Cleaning agent for museum showcase glass, and preparation method and application of cleaning agent

A cleaning agent and exhibition cabinet technology, applied in the field of cleaning agents, can solve the problems of glare increase, AR film resistance, glass reflectivity rise, etc., to achieve the effects of preventing glare, easy cleaning, and good low reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

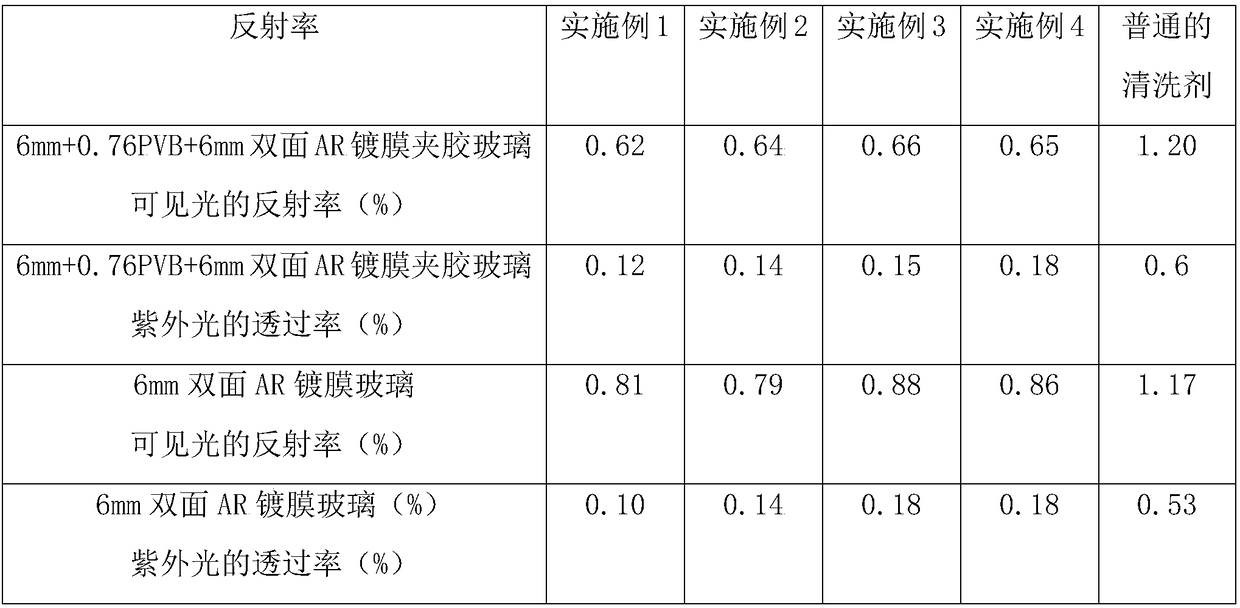

Examples

Embodiment 1

[0037] The present embodiment is a kind of cleaning agent for the glass of museum exhibition cabinets. By weight percentage, the cleaning agent is made up of the following components: 0.1% of FC-4430 fluorosurfactant, 0.1% of complexing agent and 99.8% of C5-C10 alkane , wherein the complexing agent used is sodium metasilicate, and the C5-C10 alkane used is heptane.

[0038] The preparation method of the cleaning agent that this museum exhibition cabinet glass is used is as follows:

[0039] Weigh the corresponding parts by weight of the following components: 1 part of FC-4430 fluorosurfactant, 1 part of sodium metasilicate, and 998 parts of heptane. According to the weighed weight, first put heptane into the preparation vessel, then put into FC-4430 fluorosurfactant, and finally put into sodium metasilicate and mix to obtain the cleaning agent of the present invention.

Embodiment 2

[0041] The present embodiment is a kind of cleaning agent for museum exhibition cabinet glass, and this cleaning agent is made up of following components by weight percentage: 0.2% of FC-4430 fluorochemical surfactant, 0.2% of complexing agent and 99.6% of C5-C10 alkane, The complexing agent used therein is disodium edetate, and the C5-C10 alkane used is methylcyclohexane.

[0042] The preparation method of the cleaning agent that this museum exhibition cabinet glass is used is as follows:

[0043] Weigh the corresponding parts by weight of the following components: 2 parts of FC-4430 fluorosurfactant, 2 parts of sodium metasilicate, and 996 parts of heptane. According to the weighed weight, methylcyclohexane is firstly put into the preparation vessel, then FC-4430 fluorosurfactant, and finally disodium ethylenediaminetetraacetate are put into the mixture to obtain the cleaning agent of the present invention.

Embodiment 3

[0045] Present embodiment a kind of cleaning agent for museum exhibition cabinet glass, this cleaning agent is made up of following components by weight percentage: 0.4% of FC-4430 fluorine surfactant, complexing agent 0.4% and C5-C10 alkane 99.2%, The complexing agent used therein is trisodium citrate dihydrate, and the C5-C10 alkane used is octane.

[0046] The preparation method of the cleaning agent that this museum exhibition cabinet glass is used is as follows:

[0047] Weigh the corresponding parts by weight of the following components: 4 parts of FC-4430 fluorosurfactant, 4 parts of sodium metasilicate, and 992 parts of heptane. According to the weighed weight, octane is firstly put into the preparation vessel, then FC-4430 fluorine surfactant is put in, and finally trisodium citrate dihydrate is put in and mixed to obtain the cleaning agent of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com