Patents

Literature

30 results about "Epsilon-Aminocaproic Acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epsilon-aminocaproic acid is an antifibrinolytic agent used to treat patients with hereditary angioneurotic edema and subarachnoid hemorrhage.

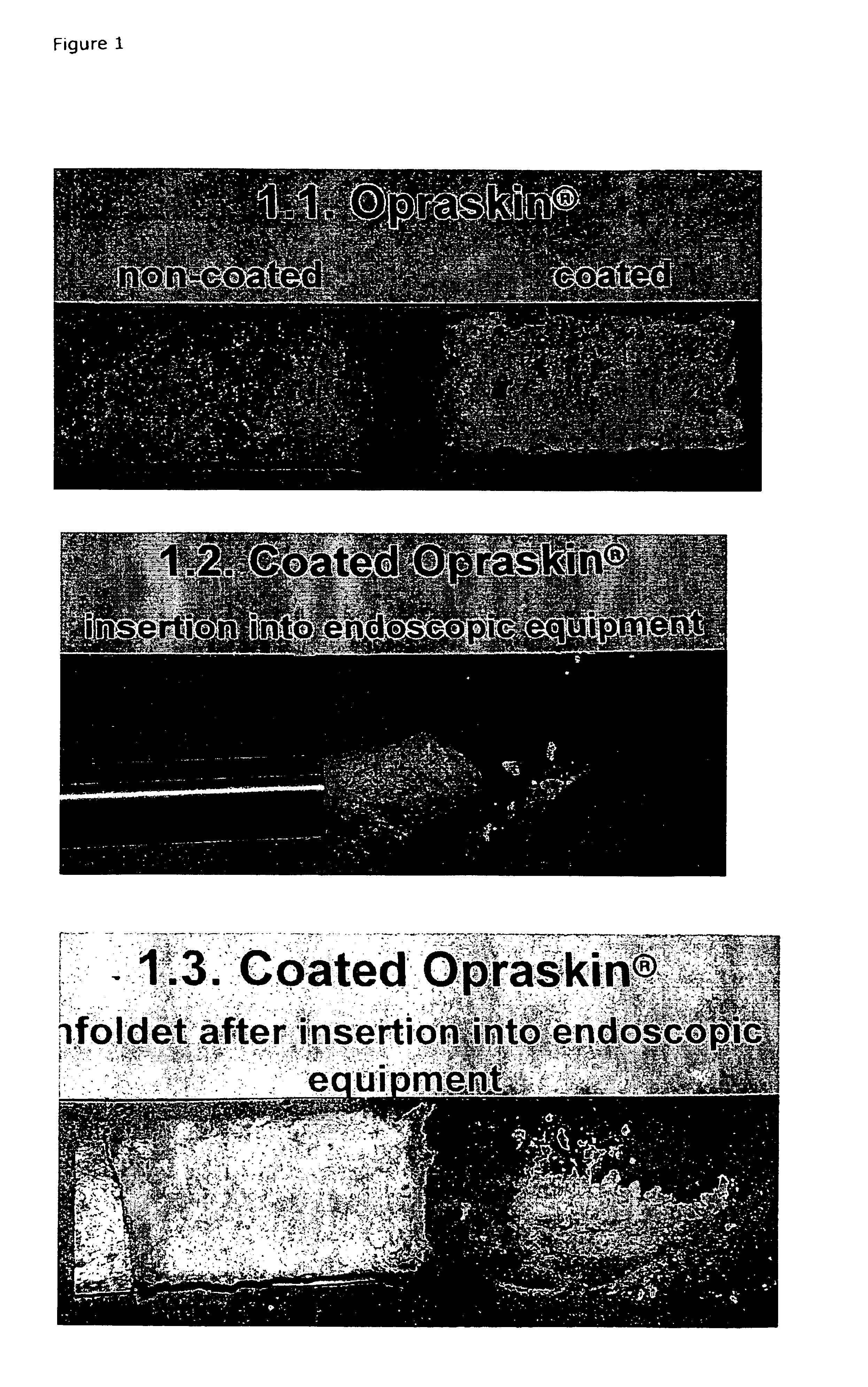

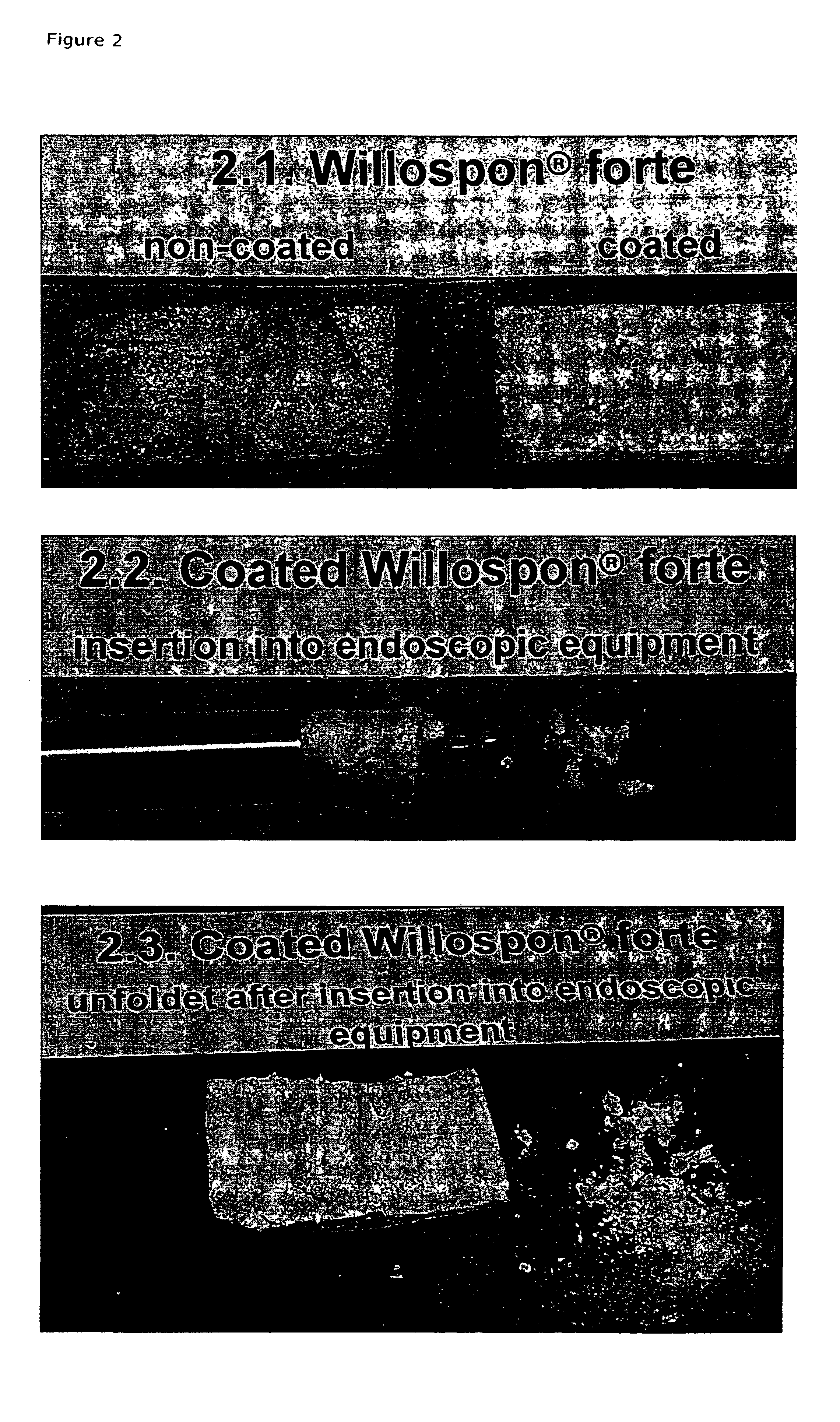

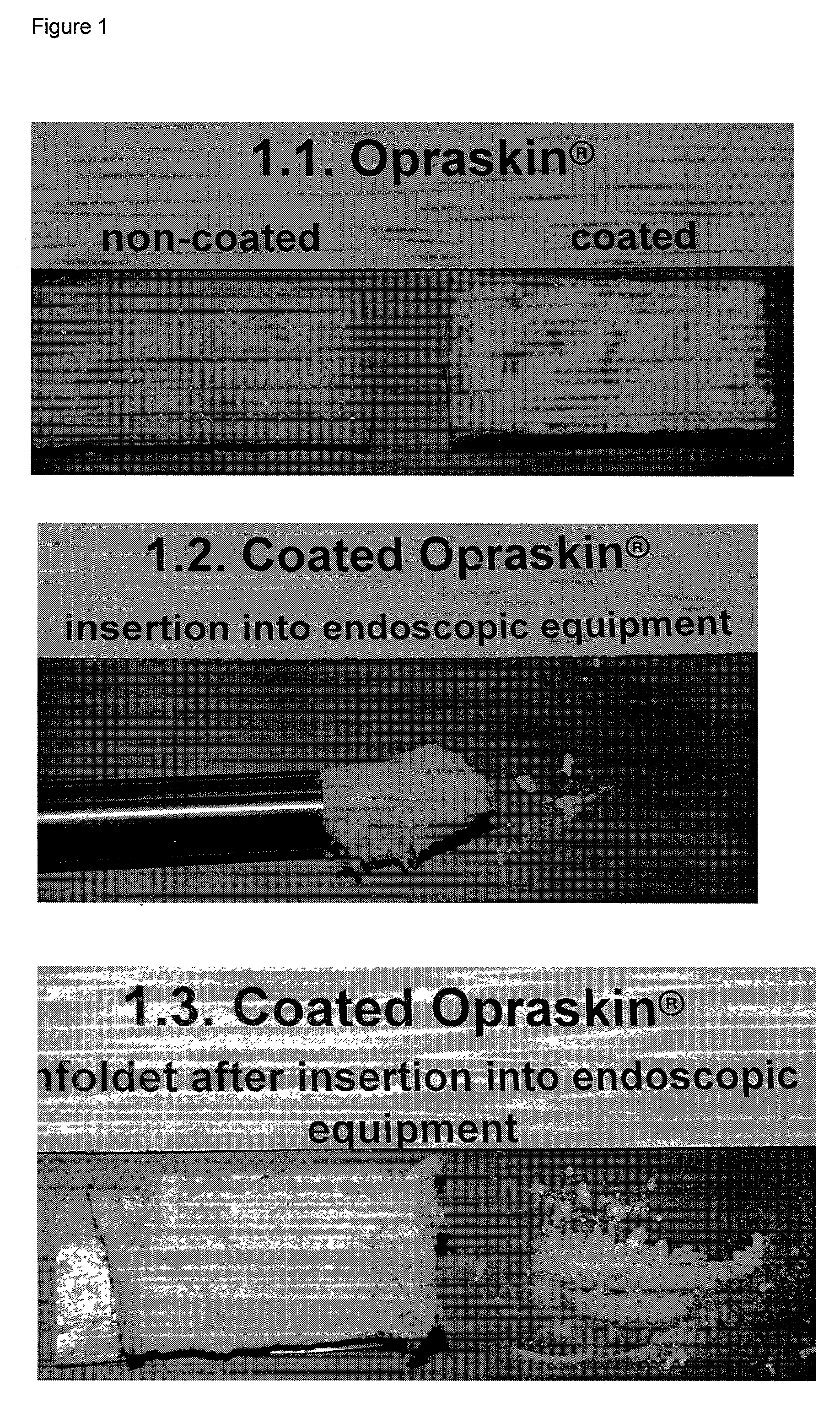

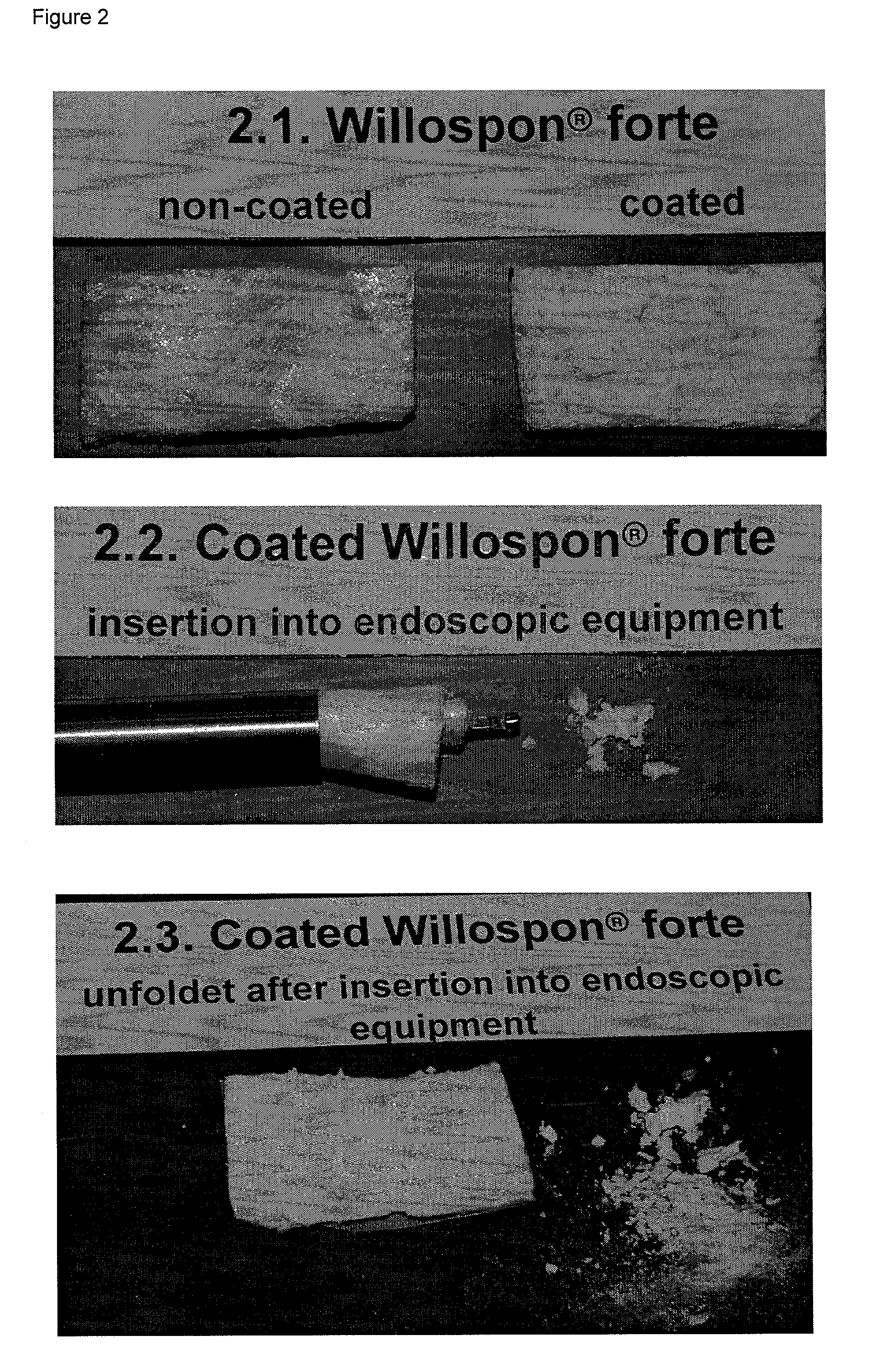

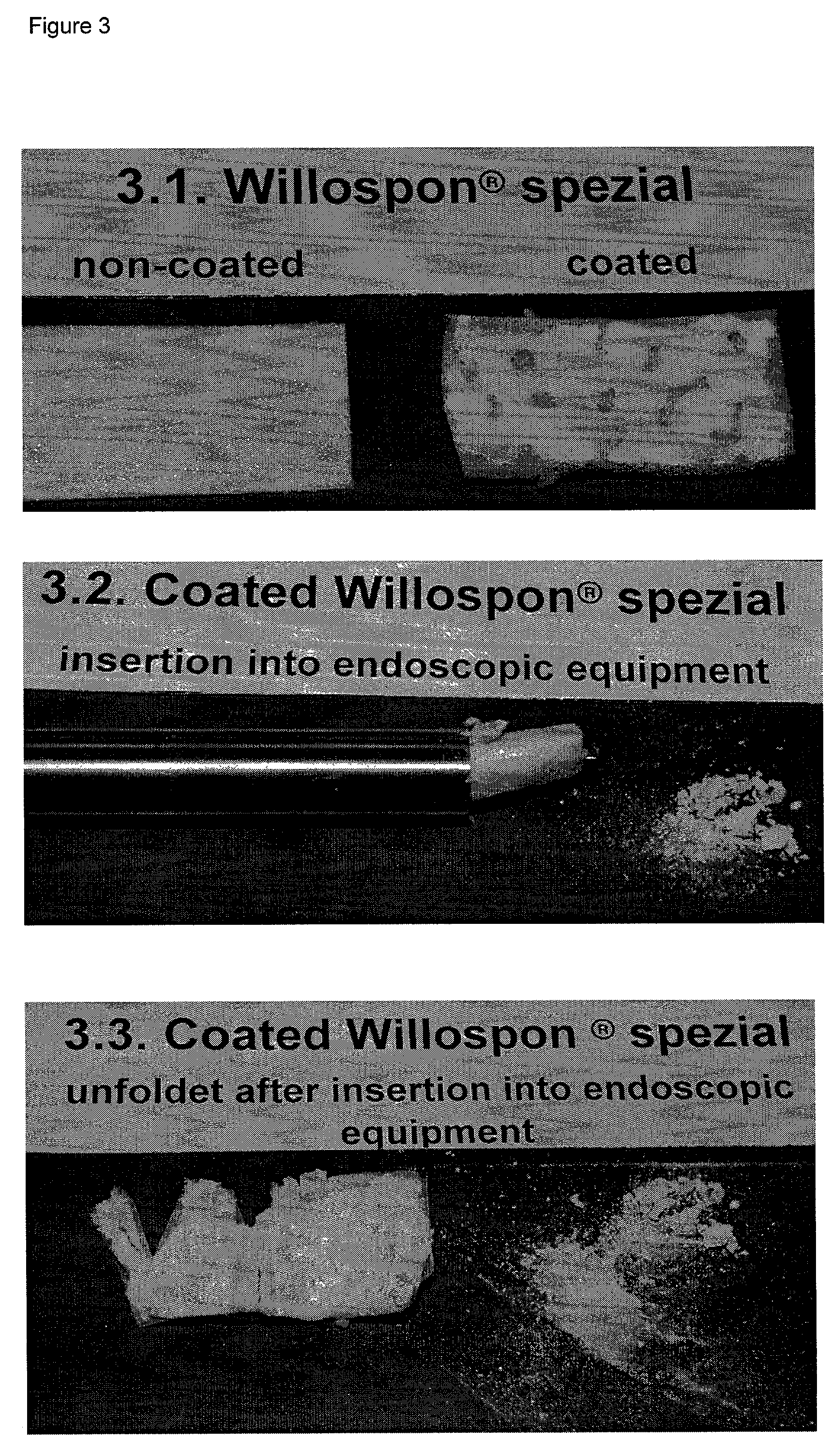

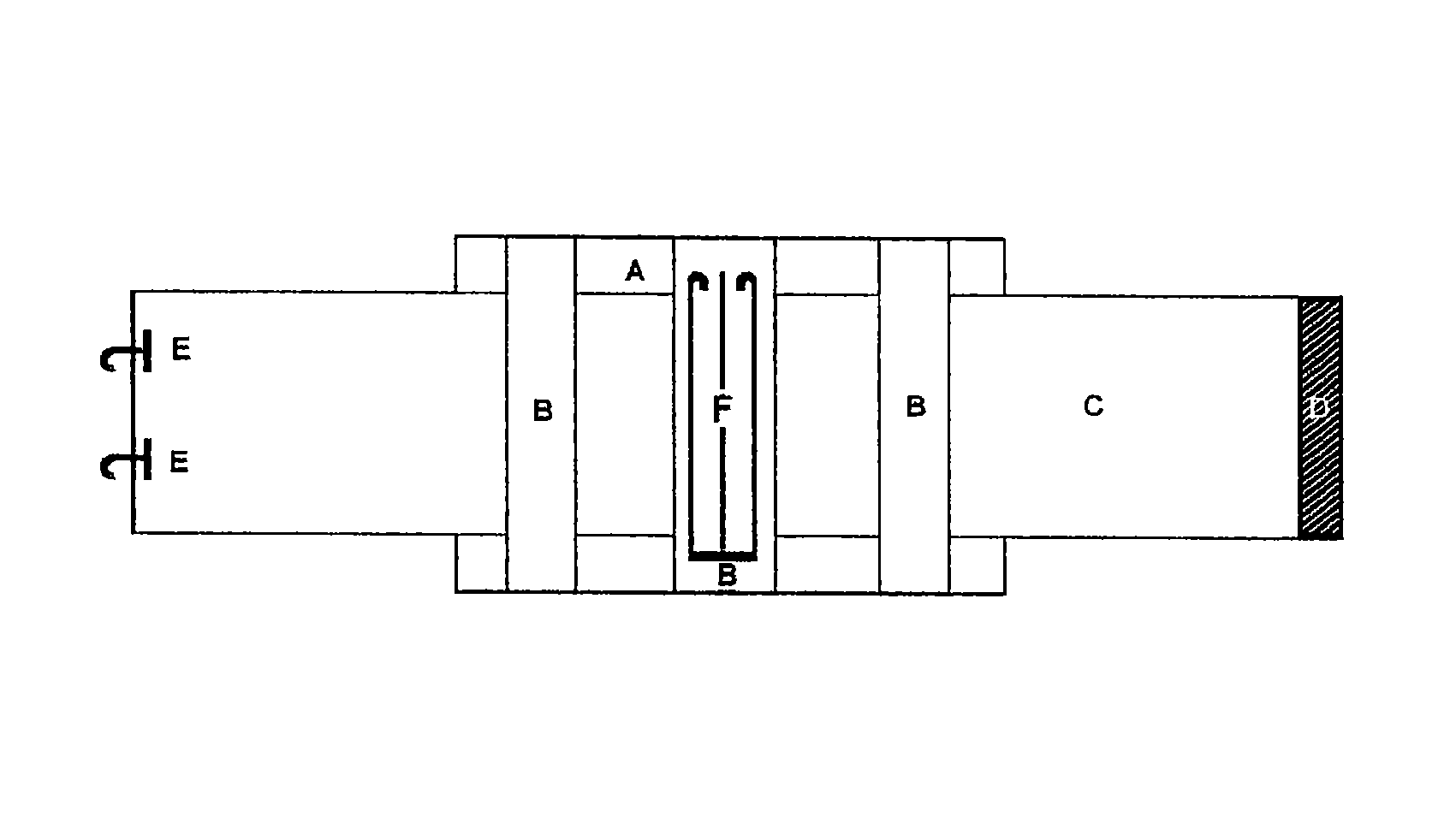

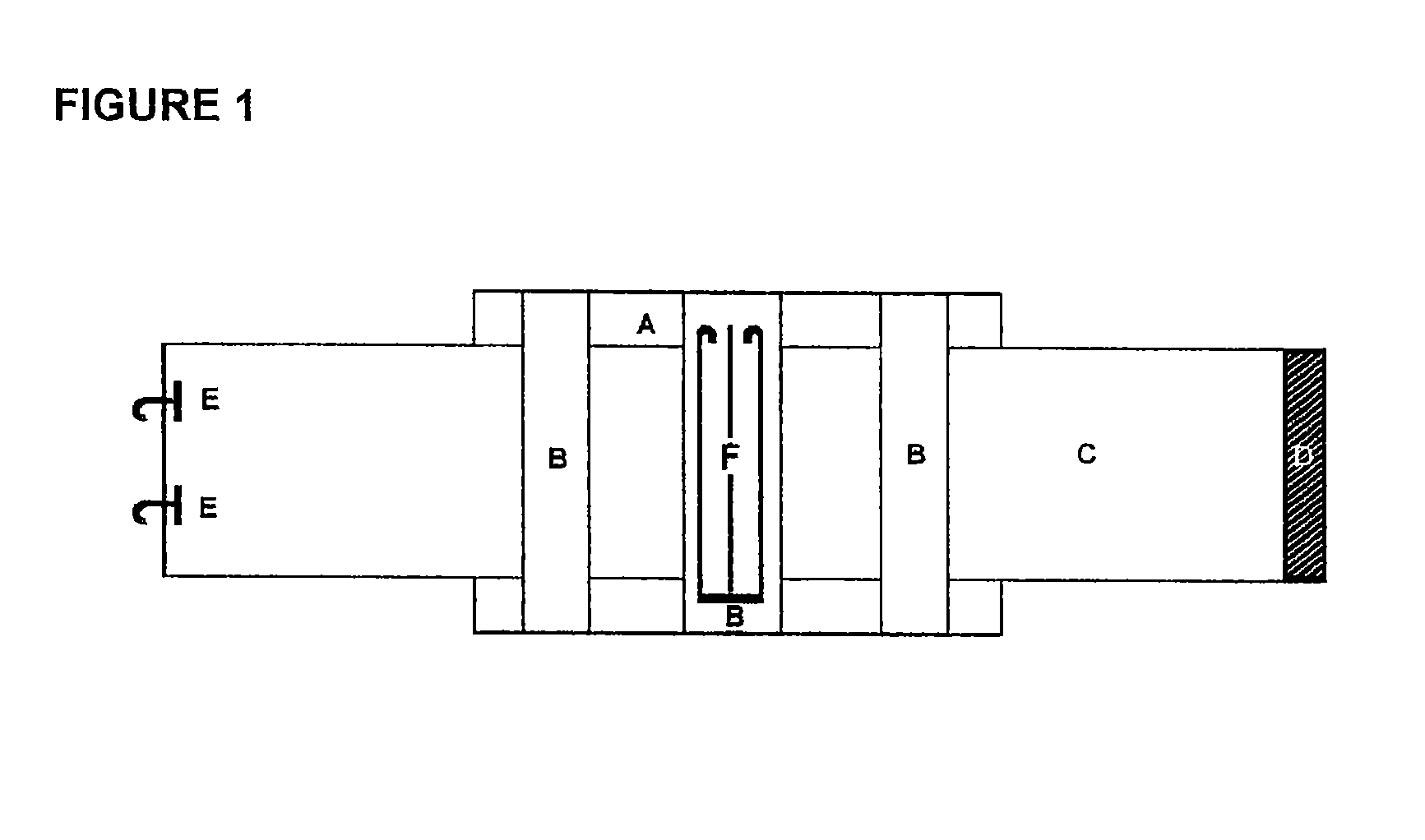

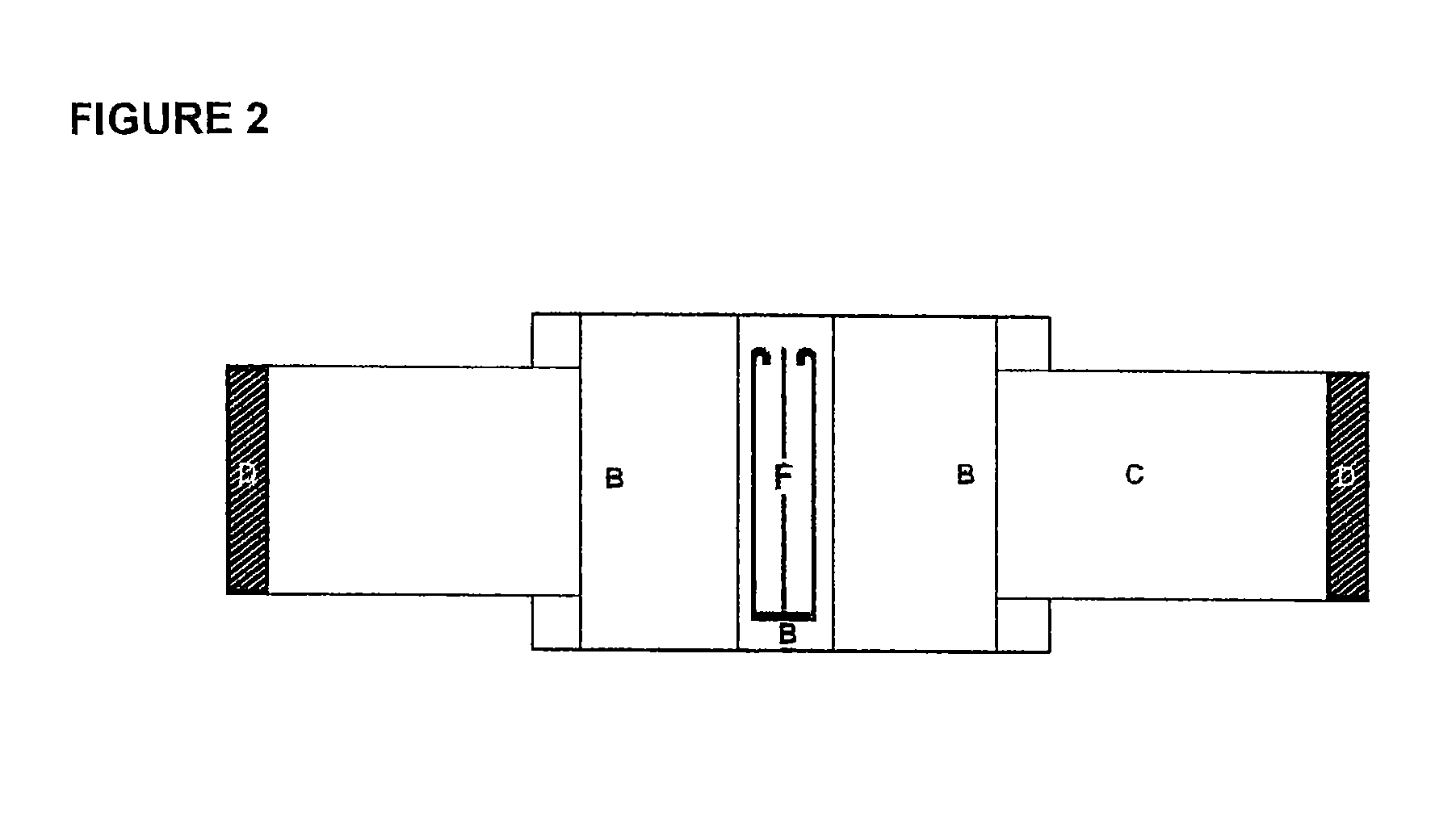

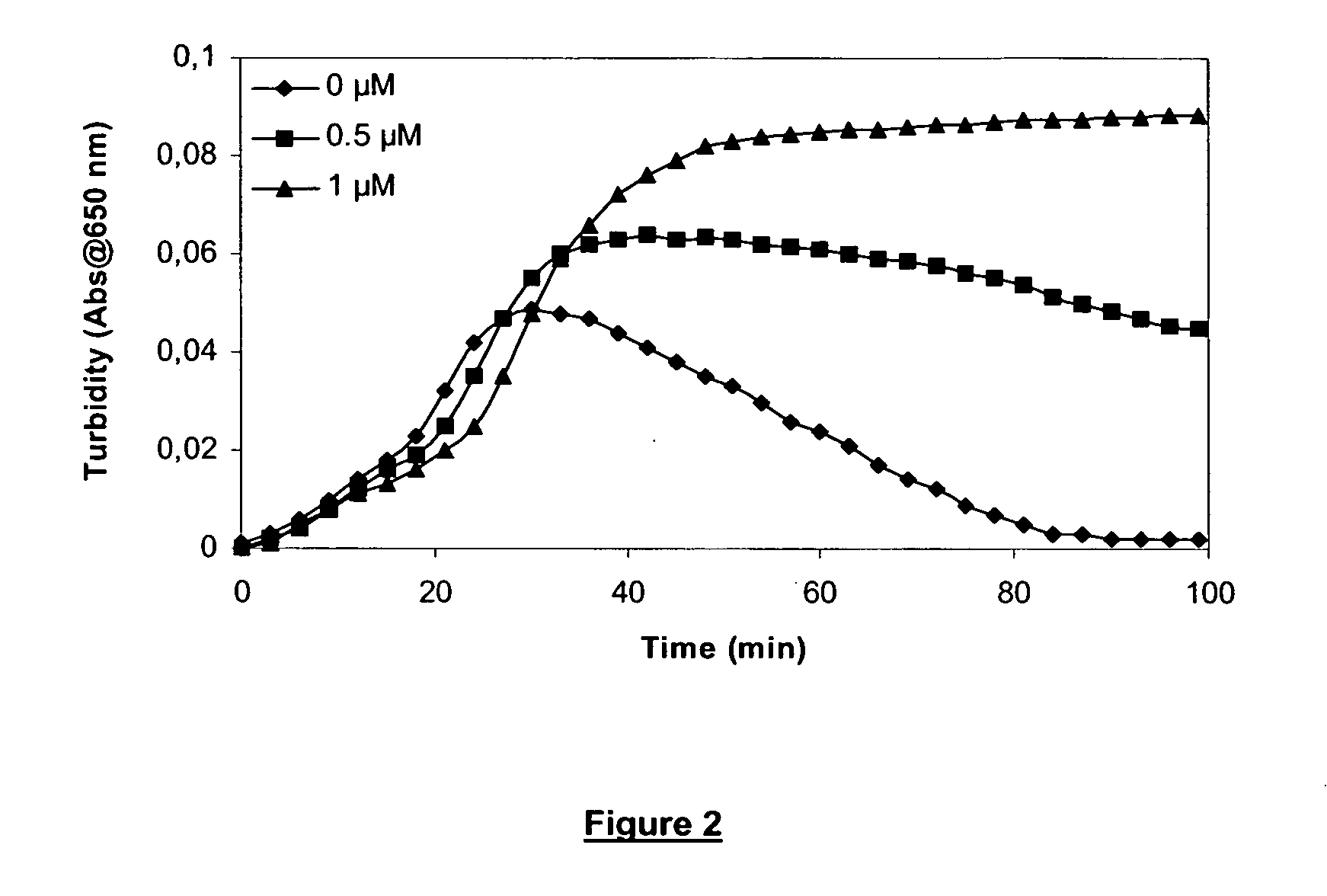

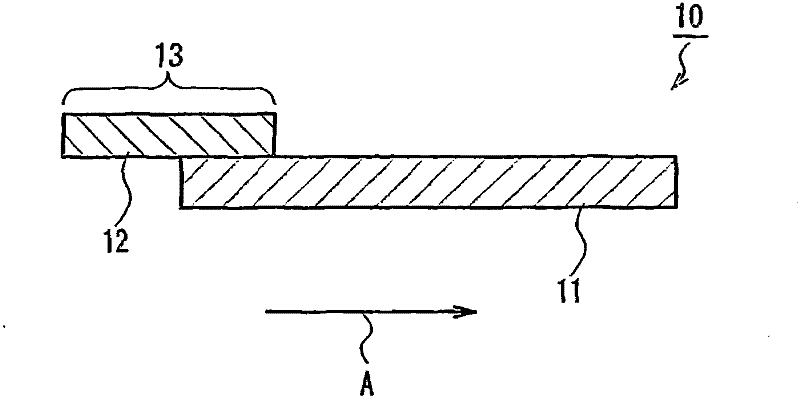

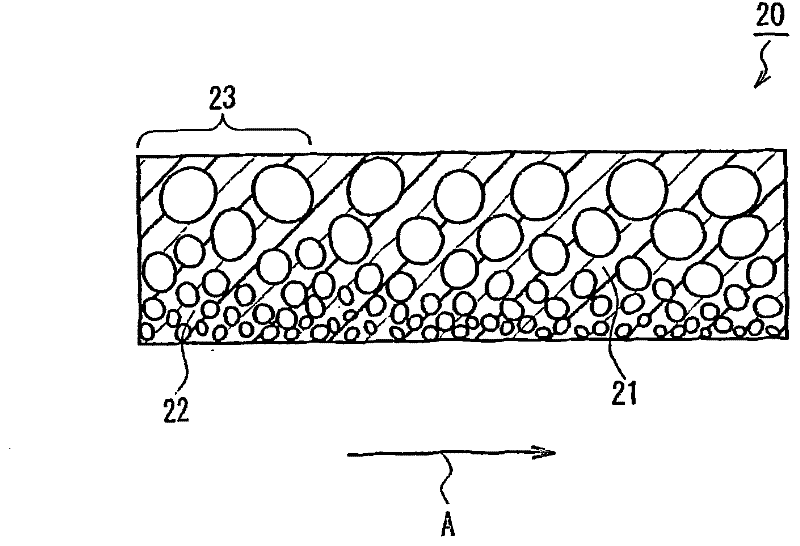

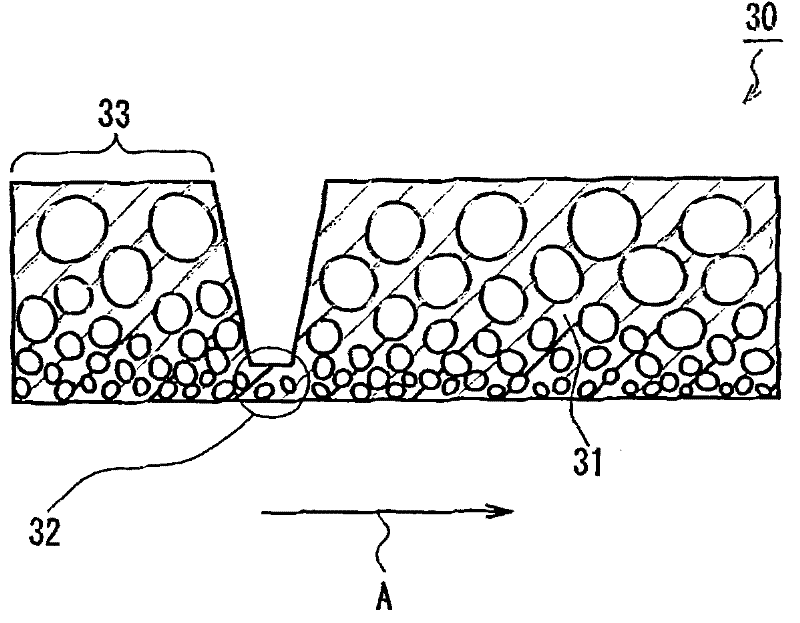

