Method for coating active component on cellular carrier with two open ends

A technology of active components and honeycomb carriers, which is applied to the field of coating active components on honeycomb carriers, can solve problems such as uneven coating, and achieve the effects of uniform coating, fast coating speed and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0029] This example illustrates the method provided by the invention.

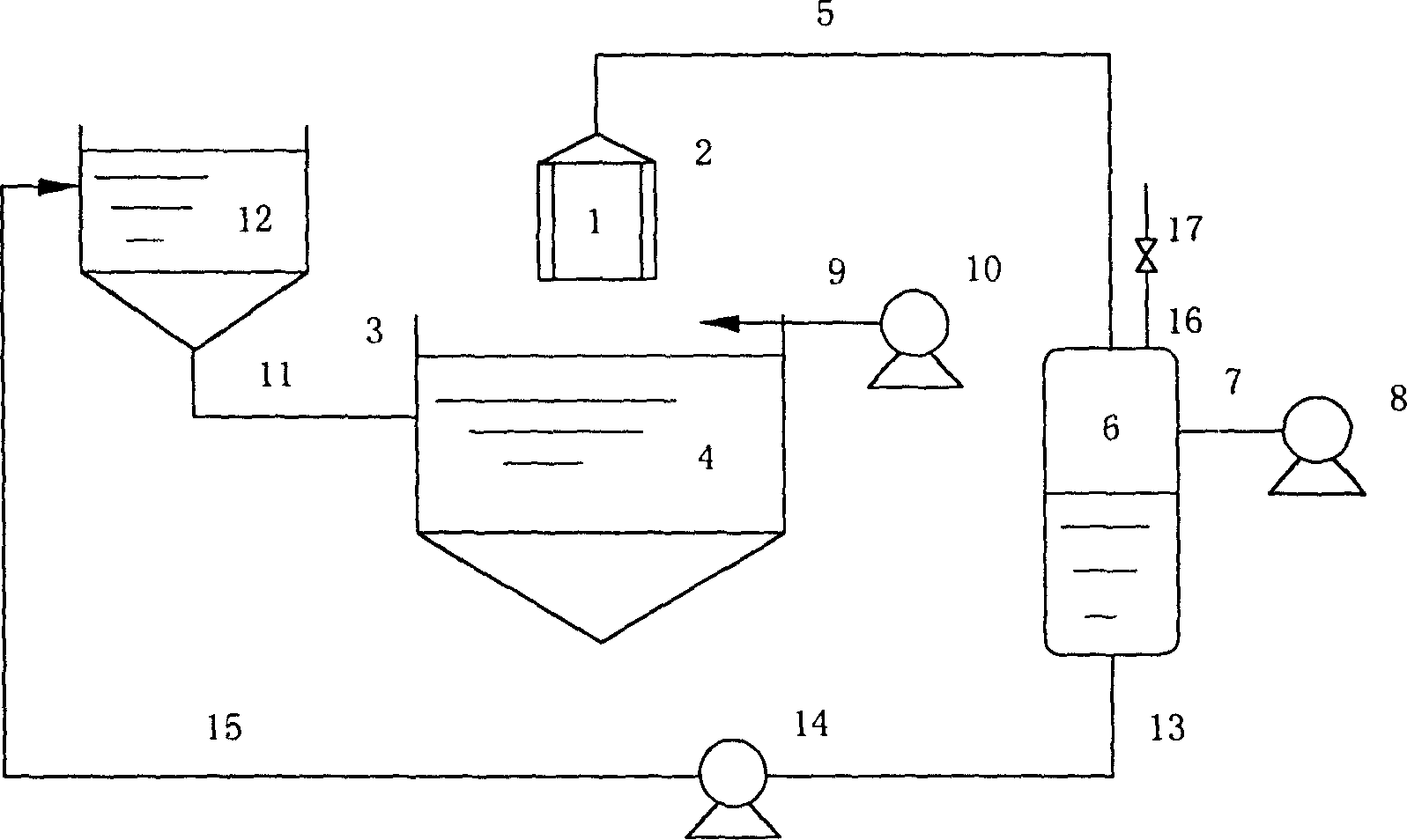

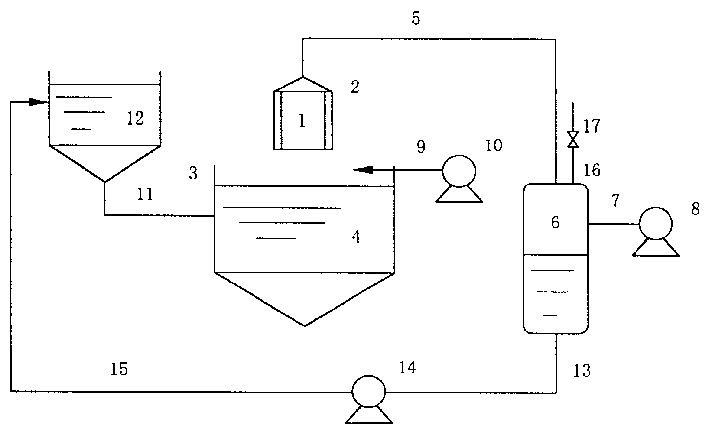

[0030] Such as figure 1 As shown, a slurry 4 is added to the dipping tank 3 . The slurry 4 is made of pseudoboehmite (containing 32% by weight of alumina, produced by Qilu Catalyst Factory), zirconium oxychloride (ZrOCl 2 ·8H 2 O, produced by Beijing Chemical Plant), rare earth chloride (containing 44% by weight of mixed rare earth oxides, wherein lanthanum oxide accounts for 40% by weight of mixed rare earth oxides, cerium oxide accounts for 53% by weight of mixed rare earth oxides, and other rare earth oxides It is prepared by mixing chloroplatinic acid solution containing 0.02082 g / ml platinum, rhodium chloride solution containing 0.0041 g / ml rhodium and deionized water. This slurry 4 contains 22.5% by weight of alumina, 1.5% by weight of zirconia, 4.5% by weight of rare earth oxides (including 1.8% by weight of lanthanum oxide, 2.4% by weight of cerium oxide, and 0.3% by weight of other rare earth o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com