Heat-insulating sound-absorbing baffle and production process thereof

A technology of heat insulation, sound insulation, and manufacturing process, which is applied in the field of transportation, can solve the problems of easy collapse and deformation, large layer structure restrictions, etc., and achieve the effects of not being easy to collapse and deform, avoiding collapse failure, and having a strong heat and sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

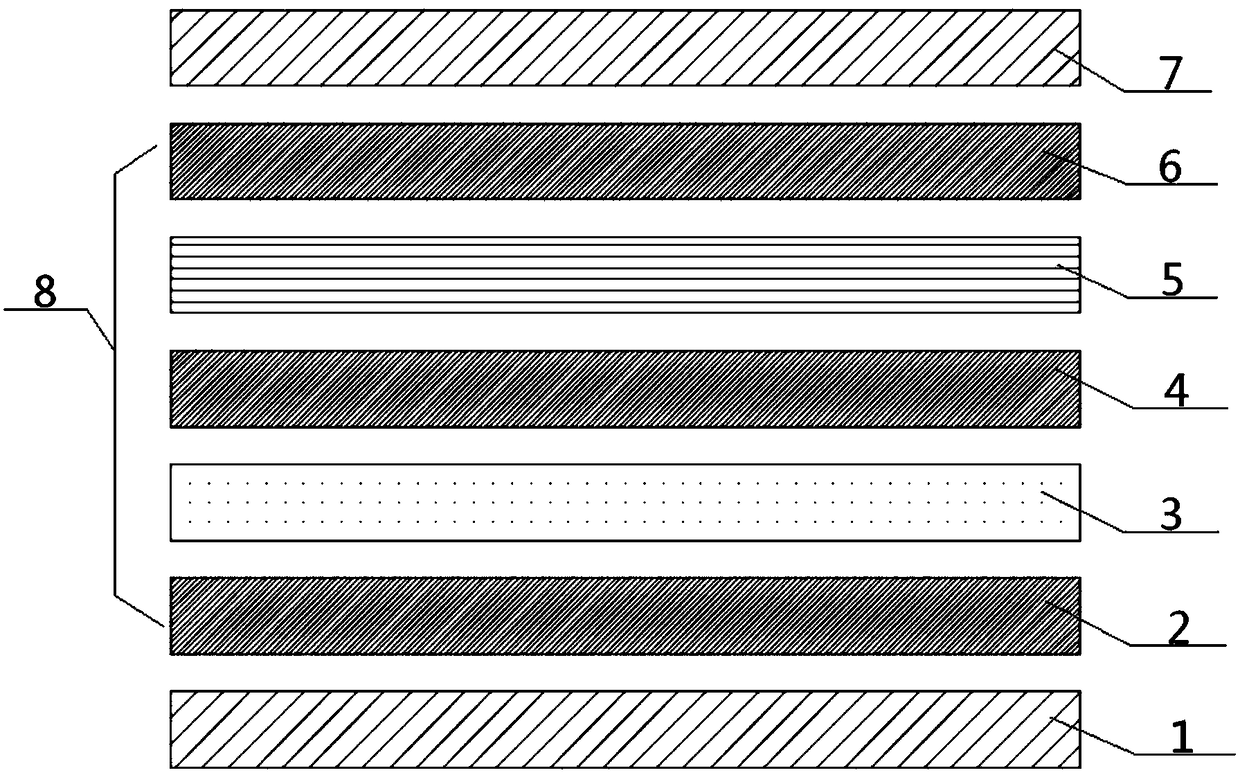

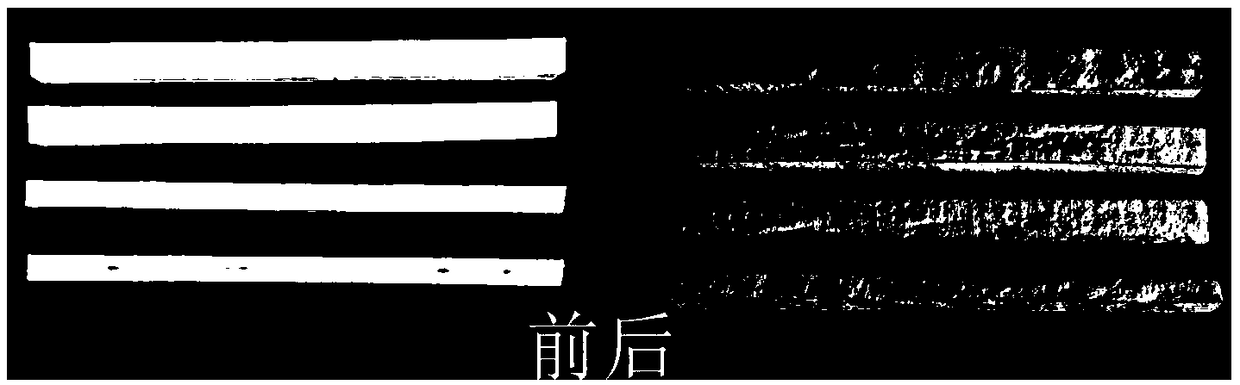

[0048] see Figure 1 to Figure 3 , a heat and sound insulation panel for automobiles, comprising a base layer 1, an intermediate layer 8 and a panel layer 7, wherein the base layer 1, the intermediate layer 8, and the panel layer 7 are stacked layer by layer from bottom to top; the intermediate layer 8 includes The first polymer film layer 2, the aluminum silicate layer 3, the second polymer film layer 4, the support plate layer 5 and the third polymer film layer 6, and the bottom plate layer 1, the aluminum silicate layer 3, the support plate layer 5 , The panel layer 7 is stacked layer by layer from bottom to top; the top surface of the bottom layer 1 is bonded to the bottom surface of the aluminum silicate layer 3 through the first polymer film layer 2, and the top surface of the aluminum silicate layer 3 is bonded to the bottom surface of the aluminum silicate layer 3 through the first polymer film layer. The second polymer film layer 4 is bonded to the bottom surface of t...

Embodiment 2

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] When heating in a heating device, the heating temperature is 270°C, and the heating time is 4 minutes; when pressing in a press, the pressure is 16Mpa, and the holding time is 2 minutes.

Embodiment 3

[0054] Basic content is the same as embodiment 1, the difference is:

[0055] The production materials of the first polymer film layer 2, the second polymer film layer 4, and the third polymer film layer 6 are polyethylene hot-melt adhesive film, modified polyethylene hot-melt adhesive film, modified polyvinyl chloride Hot-melt adhesive film, modified polypropylene hot-melt adhesive film, ethylene-vinyl acetate copolymer hot-melt adhesive film, modified ethylene-vinyl acetate copolymer hot-melt adhesive film, ethylene-acrylate copolymer hot-melt adhesive film , Ethylene-methacrylate copolymer hot-melt adhesive film, modified ethylene-methacrylate copolymer hot-melt adhesive film, nylon hot-melt adhesive film, any one of modified nylon hot-melt adhesive film. Preferably, the thicknesses of the first polymer film layer 2 , the second polymer film layer 4 and the third polymer film layer 6 are consistent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com