Novel engineering plastic crusher

A technology of engineering plastics and pulverizers, which is applied in the fields of plastic recycling, mechanical material recycling, cleaning methods and utensils, etc. It can solve problems such as low production quality, affecting use, and failure to meet the fineness requirements of new engineering plastic products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

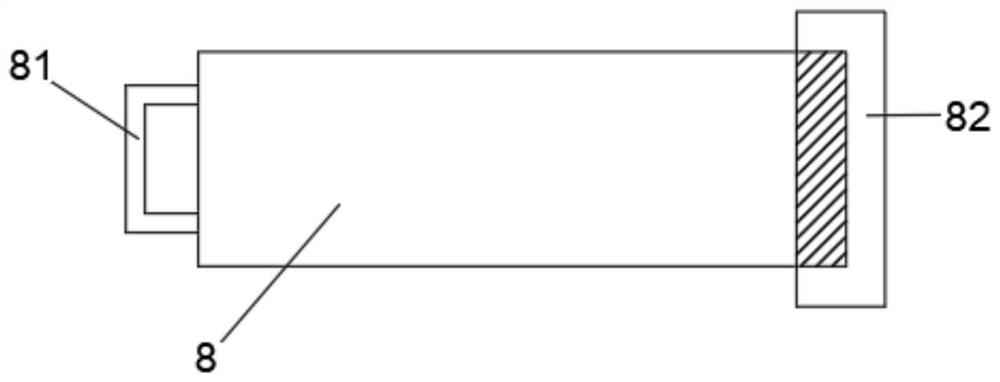

[0026] As a preferred embodiment of the present invention, the left side of the drawer 8 is fixedly connected with a drawer handle 81 , and the right side of the drawer 8 is provided with an engaging plate 82 .

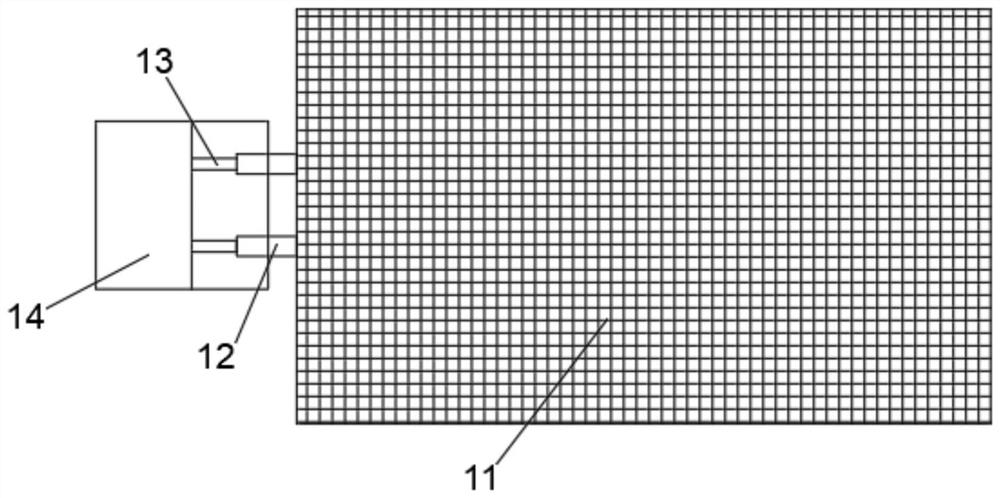

[0027] As a preferred embodiment of the present invention, the left side of the second filter plate 11 is provided with a connecting rod 12, the left side of the connecting rod 12 is fixedly connected with a brake rod 13, and the left side of the brake rod 13 is fixedly installed There is a vibrating motor 14 to speed up the filtering speed, ensure that the product is fine enough, and improve the production quality.

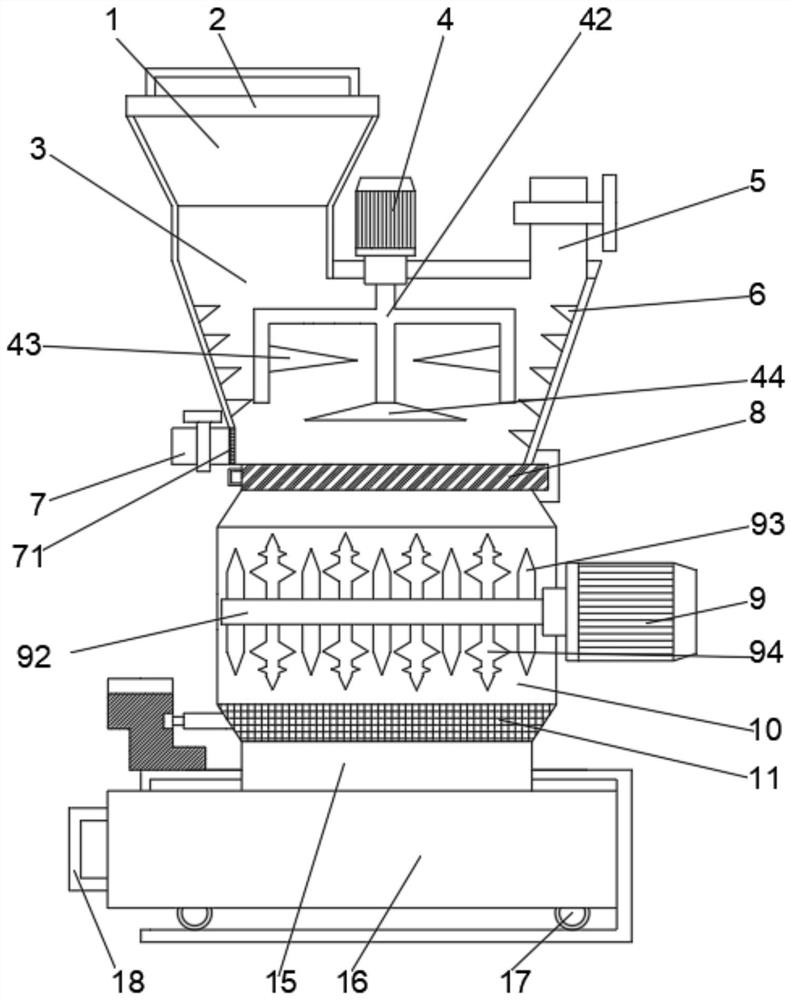

[0028] The main features of the present invention: in the present invention, a coarse crushing chamber 3 and a fine crushing chamber 10 are provided, the water inlet pipe 5 and the water outlet pipe 7 are connected to the coarse crushing chamber 3, and a vibration motor 14 is installed on the left side of the second filter plate 11 , a storage car 16 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com