Multi-system protective layer reinforcing steel bar and preparation method thereof

A protective layer, multi-system technology, applied in the direction of coating, metal material coating process, device for coating liquid on the surface, etc., can solve problems such as concrete structure damage, and achieve extended service life, reduced cost, and good protective performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

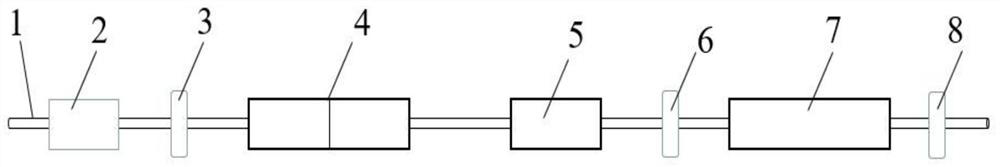

[0064] The steel bar (wire rod) with black scale after rolling is set off and straightened, and then subjected to through-type shot blasting to obtain the exposed steel bar after the scale is removed, and then washed with water or wiped with an air knife in turn (Remove residual water stains or floating dust on the surface of the steel bar), then the steel bar enters the induction heating solenoid filled with nitrogen for high-frequency induction heating, and then passes through the molten Galfan alloy liquid horizontally, and passes through the steel matrix and the molten alloy liquid (400 ~ 450 ° C ) mutual infiltration, diffusion growth and other processes to form a bright and dense zinc-aluminum alloy coating on the surface of the steel bar, and then use nitrogen to wipe with an air knife (8) to remove the alloy liquid attached to the surface of the steel bar to control the thickness of the coating (10-30 μm), with After the steel bar with zinc-aluminum alloy coating is coo...

Embodiment 2

[0066] The steel bars (wire rods) with black oxide skin after rolling are derusted with hydrochloric acid (15wt%) after being laid out and straightened. Wipe with an air knife (remove residual water stains on the surface of the steel bar), then the steel bar enters a ring-shaped spray device to spray additives, dry it in an environment of 150-200 ° C, and then enter the molten Galfan alloy liquid for hot-plating Alloy to form a Galfan alloy covering layer, wiped with nitrogen and then cooled to 200-250°C for polyester powder spraying, forming a uniform resin-based outer coating on the alloy-coated steel bar, and then solidified and cooled to obtain a hot-dip galvanized aluminum alloy Plating / coating dual-system protective layer steel bars are then inspected and packed into storage.

Embodiment 3

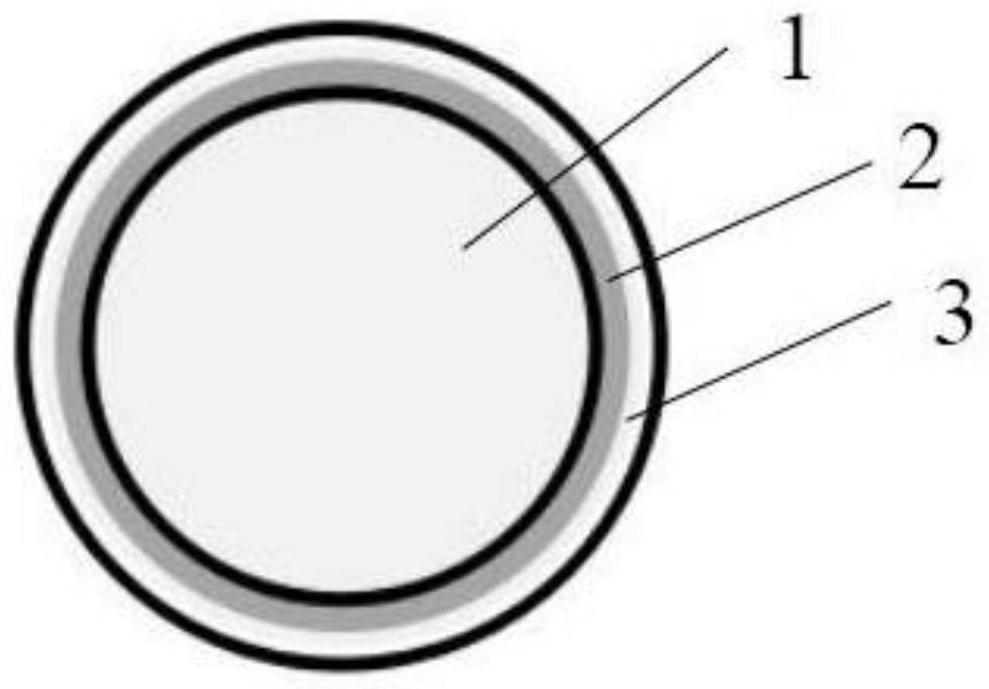

[0068] The multi-system protective layer reinforcing bar of this embodiment, the reinforcing bar comprises:

[0069] The steel matrix of the core,

[0070] Hot-dip galvanized aluminum-based alloy covering layer 2 metallurgically combined with the steel substrate,

[0071] The passivation film coated on the outer surface of the hot-dip galvanized aluminum alloy coating,

[0072] A resin-based overcoat 3 applied on the outer surface of the passivation film.

[0073] The passivation film is a silane corrosion inhibitor passivation film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com