Cement component powder grinding equipment

A grinding and cement technology, applied in cocoa, grain processing, food science, etc., can solve the problems of easy vibration of the mill, low power consumption, high cost of equipment procurement and maintenance, and achieve the effect of guaranteed grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

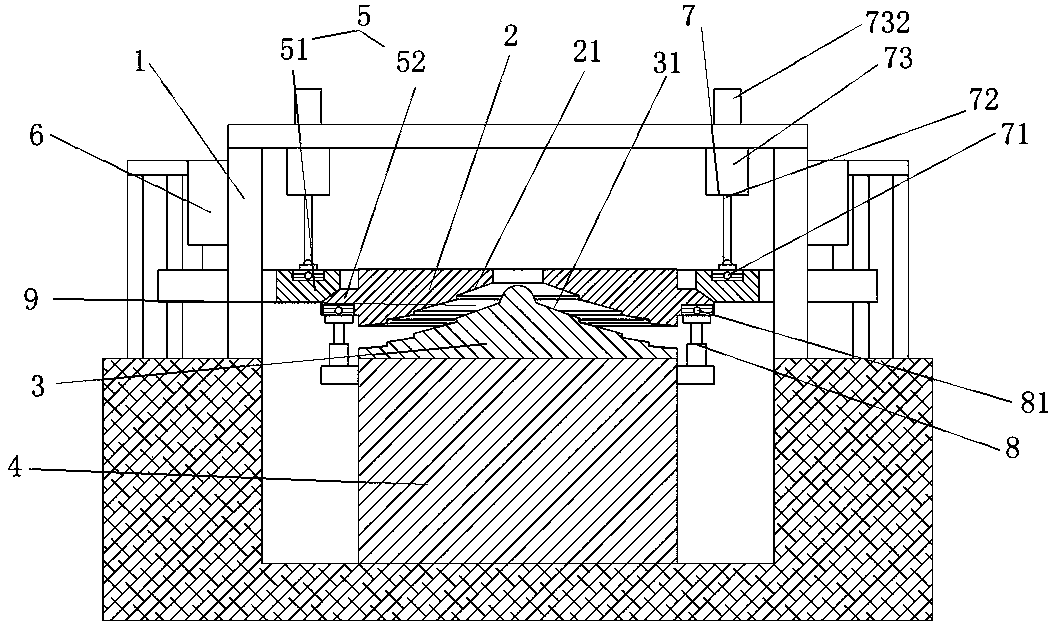

Image

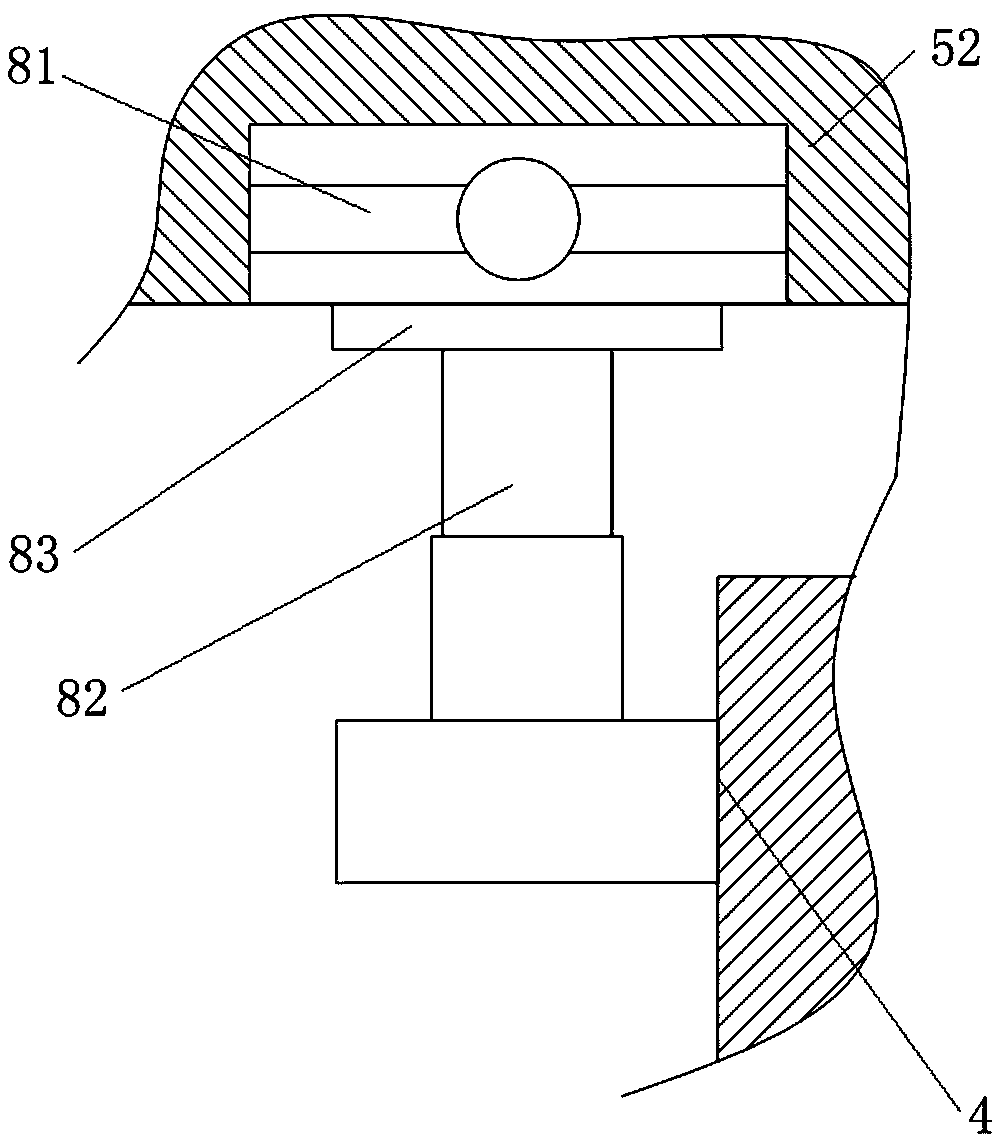

Examples

Embodiment 2

[0038] The technical scheme described in embodiment two is similar to embodiment one, and its difference is:

