Alpha-high strength gypsum production system and application thereof

A technology of high-strength gypsum and gypsum is applied in the field of material manufacturing to achieve the effects of avoiding frequent heating and cooling, increasing output and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

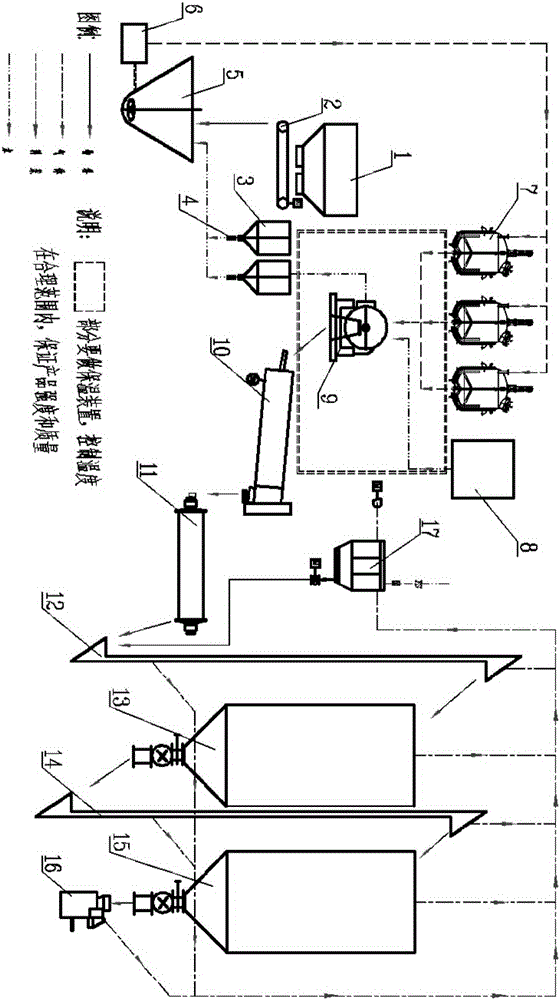

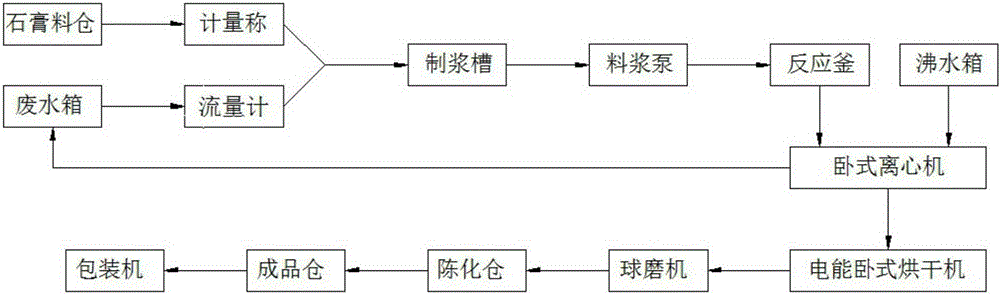

[0027] A system for producing α-high-strength gypsum. The main equipment of the system is composed of a slurry tank, a reaction kettle, a centrifuge, a dryer, a ball mill, an aging warehouse, a finished product warehouse and a packaging machine. The whole centrifugal process is equipped with a heat preservation device, wherein, The material and water are metered into the pulping tank, and the slurry pump under the pulping tank pumps the slurry to the reactor, and the material out of the reactor enters the centrifuge for centrifugal separation, and then enters the dryer for drying, Enter the ball mill and aging warehouse for modification and homogenization, and finally enter the finished product warehouse and packaging machine for packaging.

[0028] The application of the system, the system uses desulfurized gypsum, phosphogypsum or citrate gypsum as raw materials, and the steps of the application include the determination of free water for raw materials with different water co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com