Grinding equipment for manufacturing superfine sand from waste bricks and tiles

A technology of ultra-fine sand and bricks, which is applied in grain processing and other directions, can solve problems such as insufficient offset, and achieve the effect of ensuring grinding effect, improving grinding efficiency and reducing load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the purpose, technical solutions and beneficial effects of the present invention more clear, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to facilitate the understanding of technical personnel.

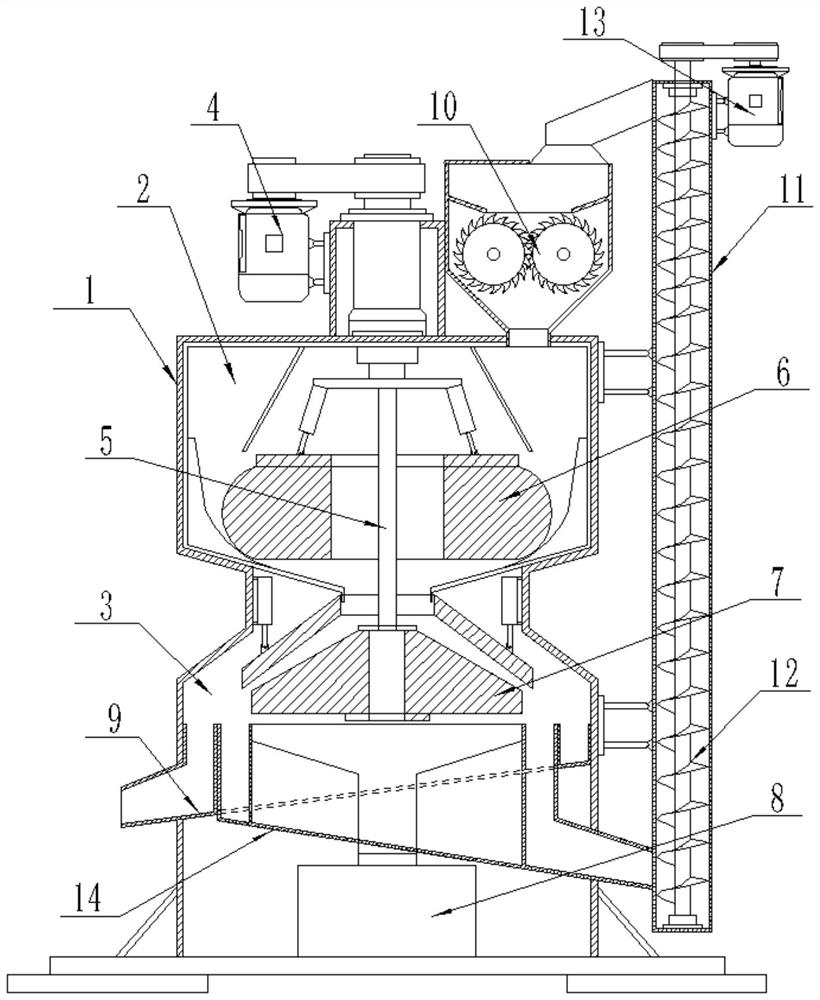

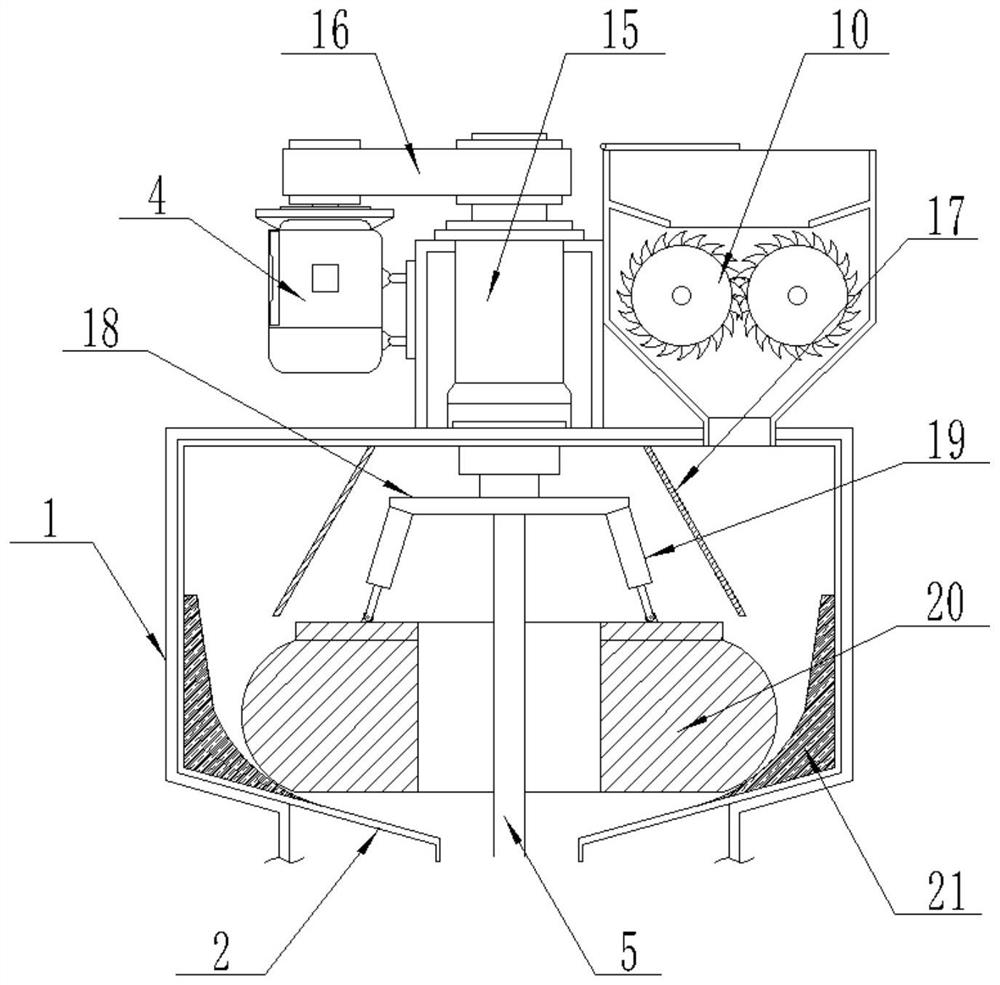

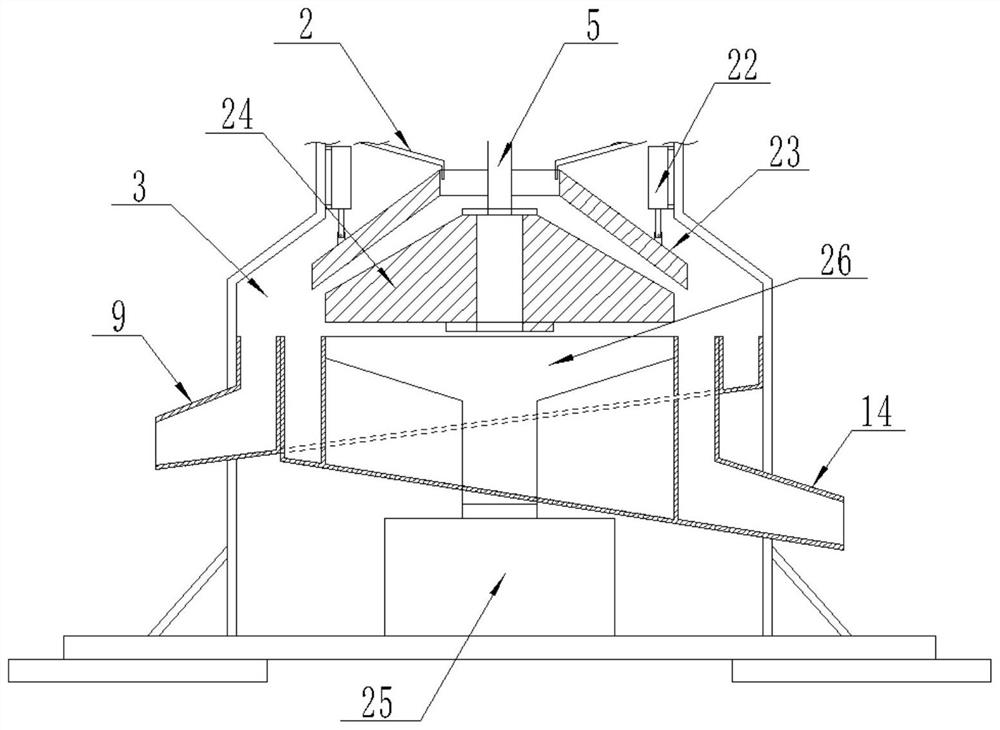

[0021] Such as Figure 1-5 As shown, the grinding equipment for producing ultrafine sand from waste bricks and tiles includes a cabinet 1, a crushing device 10, a first grinding device 6, a second grinding device 7, a winnowing device 8, and a recycling device. There is a crushing device 10 for primary crushing of waste bricks and tiles. A collection box 2 and a grinding chamber are arranged inside the cabinet 1, and a first crushing device for grinding the waste bricks and tiles after primary crushing is respectively installed inside the collection box 2 and the grinding chamber. Grinding device 6 and the second grinding device 7, air separation device 8 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com