Preparation method of carbon-containing polymer for preparing graphene three-dimensional structure powder material

A three-dimensional structure, powder material technology, applied in the field of preparing graphene three-dimensional structure powder material carbon-containing polymer, can solve the problems of high synthesis cost, incomplete reduction, high cost, etc., and achieve stable product quality and easy removal. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

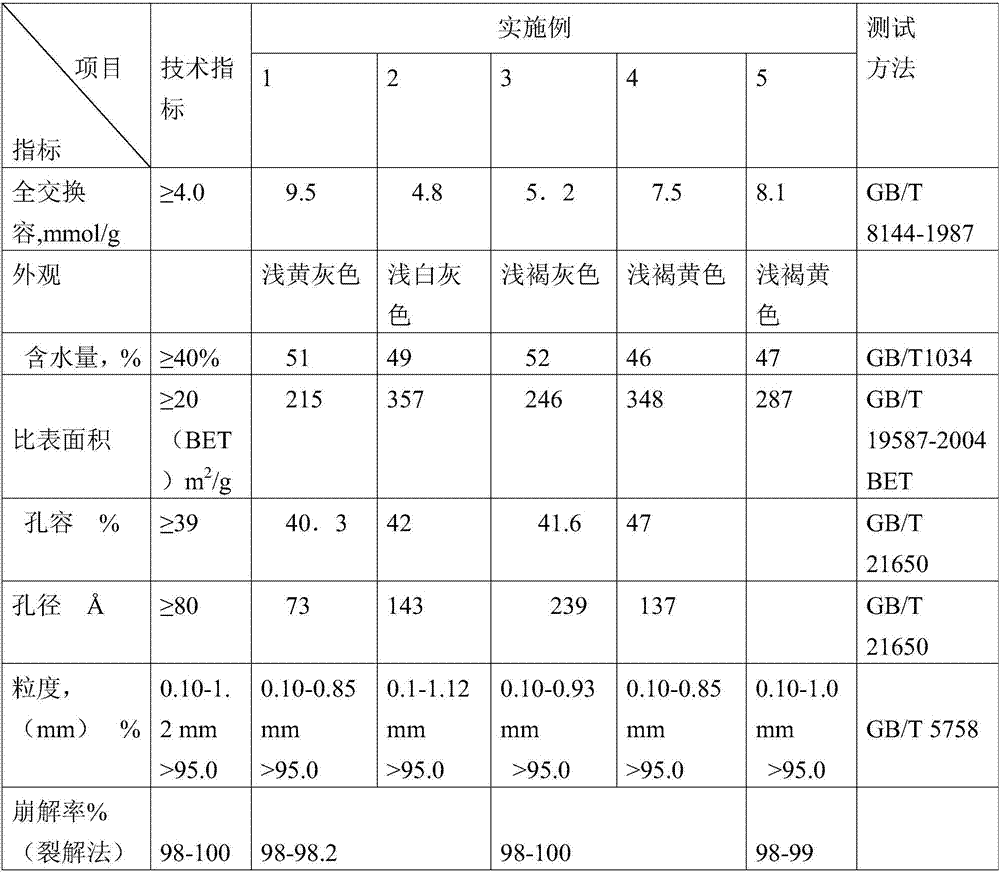

Examples

Embodiment 1

[0026] A method for preparing a graphene three-dimensional structure powder material carbon-containing polymer, the operation steps are as follows:

[0027] (1) Take by weighing 34.4% of polymerized monomer styrene (S), 11% of acrylic acid, 44% of acrylonitrile according to weight percentage, 4.5% of crosslinking agent monomer divinylbenzene (DVB), triallyl isocyanate ( TAIC) 4%, α-allyl itaconate 1%, initiator benzoyl peroxide (BPO) 0.4%, azodiethylbutyronitrile 0.2%, and then add cross-linking agent monomer to the polymerization monomer and the initiator monomer, fully stirred to dissolve the initiator monomer to obtain the monomer mixed phase, then add 35% porogen toluene of the gained monomer mixed phase by weight percentage, and stir evenly;

[0028] (2) Add the aqueous solution of 1.25 times of the weight of the monomer mixed phase obtained in step (1) in the reactor, and then account for 3.7% dispersant polyvinyl alcohol 2.3%, hydroxyethyl cellulose of the aqueous solut...

Embodiment 2

[0032] A method for preparing a graphene three-dimensional structure powder material carbon-containing polymer, the operation steps are as follows:

[0033] (1) Weigh 75.4% of polymerized monomer styrene (S), 6.8% of methyl acrylate, 8.2% of styrene-butadiene rubber / polystyrene / polyacrylate n-butyl acrylate prepolymer, crosslinking agent monomer iso Triallyl cyanate (TAIC) 9%, initiator benzoyl peroxide (BPO) 2.5% then add cross-linking agent monomer and initiator monomer in polymerized monomer styrene and methyl acrylate, fully stir Dissolve the initiator monomer, then add the obtained polymerized monomer styrene-butadiene rubber / polystyrene / polyacrylate n-butyl ester prepolymer, mix and stir evenly to obtain the monomer mixed phase, and then add the obtained monomer mixed phase 38% by weight porogen 200 # petrol, stir well;

[0034] (2) Add the aqueous solution of 1.25 times of the weight of the monomer mixed phase obtained in step (1) in the reaction kettle, then add the di...

Embodiment 3

[0038] A method for preparing a graphene three-dimensional structure powder material carbon-containing polymer, the operation steps are as follows: (1) take 59.2% of polymerized monomer styrene (S), polyurethane (PU) / poly n-butyl acrylic acid according to weight percentage (PBMA) prepolymer 5.5%, hydroxyethyl methacrylate (MEG) 6%, bis diurethane (OUDM) 7.8%, triisocyanate ethylene glycol 10.5%, crosslinking agent monomer two Vinylbenzene (DVB) 2.4%, triallyl isocyanate (TAIC) 3.6%, initiator benzoyl peroxide (BPO) 1.4%, azodiethylbutyronitrile 1.6%, and then polymerize monomer styrene (S), hydroxyethyl methacrylate (MEG), double diurethane (OUDM) and ethylene glycol triisocyanate, add crosslinking agent monomer and initiator monomer, stir fully to make the initiator Dissolve the monomer, then add the polyurethane (PU) / poly n-butyl acrylic acid (PBMA) prepolymer and mix and stir the gained to obtain the monomer mixed phase, then add 40% porogen in the weight percentage of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com