Morphology-controllable and color angle-independent photonic crystal particle and preparation method thereof

A photonic crystal and angle-free technology, which is applied in the field of photonic materials and structural color materials, can solve the problems of high difficulty in particle shape regulation, low cost, and extended preparation time of oil phase, and achieve the elimination of color angle dependence and simple regulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

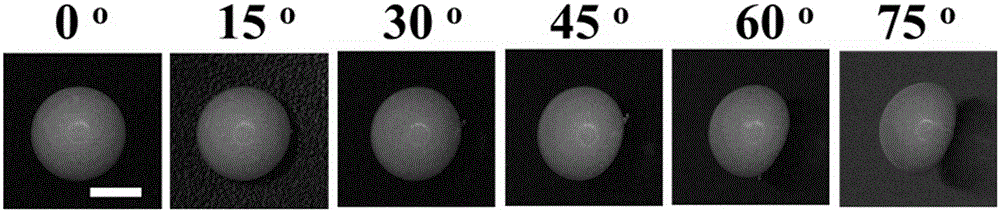

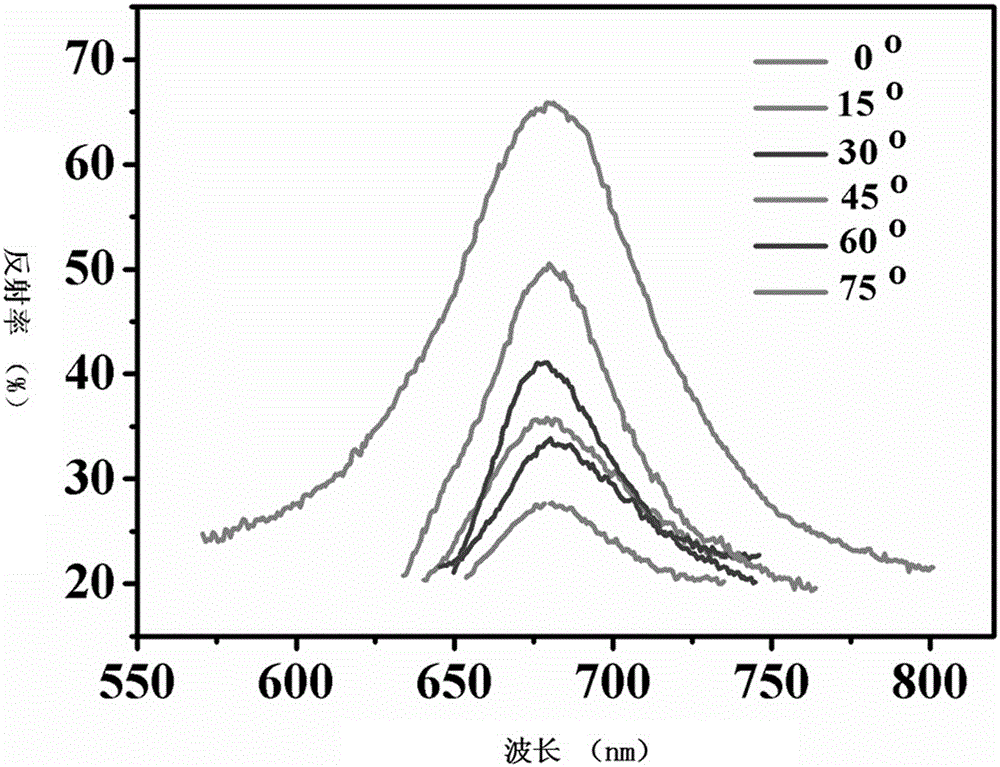

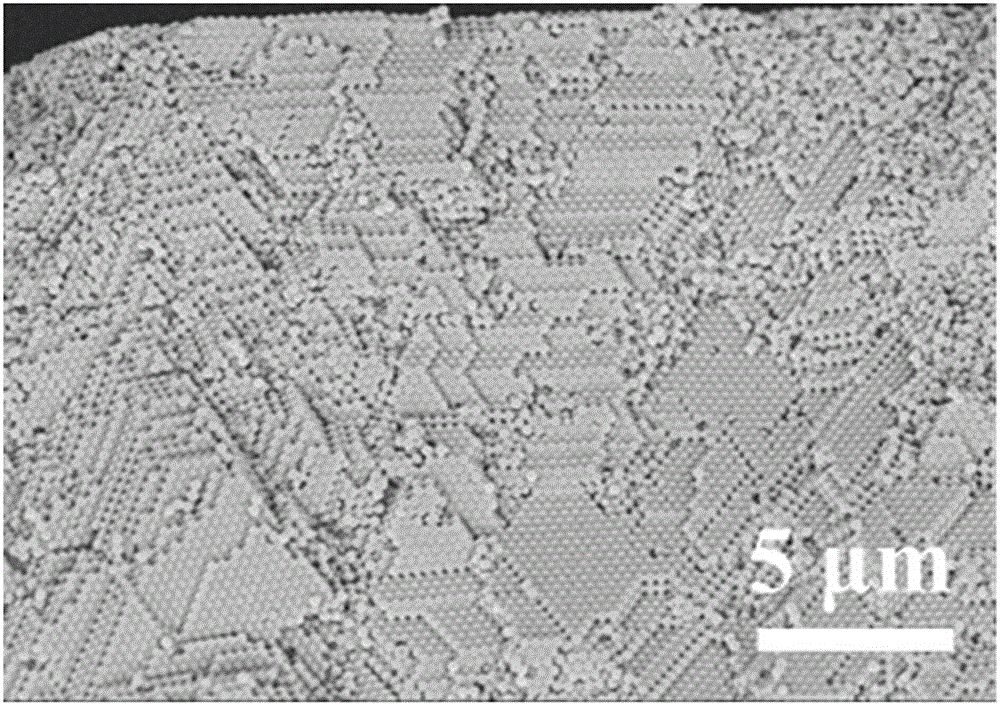

[0028] In the monodisperse poly(styrene-methyl methacrylate-acrylic acid) polymer colloidal microsphere emulsion with a particle size of 265 nm and a mass fraction of 40%, add a mass fraction of 2% Fe with a particle size of 15 nm. 3 o 4 The microparticles were ultrasonically dispersed, and then the emulsion was drop-coated on clover leaves with a contact angle with water of 150.6° to form emulsion droplets, and the size of the emulsion droplets was 1500 μm. Drying at a temperature of 40°C and a humidity of 40%, the monodisperse colloidal microspheres self-assemble to form spherical photonic crystal particles with a size of 1400 μm. Its color is red, and does not change with the viewing angle (0 o ~75 o ) changes (such as figure 1 ). Its photonic bandgap is located at 679nm and does not change with the collection angle (0 o ~75 o ) changes (such as figure 2 ). The edges of photonic crystal particles have a face-centered cubic periodic structure ( image 3 ). The in...

