High-purity high-density silicon carbide ceramic and manufacturing method thereof

A technology of silicon carbide ceramics and silicon carbide micropowder is applied in the field of engineering ceramic materials, which can solve the problem of high cost, achieve the effects of improving safety, reducing the content of metal impurities and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

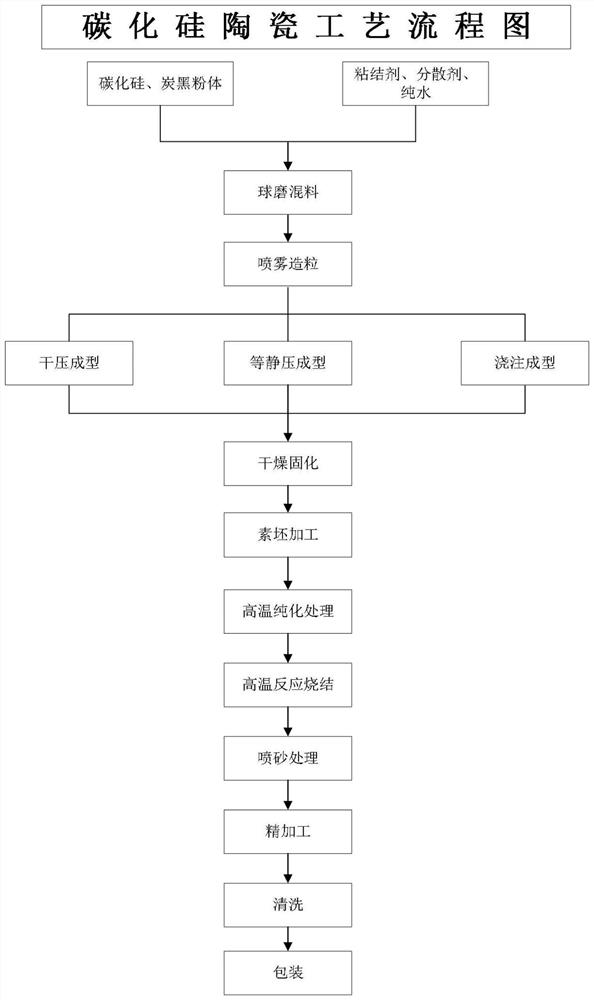

Image

Examples

Embodiment 1

[0073] A high-purity and high-density silicon carbide ceramic suction cup is manufactured through the inventive process, with an outer diameter of 290 mm and a thickness of 18 mm, with a complex flow channel structure, and is applied to high-temperature and high-purity working conditions.

[0074] Silicon carbide ceramics consist of the following components by mass:

[0075] 90 parts of silicon carbide; 8 parts of high-purity silicon;

[0076] The metal impurity content is less than 100ppm;

[0077] Boron element content is less than 1ppm;

[0078] A method for manufacturing a high-purity and high-density silicon carbide ceramic sucker, the steps of the method are:

[0079] a. Batching and mixing: add 85 parts by mass of silicon carbide and 15 parts of carbon black into the high-energy ball mill, stir and mix evenly to obtain a mixed powder;

[0080] b. Pulping: Add the mixed powder into a sand mill, add 50% of the total mass of the mixed powder with deionized water, 10 par...

Embodiment 2

[0093] A high-purity and high-density silicon carbide ceramic suction cup is manufactured through the inventive process, with an outer diameter of 290 mm and a thickness of 18 mm, with a complex flow channel structure, and is applied to high-temperature and high-purity working conditions.

[0094] Silicon carbide ceramics consist of the following components by mass:

[0095] 92 parts of silicon carbide; 8 parts of silicon;

[0096] A method for manufacturing a high-purity and high-density silicon carbide ceramic sucker, the steps of the method are:

[0097] a. Batching and mixing: add 85 parts by mass of silicon carbide and 15 parts of carbon black into the high-energy ball mill, stir and mix evenly to obtain a mixed powder;

[0098] b. Pulping: Add the mixed powder into a sand mill, add 50% of the total mass of the mixed powder with deionized water, 10 parts of binder and 0.5 part of dispersant, stir and mix evenly to obtain a mixed slurry ;

[0099] c, spray drying: dry t...

Embodiment 3

[0111] A high-purity and high-density silicon carbide ceramic cylinder is manufactured through the inventive process, with an outer diameter of 800mm, an inner diameter of 760mm, and a height of 650mm, with sealing grooves on the edge, and is used in high-temperature and high-purity working conditions.

[0112] A method for manufacturing a high-purity and high-density silicon carbide ceramic sucker, the steps of the method are:

[0113] a. Batching and mixing: add 85 parts by mass of silicon carbide and 15 parts of carbon black into the high-energy ball mill, stir and mix evenly to obtain a mixed powder;

[0114] b. Pulping: Add the mixed powder into a sand mill, add 50% of the total mass of the mixed powder with deionized water, 10 parts of binder and 0.5 part of dispersant, stir and mix evenly to obtain a mixed slurry ;

[0115] c, spray drying: dry the mixed slurry in a spray granulator, and sieve to obtain a composite powder;

[0116] d1. Isostatic pressing: put the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| High temperature strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com