High-blackness polypropylene composition and preparation method thereof

A polypropylene composition and high blackness technology, applied in the field of polypropylene preparation, can solve the problems of complex color masterbatch processing, complex color masterbatch manufacturing process, limited material blackness, etc., achieve high coloring strength, improve blackness degree, reducing the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

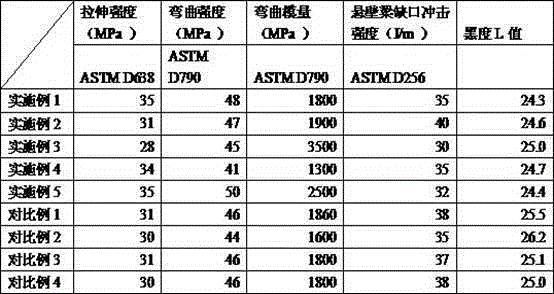

Examples

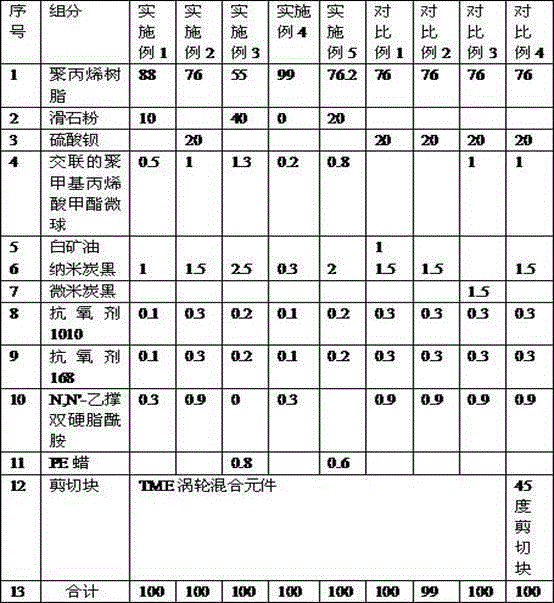

Embodiment 1

[0044] A high-blackness polypropylene composition, consisting of the following components by weight:

[0045] 88 parts of polypropylene resin

[0046] 10 parts talcum powder

[0047] 0.5 parts of cross-linked polymethyl methacrylate microspheres

[0048] Nano carbon black 1 part

[0049] Antioxidant 10100.1 parts

[0050] Antioxidant 1680.1 parts

[0051] 0.3 parts of N,N'-ethylene bisstearamide

[0052] Step 1. Add polypropylene resin, cross-linked polymethyl methacrylate microspheres, and nano-carbon black into a high-speed mixer with heating control, at a temperature of 85°C, at a speed of 850r / min, and stir for 1min, then add an antioxidant 1010. Antioxidant 168, lubricant N,N'-ethylene bisstearamide, and talcum powder were stirred at a high speed of 1000 r / min for 2 minutes.

[0053] Step 2. Melt, extrude and granulate the material mixed in step 1 with a twin-screw extruder. The screw speed is 350r / min, and the vacuum degree during extrusion and granulation is -0.08...

Embodiment 2

[0055] A high-blackness polypropylene composition, consisting of the following components by weight:

[0056] 76 parts of polypropylene resin

[0057] Barium sulfate 20 parts

[0058] 1 part of cross-linked polymethyl methacrylate microspheres

[0059] Nano carbon black 1.5 parts

[0060] Antioxidant 10100.3 parts

[0061] Antioxidant 1680.3 parts

[0062] 0.9 parts of N,N'-ethylene bisstearamide

[0063] Step 1. Add polypropylene resin, cross-linked polymethyl methacrylate microspheres, and nano-carbon black into a high-speed mixer with heating control, at a temperature of 80°C, at a speed of 1000r / min, and stir for 2 minutes, then add antioxidants 1010. Antioxidant 168, lubricant N,N'-ethylene bisstearamide, and barium sulfate were stirred at a high speed of 1200 r / min for 1 min.

[0064] Step 2. Melt, extrude and granulate the material mixed in step 1 with a twin-screw extruder. The screw speed is 100r / min, and the vacuum degree during extrusion and granulation is -0....

Embodiment 3

[0066] A high-blackness polypropylene composition, consisting of the following components by weight:

[0067] 55 parts of polypropylene resin

[0068] 40 parts of talcum powder

[0069] 1.3 parts of cross-linked polymethyl methacrylate microspheres

[0070] Nano carbon black 2.5 parts

[0071] Antioxidant 10100.2 parts

[0072] Antioxidant 1680.2 parts

[0073] PE wax 0.8 parts

[0074] Step 1. Add polypropylene resin, cross-linked polymethyl methacrylate microspheres, and nano-carbon black into a high-speed mixer with heating control, at a temperature of 90°C, at a speed of 1200r / min, and stir for 1min, then add an antioxidant 1010, antioxidant 168, lubricant PE wax, and talc powder were stirred at a high speed of 1000 r / min for 3 minutes.

[0075] Step 2. Melt, extrude and granulate the material mixed in step 1 with a twin-screw extruder. The screw speed is 500r / min, and the vacuum degree during extrusion and granulation is -0.09MPa. The screw temperature of the twin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com