Tissue engineering artificial tendon scaffold enhanced body and preparation method thereof

A scaffold reinforcement and artificial tendon technology, applied in prosthetics, textiles and papermaking, medical science, etc., can solve the problems of scaffold fragmentation, in vitro construction or graft failure, etc., and achieve convenient operation and use, good biomechanical properties, and high mechanical strength effect of nature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

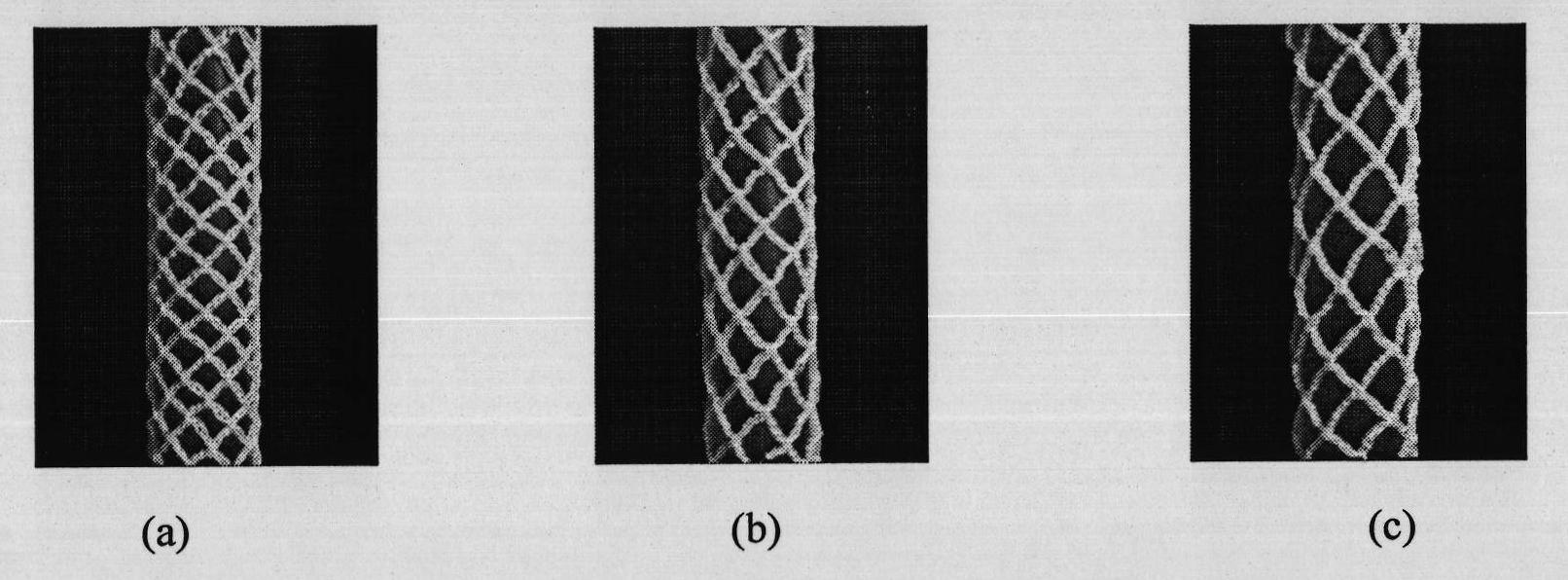

[0028] (1) Preparation of braided wire: 4 strands of PGA multifilament with a linear density of 0.43tex and 2 strands of PLA multifilament with a linear density of 0.56tex (the mixing ratio of PGA and PLA is 60:40), at a temperature of 20°C , Under the atmospheric condition of relative humidity 65%, carry out coreless cross weaving into yarn on 12 vertical spindle knitting machines, braiding angle 54.5 °.

[0029] (2) Preparation of tissue-engineered artificial tendon scaffold reinforcement: use crochet needles with braided needles as mesh edges, 30 stitches, and a loop diameter of 10 mm. Knit the mesh circular fabric with braided needles and short needles, with 6 braided needles and a length of 40mm, then narrow the needles.

