Sand and stone crushing equipment for building engineering

A technology for construction engineering and crushing equipment, applied in application, cocoa, grain processing and other directions, can solve the problems of poor primary crushing effect, unfavorable crushing use, inconvenient use, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

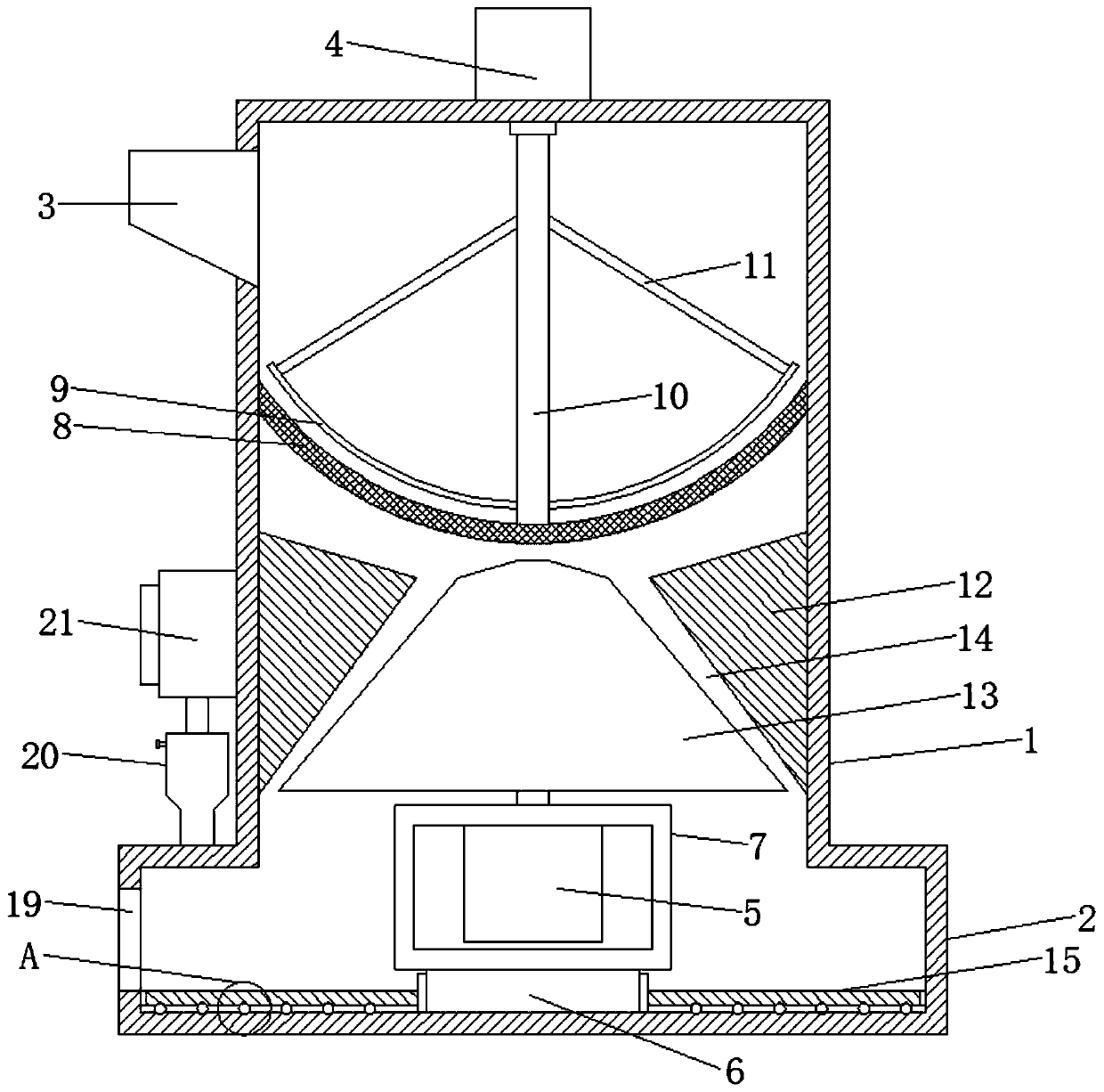

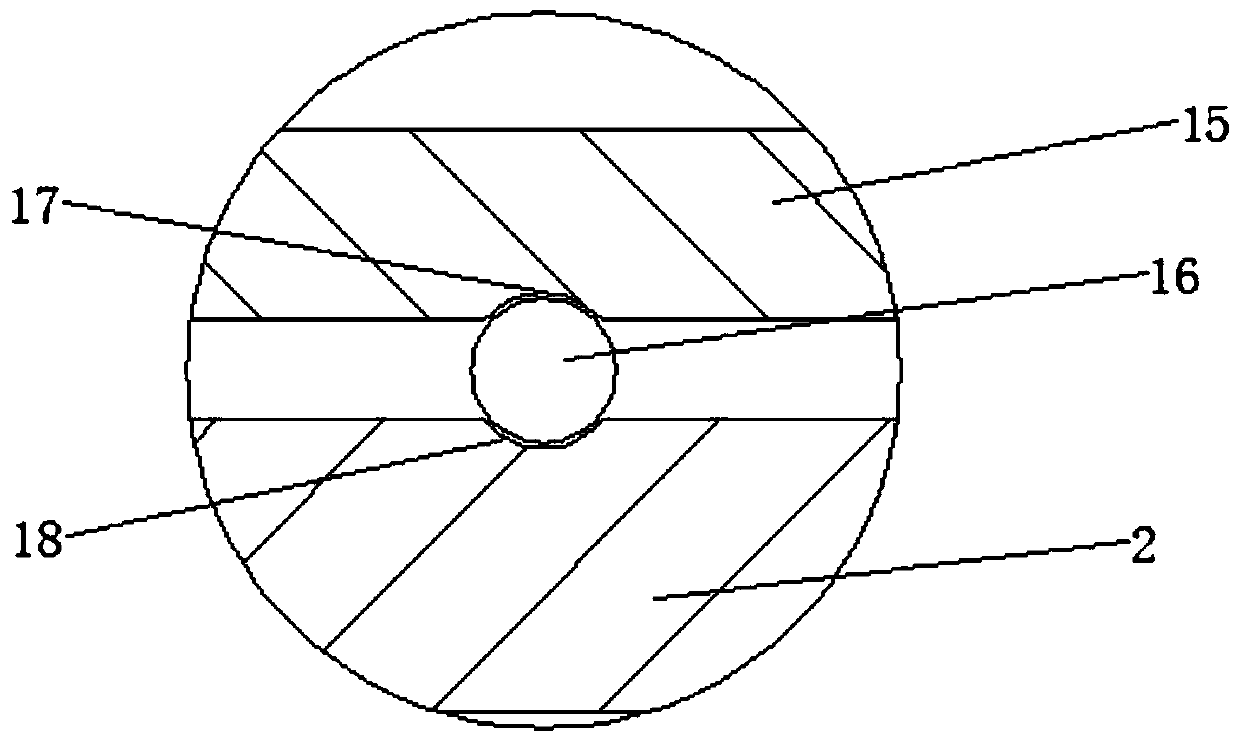

[0024] Please refer to the figure, in the embodiment of the present invention, a sandstone crushing equipment for construction engineering includes a crushing shell 1, a collection box 2, a feed hopper 3, a first motor 4 and a second motor 5; the crushing shell 1 is coaxially fixed on the top of the collection box 2, and the crushing shell 1 is connected to the inside, and the sand falling from the crushing shell 1 enters the collection box 2; the upper end of the side wall of the crushing shell 1 is connected to the feed hopper 3. The sand to be crushed is fed into the crushing shell 1 from the feed hopper 3 .

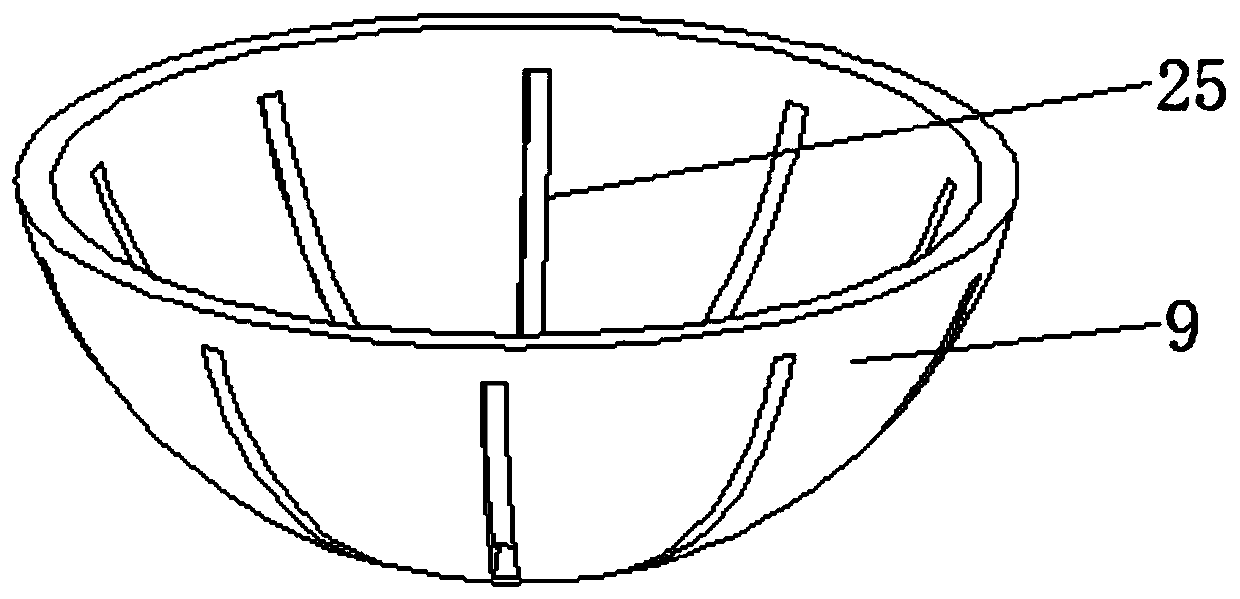

[0025] A primary crushing net 8 with a spherical structure is fixed on the middle part of the crushing shell 1, and the primary crushing net 8 is processed by a stainless steel mesh plate, and the mesh size is selected according to the requirements of the primary crushing; in the crushing shell The top of the body 1 is coaxially fixed with a vertical first motor 4, th...

Embodiment 2

[0029] On the basis of Embodiment 1, the collection box 2 is connected with a purification and dust removal mechanism, which includes a filter cartridge 20, an exhaust fan 21, a filter bag 22, a mounting plate 23, and a support rod 24, and the filter cartridge 20 is connected to the collection box. 2, the filter bag 22 is set in the filter cartridge 20, and the opening of the filter bag 22 communicates with the bottom, so that the air entering the filter cartridge 20 is directly sent into the filter bag 22, and the top of the filter bag 22 is fixedly connected On the horizontal mounting plate 23, the upper end of the filter bag 22 is easy to move. Both sides of the mounting plate 23 are fixedly connected with a support rod 24 that passes through the filter cartridge 20 horizontally, and the support rod 24 is slidably connected with the filter bag 22. By pushing The support rods 24 on both sides shake the top of the filter bag 22 to shake off the filtered dust inside; the top of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com