Nano-sized carbon black heat dissipating paint and preparation method thereof

A nano-carbon black and heat-dissipating coating technology, used in epoxy resin coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as serious environmental pollution and high toxicity, and achieve good adhesion performance, low price, and high price. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First mix 30 g of water-based silicone resin (H-900) and 30 g of water to form a mixed solution. Then take 3 g of nano carbon black powder (particle size 15 nm) in the mixed solution, stir for 1 minute, add nano carbon black dispersant (TAZ-CNT1), water-based leveling agent (BD-3033) and 0.5 g each of water-based defoamer (BD-304) in this mixed solution. Finally, the mixed solution is placed in a ball mill for grinding to obtain the nano carbon black heat dissipation paint of the present invention, wherein the grinding speed is 400 r / min and the grinding time is 6 hours. Pour out the ground paint and seal it for later use.

[0034] testing method:

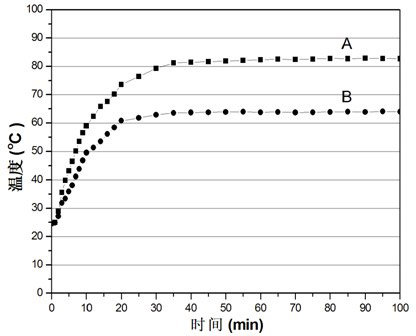

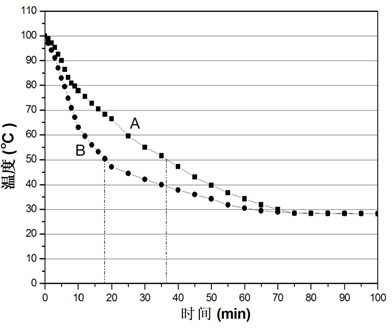

[0035] Prepare two aluminum sheets with the size of 7.5 cm×7.5 cm×0.2 cm, one of which is the control group, and its surface is not coated with heat dissipation paint; the other is the experimental group, whose surface is coated with the heat dissipation paint prepared in the examples . Apply thermal paste to the bottom of th...

Embodiment 2

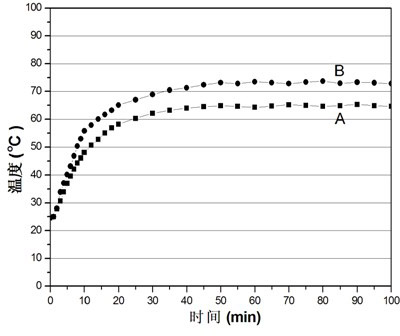

[0037] First mix 40 g of water-based epoxy resin (E44) and 35 g of ethanol to form a mixed solution. Then take 6 g of nano carbon black powder (particle size 15 nm) in the mixed solution, stir for 1 minute, add 1.5 g of nano carbon black dispersant (TAZ-CNT1), water-based leveling agent (BD-3033) ) And 1.0 g of water-based defoamer (BD-304) in the mixed solution. Finally, the mixed solution is placed in a ball mill for grinding to obtain the nano carbon black heat dissipation paint of the present invention, wherein the grinding speed is 500 r / min and the grinding time is 5 hours. Pour out the ball-milled paint and store it for later use.

[0038] testing method:

[0039] Prepare two aluminum sheets with a size of 7.5cm×7.5cm×0.2cm, one of which is the control group, and its surface is not coated with heat dissipation paint; the other is the experimental group, whose surface is coated with the heat dissipation paint prepared in the examples. Place the two aluminum plates on the 9...

Embodiment 3

[0041] First mix 50 g of water-based polyurethane resin (CS1600) and 40 g of water to form a mixed solution. Then take 9 g of nano carbon black powder (particle size 18 nm) in the mixed solution, stir for 1 minute, add 2.5 g of nano carbon black dispersant (TAZ-CNT1), water-based leveling agent (BD-3033) ) And water-based defoamer (BD-304) 1.5 g each in the mixed solution. Finally, the mixed solution is placed in a ball mill for grinding to obtain the nano carbon black heat dissipation paint of the present invention, wherein the grinding speed is 600 r / min and the grinding time is 4 hours. Pour out the ball-milled paint and store it for later use.

[0042] According to the method described in Example 1 and Example 2, it can be seen that the coating prepared in this example also has similar heating and cooling trends as in Example 1 and Example 2, indicating that the nano carbon black heat dissipation coating of the present invention Has good heat dissipation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com