Sandwich type cushion packaging material and manufacturing method thereof

A technology of buffer packaging and manufacturing method, applied in the directions of transportation and packaging, containers, containers to prevent mechanical damage, etc., can solve the problems of heavy corrugated paper, not easy to bend, lack of flexibility, etc., to achieve stable supporting force, not easy to collapse and deform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

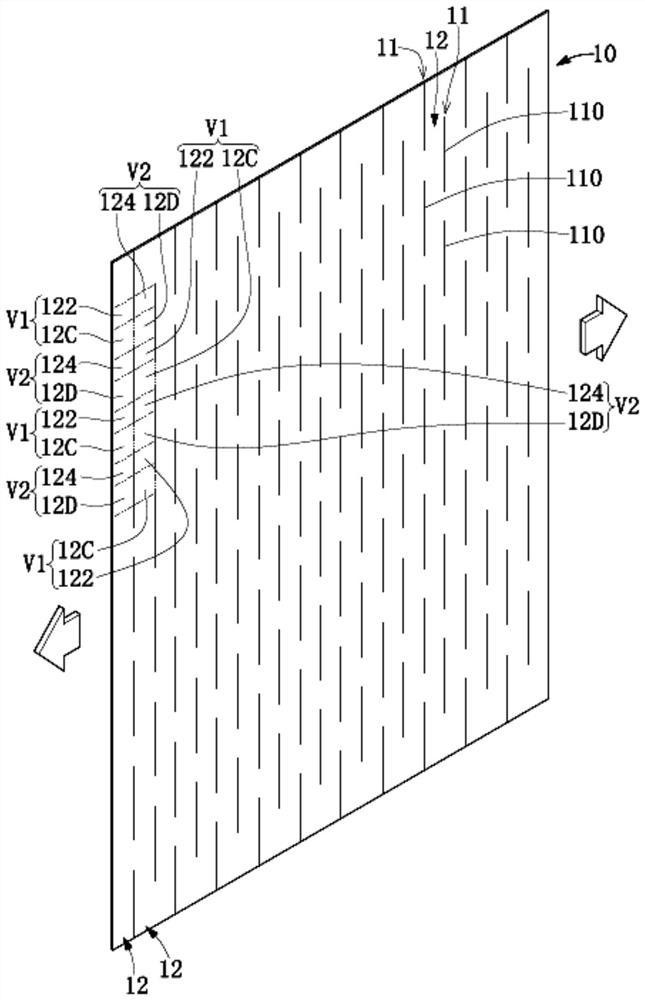

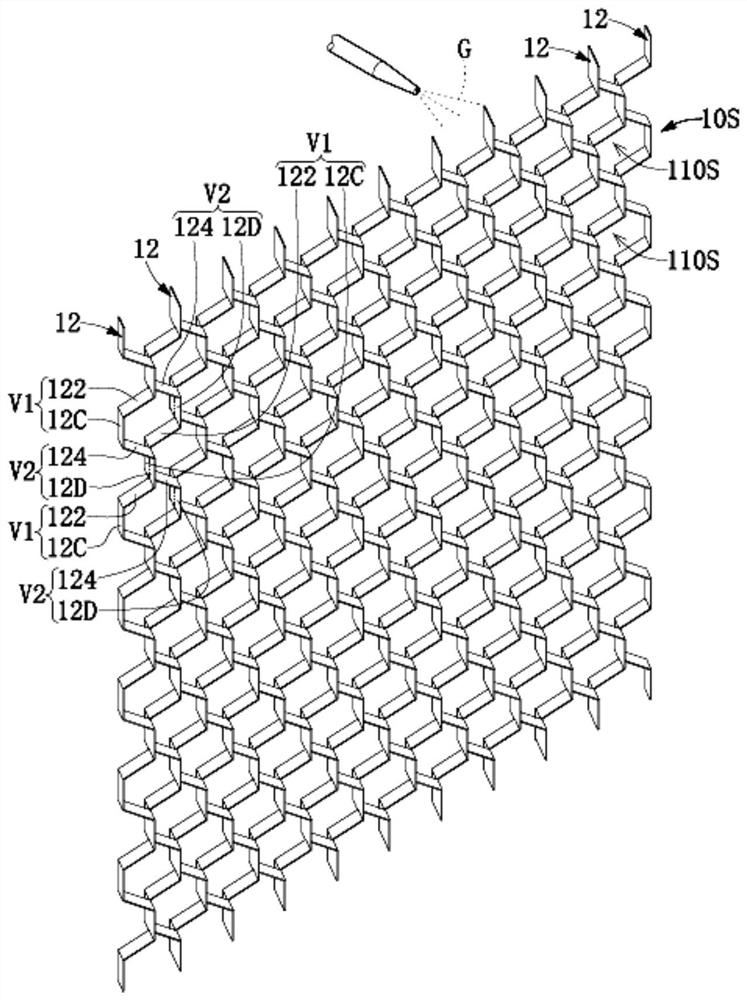

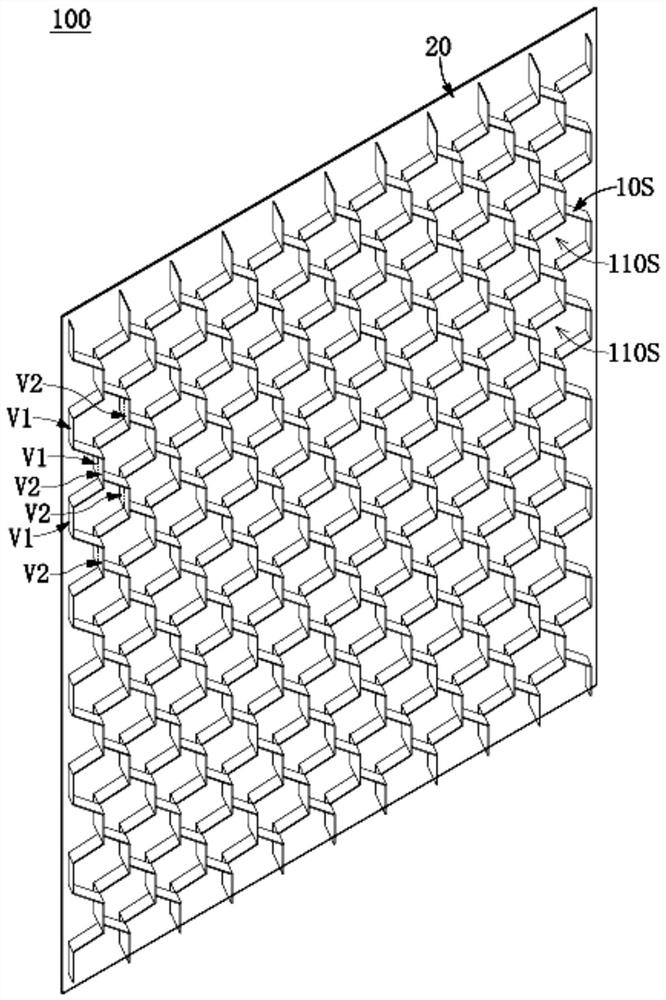

[0049] refer to Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a sandwich type cushioning packaging material 100, which includes a supporting cushioning layer 10S (refer to figure 2 and image 3 ) and an outer layer 20. The outer layer 20 is pasted on one side of the supporting buffer layer 10S. In this embodiment, the supporting buffer layer 10S and the outer layer 20 can be made of kraft paper, which can meet the trend of environmental protection. But the present invention is not limited thereto, and any planar material that can be bonded can be made.

[0050] The method for manufacturing sandwich type cushioning packaging material of the present invention comprises the following steps: as figure 1As shown, a planar support layer 10 is provided, and a plurality of cutting lines 11 are formed on the planar support layer 10 . A rib 12 is formed between two adjacent cutting lines 11, each of the cutting lines 11 has a plurality of incisio...

no. 2 example

[0061] Such as Figure 5 As shown, one of the outer layers 20, 20' is pasted on both sides of the supporting cushioning layer 10S to form a sandwich cushioning packaging material 200. The upper outer surface layer 20 is pasted on one side of the supporting buffer layer 10S, that is, on the plurality of first side convex portions V1; the lower outer layer 20' is pasted on the other side of the supporting buffer layer 10S, that is, Paste on multiple second lateral protrusions V2. In this embodiment, by sticking the outer layers 20, 20' to the first side convex portion V1 and the second side convex portion V2 of the supporting buffer layer 10S, the nest unit 110S can be shaped, and the nest unit 110S is fixed and inclined. It is firmly bonded to the outer layers 20, 20' to provide a stable supporting force, so that the sandwich-type cushioning packaging material 200 is not easy to collapse and deform, and can continuously provide a considerable cushioning protection effect.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com