Cement grinding device capable of processing cement of different particle sizes

A cement grinding and pulverizing technology, applied in grain processing and other directions, can solve the problems of affecting the overall quality of cement, small extrusion area, and low degree of automation, and achieve the effect of improving grinding effect, reducing extraction and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, but do not limit protection scope and application scope of the present invention:

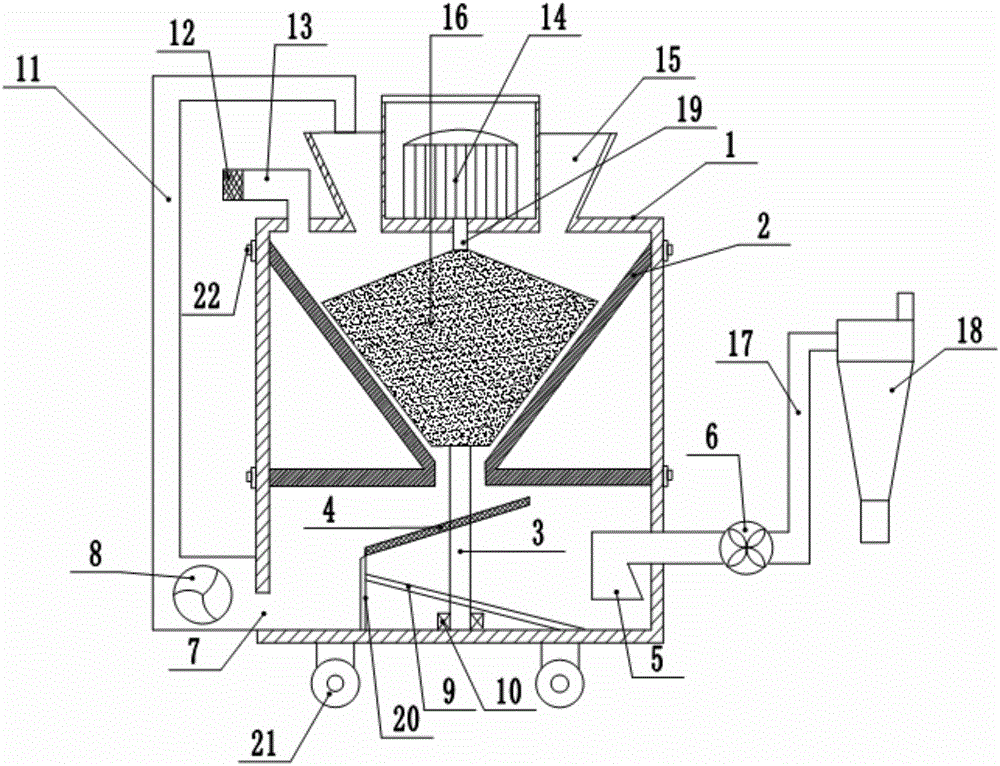

[0015] Such as figure 1 As shown, a cement grinding device capable of processing cement with different particle sizes includes a grinding box 1. The upper end of the grinding box 1 is provided with a discharge port 15. The upper end opening of the discharge port 15 is larger than the lower end opening, which can limit the discharge. Speed, the central position of discharge opening 15 is provided with rotating motor 14, and rotating motor 14 outside is provided with soundproof box, reduces noise pollution. The bottom of the rotating motor 14 is connected with a milling cone 16 whose diameter of the cross section gradually decreases from top to bottom by the first rotating shaft 19. The both sides of the milling cone 16 are provided with a milling wall 2, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com