Active multi-component bone repair/reconstruct composite material with controllable degradation and preparation method thereof

A composite material, multi-component technology, applied in medical science, prosthesis, etc., can solve the problems of mechanical properties of composite materials, can not meet the requirements of biomechanical properties, etc., achieve controllable degradation rate, good biological activity and compatibility the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~20

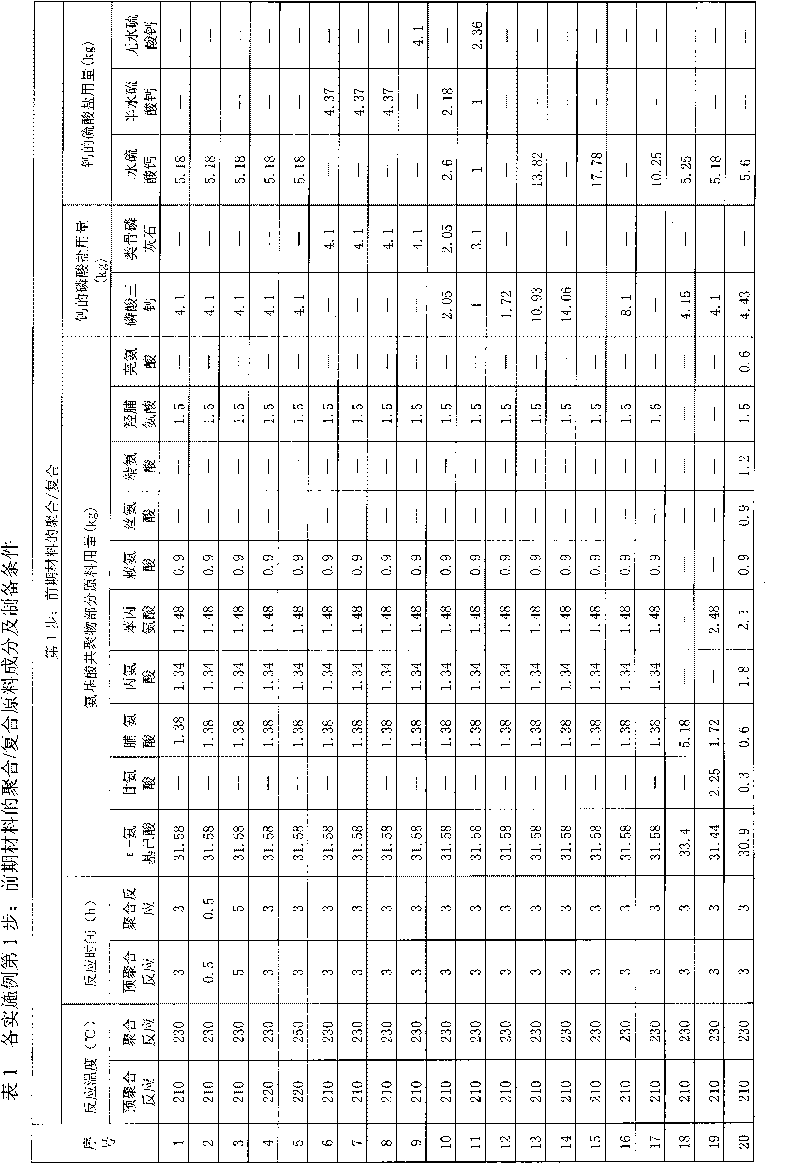

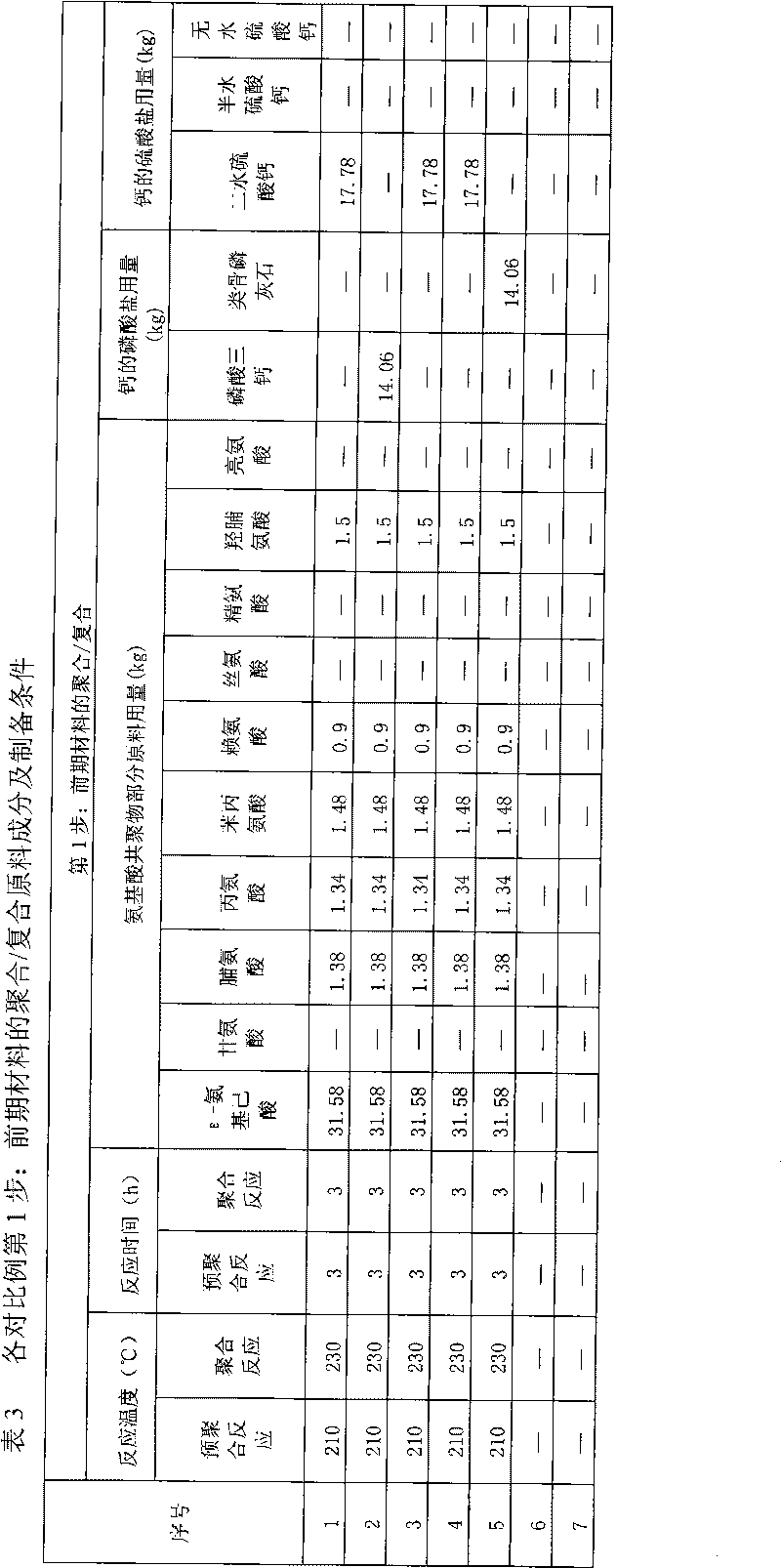

[0023] In Table 1, each amino acid component of the first step of the polymerization compound reaction in Examples 1 to 20 and the calcium sulfate salts and / or calcium phosphate salts with a total content of inorganic calcium salt of 5 to 40% are