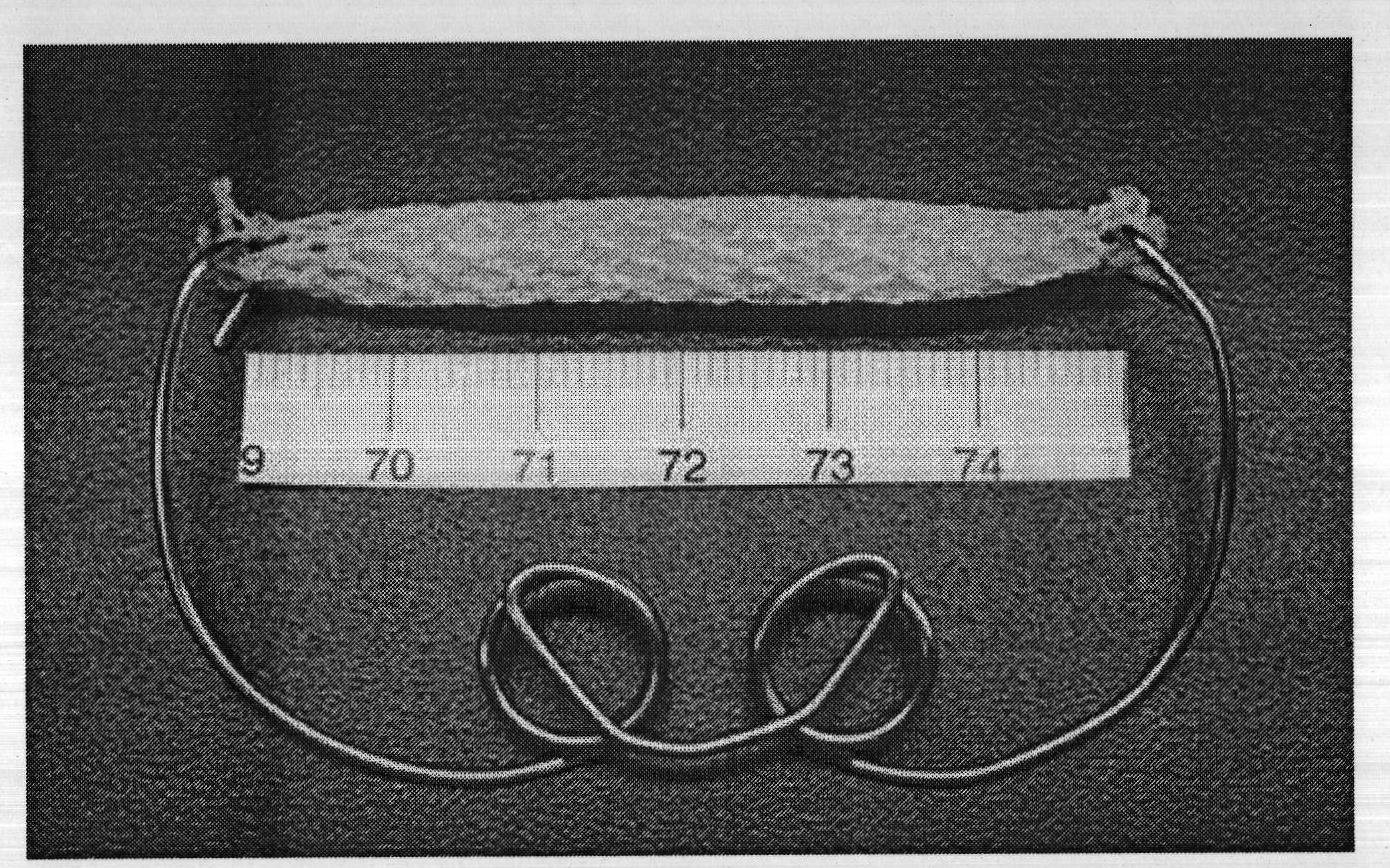

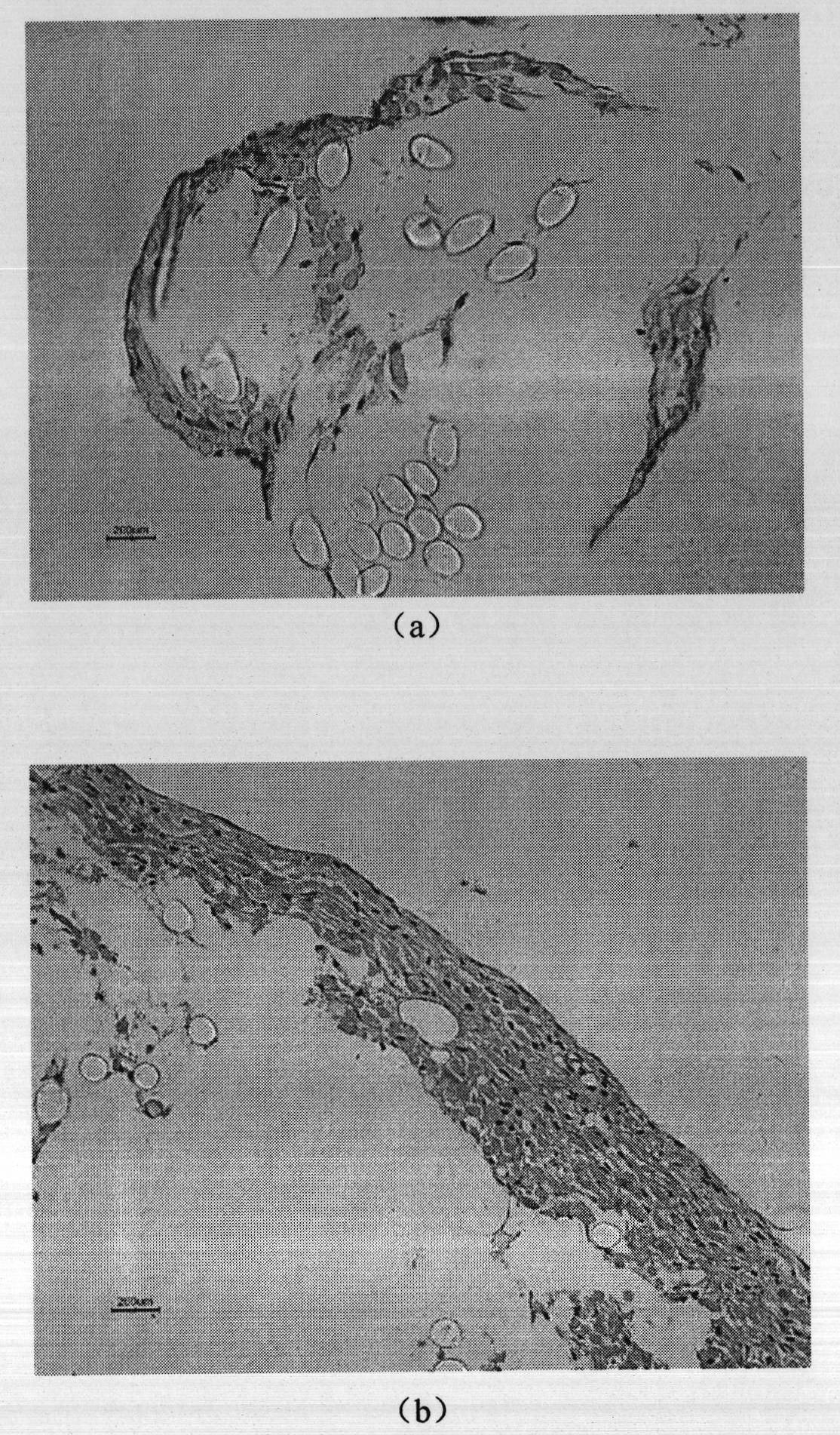

[0030] (3) Preparation of tissue engineering artificial tendon scaffold: 20 mg of PGA fibers (15 microns in diameter) were filled into the tissue engineering scaffold reinforcement to form a tissue engineering tendon scaffold with a length of 40 mm and ...

Embodiment 2

[0032] (1) Preparation of strands: PGA monofilament with a linear density of 18dtex and PLA monofilament with a linear density of 4.5dtex (the mixing ratio of PGA and PLA is 80:20), at a temperature of 20°C and a relative humidity of 65%. Under atmospheric conditions, they are plied into strands on the doubling machine.

[0033] (2) Preparation of tissue-engineered artificial tendon scaffold reinforcement: use crochet needles with braided needles as mesh edges, 40 stitches, and a loop diameter of 12 mm. Knit the mesh circular fabric with braided needles and short needles, 10 braided needles, 50mm in length, and narrow the needles.

[0034] (3) Preparation of tissue-engineered artificial tendon scaffold: 30 mg of PGA fibers (15 microns in diameter) were filled into the tissue-engineered scaffold reinforcement to form a tissue-engineered tendon scaffold with a length of 50 mm and a diameter of 10 mm, and the porosity of the PGA fibers was 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com