Eta-Al2O3 microsphere and preparation method and application thereof

A microsphere, sodium aluminate technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of preparing dispersion To solve the problems of micron-sized spherical alumina, it can achieve the effect of excellent catalytic performance, favorable for morphology control, high repeatability and magnification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

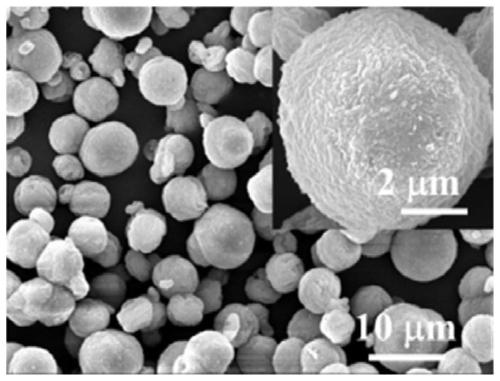

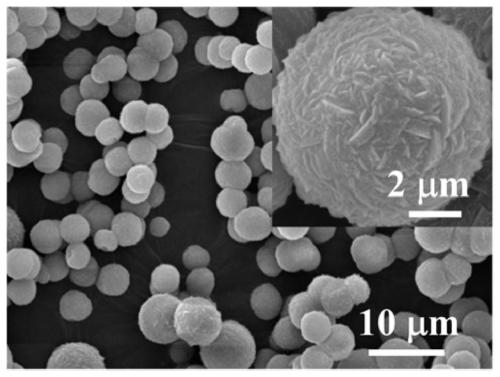

[0044] (1) η-Al 2 o 3 Preparation of microspheres: Dissolve 2.46g of sodium aluminate in 30mL of deionized water, and magnetically stir at room temperature (25°C) for 15min to form a sodium aluminate solution; then use a pipette to draw 20mL of N,N-dimethyl Add formamide to the above solution, continue magnetic stirring for 1 min to form a uniform clear liquid, then seal and let stand for 20 min; filter the above precipitate, wash twice with deionized water first, and finally wash once with absolute ethanol, and then dry in the air Dry in an oven at 60°C for 12h, and finally place it in a muffle furnace, bake in air at 500°C for 2h, with a heating rate of 2°C / min, and cool naturally to room temperature to obtain η-Al 2 o 3 Microspheres.

[0045] (2) preparation of catalyst: get the η-Al of 1.0g roasting 2 o 3 Microspheres, 0.0030 g of PdCl 2 Na prepared with 0.0020 g of NaCl 2 PdCl 4 The solution was added dropwise to 0.60g of the above η-Al 2 o 3 In the microspheres...

Embodiment 2

[0048] (1) η-Al 2 o 3 Preparation of microspheres: Dissolve 1.64g of sodium aluminate in 35mL of deionized water, and magnetically stir at room temperature (25°C) for 15min to form a sodium aluminate solution; then pipette 15mL of N,N-dimethyl Add methyl formamide to the above solution, continue magnetic stirring for 1 min to form a uniform clear liquid, then seal and let stand for 30 min; filter the above precipitate, and wash twice with deionized water first, and finally once with absolute ethanol, and then in the air blast Dry in a drying oven at 60°C for 12h, and finally place it in a muffle furnace, bake it in air at 500°C for 2h, the heating rate is 2°C / min, and cool naturally to room temperature to obtain η-Al 2 o 3 Microspheres.

[0049] (2) Preparation of catalyst: the loading process is the same as in Example 1.

[0050] The resulting η-Al 2 o 3 It is a rough microsphere assembled by nanosheets, with an average diameter of 4.67μm and a specific surface area of ...

Embodiment 3

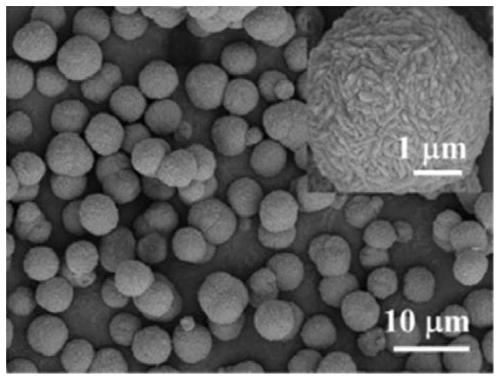

[0052] (1) η-Al 2 o 3 Preparation of microspheres: Dissolve 2.46g of sodium aluminate in 40mL of deionized water, and magnetically stir at room temperature (25°C) for 15min to form a sodium aluminate solution; then use a pipette to draw 10mL of N,N-dimethyl Add acetamide to the above solution, continue magnetic stirring for 1 min to form a uniform clear liquid, then seal and let stand for 30 min; filter the above precipitate, wash twice with deionized water first, and finally wash once with absolute ethanol, and then dry in the air Dry in a box at 60°C for 12h, and finally place it in a muffle furnace, bake in air at 500°C for 2h, the heating rate is 2°C / min, and cool naturally to room temperature to obtain η-Al 2 o 3 Microspheres.

[0053] (2) Preparation of catalyst: the loading process is the same as in Example 1.

[0054] The resulting η-Al 2 o 3 It is a rough microsphere assembled by nanosheets, with an average diameter of 3.52μm and a specific surface area of 331...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com