added to the reactor respectively. Add 10-15L of water, stir and dehydrate at 150°C-170°C (observe that the amino acid in the reactant starts to melt, which means that the dehydration treatment stage has been completed). Carry out in-situ polymerization composite reaction according to the time and temperature listed in Table 1.

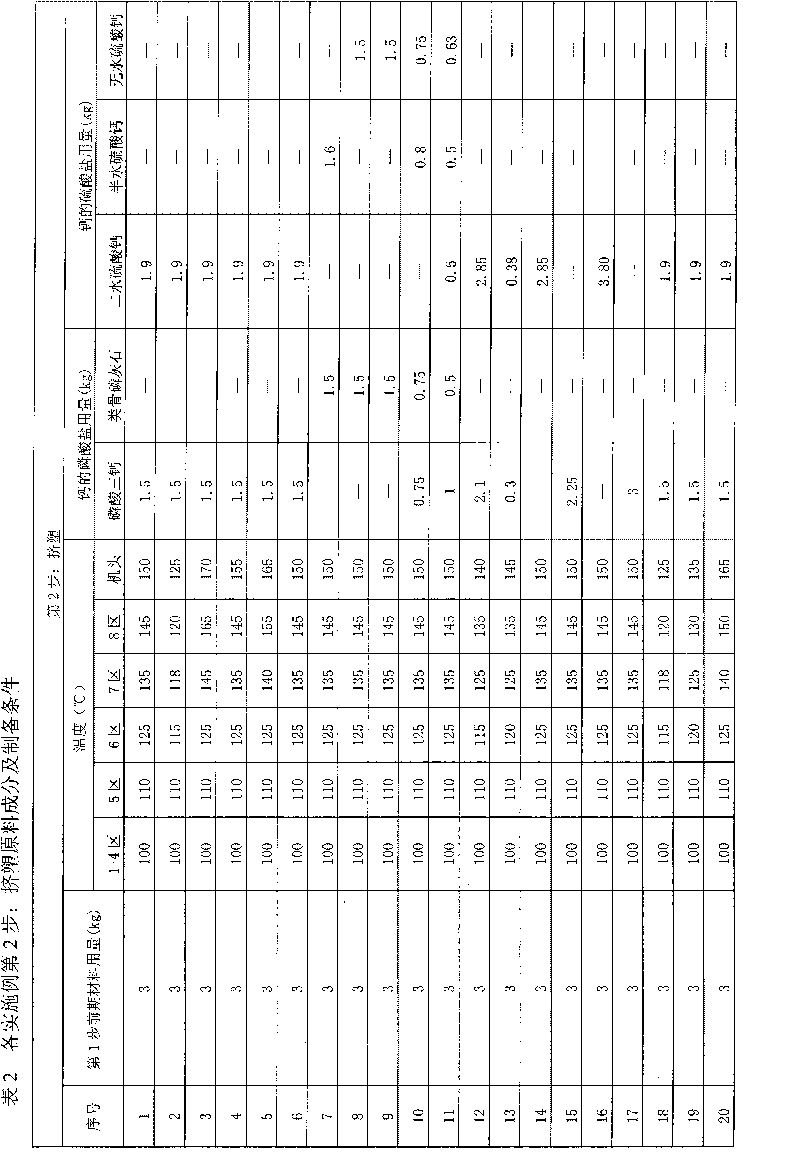

[0024] The intermediate material obtained in the first step is crushed into particles with a particle size of 5-10 meshes, and after continuing to add the remaining amount of inorganic calcium salt raw materials in the manner in Table 2 and mixing evenly, the TSE-30A / 420-36-11 type (or Other suitable form) twin-screw extruder, extruding under the condition of 100-180°C to obtain the active controllable degrad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com