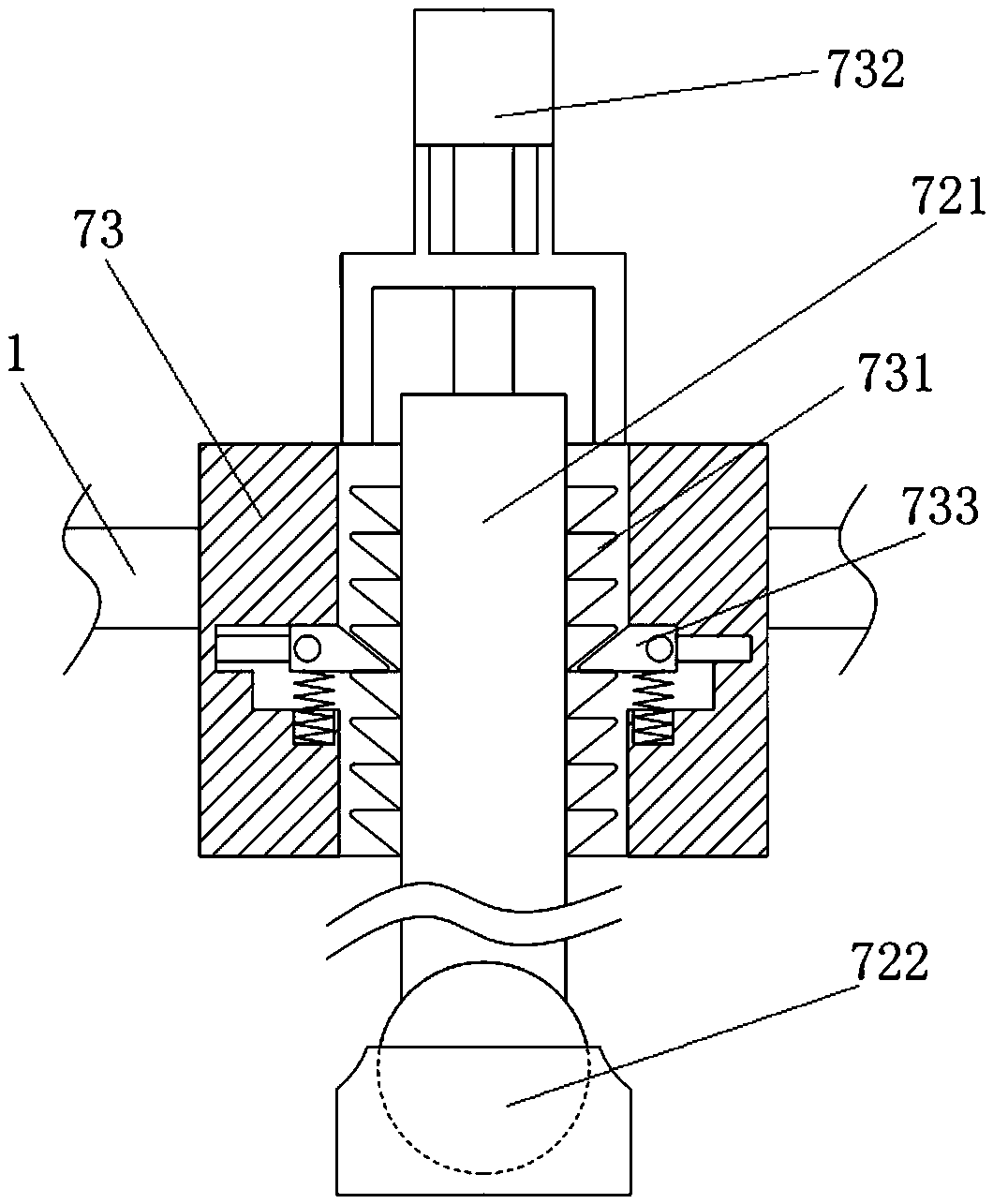

[0039] like Figure 5 As shown, the cylinder 721 is a cylinder 721, and the ratchet 731 is linearly distributed on one side of the cylinder 721 cylinder along the radial direction of the cylinder 721. The splines 723 connected to the adjustment frame 73 are evenly distributed on the circumference of the axis, so that compared with the first embodiment, it has better contact balance and better stability in all directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com