YAG fluorescent powder used in semiconductor illumination and preparation method thereof

A phosphor and semiconductor technology, applied in the field of semiconductor lighting, can solve the problems affecting the optical performance of white light LED devices, irregular particle shape, cumbersome preparation process, etc., and achieve the effect of regular shape, simple equipment and uniform size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

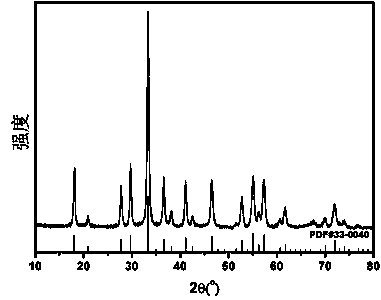

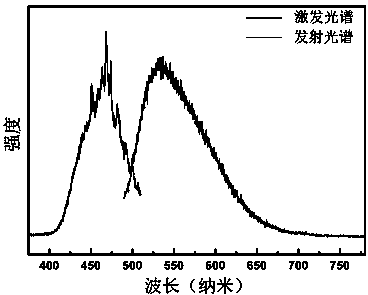

Image

Examples

Embodiment 1

[0018] 1) Crystalline aluminum chloride by mass ratio: yttrium chloride hexahydrate: cerium chloride hexahydrate: ethanol: deionized water: formamide: 1,2-propylene oxide = 1:0.46:0.07:1.34:1.24:0.35 : 1.79, weigh crystalline aluminum chloride, yttrium chloride hexahydrate, cerium chloride hexahydrate, ethanol, deionized water, formamide and 1,2-propylene oxide;

[0019] 2) Fully dissolve the crystalline aluminum chloride, yttrium chloride hexahydrate, and cerium chloride hexahydrate in step 1) in a mixed solution of deionized water, ethanol, and formamide under the condition of a constant temperature water bath at 25°C, and then Add 1-2 propylene oxide, stir and mix thoroughly, put it into a sealed container, and keep warm at a constant temperature of 60°C until the mixed solution forms a gel;

[0020] 3) Dry the gel at a constant temperature of 60°C for 24 hours, then grind and disperse it, keep it at 500°C for 4 hours, and then in H 2 and N 2 In a gas atmosphere mixed at ...

Embodiment 2

[0023] 1) Crystalline aluminum chloride by mass ratio: yttrium chloride hexahydrate: cerium chloride hexahydrate: ethanol: deionized water: formamide: 1,2-propylene oxide = 1:0.46:0.14:1.34:1.24:0.35 : 1.79, weigh crystalline aluminum chloride, yttrium chloride hexahydrate, cerium chloride hexahydrate, ethanol, deionized water, formamide and 1,2-propylene oxide;

[0024] 2) Under the condition of a constant temperature water bath at 15°C, fully dissolve the crystalline aluminum chloride, yttrium chloride hexahydrate and cerium chloride hexahydrate in step 1) in a mixed solution of deionized water, ethanol and formamide, and then Add 1-2 propylene oxide, stir and mix thoroughly, put it into a sealed container, and keep warm at a constant temperature of 60°C until the mixed solution forms a gel;

[0025] 3) Dry the gel at a constant temperature of 70°C for 24 hours, then grind and disperse it, keep it at 600°C for 4 hours, and then heat it under H 2 and N 2 In a gas atmosphere...

Embodiment 3

[0027] 1) Crystalline aluminum chloride by mass ratio: yttrium chloride hexahydrate: cerium chloride hexahydrate: ethanol: deionized water: formamide: 1,2-propylene oxide = 1:0.46:0.07:0.85:1.85:0.35 : 1.79, weigh crystalline aluminum chloride, yttrium chloride hexahydrate, cerium chloride hexahydrate, ethanol, deionized water, formamide and 1,2-propylene oxide;

[0028] 2) Under the condition of a constant temperature water bath at 20°C, fully dissolve the crystalline aluminum chloride, yttrium chloride hexahydrate and cerium chloride hexahydrate in step 1) in a mixed solution of deionized water, ethanol and formamide, and then Add 1-2 propylene oxide, stir and mix thoroughly, put it into a sealed container, and keep warm at a constant temperature of 50°C until the mixed solution forms a gel;

[0029] 3) Dry the gel at a constant temperature of 80°C for 6 hours, then grind and disperse it, keep it at 600°C for 4 hours, and then place it under H 2 and N 2 In a gas atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com