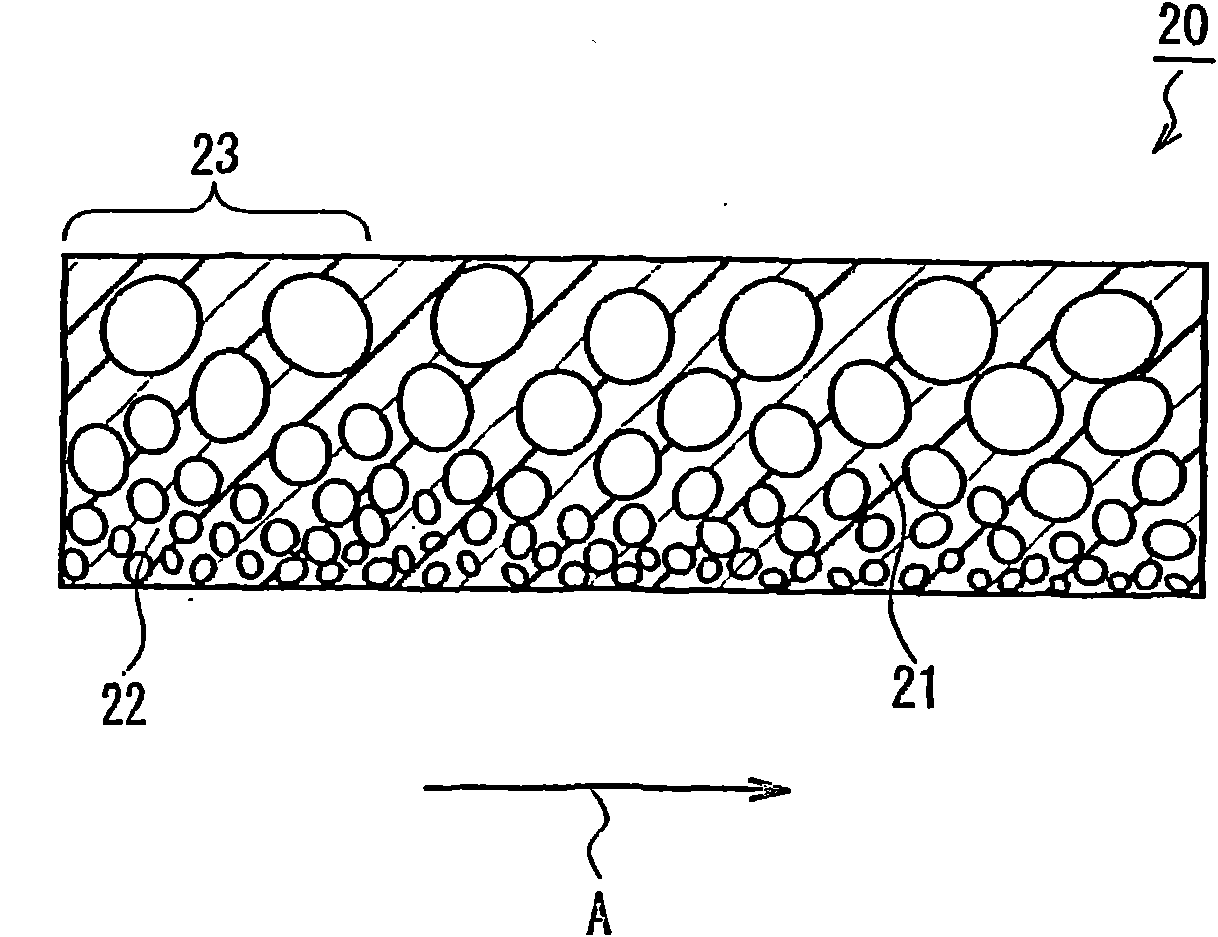

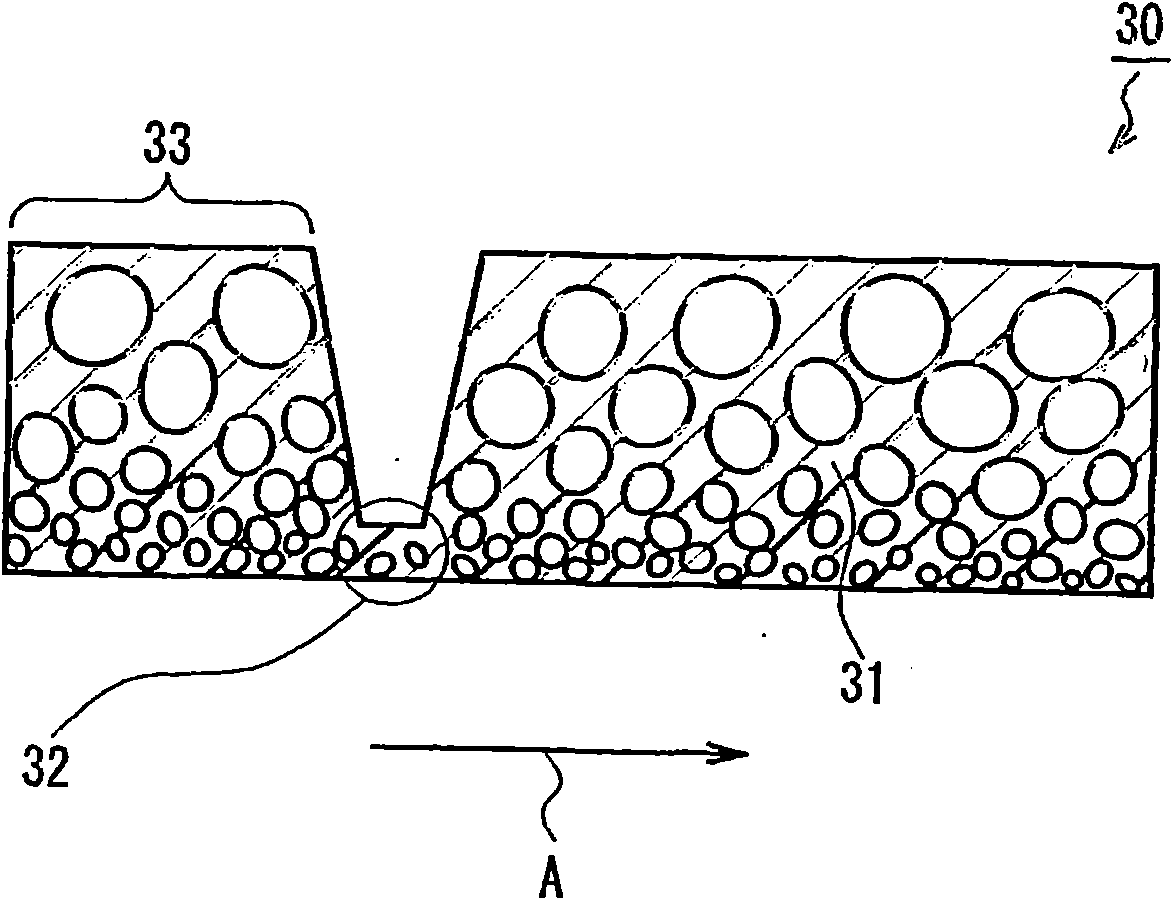

Carrier with solid fibrinogen and solid thrombin

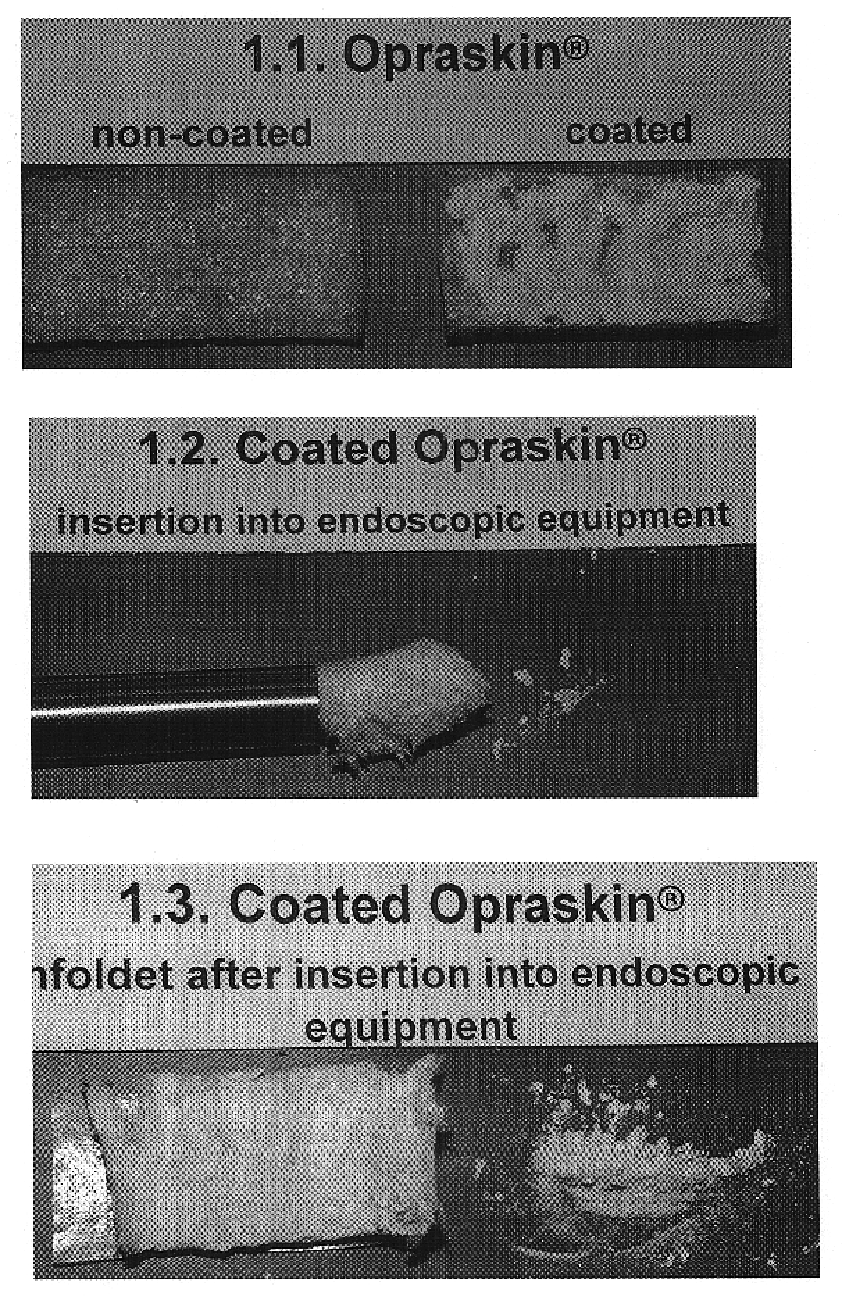

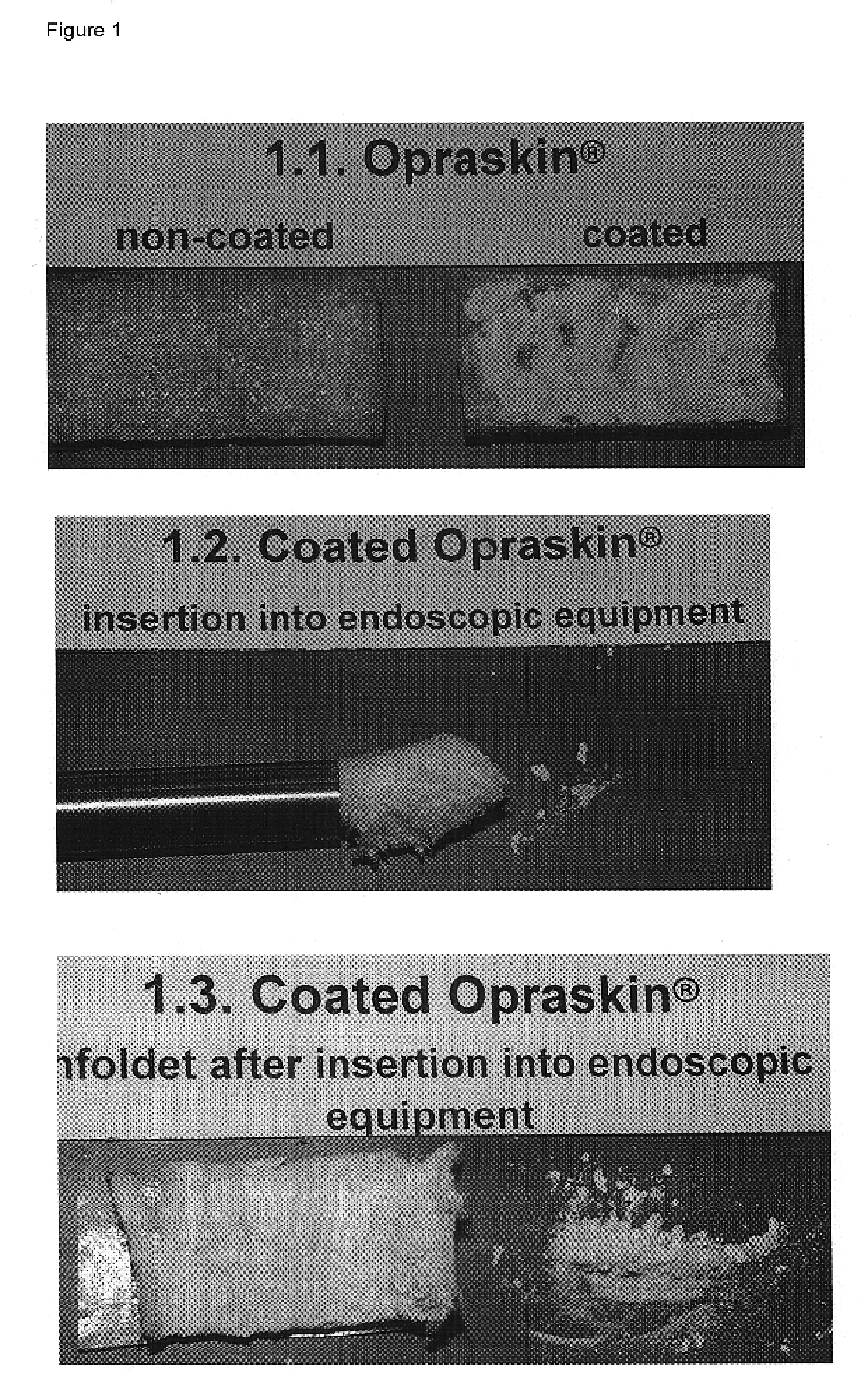

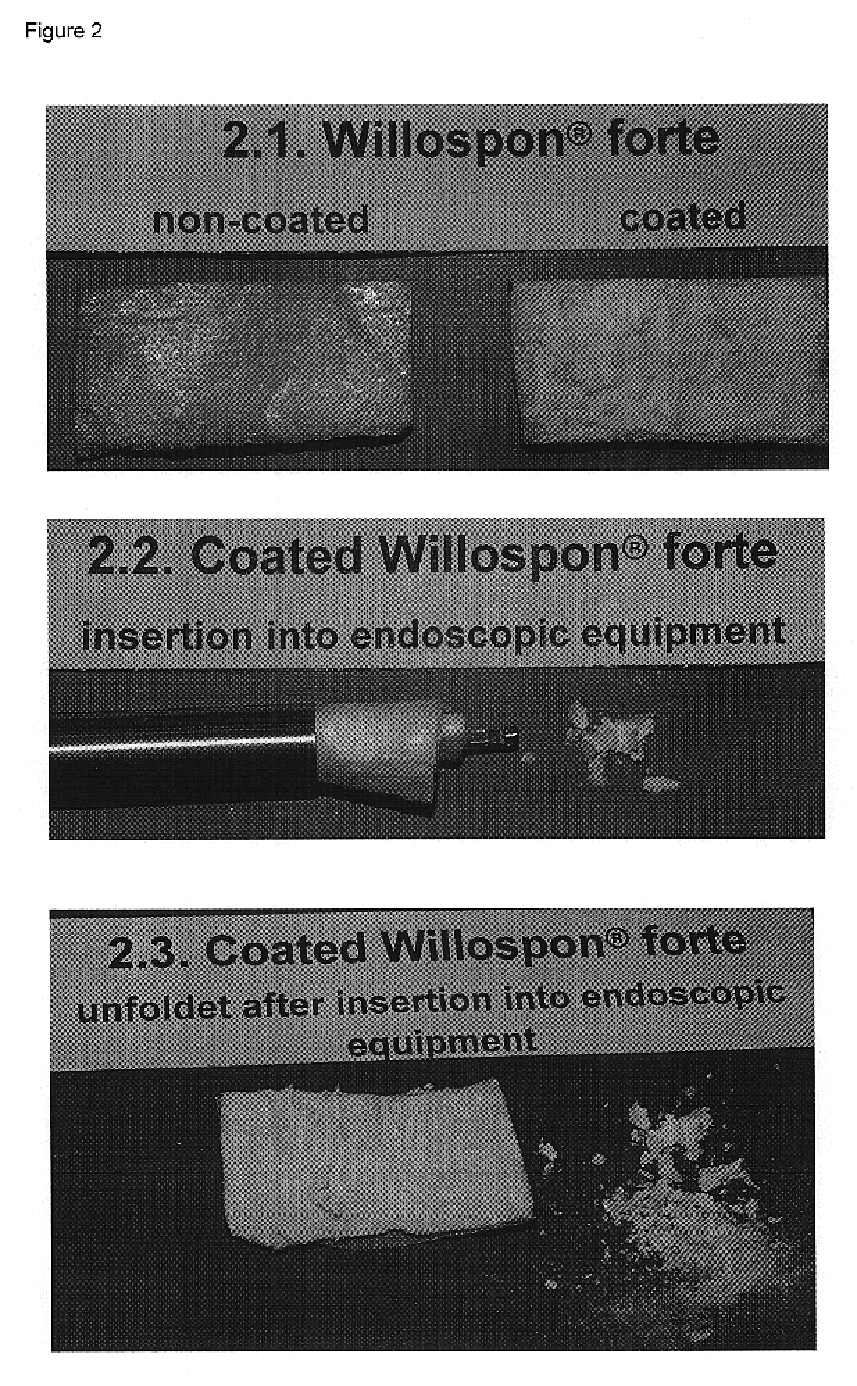

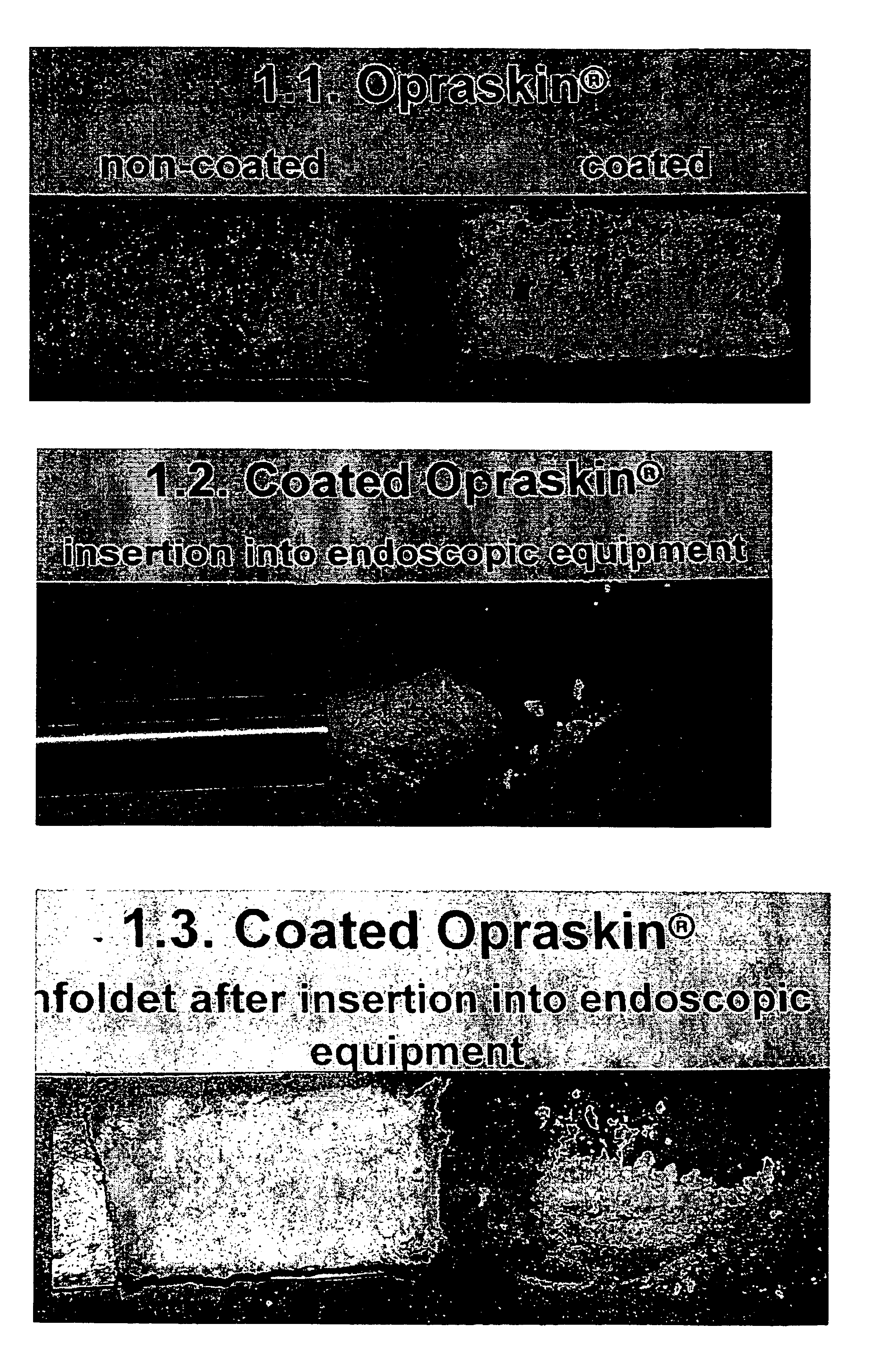

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and haemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm<3>, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin.The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibres. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, epsilon-aminocaproic acid or alpha2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

Carrier with solid fibrinogen and solid thrombin

