Preparation method of modified white carbon black with chemical isolating structures

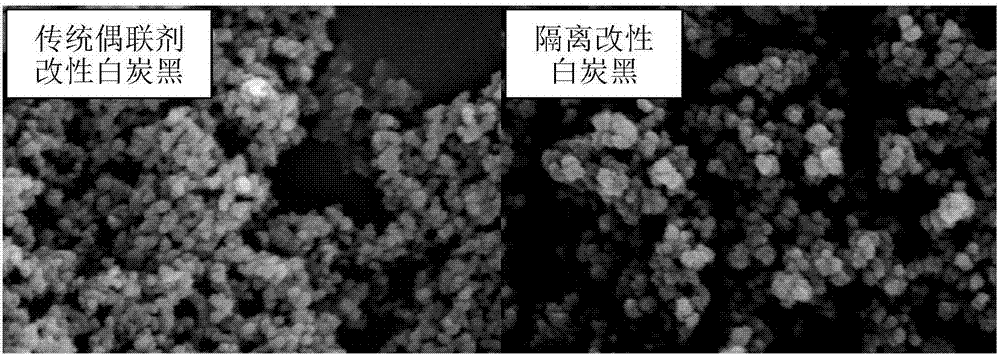

A technology of isolation structure and silica, applied in the field of inorganic nano-powder modification, can solve the problems that the uniform dispersion of silica cannot be guaranteed, and the existence of primary particles of silica cannot be completely guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

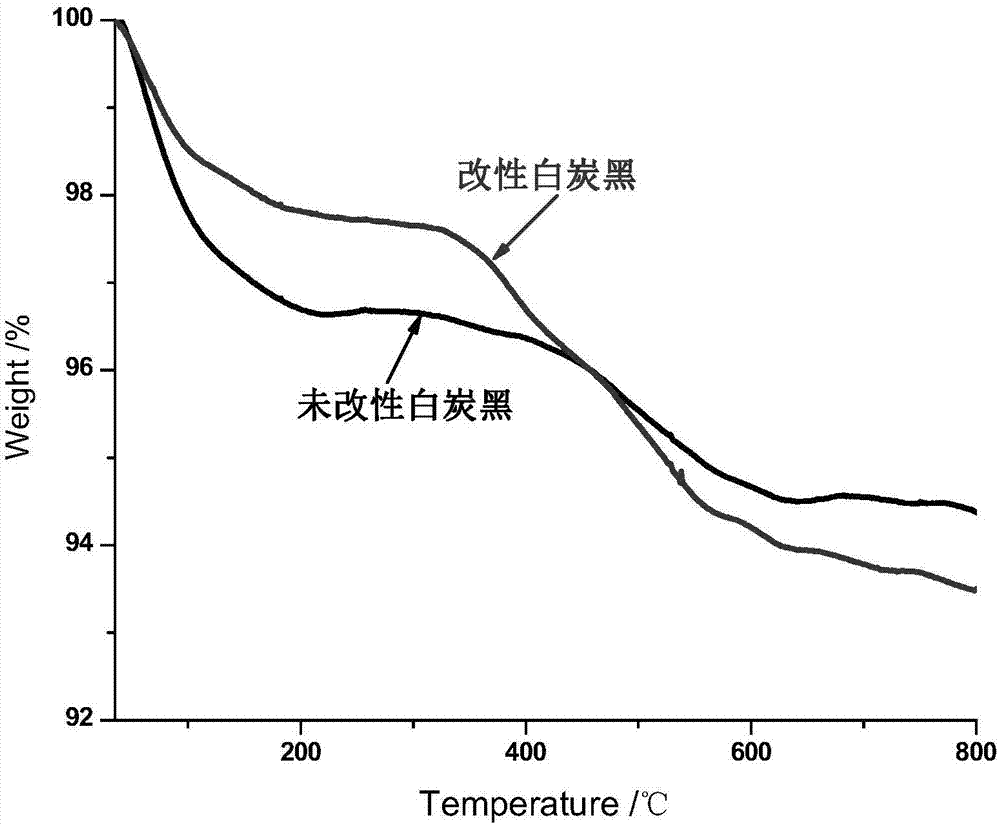

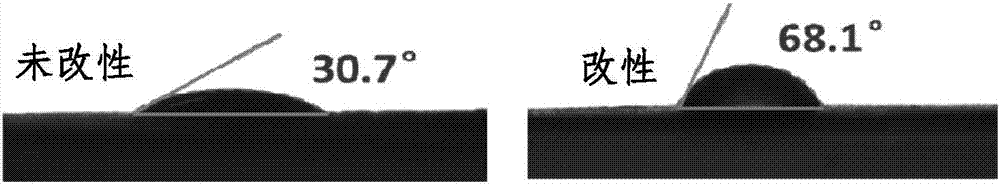

Method used

Image

Examples

Embodiment 1

[0051] Get the white carbon black VN3 powder and water by mass percentage as 15:85 stirring and mixing, and this white carbon black suspension is further stirred for 10 hours at a speed of 3500rpm using high-speed stirring, so as to obtain a uniform and stable white carbon black- Aqueous suspension, the particle size of silica in water was tested to be 538 nm. Take 600 g of the silica-water suspension and transfer it to an ultrasonic cleaning tank with a heating function. At the same time, the suspension is stirred, and the rotational speed is set to 800 rpm to keep the suspension with good fluidity. The suspension was heated to 75°C and the ultrasonic frequency was set to 30KHz. 9 g of a silane coupling agent (A) was added to this suspension, stirring was maintained, and the modification temperature was maintained, and it was made to react for 4 hours. Adjust the temperature of the tank inlet of the spray drying equipment to 160-220°C, and control the outlet temperature of t...

Embodiment 2

[0055] Take the silica Z2000 suspension slurry and mix it with water, adjust the solid mass of silica to 12% of the total mass of the suspension, stir and mix, and stir the silica suspension for 8 hours at a speed of 4500 rpm. A homogeneous and stable silica-water suspension was obtained, the dispersion state of silica in water was good, and the particle size of the silica was 513 nm after testing. Take 1000 g of the silica-water suspension and transfer it to an ultrasonic cleaning tank with a heating function. At the same time, the suspension is stirred, and the rotating speed is set to 600 rpm to keep the suspension with good fluidity. The suspension was heated to 70°C and the ultrasonic frequency was set to 25KHz. 10 g of the silane coupling agent (B) was added to this suspension, stirring was maintained, and the modification temperature was maintained, and it was made to react for 3 hours. Adjust the temperature of the tank inlet of the spray drying equipment to 160-220°C...

Embodiment 3

[0059] Take the silica K170 suspension slurry and mix it with water, adjust the solid mass of silica to 10% of the total mass of the suspension, and stir and mix, this silica suspension is further stirred at a speed of 4000rpm for 9 hours using high-speed stirring , so as to obtain a uniform and stable silica-water suspension, the dispersion state of silica in water is good, and its particle size is 487nm after testing. Take 500 g of the silica-water suspension and transfer it to an ultrasonic cleaning tank with a heating function, while stirring the suspension at 800 rpm to keep the suspension with good fluidity. The suspension was heated to 70°C and the ultrasonic frequency was set to 30KHz. 5 g of a silane coupling agent (C) was added to this silica-water suspension, stirring was maintained, and the modification temperature was maintained, and the reaction was carried out for 4 hours. Then take 500 g of the silica-water suspension and transfer it to an ultrasonic cleaning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com