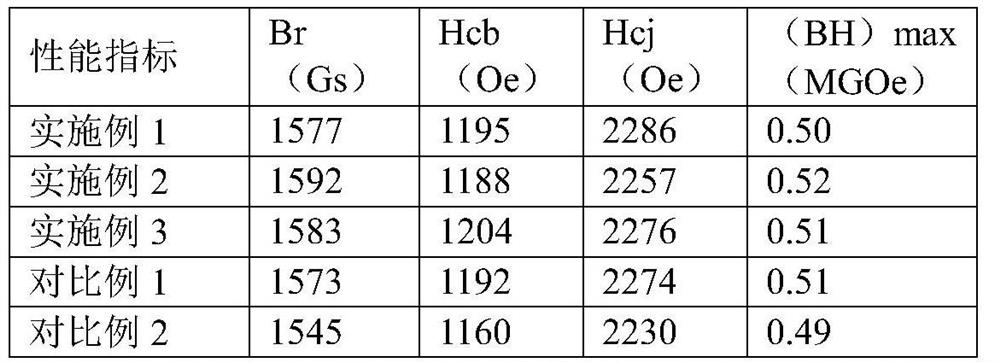

Examples

Embodiment 1

[0026] (1) finely grind iron and phosphorus, the particle size is 6 μm, then mix with barium carbonate at an element molar ratio of 11:1, and add 1wt% kaolin to the total weight of the mixture to obtain a mixture;

[0027] (2) Add water to the above-mentioned mixture to make pellets, and fire them in a rotary kiln at a temperature of 1200°C to form pre-fired pellets, and the particle size of the pellets is controlled within 10mm;

[0028] (3) put the ball material after pre-burning into a Raymond machine and pulverize it into a coarse powder with an average particle diameter of 6 μm;

[0029] (4) The coarsely pulverized powder is dry-milled by a jet mill to obtain a ferrite rubber-plastic magnetic powder with an average particle size of 2.5 μm.

Embodiment 2

[0031] (1) Mix iron red and strontium carbonate at an element molar ratio of 11.8:1 to obtain a mixture;

[0032] (2) Add water to the above-mentioned mixed material to form pellets, and fire them into pre-fired pellets at a temperature of 1150° C. in a rotary kiln. The particle size of the pellets is controlled within 10 mm;

[0033] (3) put the ball material after pre-burning into a Raymond machine and pulverize it into a coarse powder with an average particle diameter of 4 μm;

[0034] (4) Finely grind the coarse powder through a jet mill to obtain ferrite rubber and plastic magnetic powder with an average particle size of 1 μm.

Embodiment 3

[0036] (1) Finely grind iron and phosphorus with a particle size of 5 μm, add iron red with 30wt% iron and phosphorus mass, then mix with barium carbonate at an elemental molar ratio of 10.4:1, and add 0.5wt% kaolin of the total weight of the mixture to obtain a mixture material;

[0037] (2) Add water to the above mixture to make pellets, and fire them in a rotary kiln at a temperature of 1170° C. to form pre-fired pellets. The particle size of the pellets is controlled within 10 mm;

[0038] (3) put the ball material after pre-burning into a Raymond machine and pulverize it into a coarse powder with an average particle diameter of 5 μm;

[0039] (4) Finely grind the coarse powder through a jet mill to obtain ferrite rubber and plastic magnetic powder with an average particle size of 1.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com