InactiveUS7052713B2Safety and efficacyShorten hemostasis timePowder deliverySurgical adhesivesNatural sourceFiber

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and hemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm3, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin.The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibers. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, ε-aminocaproic acid or α2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

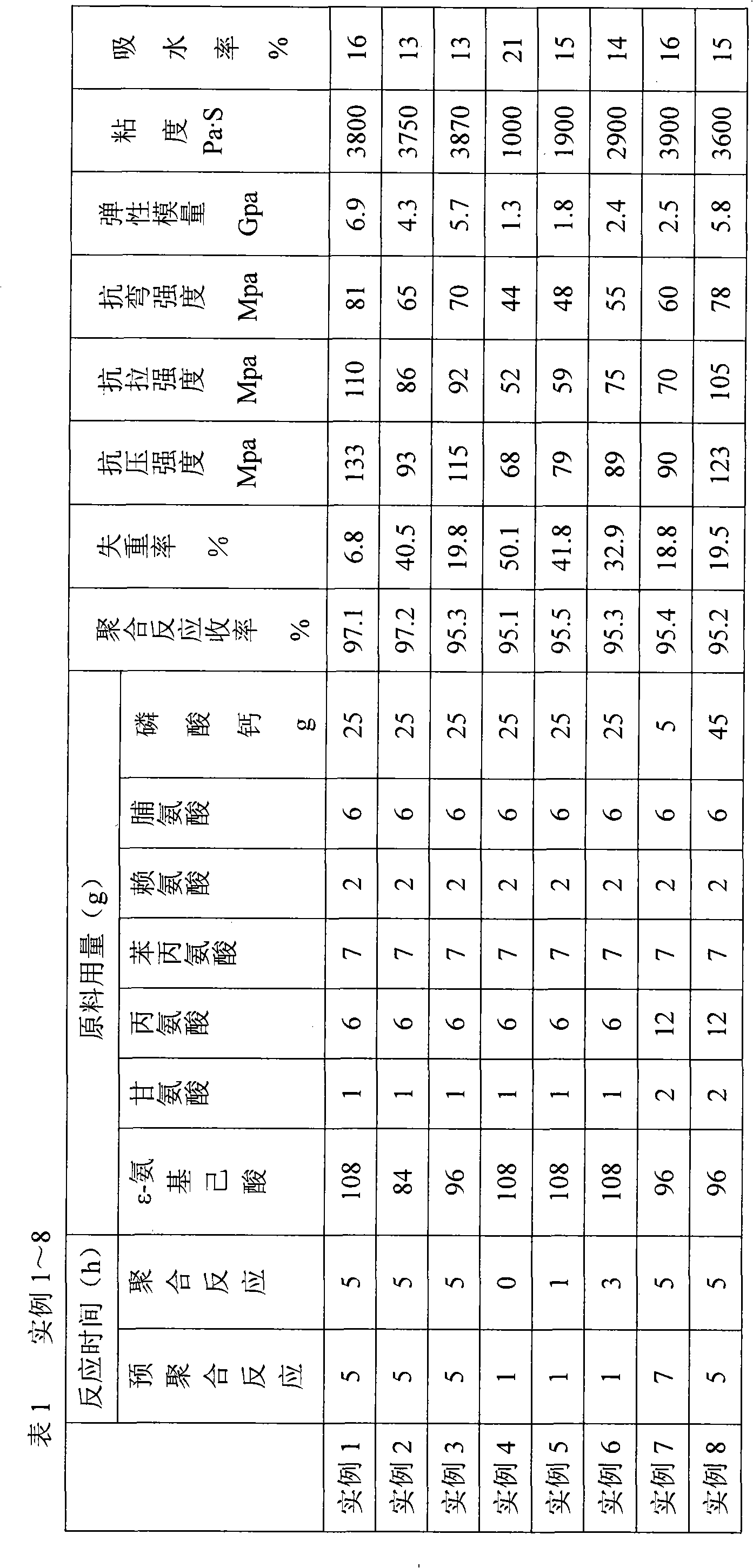

Composite polymer bone-renovation material containing ceramic component and preparation method thereof

InactiveCN101342384AImprove securityImprove hydrophilicityProsthesisAdditive ingredientBiocompatibility Testing

