Double layer PET structural heat-insulation film

A heat insulation film, double-layer technology, applied in the field of double-layer PET structure heat insulation film, can solve the problems of light pollution, poor heat insulation effect, etc., and achieve the effect of good heat insulation performance and low visible light reflectance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

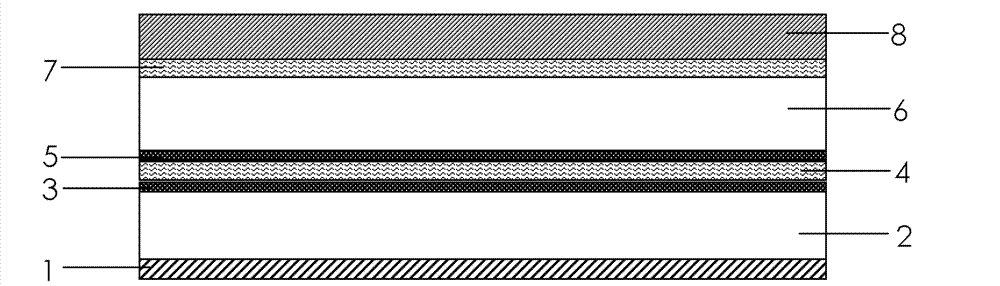

[0022] A double-layer PET structure heat insulation film, its composition and structure are: 3μm thick hardened coating 1, 30μm thick transparent and colorless first PET layer 2, 13nm thick metal titanium coating layer A3, 3μm thick second layer An adhesive layer 4 (using pressure sensitive adhesive), a 20 μm black transparent second PET layer 6 , a 5 μm thick second pressure sensitive adhesive layer 7 and a 20 μm thick release layer 8 .

Embodiment 2

[0024] A double-layer PET structure heat insulation film, its composition and structure are: 5μm thick hardened coating 1, 20μm thick transparent and colorless first PET layer 2, 10nm thick metal titanium coating layer A3, 4μm thick second layer An adhesive layer 4 (composite adhesive), 5nm thick metal titanium coating layer B5, 60 μm black transparent second PET layer 6, 4 μm thick second pressure sensitive adhesive layer 7 and 25 μm thick release layer 8.

Embodiment 3

[0026] A double-layer PET structure heat insulation film, its composition and structure are: 3μm thick hard coating 1, 50μm thick transparent and colorless first PET layer 2, 33nmTiO 2 +12nmAg+2nmTi+40nmTiO 2 Thick coating layer A3, 3μm thick first adhesive layer 4 (using pressure-sensitive adhesive), 33nmTiO 2 +12nmAg+2nmTi+33nmTiO 2 Thick coating layer B5, 50 μm colorless transparent PET layer 6, 5 μm thick second pressure-sensitive adhesive layer 7 and 15 μm thick release layer 8.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com