Embodiment 2

[0030] In the monodisperse poly(styrene-methyl methacrylate-acrylic acid) polymer colloidal microsphere emulsion with a particle size of 80nm and a mass fraction of 5%, add 0.1% of Fe with a particle size of 2nm 3 o 4The microparticles were ultrasonically dispersed, and then the emulsion was sprayed onto the lotus leaf with a water contact angle of 180° to form emulsion droplets, and the size of the emulsion droplets was 11 μm. Drying at a temperature of 15°C and a humidity of 15%, monodisperse colloidal microspheres self-assemble to form a size of 10 μm and a photonic band gap of 200 nm (acquisition angle, 0 o ~75 o ) of concave spherical photonic crystal particles.

Embodiment 3

[0032] In the monodisperse silica colloidal microsphere emulsion containing 60% of the particle size of 1100nm mass fraction, adding 5% of Fe with a particle size of 50nm 3 o 4 The microparticles were dispersed by ultrasonic, and then the emulsion droplets were applied to the leaves of violets with a contact angle of 150° to form emulsion droplets, and the size of the emulsion droplets was 1600 μm. Drying at a temperature of 90°C and a humidity of 90%, the self-assembled monodisperse colloidal microspheres have a size of 1500 μm and a photonic band gap of 2500 nm (acquisition angle, 0 o ~75 o ) of spherical photonic crystal particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com