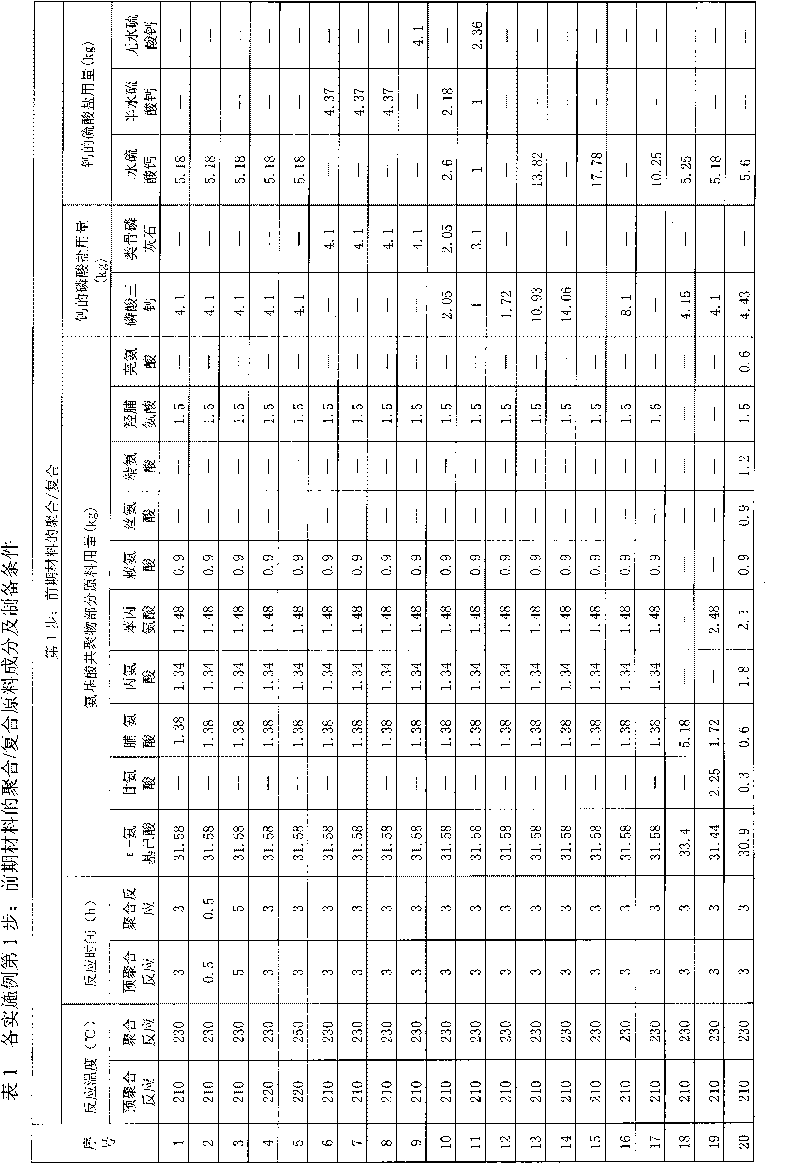

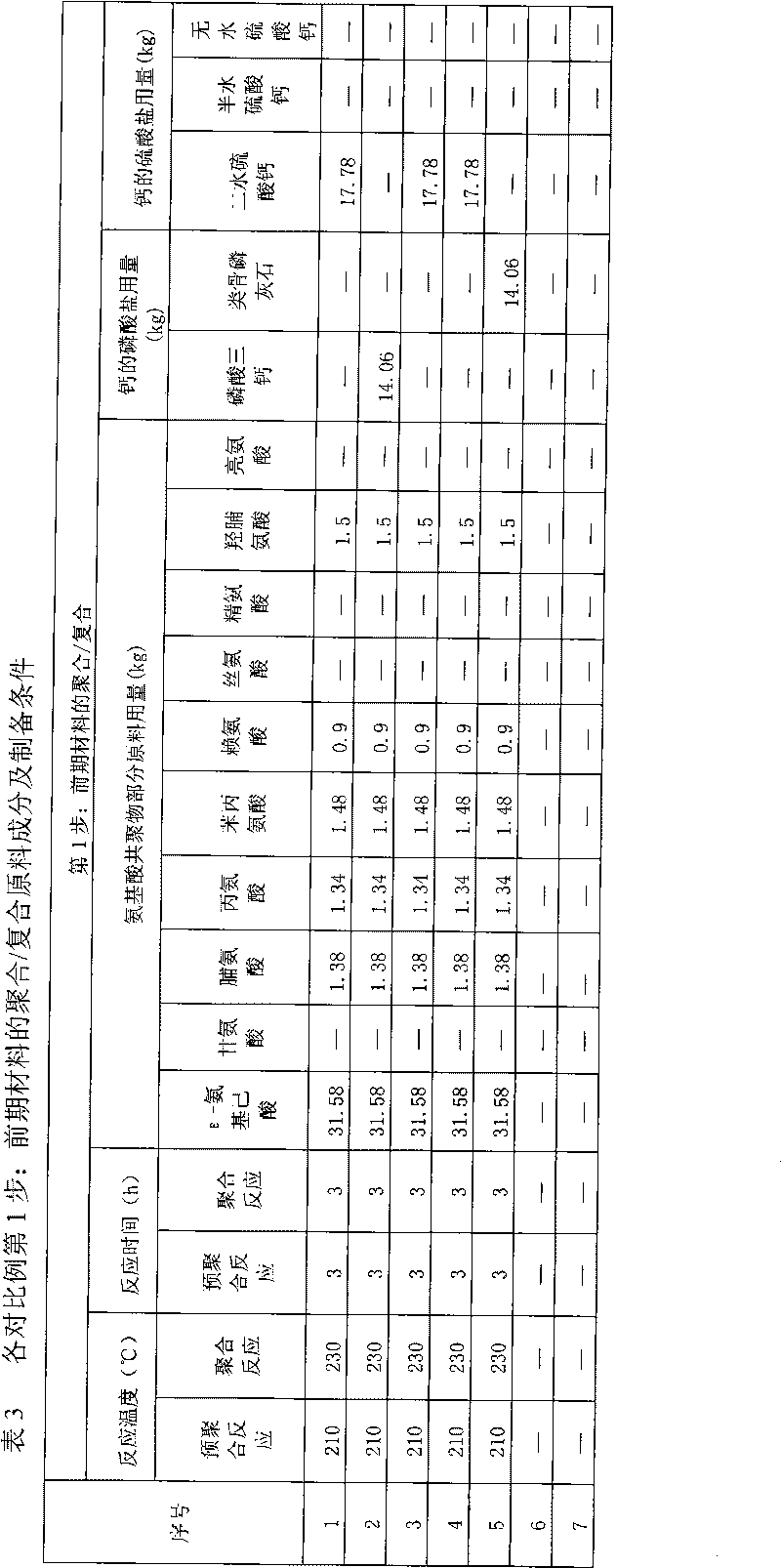

The present invention relates to a bone-repairing composite polymer material containing a ceramic ingredient and a preparation method thereof. The bone-repairing composite polymer material is composed of the calcium phosphate ceramic ingredient and a polybasic amino acid polymer ingredient, wherein, the mass ratio of the calcium phosphate ceramic ingredient is between 5 percent and 30 percent, and the rest is the polybasic amino acid polymer ingredient. Epsilon-aminocaproic acid is polymerized with at least two other types of amine acids to form the polybasic amino acid polymer ingredient, wherein, the mole ratio of the epsilon-aminocaproic acid in the polybasic amino acid polymer ingredient is between 50 percent and 90 percent, and the rest is the other amine acids including aminoacetic acid, lactamic acid, phenylalanine, lysine and proline. Under the protection of a inert gas, the materials, the amine acids and the calcium phosphate, are sufficiently and uniformly dispersed into water and then heated, so that various forms of waters can be removed from the materials, and finally, the materials are polymerized in two steps, respectively under a temperature between 200 DEG C and 220 DEG C and a temperature between 230 DEG C and 250 DEG C. The bone-repairing composite polymer material, which has excellent mechanical property, bioactivity, biocompatibility and controllable degradation property, can be perfectly combined with the interface of the bone tissue, and moreover, the degradation product is non-toxic and non-irritant.

Owner:SICHUAN GUONA TECH

Carrier with solid fibrinogen and solid thrombin

The present invention relates to a solid composition useful for tissue gluing, tissue sealing and haemostasis consisting essentially of a) a carrier which has at least one of the following physical properties: elasticity module in the range of 5-100 N / cm, density of 1-10 mg / cm3, chamber diameter of more than 0.75 mm and less than 4 mm and / or having a chamber diameter average below 3 mm and evenly distributed and fixed upon said carrier, b) solid fibrinogen, and c) solid thrombin. The carrier is a biodegradable polymer such as a polyhyaluronic acid, polyhydroxy acid, e.g. lactic acid, glucolic acid, hydroxybutanoic acid, a cellulose, gelatine or collagen, such as a collagen sponge, e.g. a collagen sponge consisting essentially of collagen type I fibres. The fibrinogen and thrombin are preferably human, purified from a natural source, or transgenic or recombinant human fibrinogen and / or thrombin. In a preferred embodiment the composition does not comprise any antifibronolytic agent such as aprotinin, epsi-aminocaproic acid or alpha2-antiplasmin,

Owner:TOPAZ INVESTMENT AS

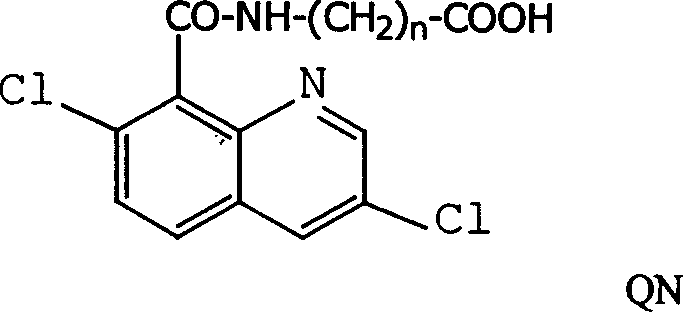

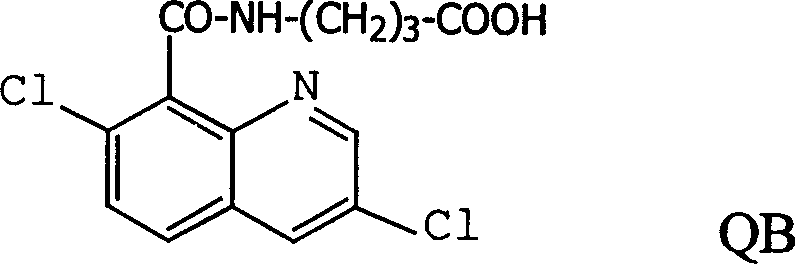

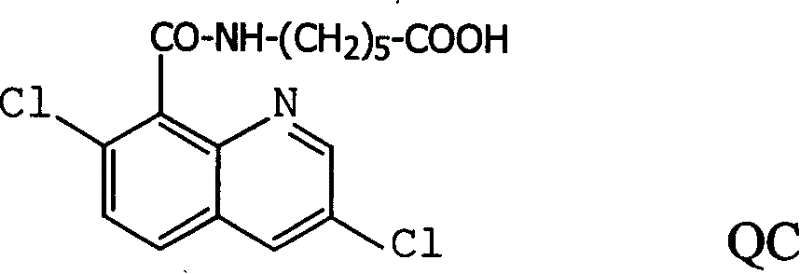

Production method and use for dichloro quinolinic acid artificial hapten, artificial antigen and specific antibody

InactiveCN1569835AEasy to handleFast and accurate analysis and detectionImmunoglobulinsTesting foodQuinolineCarboxylic acid

The invention discloses a process for preparing Quinclorac artificial semiantigen, artificial antigen, specific antibody and use thereof, wherein the preparation comprises, subjecting the dichloroquine (3,7-dichlorine-8-quinoline carboxylic acid) to sulfoxide chlorinated acylation, reacting with reanal and aminocaproic acid, thus obtaining semiantigen 4-(3,7-dichlorine-8-quinolineformyl) reanal or 6-(3,7-dichlorine-8-quinolineformyl) aminocaproic acid (QB or QC).

Owner:ZHEJIANG UNIV

Hemostatic textile material

ActiveUS8722081B2Improve bindingGood hemostatic effectAntibacterial agentsBiocideHemolysisChlorhexidine

A hemostatic textile material to stop bleeding comprising a dialdehyde cellulose (DAC) carrier wherein the degree of oxidation of the dialdehyde cellulose varies from about 1.5% to 12%; and a blood coagulation factor selected from the group consisting of chitosan and gelatin; the blood coagulation factor being chemically immobilized thereon; and further optionally comprising a bacteriolytic agent selected from the group consisting of a lysozyme enzyme, silver nitrate, and chlorhexidine; and further optionally comprising a selected component that prevents hemolysis, the component selected from the group consisting of tranexamic acid or ε-aminocaproic acid chemically immobilized thereon.

Owner:FILATOV VLADIMIR N +2

Injection moldable bone repair composite material and preparation method thereof

InactiveCN101716380ARelieve painAppropriate selection rangeProsthesisIn situ polymerizationBiocompatibility Testing

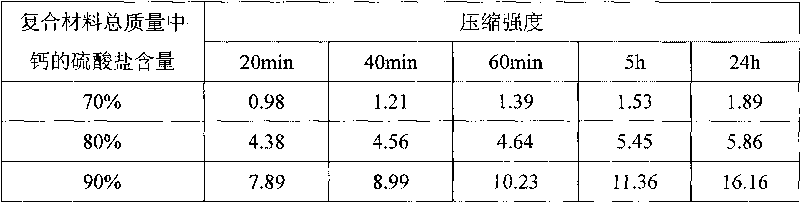

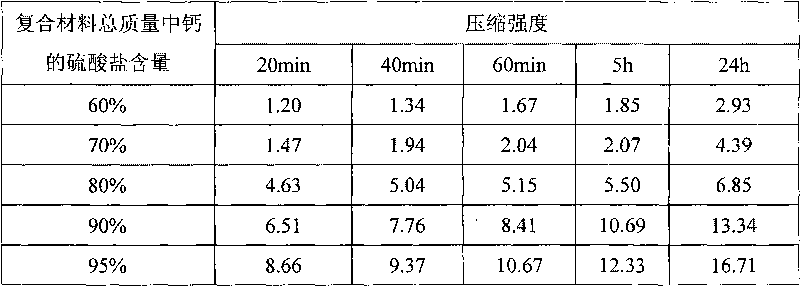

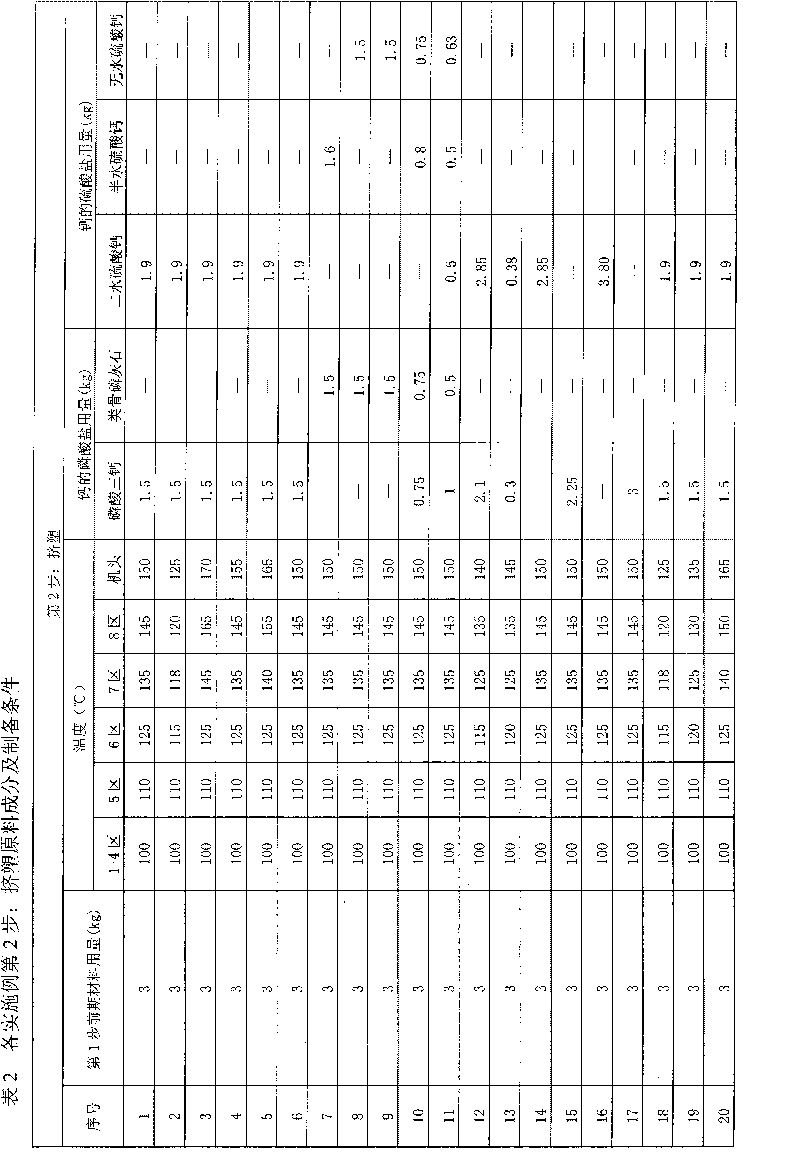

The invention relates to an injection moldable bone repair composite material and a preparation method and a using method thereof. The composite material is a powder material consisting of a copolymer of multiple amino acids and a sulfate component of calcium, the sulfate component of the calcium accounts for 60-95% of total weight of the component material, and the balance is the copolymer of the multiple amino acids. The sulfate component of the calcium comprises alpha-hemihydrated calcium sulfate which accounts for 15%-60% of the total weight of the composite material and the balance of other sulfates of the calcium. The copolymer of the multiple amino acids is formed by polymerizing epsilon-aminocaproic acid and at least two types of other amino acids, and the molar ratio of each amino acid in the other amino acids is not less than 1% of the total weight of the amino acids. When in preparation, an intermediate parent body is obtained by in-situ polymerization and composition of other sulfates of the calcium and the amino acid monomers under inert gas protection and heating, and the composite material is prepared by smashing and then being composed with the alpha-hemihydrated calcium sulfate. The composite material powder is mixed with curing liquid, and then the composite material can be used by injection. The composite material can be fast molded after the injection and has the strength which is equivalent to that of cancellous bone, good biocompatibility and adjustable degradation speed, thereby being applicable to fixation and repair of clinical orthopedic complicated and irregular traumas.

Owner:SICHUAN UNIV

Composite material containing microelement for hard tissue repair and reconstruction and preparation method thereof

The invention relates to a composite material containing microelement for hard tissue repair and reconstruction and a preparation method thereof. The composite material further contains at least one of three microelements of strontium, zinc and copper acceptable in human body with the calcium mole ratio of 0.01-0.5% in ceramic component of calcium phosphate in the ceramic component containing the calcium phosphate and the substrate material of multi-amino acid polymer, wherein the mass ratio of the ceramic component of calcium phosphate is 30-65%, and the balance of multi-amino acid polymer polymerized by epsilon-aminocaproic acid and other amino acids. The process for preparing the calcium phosphate ceramic comprises the following steps of: adding microelement, then mixing the amino acid components evenly, removing water of various forms in the mixture at a temperature lower than or equal to 200 DEG C under the protection of inert gas, then composing in situ polymerization under the condition of 210-250 DEG C and pH of 6.5-7.5. The composite material is a bionic biomedical and tissue engineering material which has controllable degradation speed, good bioactivity and compatibility and overcomes deficiencies and problems of similar repair materials at present.

