Process method of 3D printing solder paste body on printed circuit board

A printed circuit board, 3D printing technology, applied in the direction of assembling printed circuits with electrical components, can solve the problems of poor shape accuracy of solder paste, low efficiency of solder paste, uncontrollable shape, etc. High coverage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

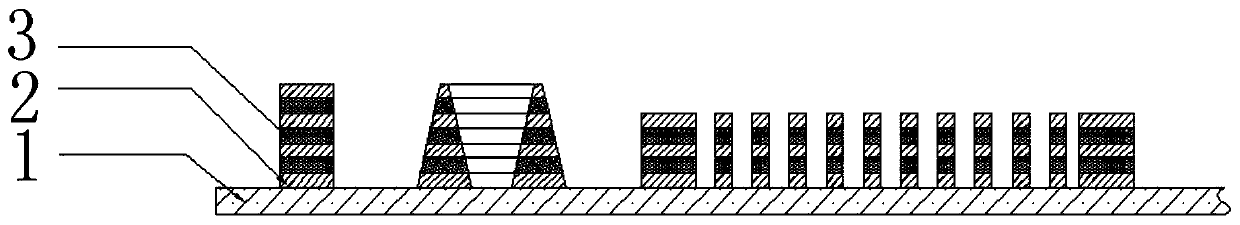

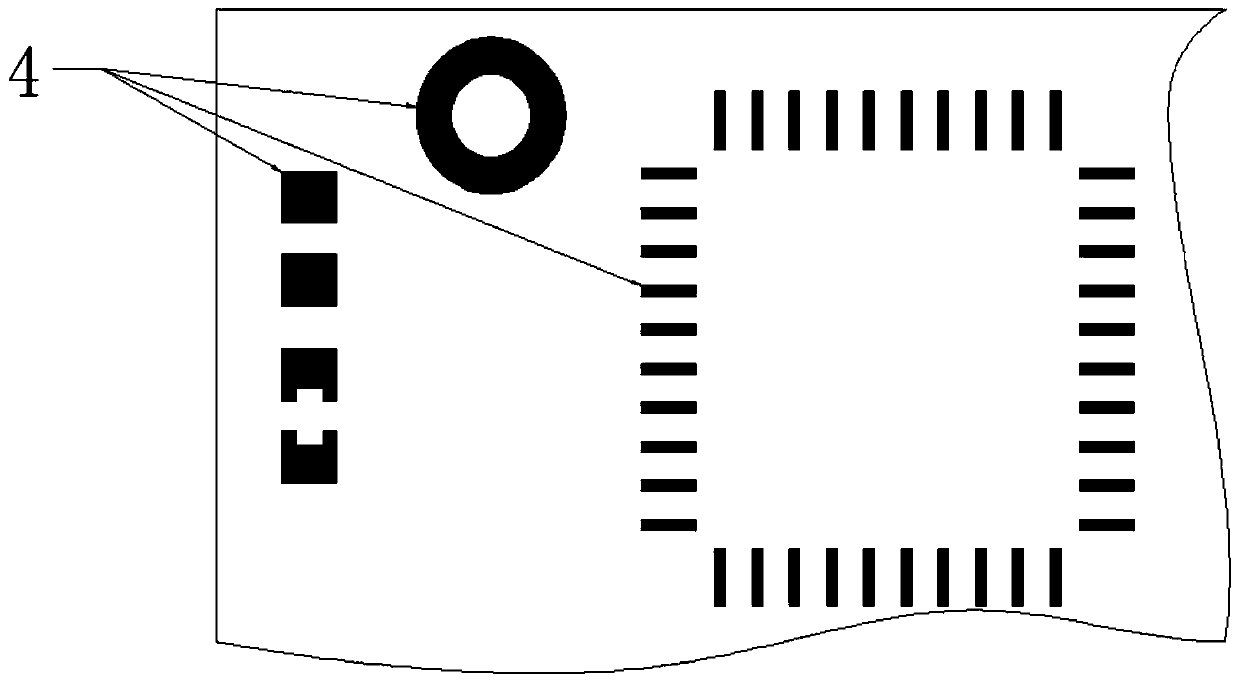

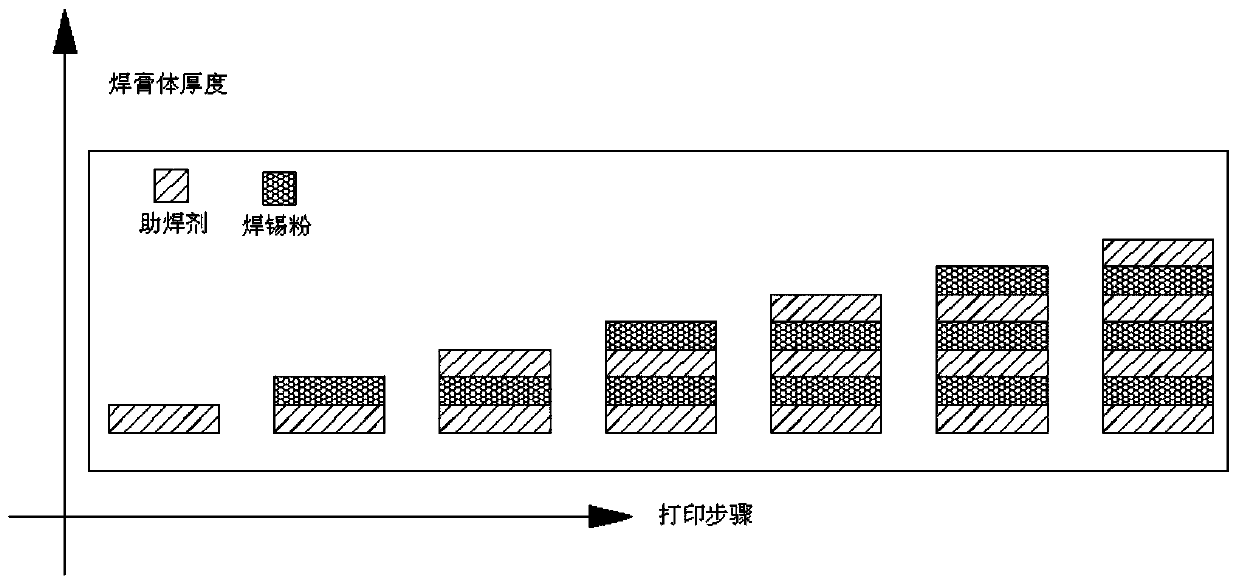

[0019] refer to Figure 1 ~ Figure 4 . According to the present invention, at the component pad position on the printed circuit board, the thickness of each layer of flux in the solder paste body and the thickness of each layer of solder layer are controlled by different 3D printing heads, 3D printed layer files and printing programs. The thickness of the powder, first print a layer of flux consistent with the shape of the pad on all pads of the printed board as the solder powder fixing medium, then print a layer of solder powder on the flux at these positions, and print layer by layer After completing an independent solder paste body, the next solder paste body is printed, and the flux 2 and solder powder 3 printed layer by layer are mixed, and the solder paste body 4 is formed in real time during the printing process, so that the layer-by-layer printing is alternately printed one by one. Layers of flux and solder powder are alternately printed to form the required solder pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com