Sponge sofa and making method thereof

A technology for sofas and sponges, which is applied in the direction of sofas, couches, and other seating furniture, etc. It can solve the problems of low production efficiency, separation, and difficulty in ensuring the uniformity of product shapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

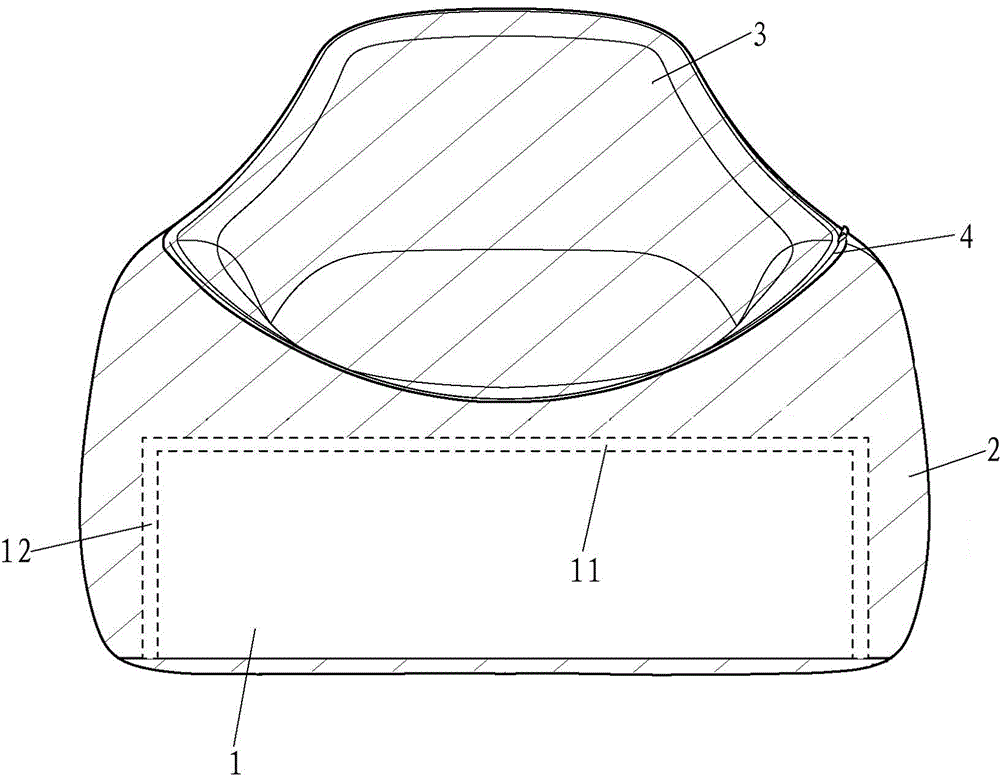

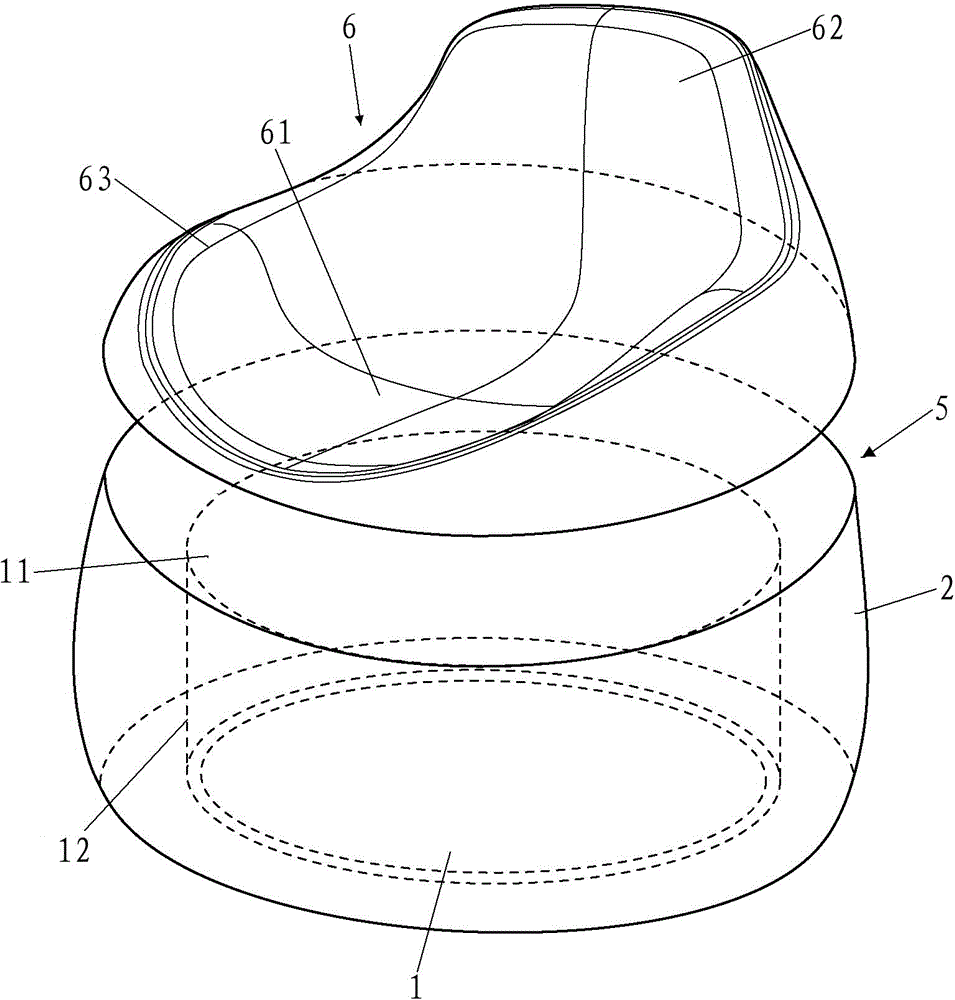

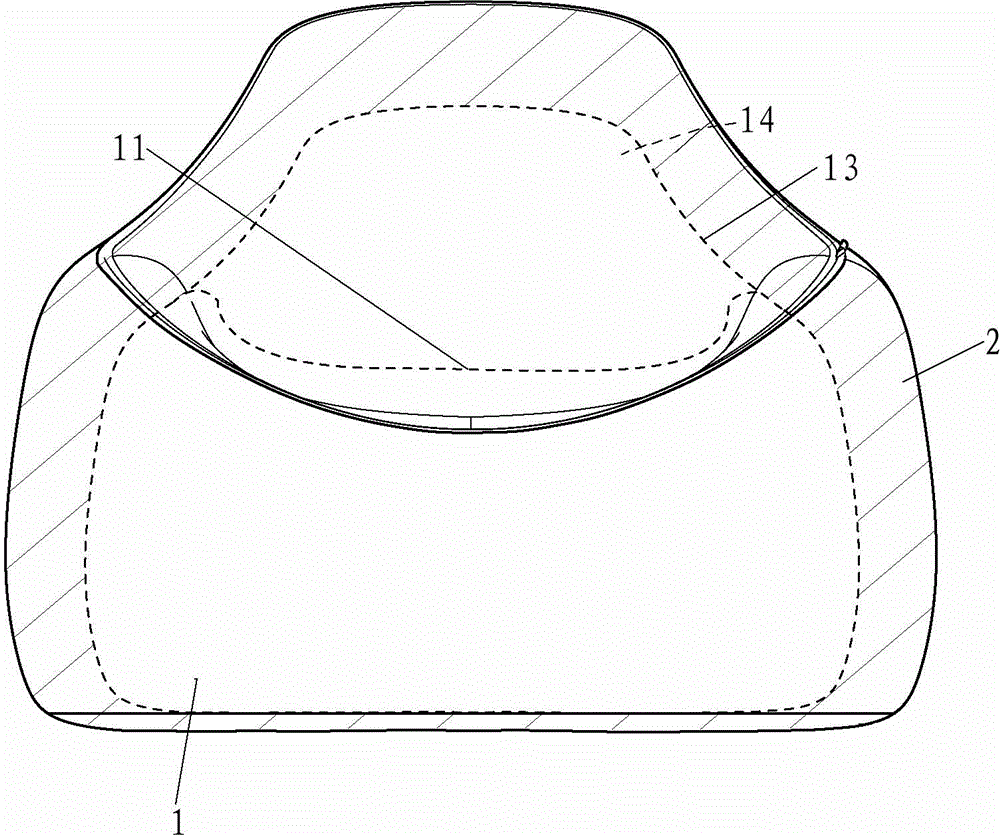

[0032] like Figure 1 to Figure 10 As shown, the present invention discloses a sponge sofa structure, which includes a sofa frame 1, and a sponge layer 2 is integrally foamed on the outer surface of the sofa frame 1.

[0033] The sofa frame 1 is made of a material with supporting strength, which can be wood material or metal material, or plastic material.

[0034] like figure 1 As shown, the sofa frame 1 includes a seating surface 11 and a surrounding surface 12 supporting the seating surface 11, and the sponge layer 2 is directly integrally foamed on the outer surface of the seating surface 11 and the surrounding surface 12, and is directly formed on the seating surface 11. Foaming has sofa backrest 3 and sofa armrest 4. The sponge can be made of hard foam to ensure the support strength of the sofa backrest 3 and the sofa armrest 4. Of course, the support strength of the sofa backrest 3 and the sofa armrest 4 can be bound by leather or cloth outsourced to the sofa.

[0035...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com