Owner:SICHUAN GUONA TECH

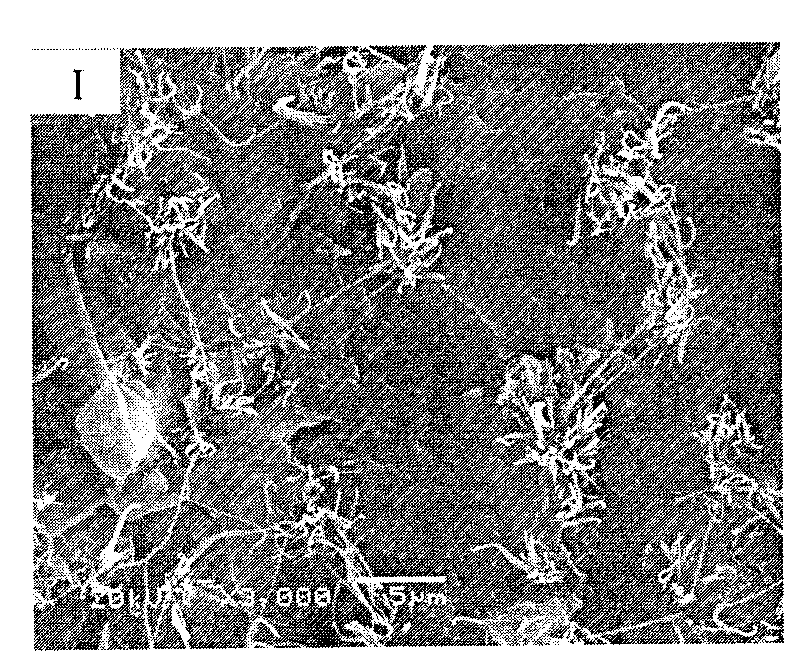

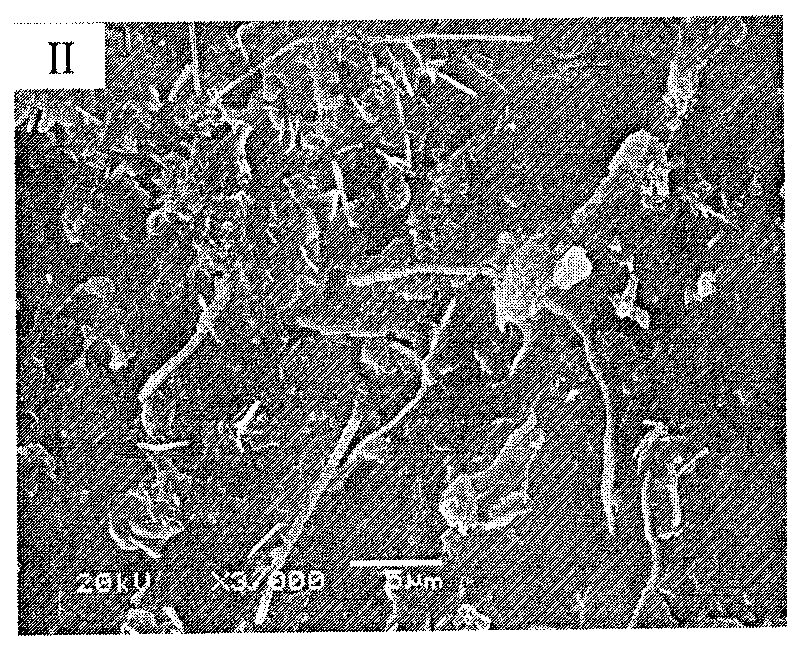

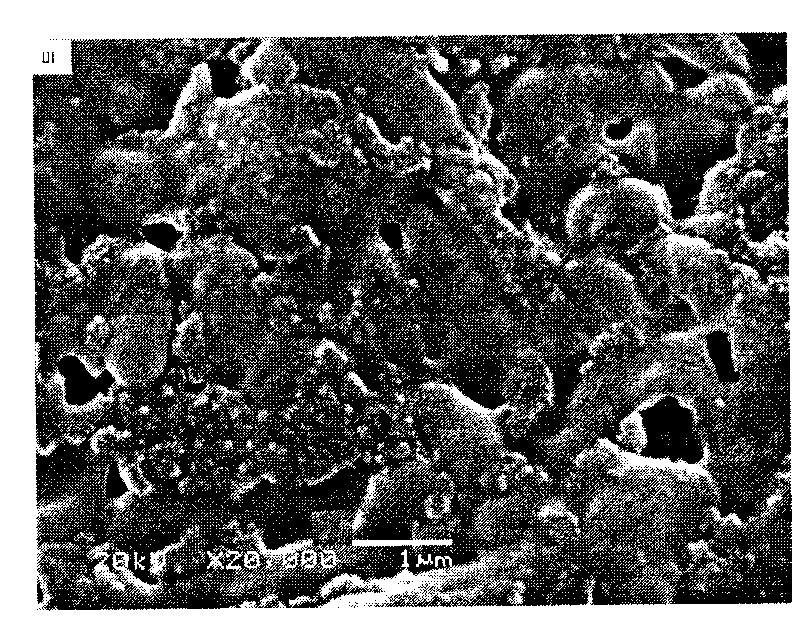

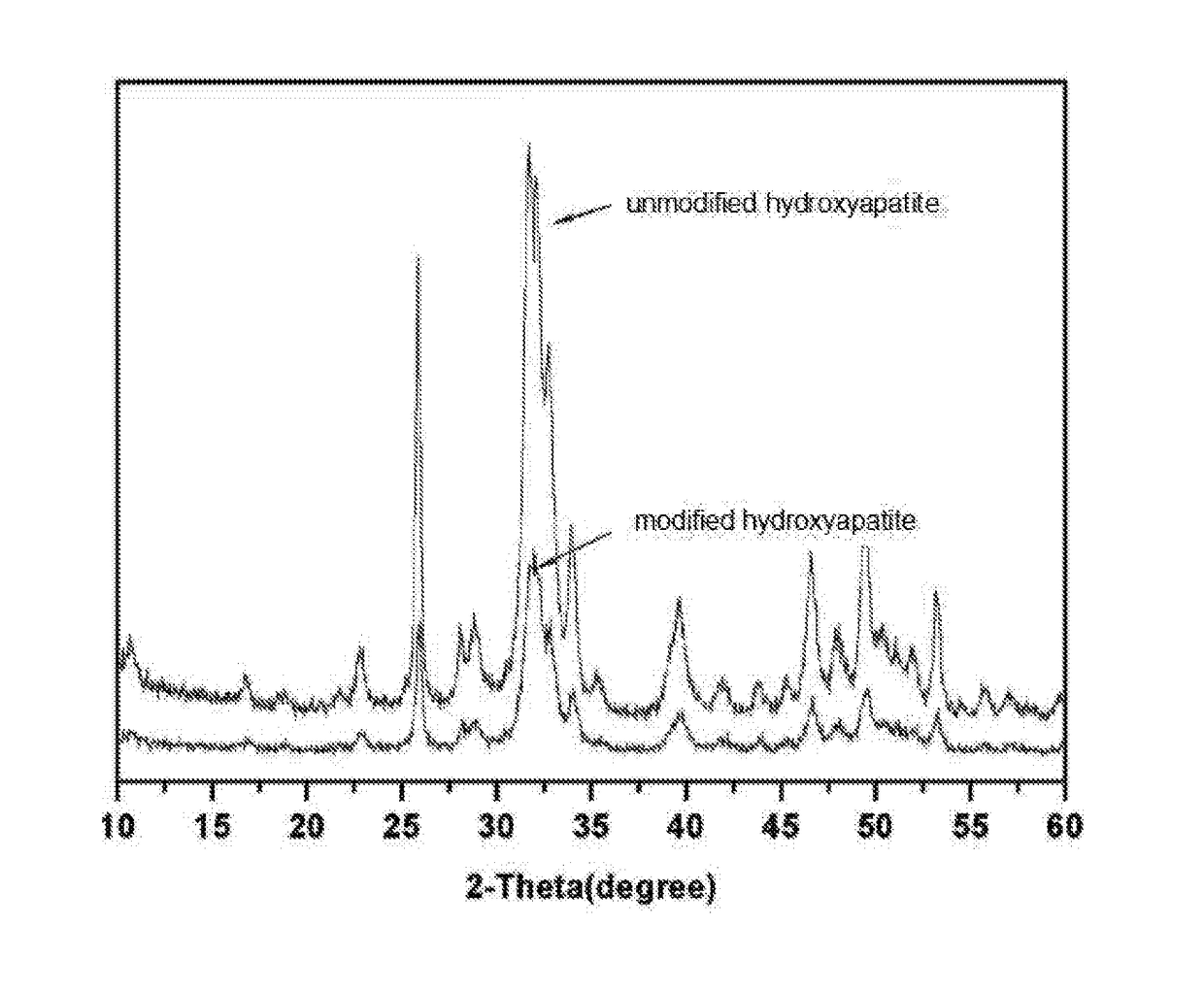

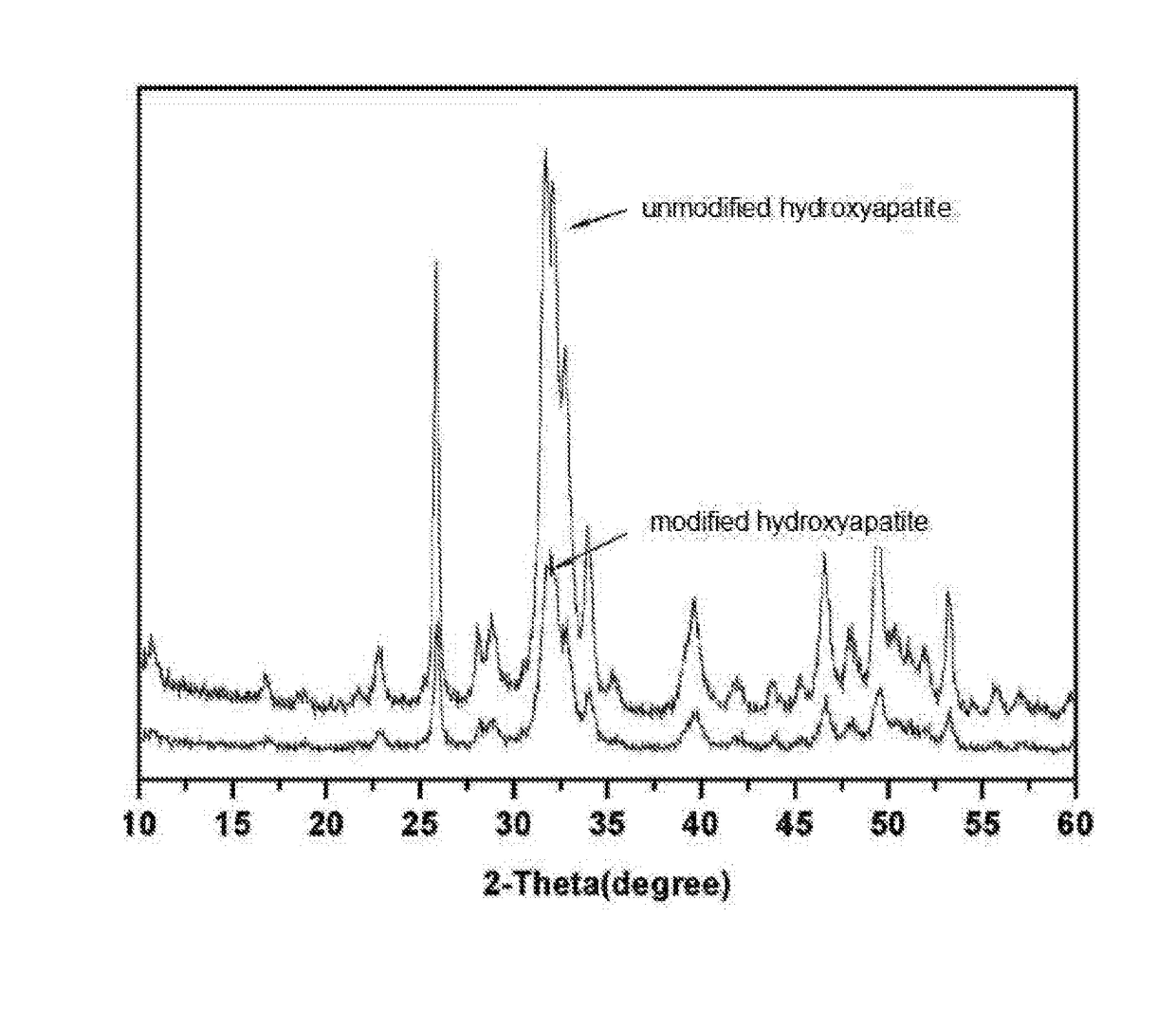

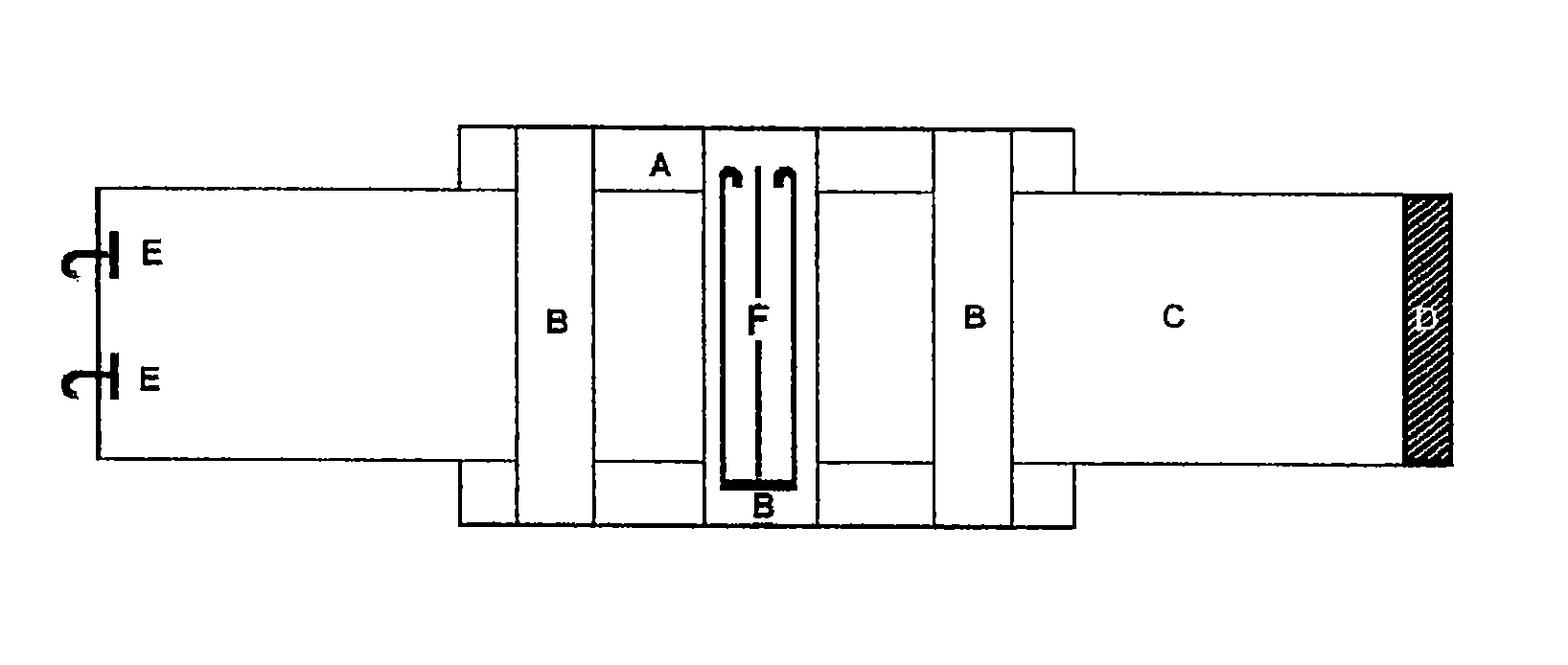

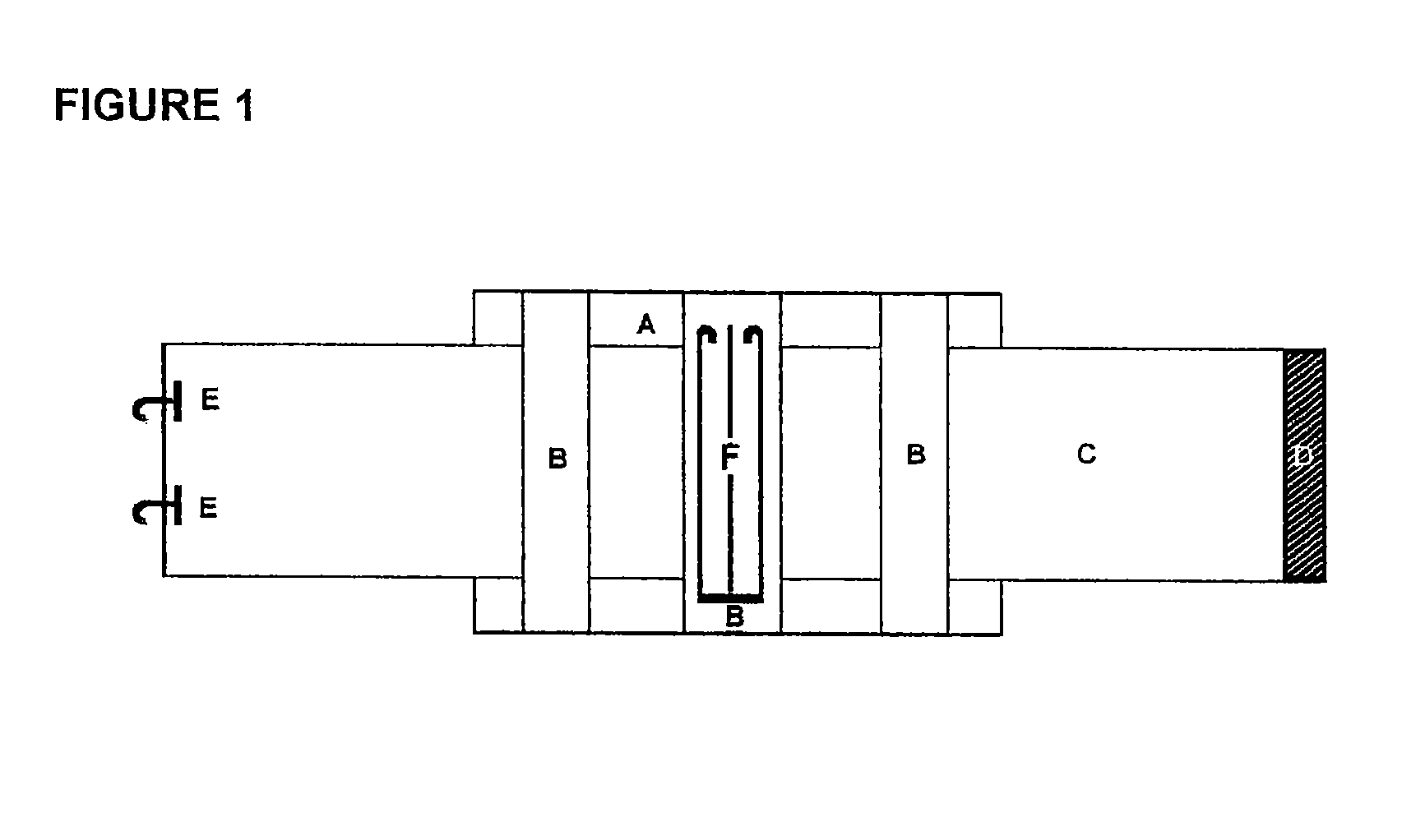

Bone repair material of multivariant amino acid polymer-hydroxyapatite, supportive implants and the preparation method thereof

ActiveUS20170327643A1Fast healing of bone tissueFacilitated releaseTissue regenerationProsthesisSolubilityApatite

The present invention relates to bone repair material of multivariant amino acid polymer-hydroxyapatite, supportive implants and preparation method. Said restorative material is made of multivariant amino acid polymers consisted with ε-aminocaproic acid and other α-amino acids, together with constituents modified hydroxyapatite, in which the constituent modified hydroxyapatite uses calcium salt as modified constituents that can be accepted in medicine and has a more solubility compared with hydroxyapatite. Modified hydroxyapatite is constructed from said calcium salt and hydroxyapatite, with a mass ratio of (2-20):(98-80), and the content of modified hydroxyapatite is 10-70% based on the mass of said bone repair material; the content of ε-aminocaproic acid in multivariant amino acid polymers is 60-99% based on the total molar quantity of multivariant amino acid polymers.

Owner:SICHUAN GUONA TECH

Hemostatic composition and device

InactiveUS20160346239A1Reduced tendency to swellEasy to useOrganic active ingredientsSurgical adhesivesFibrinolytic inhibitorEpsilon-Aminocaproic Acid

A hemostatic composition comprises calcium alginate, a chitosan, epsilon-aminocaproic acid, an acid selected from aminomethylbenzoic acid and tranexamic acid, and tannin. The method of making the hemostatic composition comprises mixing one or more polysaccharide bases, tannin, a fibrinolytic inhibitor, colloidal silver and a solvent to form a mixture, and drying the mixture at a temperature between 25° C. and 80° C. until residual moisture content is approximately 15 to 20%.

Owner:KOROBOV MAXIM

Hemostatic textile material

ActiveUS20080181936A1Facilitate fast stoppageDegree of compression can be adjustedOrganic active ingredientsBiocideHemolysisChlorhexidine

A hemostatic textile material to stop bleeding comprising a dialdehyde cellulose (DAC) carrier wherein the degree of oxidation of the dialdehyde cellulose varies from about 1.5% to 12%; and a blood coagulation factor selected from the group consisting of chitosan and gelatin; the blood coagulation factor being chemically immobilized thereon; and further optionally comprising a bacteriolytic agent selected from the group consisting of a lysozyme enzyme, silver nitrate, and chlorhexidine; and further optionally comprising a selected component that prevents hemolysis, the component selected from the group consisting of tranexamic acid or ε-aminocaproic acid chemically immobilized thereon.

Owner:FILATOV VLADIMIR N +2

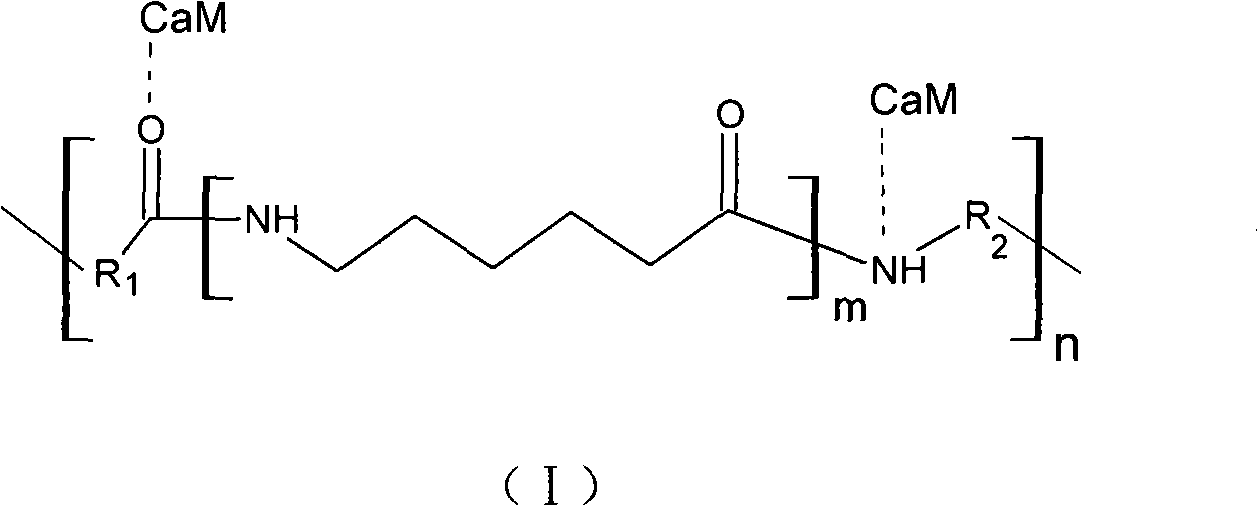

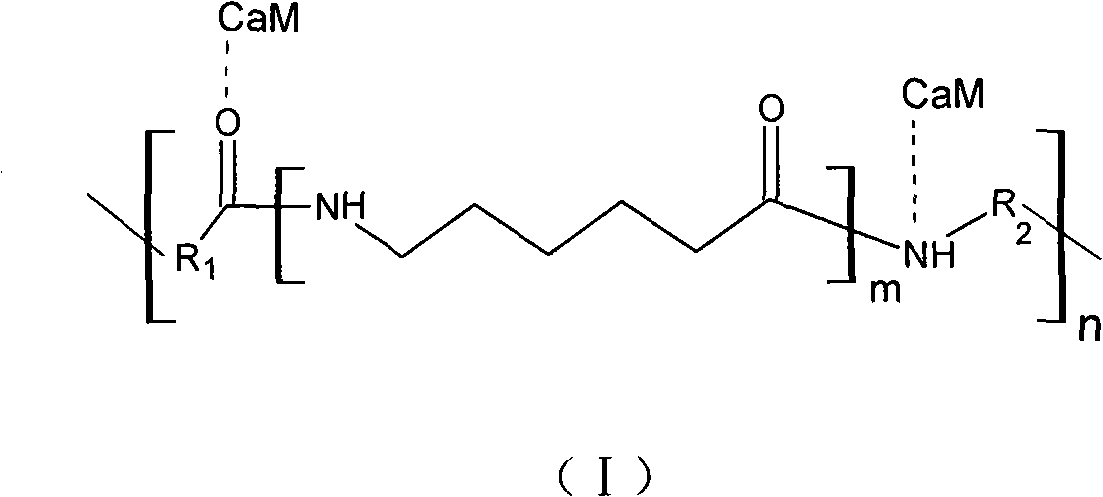

Tissue renovation material of polymer form and preparation method thereof

ActiveCN101342383BImprove hydrophilicityNo allergiesProsthesisTissue repairEpsilon-Aminocaproic Acid

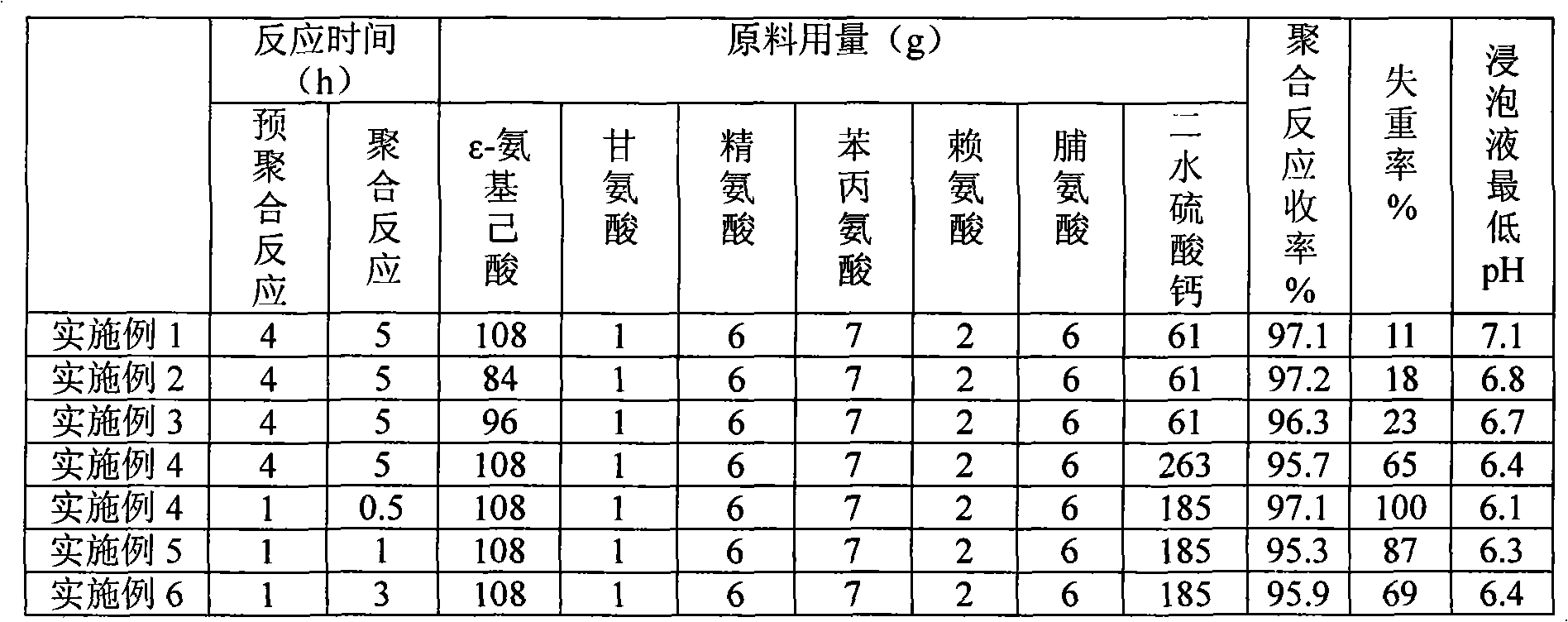

The present invention relates to a tissue-repairing material in the form of a polymer and a preparation method thereof. Epsilon-aminocaproic acid is polymerized with at least two other types of amine acids to form the tissue-repairing material shown in the formula, wherein, the mole ratio of the Epsilon-aminocaproic acid is 50 percent to 90 percent, and the rest is the other amine acids includingaminoacetic acid, lactamic acid, phenylalanine, lysine and proline. After being sufficiently and uniformly dispersed into water, the materials, amine acids, are heated to less than or equal to 200 DEG C, so that various forms of water can be removed from the materials; the materials are then pre-polymerized under the temperature between 200 DEG C and 220 DEG C and polymerized under the temperature between 220 DEG C and 250 DEG C; and the preparation process is conducted and fulfilled under the protection of an inert gas. The tissue-repairing material has ideal mechanical property, biological activity and controllable degradation property, and the degradation product of the tissue-repairing material is non-toxic and non-irritant. The tissue-repairing material can be widely used for the reparation and reconstruction of the tissues of the human body.

