Automobile window film capable of reducing visible light reflectance and preparation process of automobile window film

A technology of reflectivity and visible light, applied in windows, vehicle parts, lamination and other directions, can solve the problem of high reflectivity of visible light, and achieve the effect of improving the performance of explosion-proof heat insulation, excellent heat insulation performance, and reducing the reflectivity of visible light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

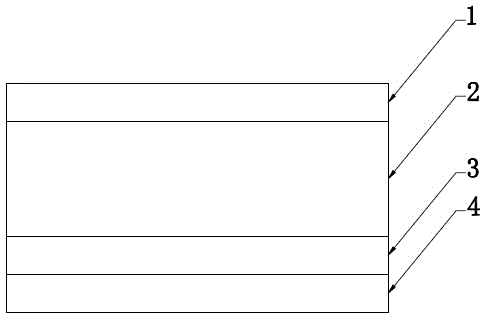

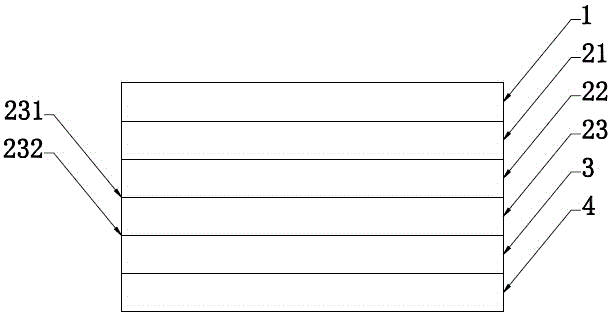

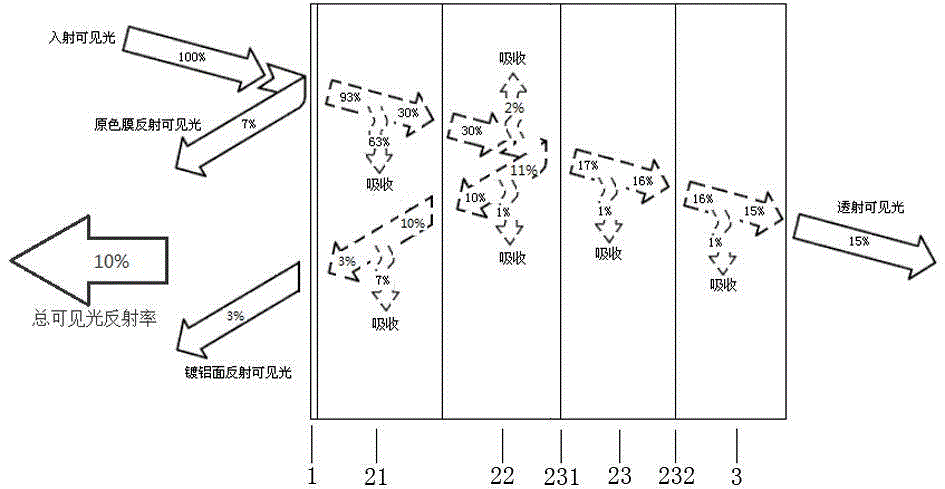

[0023] Embodiment 1 Use the primary color film to reduce the reflectivity of the light incident from the scratch-resistant layer to the aluminum-coated film. The structure is as follows figure 2 As shown, the anti-scratch layer 1, primary color film 21, composite layer 22, aluminized film 23, installation layer 3 and release film 4 are included in sequence. First, the primary color film 21 and the aluminized surface 231 of the aluminized film 23 are combined through the composite layer 22, and then the installation layer 3 is coated on the non-aluminized surface 232 of the aluminized film 23 and compounded with the release film 4, and finally the The anti-scratch layer 1 is coated on the primary color film 21 .

[0024] Select primary color film 21 with visible light transmittance of 30% (visible light reflectance is 7%) and aluminized film 23 with visible light transmittance of 41% (aluminized surface 231 visible light reflectance is 41.1%, non-aluminized surface 232 The re...

Embodiment 2

[0029] Embodiment 2 Utilizes the primary color film to reduce the reflectivity of the light incident from the automobile glass to the aluminized film, the structure is as follows Figure 4 As shown, it includes the anti-scratch layer 1, the aluminized film 23, the composite layer 22, the primary color film 21, the installation layer 3 and the release film 4 in sequence. First, the primary color film 21 and the aluminum-plated surface 231 of the aluminum-plated film 23 are combined through the composite layer 22, then the installation layer 3 is coated on the primary-color film 21 and compounded with the release film 4, and finally the non-plated surface of the aluminum-plated film 23 is The anti-scratch layer 1 is coated on the aluminum surface 232 .

[0030] If you want to reduce the visible light reflectance on both sides of the product at the same time, you can increase the second composite layer 24 and the second primary color film 25 in the core layer 2, use the primary c...

Embodiment 3

[0031] Embodiment three such as Figure 4 As shown, the structure includes an anti-scratch layer 1 , a primary color film 21 , a composite layer 22 , an aluminized film 23 , a second composite layer 24 , a second primary color film 25 , an installation layer 3 and a release film 4 . First, the primary color film 21 and the aluminized surface 231 of the aluminized film 23 are composited through the composite layer 22, and then the second primary color film 25 and the non-aluminized surface 232 of the aluminized film 23 are composited through the second composite layer 24, and then The installation layer 3 is coated on the second primary color film 25 and combined with the release film 4 , and finally the anti-scratch layer 1 is coated on the primary color film 21 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com