Fe-based alloy reactive armor shell with low collateral damage and preparation method thereof

A reactive armor and iron-based alloy technology, applied in armored vehicles, transportation and packaging, motor vehicles, etc., can solve the problems of limited application scope, low tensile strength, and high economic cost, and achieve simple and controllable processes, low cost, and high cost. The effect of high tensile strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 (each serving is 1kg)

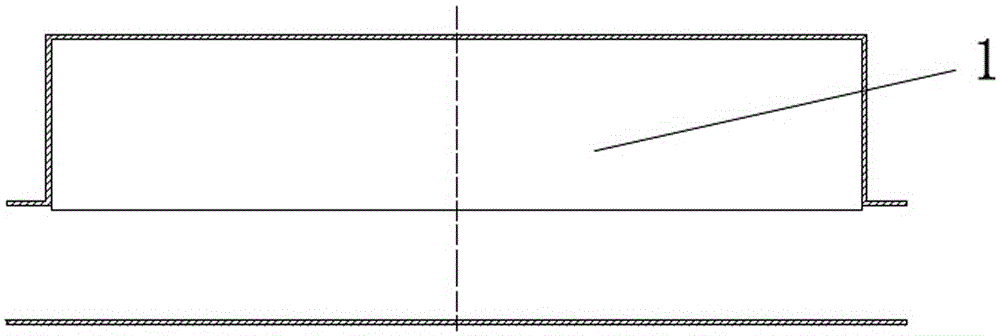

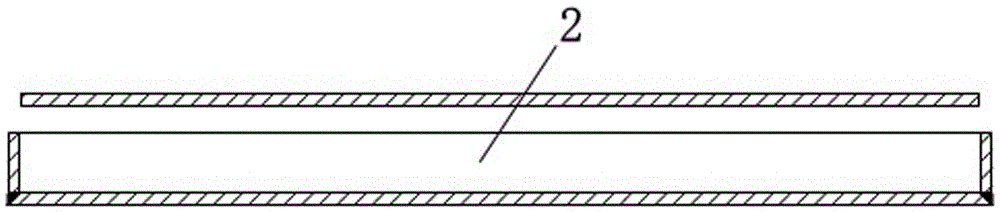

[0016] A low incidental damage iron-based alloy reactive armor shell, comprising a reactive armor shell 1 and a reactive armor chamber shell 2 placed in the reactive armor shell 1, which is composed of 90 parts by weight of iron powder, 10 parts by weight of Copper powder and 1 weight part of graphite powder are made through powder metallurgy and subsequent processing.

[0017] Concrete preparation method comprises the following steps:

[0018] 1) Powder mixing: Weigh each raw material powder by weight, add a small amount of engine oil or zinc stearate, pour it into a mixer and mix until uniform; 2) Compression molding: put the uniformly mixed raw material powder into a mold and press it into a reaction The plate body of the armored shell; 3) Sintering: put the plate body into the sintering boat, and the sintering boat is sintered under the protective atmosphere of methanol cracking gas. The temperature in the high temperature zone is ...

Embodiment 2

[0019] Embodiment 2 (every part is 10kg)

[0020] A low incidental damage iron-based alloy reactive armor shell, comprising a reactive armor shell 1 and a reactive armor chamber shell 2 placed in the reactive armor shell 1, which is composed of 75 parts by weight of iron powder, 15 parts by weight of Copper powder and 0.5 parts by weight of graphite powder are made through powder metallurgy and subsequent processing.

[0021] Concrete preparation method comprises the following steps:

[0022] 1) Powder mixing: Weigh each raw material powder by weight, add a small amount of engine oil or zinc stearate, pour it into a mixer and mix until uniform; 2) Compression molding: put the uniformly mixed raw material powder into a mold and press it into a reaction The plate body of the armored shell; 3) Sintering: put the plate body into the sintering boat, and the sintering boat is sintered under the protective atmosphere of methanol cracking gas. The temperature in the high temperature ...

Embodiment 3

[0023] Embodiment 3 (every portion is 500g)

[0024] A low incidental damage iron-based alloy reactive armor shell, comprising a reactive armor shell 1 and a reactive armor chamber shell 2 placed in the reactive armor shell 1, which is composed of 97 parts by weight of iron powder, 25 parts by weight of Copper powder and 0.8 parts by weight of graphite powder are made through powder metallurgy and subsequent processing.

[0025] Concrete preparation method comprises the following steps:

[0026]1) Powder mixing: Weigh each raw material powder by weight, add a small amount of engine oil or zinc stearate, pour it into a mixer and mix until uniform; 2) Compression molding: put the uniformly mixed raw material powder into a mold and press it into a reaction The plate body of the armored shell; 3) Sintering: put the plate body into the sintering boat, and the sintering boat is sintered under the protective atmosphere of methanol cracking gas. The temperature in the high temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com