Owner:SICHUAN GUONA TECH

Amino acid copolymer-calcium sulfate composite material and preparation method thereof

The invention discloses an amino acid copolymer-calcium sulfate composite material and a preparation method thereof. The composite material mainly comprises a polyamino acid copolymer and calcium sulfate, wherein the polyamino acid copolymer at least contains epsilon- aminocaproic acid, and other amino acids are selected from glycin, lactamine, leucine, isoleucine, valine, threonine, serine, phenylalanine, tyrosine, tryptophan, praline, hydroxyproline, lysine and arginine. The calcium sulfate and amino acid monomers are fully stirred and mixed under the protection of inert gas at a temperatureof between 150 and 160 DEG C, the mixture is removed with moisture, then the mixture is subjected to in-situ polymerization complex reaction at a temperature of between 200 and 250 DEG C, and thus the composite material can be obtained. The degradation proportion of the composite material after the composite material is soaked in a simulated body fluid for 12w can be between 10 and 100 percent, the pH value of a soaking solution is more than 6, and the controllability and adjustability of the degradation rate of the composite material can be realized by a plurality of modes so as to greatly overcome the disadvantages of overquick degradation and the formation of an acid environment when the calcium sulfate is independently taken as a bone repair material.

Owner:SICHUAN GUONA TECH

Active multi-component bone repair/reconstruct composite material with controllable degradation and preparation method thereof

InactiveCN101716377AGood effectIdeally controllable degradation rateProsthesisIn situ polymerizationPhosphate

The invention relates to an active multi-component bone repair / reconstruct composite material with controllable degradation, which comprises a multi-component amino acid copolymer formed by polymerizing epsilon-aminocaproic acid and other amino acid, and inorganic calcium salt components containing phosphates and sulphates of calcium with the grain diameter of 200 meshes, wherein the weight of the inorganic calcium salt accounts for 30-65 percent of the total weight of the composite material. A preparation method comprises the following steps of: carrying out in situ polymerization and combination on amino acid monomers and part of the inorganic calcium salt components under the protection of inert gas to obtain an intermediate, crushing the intermediate, sufficiently mixing the crushed intermediate and the rest inorganic calcium salt components of the phosphates of calcium and / or the sulphates of calcium, and carrying out extrusion molding to obtain the composite material. The composite material has favorable bioactivity and compatibility, and the degradation product of the composite material is innoxious and has no irritant. Through adjusting the proportion of the phosphates of calcium and the sulphates of calcium, the degradation speed and the pH value in the degradation process can be effectively realized.

Owner:SICHUAN GUONA TECH

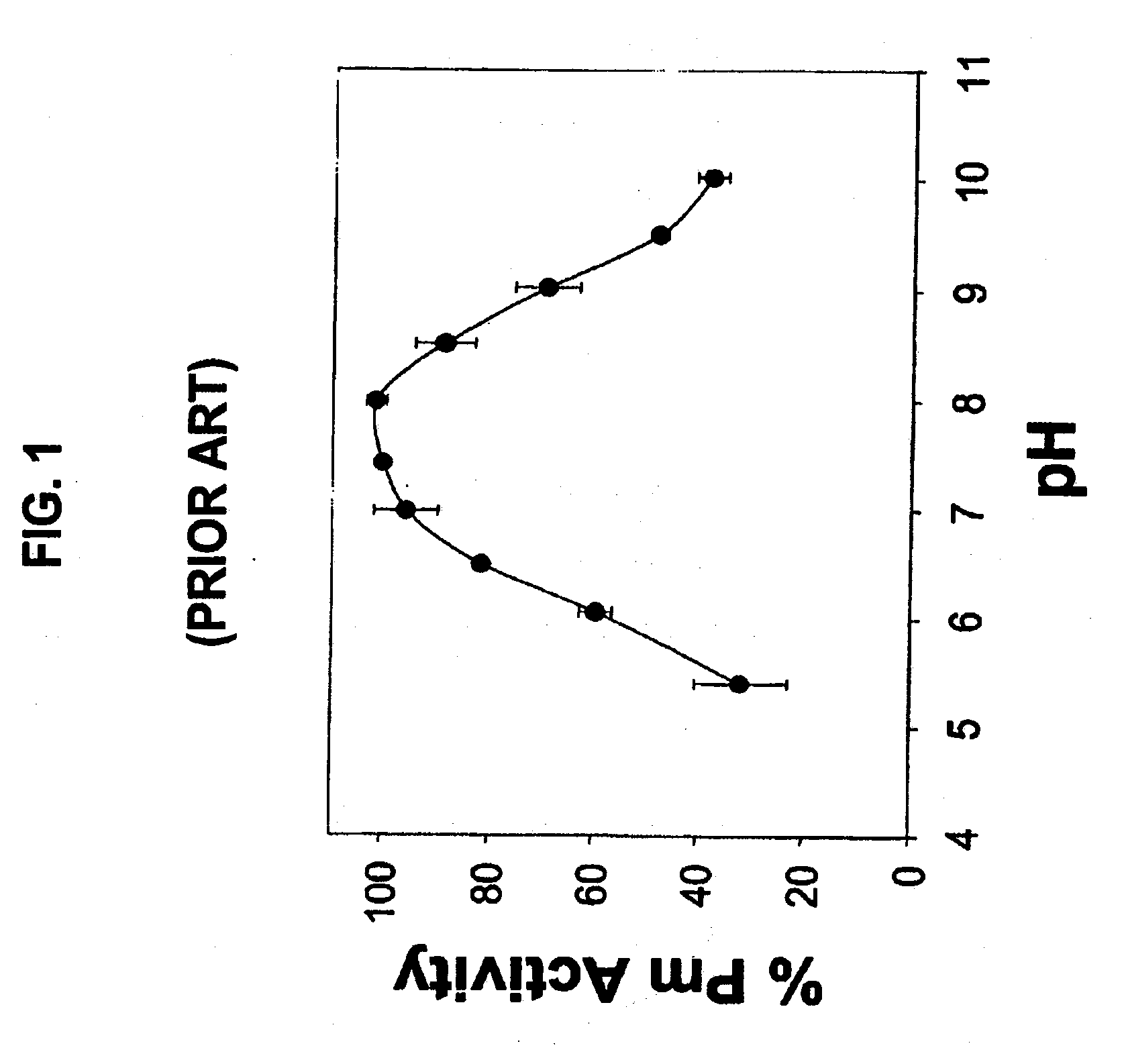

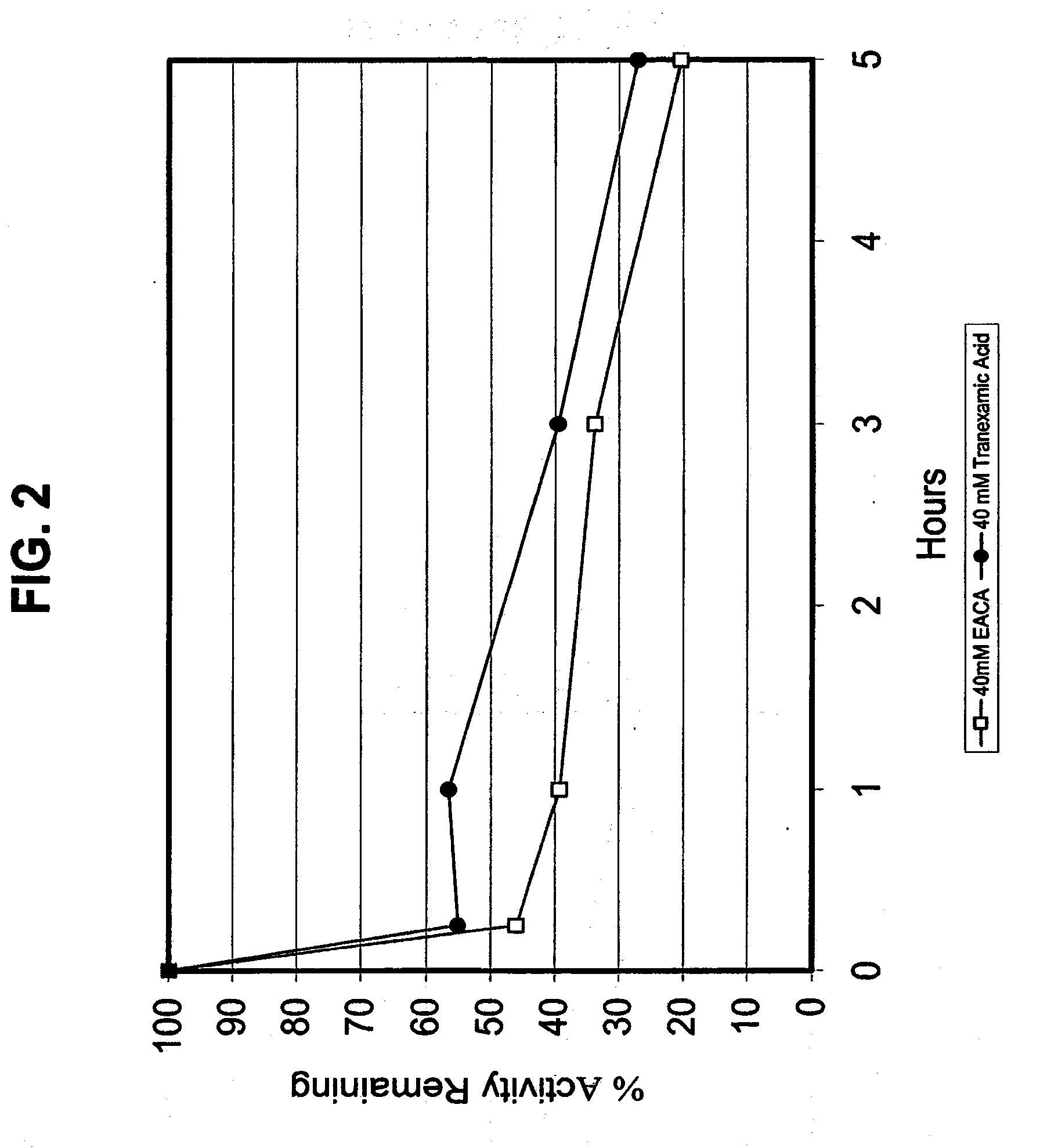

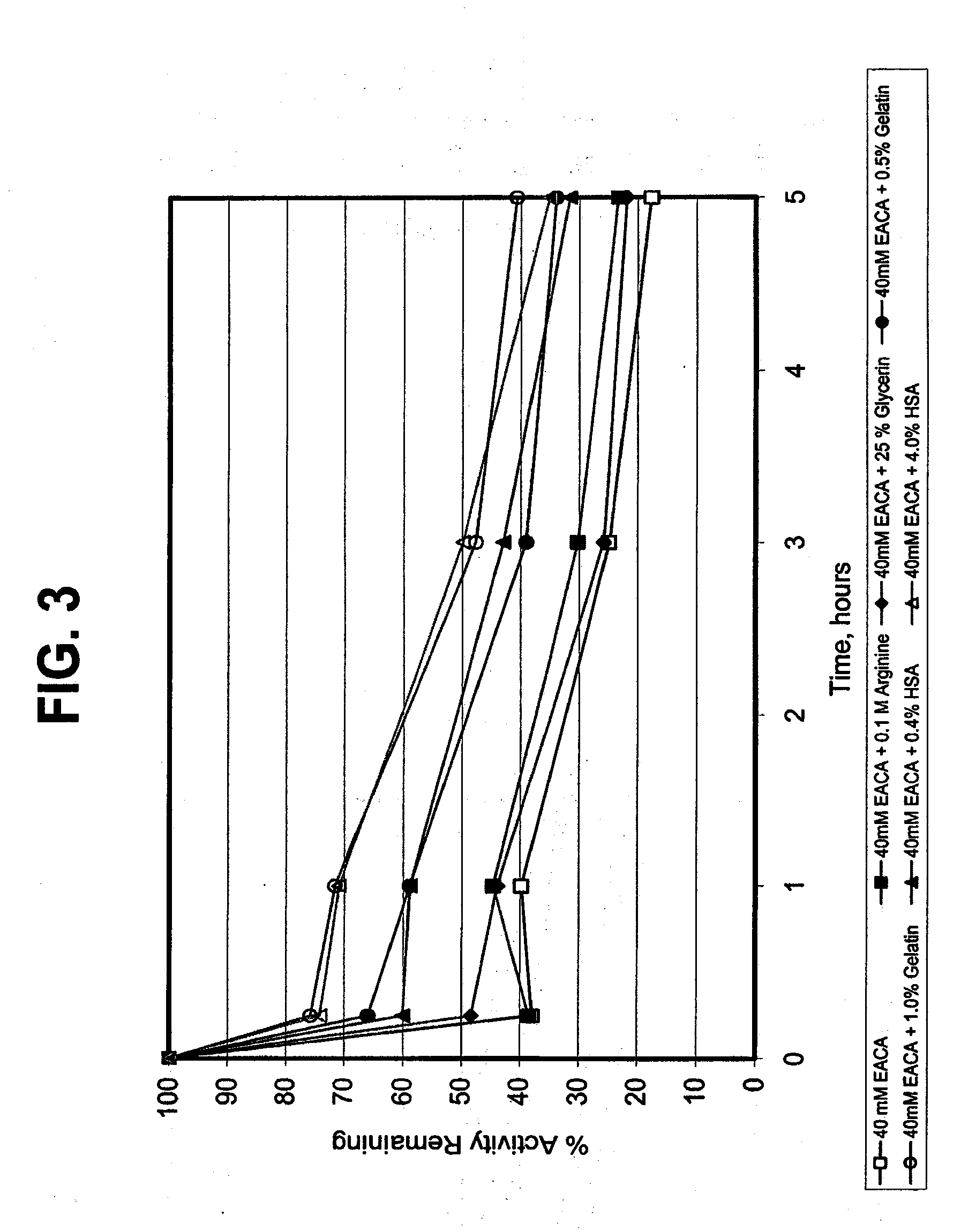

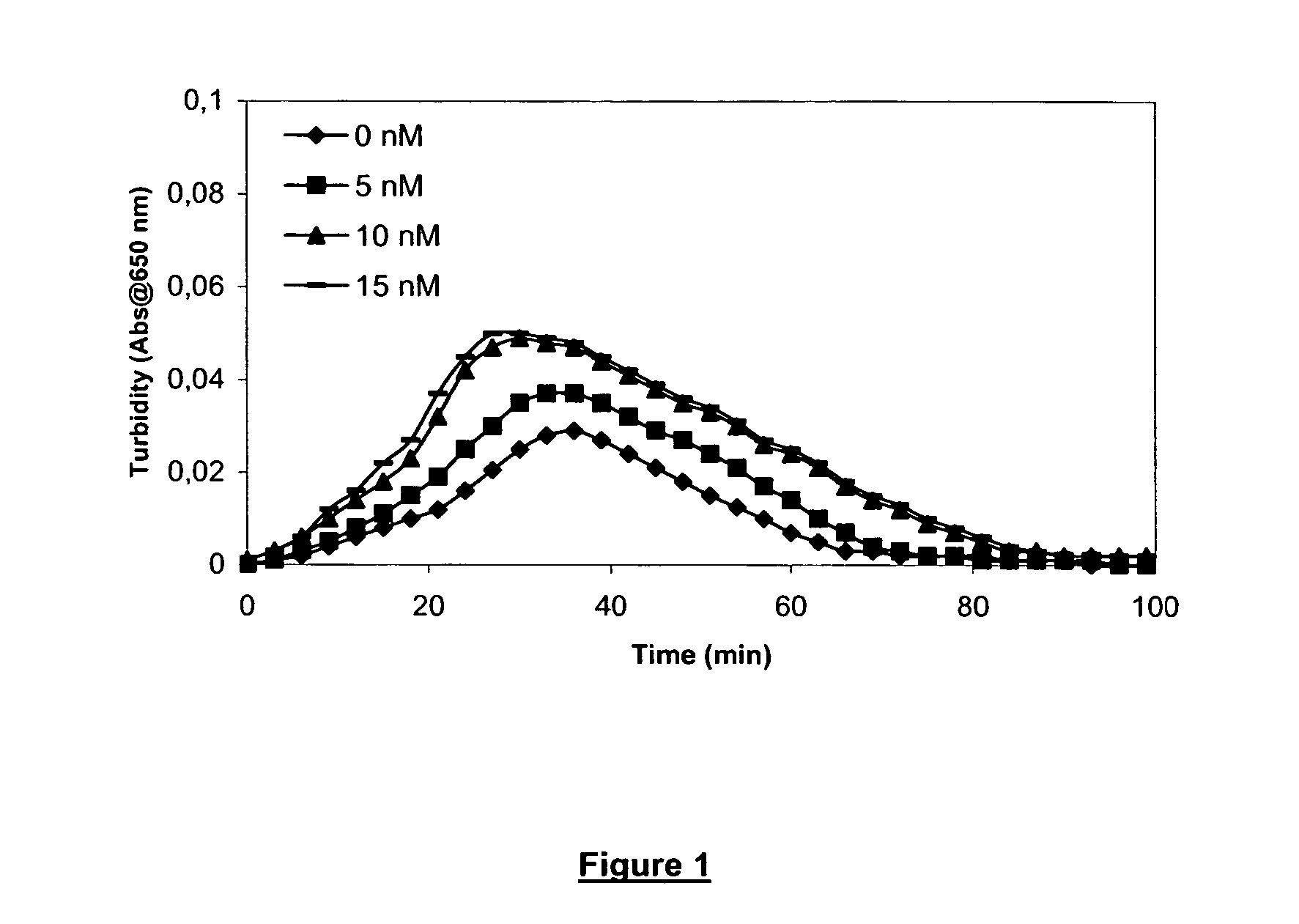

Method for prolonging activity of autodegradable enzymes and compositions thereof

A composition of a long-acting enzyme comprises the enzyme in a formulation comprising a buffer and an additive selected from the group consisting of tranexamic acid, ε-aminocaproic acid, and analogs of L-lysine other than tranexamic acid and ε-aminocaproic acid, combinations thereof, and mixtures thereof. The composition can further comprise another additive selected from the group consisting of L-lysine, L-arginine, L-ornithine (or its pharmaceutically acceptable salts; e.g., L-ornithine hydrochloride), γ-aminobutyric acid, 5-aminovaleric acid, 7-aminoheptanoic acid, glycylglycine, triglycine, N-α-acetyl-L-arginine, betaine, sarcosine, gelatin, HSA, streptokinase, tPA, uPA, non-ionic surfactants, glycerin, D-sorbitol, combinations thereof, and mixtures thereof. A method for prolonging the activity of an autodegradable enzyme comprises storing the enzyme after manufacture at a low pH, and reconstituting the acidified enzyme before use with a solution containing at least one of such additives. The method is useful to provide enzyme for wide use, which otherwise would lose activity upon long storage. In one embodiment the method is applicable to provide enzyme for inducing controlled posterior vitreous detachment.

Owner:TALECRIS BIOTHERAPEUTICS INC

Pharmaceutical composition comprising a factor VII polypeptide and epsilon-aminocaproic acid

InactiveUS20060293241A1Effective treatmentBiocideOrganic active ingredientsEpsilon-Aminocaproic AcidBleeding episodes

The present invention relates to compositions or kits comprising factor VII or a factor VII-related polypeptide and epsilon-aminocaproic acid, and the use thereof for the treatment of bleeding episodes or enhancement of hemostasis.

Owner:NOVO NORDISK AS

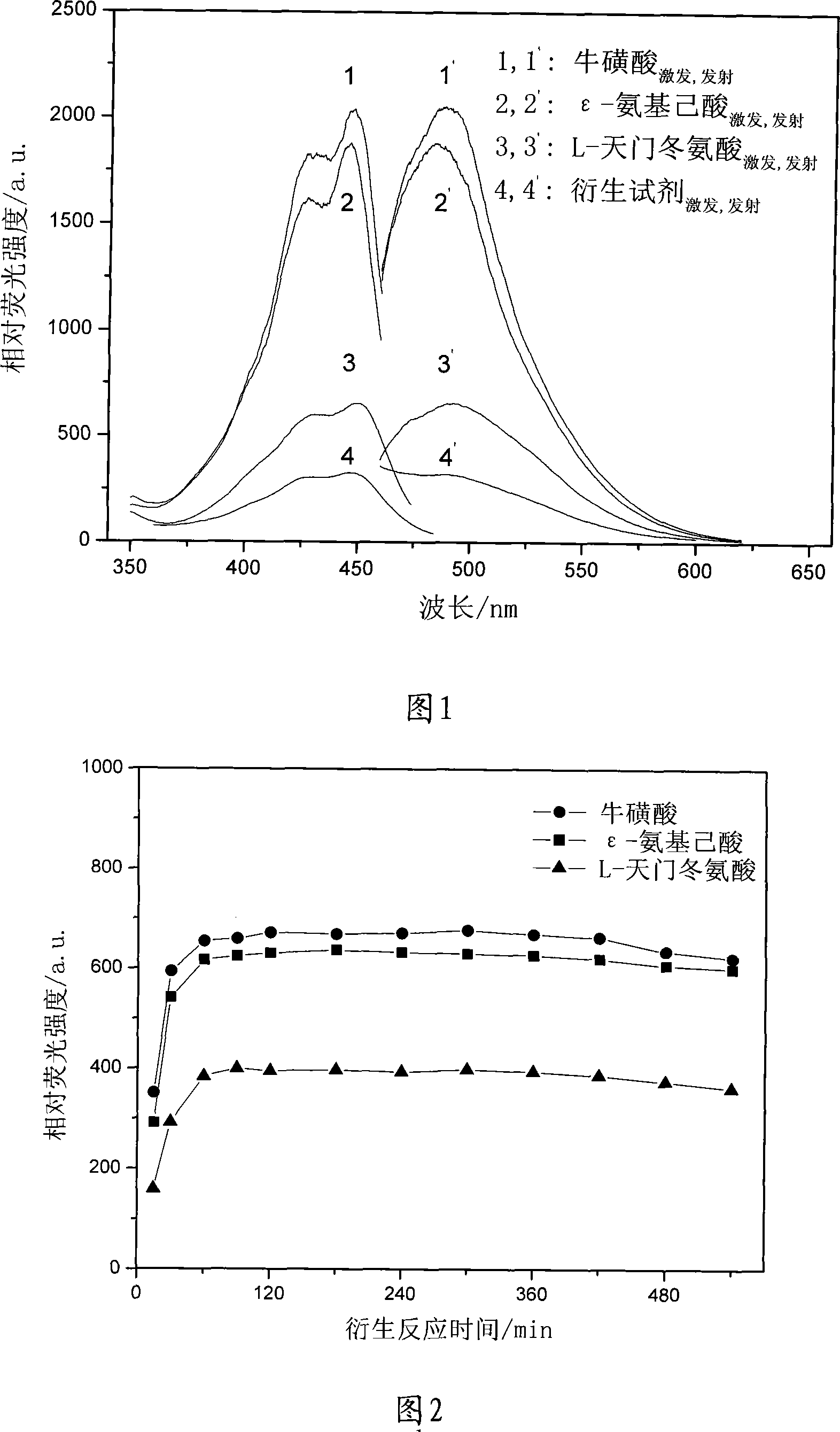

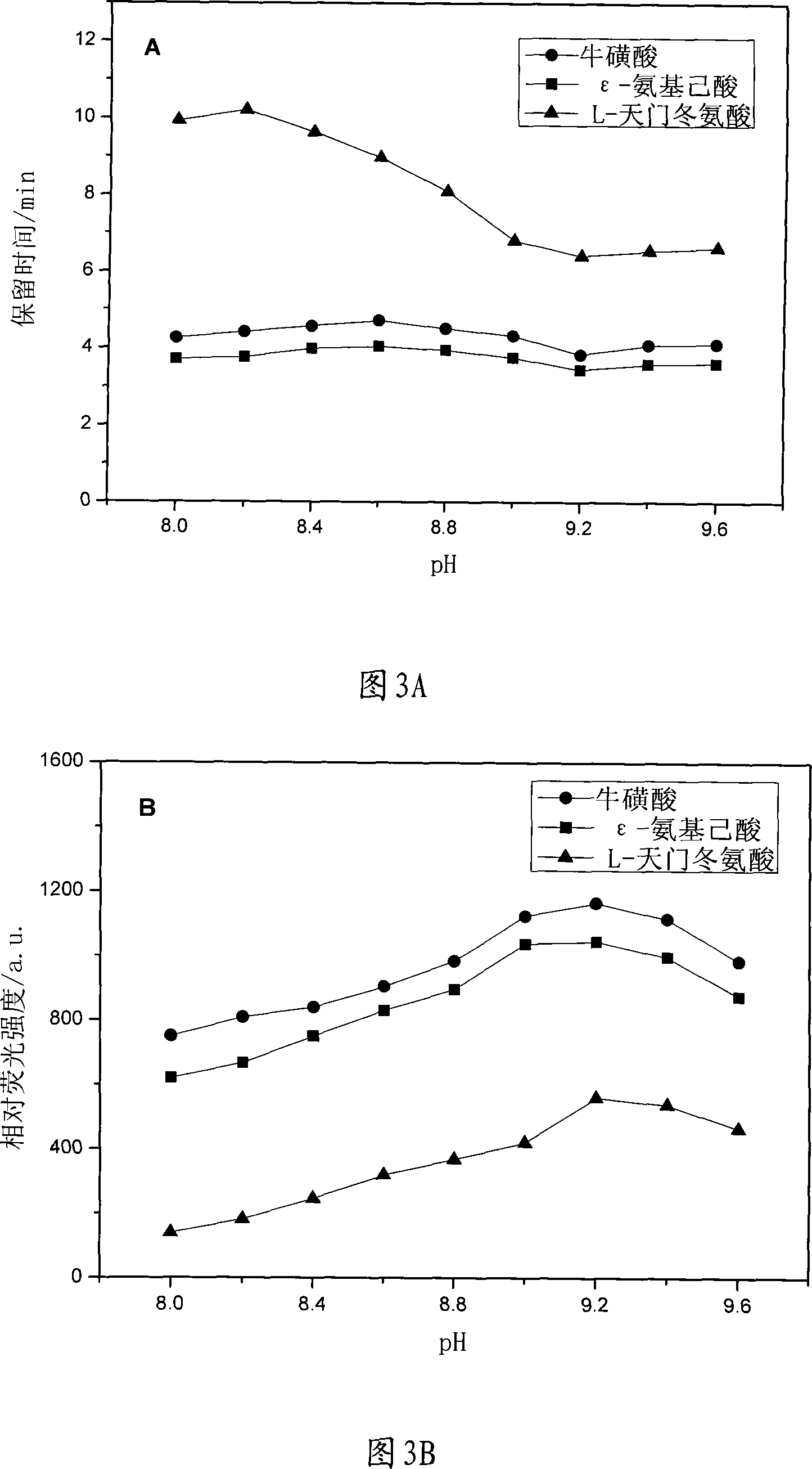

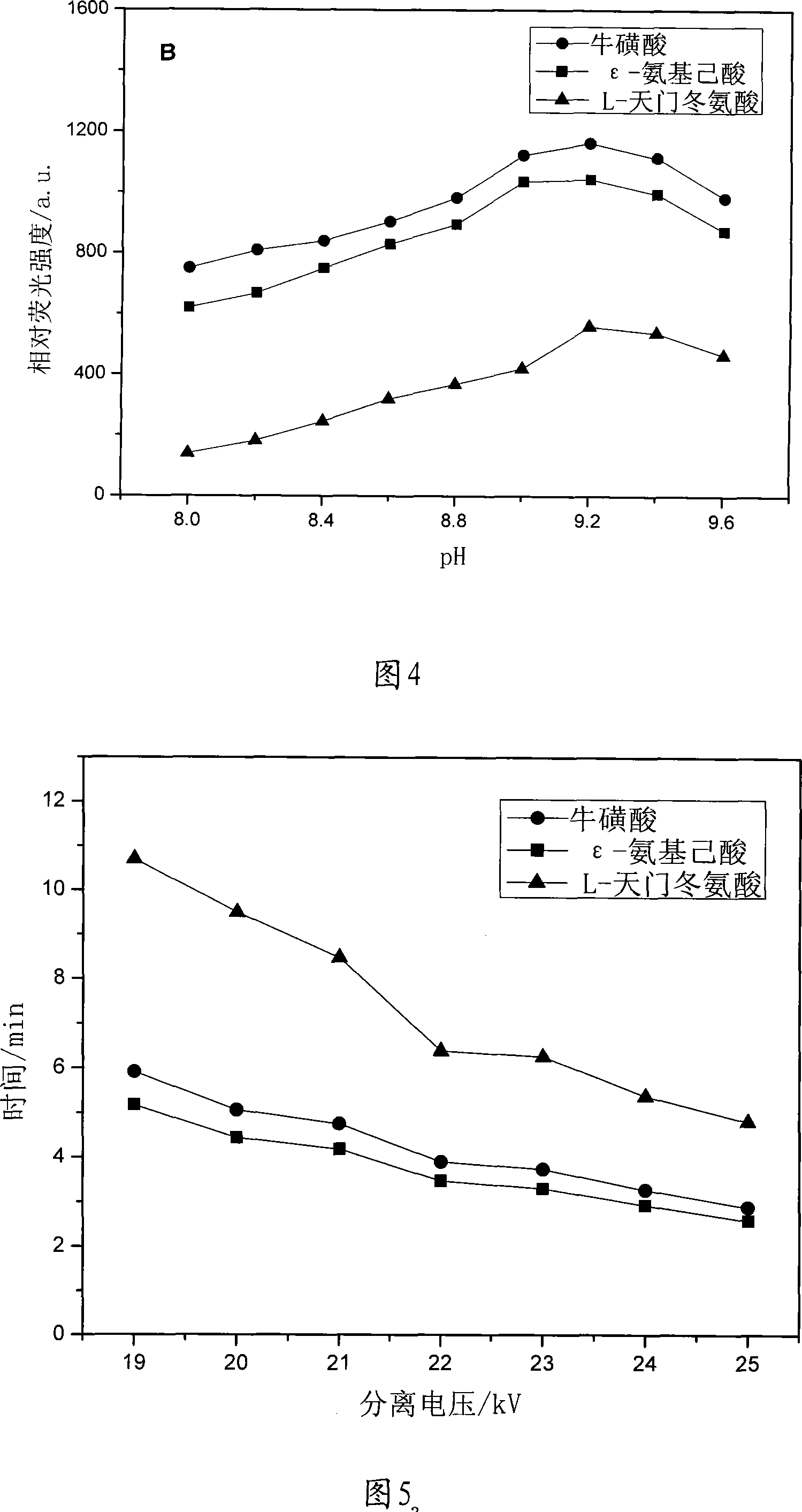

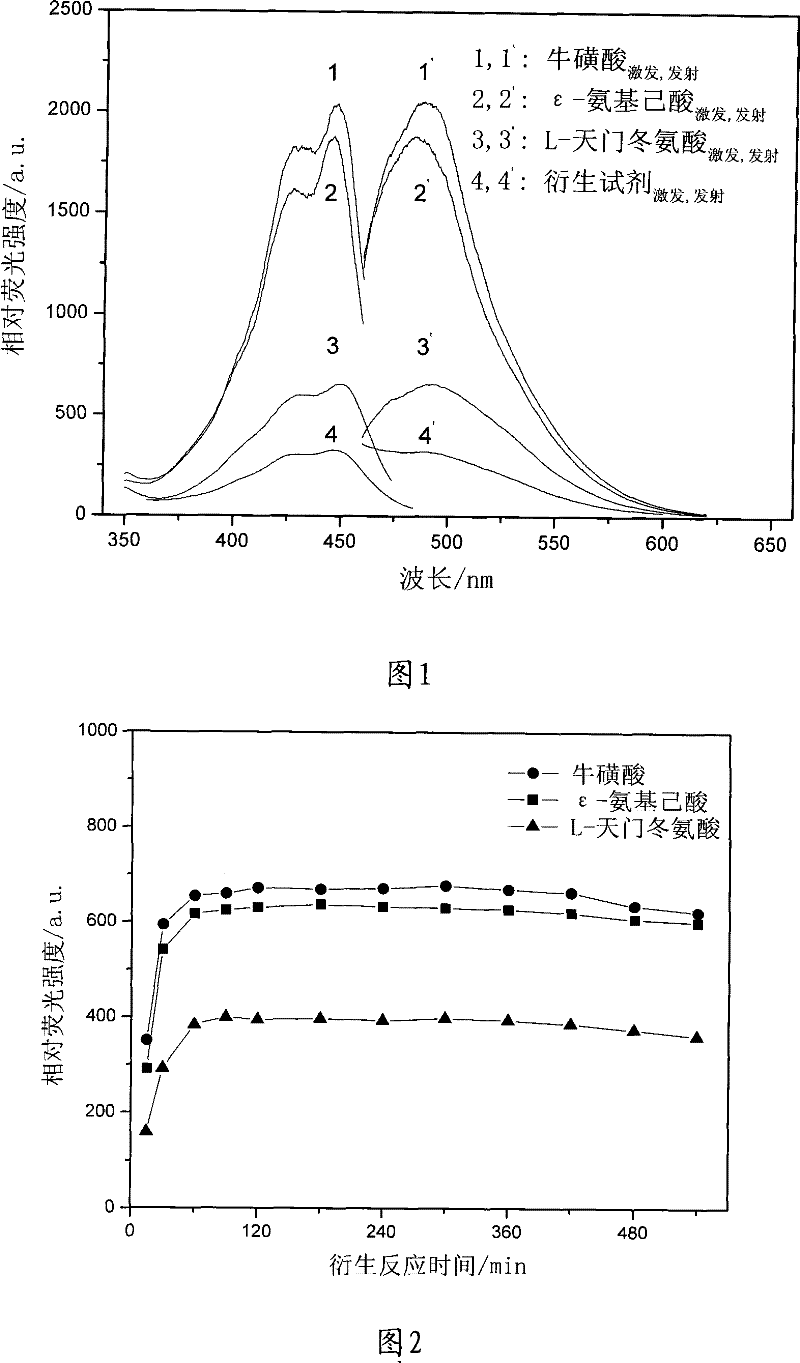

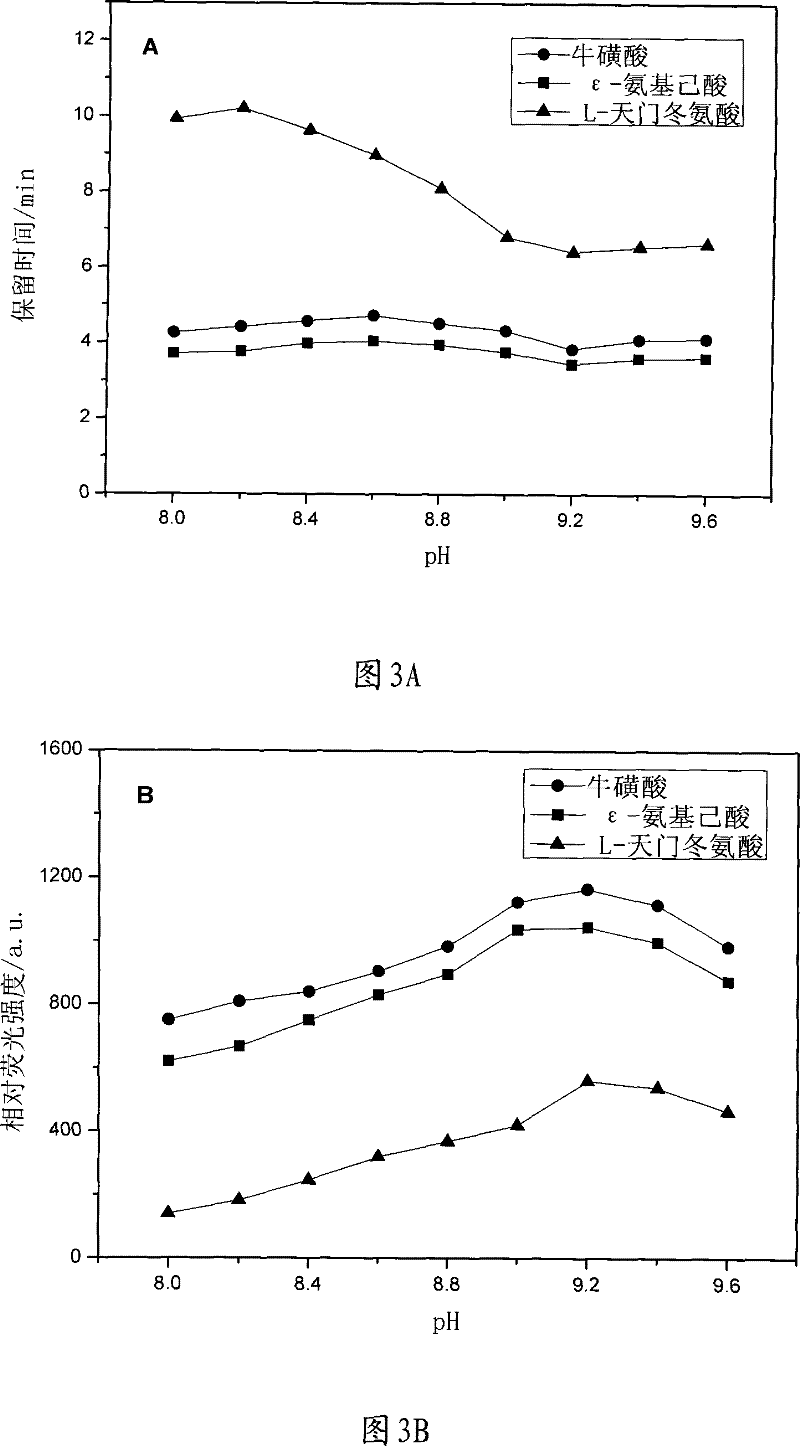

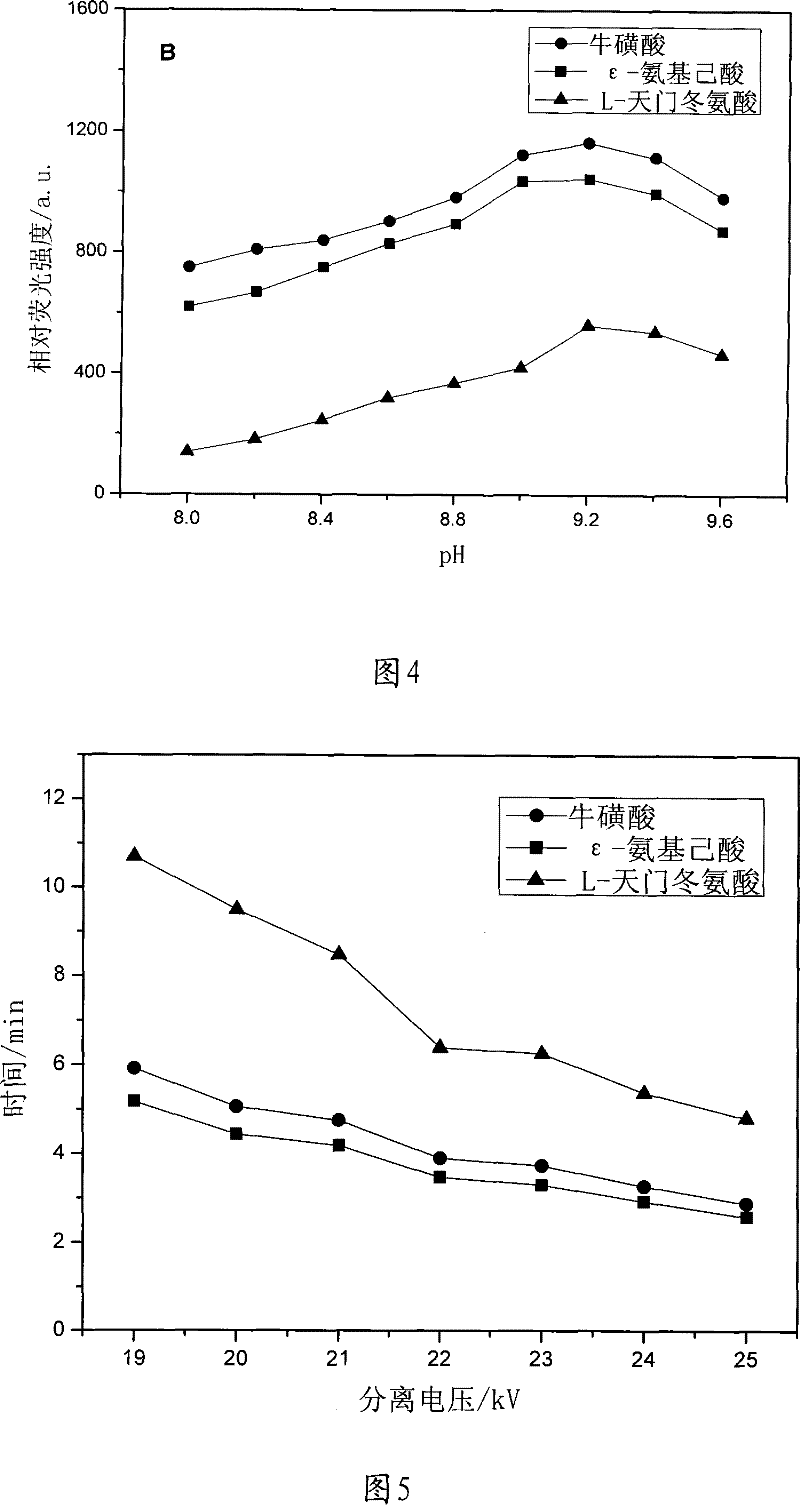

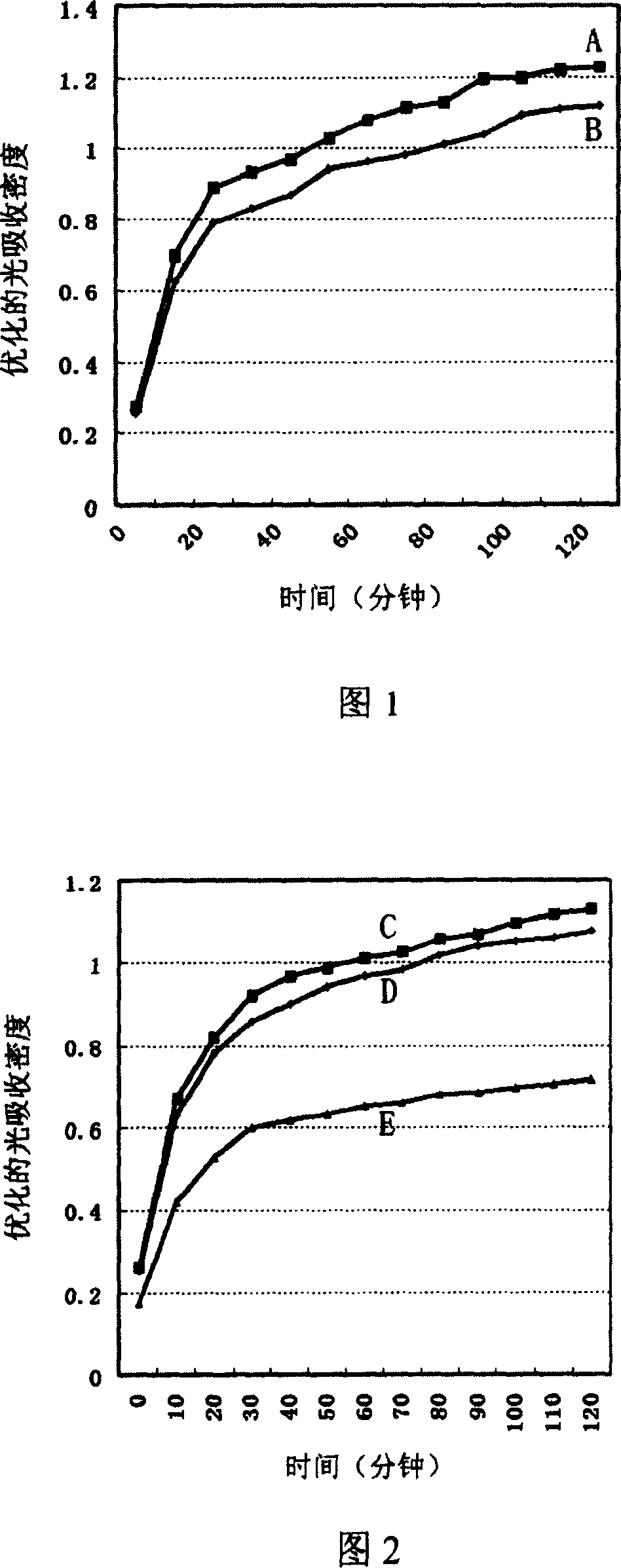

Method for simultaneous determination for taurine, epsilon-amino caproic acid and L-aspartic acid content of medicament

InactiveCN101241104AConvenient and fast simultaneous determinationReduce consumptionMaterial analysis by electric/magnetic meansCapillary electrophoresisPotassium cyanide

The present invention discloses a method for determining content of taurine, epsilon aminocaproic acid and L-aspartic acid in medicine at the same time, which comprises steps of: preparing sample solution to be measured; adding sample solution to be measured, naphthalenedicarboxaldehyde solution and potassium cyanide solution to process derivative reaction with borate buffer solution as reaction medium; entering capillary electrophoretic system to separate and detect, obtaining electrophoretogram of sample solution to be measured; comparing to electrophoretogram of mixture standard solution of taurine, epsilon aminocaproic acid and L-aspartic acid, confirming content of taurine, epsilon aminocaproic acid and L-aspartic acid in sample solution to be measured. The present invention can determine content of taurine, epsilon aminocaproic acid and L-aspartic acid in medicine expediently and rapidly, and has merits of simple operation, short analysis time, a little wastage of reagent and provides an optional method for general analysis and quality control of medicine.

Owner:SICHUAN UNIV

Preparing method for bioglass/amino acid polymer composite

InactiveCN105597147AEnhanced interactionImprove biological activityTissue regenerationProsthesisAminocaproic acidNitrogen

The invention discloses a preparing method for a bioglass / amino acid polymer composite. The preparing method comprises the following steps that epsilon-aminocaproic acid and other alpha-amino acid are taken and added with water, the mixture is dehydrated at 150-160 DEG C and then heated to 200-220 DEG C to be reacted for 2-3 h under the protection of nitrogen, the mixture is then heated to 230-235 DEG C to be reacted for 1-2 h, and an amino acid polymer is generated; then, bioglass is added, the mixture is evenly mixed and cooled, and the bioglass / amino acid polymer composite is obtained. The composite prepared through the method can have enough mechanical strength in the initial stage, can also be quickly degraded in the later stage and can meet the requirements for the mechanical strength and the degradation property at the same time; in addition, the method is easy and convenient to implement, simple in operation, convenient to control, safe, environmentally friendly, low in energy consumption, short in cycle, high in production efficiency and suitable for industrial application.

Owner:SICHUAN UNIV

Controllable degradation, filling-type complex bone implant of multivariant amino acid polymer-organic calcium/phosphorus salts, and prepration method thereof

ActiveUS20170340776A1Increase the degree of polymerizationHigh molecular weightTissue regenerationCoatingsAminocaproic acidBone implant

The present invention relates to the controllable degradation, filling-type complex bone implant of multivariant amino acid polymer-organic calcium / phosphorus salts, as well as to the preparative method thereof. The complex bone implant is consisted of multivariant amino acid polymers and medically acceptable organic calcium / phosphorus salts, while the content of organic calcium / phosphorus salts is 20-90% based on the total mass of composite material; the multivariant amino acid polymer is polymerized by ε-aminocaproic acid and at least two other amino acids, in which the molar content of ε-aminocaproic acid is at least 50% of the total molar quantity of amino acid polymers, while the amounts of other amino acids are at least 0.5% of the total molar quantity of amino acid polymers.

Owner:SICHUAN GUONA TECH

Traditional Chinese medicine capable of alleviating asthenopia and preparation method of traditional Chinese medicine

InactiveCN106620165ATreat pseudomyopiaImprove or relieve visual impairmentSenses disorderHydroxy compound active ingredientsAdditive ingredientL-Aspartate

The invention discloses a traditional Chinese medicine capable of alleviating asthenopia and a preparation method of the traditional Chinese medicine. The traditional Chinese medicine is prepared from the following raw materials in parts by weight: 16-22 parts of vaccinium vitis-idaea lutein, 10-20 parts of all-grass of silybum marianum, 10-15 parts of zinc oxide, 10-15 parts of copper oxide, 17-23 parts of blueberries, 9-14 parts of flos buddlejae, 3-5 parts of licorice root,10-20 parts of semen cassiae, 13-27 parts of flos chrysanthemi indici, 3-5 parts of epsilon-aminocaproic acid, 3-5 parts of potassium L-aspartate, 4-6 parts of rose flowers, 5-7 parts of nostoc commune, 4-8 parts of fructus kochiae, and 5-7 parts of succus aloes folii siccatus. For the traditional Chinese medicine, through the reasonable mixing of the active ingredients, the traditional Chinese medicine has multiple efficacies of treating pseudomyopia, preventing and treating xerophthalmus, and protecting and brightening the eyes, and also can improve or alleviate the asthenopia symptoms including visual impairment, eye fatigue, photaesthesia, ache, lacrimation, foreign body sensation, ocular dryness, ophthalmospasm, and the like, and meanwhile, the traditional Chinese medical ingredients contained in the traditional Chinese medicine can directly participate in the tissue metabolism of eyes, and have the efficacy of removing liver-fire for improving eyesight.

Owner:HENAN UNIV OF CHINESE MEDICINE

Wound dressing for first aid

ActiveCN1772312AInhibit arterial and venous hemorrhageAvoid pollutionPeptide/protein ingredientsAbsorbent padsWound dressingDissolution

The wound dressing for first aid is one support matter made of biocompatible synthetic material and sprayed with additive containing calcium ion, animal thrombase, aminocaproic acid, antibiotic resisting secondary infection, analgetic, and fibrous primordial cell growth factor or epithelial cell growth factor. The present invention controls hemorrhage through activating bodyí»s blood coagulation mechanism and inhibiting fibrin dissolution, and can inhibit massive haemorrhage of both artery and vein effectively in short time. The present invention has no any foreign human protein and thus has no hematogenic virus contamination and excellent safety.

Owner:YANG LING ANDIYUAN BIOTECHNOLOGY CO LTD

High-performance asphalt pavement repair material

InactiveCN106118096AHigh viscosityImprove anti-agingIn situ pavingsBuilding insulationsCrack resistancePolyvinyl alcohol

A high-performance asphalt pavement repair material, which is made of the following raw materials in parts by weight: 25-35 parts of petroleum asphalt, 3-7 parts of micaceous iron oxide, 6-11 parts of butanol, and 7-9 parts of aluminum stearate , 2-4 parts of accelerator, 12-16 parts of rubber particles, 3-5 parts of hexaaminocaproic acid, 6-8 parts of polyvinyl alcohol, 0.4-1.2 parts of sodium aluminate, 0.5-1.2 parts of disodium octaborate tetrahydrate , 5-8 parts of fluorite powder, 4-8 parts of film-forming aids, 6-13 parts of acrylate, 5-7 parts of p-phenylenediamine, 4-8 parts of triethanolamine, 5-9 parts of sodium silicate, and 4 parts of sulfur ‑8 parts, polyamide 2‑4 parts. The beneficial effects of the present invention are: the high-performance asphalt pavement repair material of the present invention has very good viscosity and anti-aging properties, excellent repair performance, improves the anti-cracking ability of the material under low temperature conditions, and provides relatively high-demand road pavement. good guarantee.

Owner:青岛百千川海洋生态科技有限公司

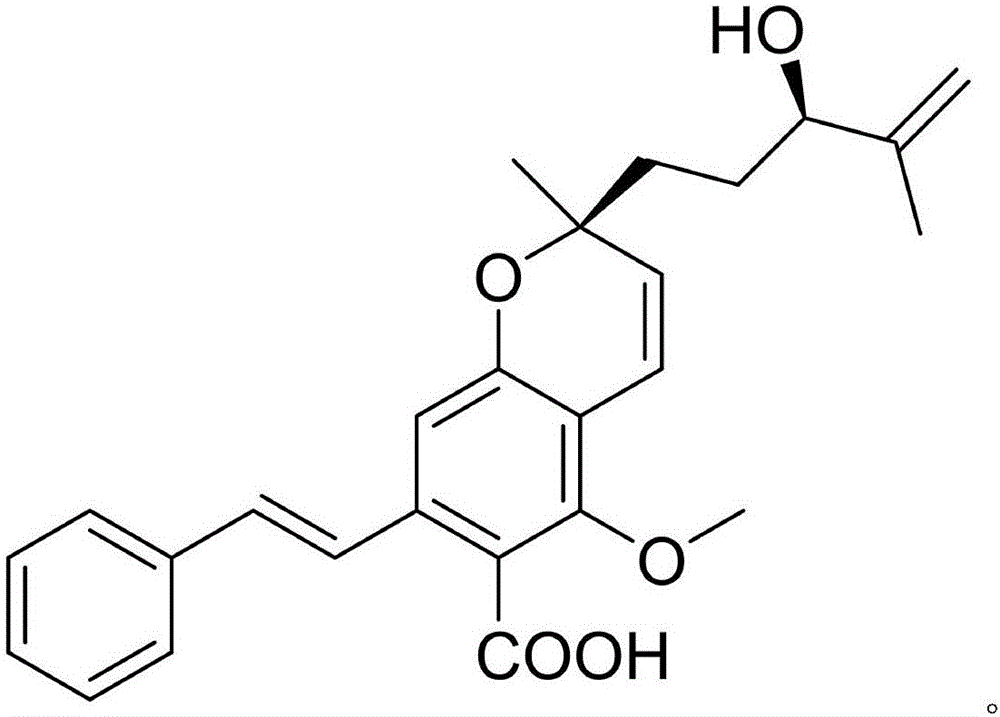

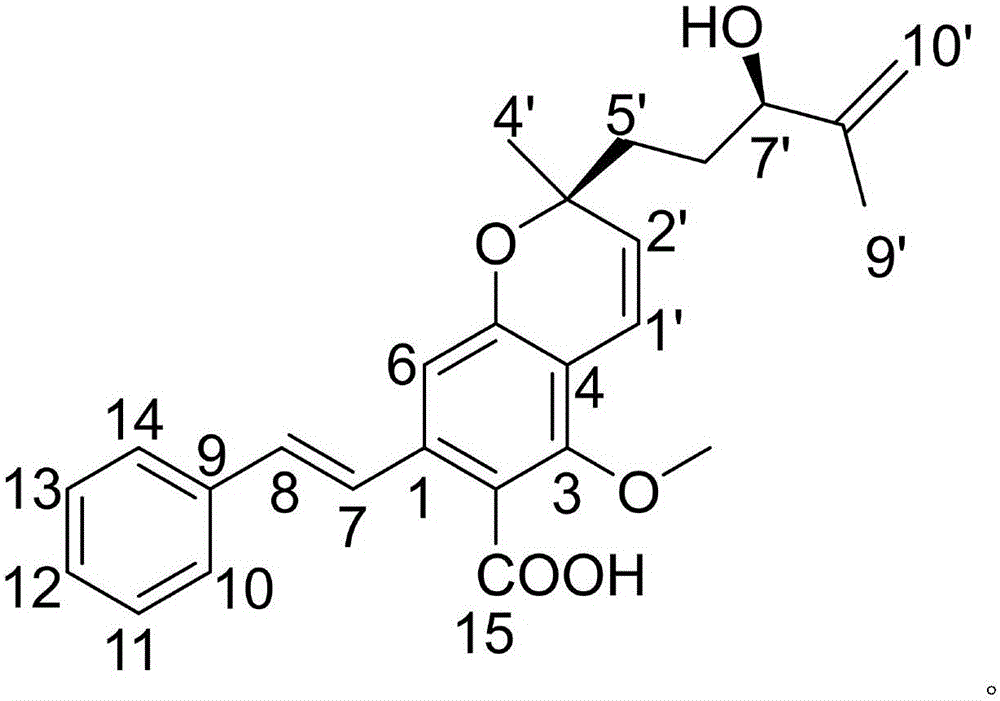

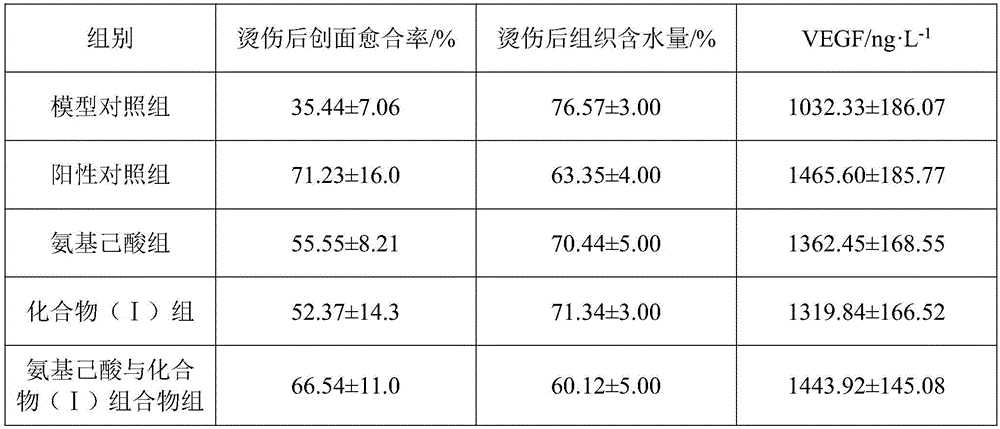

Aminocaproic acid medicine composition and pharmaceutical application thereof

InactiveCN105777694AIncreased protection against deep burnsHighlight substantiveOrganic active ingredientsOrganic chemistryNatural productMedicine

The invention discloses an aminocaproic acid medicine composition and pharmaceutical application thereof. The aminocaproic acid medicine composition contains aminocaproic acid and a natural product compound (I) which is separated from dried folium sennae and is of a novel structure. Only common deep-scald protection effects can be realized when the aminocaproic acid and the natural product compound (I) are individually used, but deep-scald protection effects can be obviously improved when the aminocaproic acid and the natural product compound (I) are used with each other, and accordingly the aminocaproic acid medicine composition can be developed to obtain deep-scald protection medicines. Compared with the prior art, the aminocaproic acid medicine composition and the pharmaceutical application have the advantages of outstanding substantial characteristics and obvious advancement.

Owner:李晨露

Blood cell separation membrane

ActiveCN101819198BSemi-permeable membranesMammal material medical ingredientsHemolysisRed blood cell

A blood cell separation membrane capable of separating blood cells from serum and plasma while preventing blood cell hemolysis. Such a blood cell separation membrane can be obtained by impregnating a porous membrane capable of separating cells from fed blood with a solution containing a hydrophobic aminocarboxylic acid, a protein derived from silk, Tris, TES, [epsilon]-aminohexanoic acid, tranexamic acid or heparin and drying the impregnated membrane.

Owner:ARKRAY INC

Use of decamethylene diamine in preparing copolyamide hot sol

The invention relates to the application of a class of long carbon chain diamine products in the preparation of copolyamide hot-melt adhesives, in particular the application of decane diamine products in the preparation of copolyamide hot-melt adhesives. Its main technical solutions are: ① Decanediamine does not need to be salt-formed, and can be directly fed to participate in copolymerization to obtain hot-melt adhesives; ② Copolymerized hot-melt adhesives can be composed of ternary components or multiple components; ③ Copolymerized hot-melt adhesives generally contain a , b Two basic units: a. Two or more C6-13 diamines and two or more C6-13 dibasic acids (amine, acid equimolar ratio); b. Caprolactam or ε-aminocaproic acid ; The two units of a and b are composed of: raw material a.60-80%; raw material b.20-40%. Decanediamine belongs to a raw material. Adopting the preparation method of the invention can simplify the technological process, reduce the production cost, and make the operation convenient. The copolyamide hot-melt adhesive produced is widely used in industries such as garment adhesive interlining, shoemaking, automobile industry, packaging and printing.

Owner:WUXI YINDA NYLON

Blood cell separation membrane and blood retention tool using the same

InactiveUS20090145840A1Avoid hemolysisImprove accuracyAnalysis using chemical indicatorsMaterial analysis by observing effect on chemical indicatorHemolysisRed blood cell

The present invention provides a blood cell separation membrane for separating blood into serum or plasma and blood cells while preventing hemolysis of the blood cells. Such a blood cell separation membrane can be obtained by impregnating a porous membrane for separating blood cells from blood supplied thereto with a solution containing a hydrophobic aminocarboxylic acid, a protein derived from silk, Tris, TES, ε-aminohexanoic acid, tranexanmic acid, or heparin and then drying the membrane.

Owner:ARKRAY INC

A kind of preparation method of bioglass/amino acid polymer composite material

InactiveCN105597147BEnhanced interactionImprove biological activityTissue regenerationProsthesisNitrogenEpsilon-Aminocaproic Acid

The invention discloses a preparing method for a bioglass / amino acid polymer composite. The preparing method comprises the following steps that epsilon-aminocaproic acid and other alpha-amino acid are taken and added with water, the mixture is dehydrated at 150-160 DEG C and then heated to 200-220 DEG C to be reacted for 2-3 h under the protection of nitrogen, the mixture is then heated to 230-235 DEG C to be reacted for 1-2 h, and an amino acid polymer is generated; then, bioglass is added, the mixture is evenly mixed and cooled, and the bioglass / amino acid polymer composite is obtained. The composite prepared through the method can have enough mechanical strength in the initial stage, can also be quickly degraded in the later stage and can meet the requirements for the mechanical strength and the degradation property at the same time; in addition, the method is easy and convenient to implement, simple in operation, convenient to control, safe, environmentally friendly, low in energy consumption, short in cycle, high in production efficiency and suitable for industrial application.

Owner:SICHUAN UNIV

Blood cell separation membrane and blood retention tool including the same

ActiveCN101819198ASemi-permeable membranesMammal material medical ingredientsHemolysisRed blood cell

A blood cell separation membrane capable of separating blood cells from serum and plasma while preventing blood cell hemolysis. Such a blood cell separation membrane can be obtained by impregnating a porous membrane capable of separating cells from fed blood with a solution containing a hydrophobic aminocarboxylic acid, a protein derived from silk, Tris, TES, [epsilon]-aminohexanoic acid, tranexamic acid or heparin and drying the impregnated membrane.

Owner:ARKRAY INC

Method for simultaneous determination for taurine, epsilon-amino caproic acid and L-aspartic acid content of medicament

InactiveCN101241104BConvenient and fast simultaneous determinationReduce consumptionMaterial analysis by electric/magnetic meansPotassium cyanideTaurine

The present invention discloses a method for determining content of taurine, epsilon aminocaproic acid and L-aspartic acid in medicine at the same time, which comprises steps of: preparing sample solution to be measured; adding sample solution to be measured, naphthalenedicarboxaldehyde solution and potassium cyanide solution to process derivative reaction with borate buffer solution as reaction medium; entering capillary electrophoretic system to separate and detect, obtaining electrophoretogram of sample solution to be measured; comparing to electrophoretogram of mixture standard solution of taurine, epsilon aminocaproic acid and L-aspartic acid, confirming content of taurine, epsilon aminocaproic acid and L-aspartic acid in sample solution to be measured. The present invention can determine content of taurine, epsilon aminocaproic acid and L-aspartic acid in medicine expediently and rapidly, and has merits of simple operation, short analysis time, a little wastage of reagent and provides an optional method for general analysis and quality control of medicine.

Owner:SICHUAN UNIV

Wound dressing for first aid

ActiveCN1321702CAvoid pollutionImprove securityPeptide/protein ingredientsAbsorbent padsWound dressingDissolution

The wound dressing for first aid is one support matter made of biocompatible synthetic material and sprayed with additive containing calcium ion, animal thrombase, aminocaproic acid, antibiotic resisting secondary infection, analgetic, and fibrous primordial cell growth factor or epithelial cell growth factor. The present invention controls hemorrhage through activating body's blood coagulation mechanism and inhibiting fibrin dissolution, and can inhibit massive haemorrhage of both artery and vein effectively in short time. The present invention has no any foreign human protein and thus has no hematogenic virus contamination and excellent safety.

Owner:YANG LING ANDIYUAN BIOTECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com