Heat insulation and preservation plastic film

A plastic film, heat insulation technology, applied in the field of plastic film, can solve the problems of reducing greenhouse temperature and loss of greenhouse film, and achieve the effect of preventing energy loss, good performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

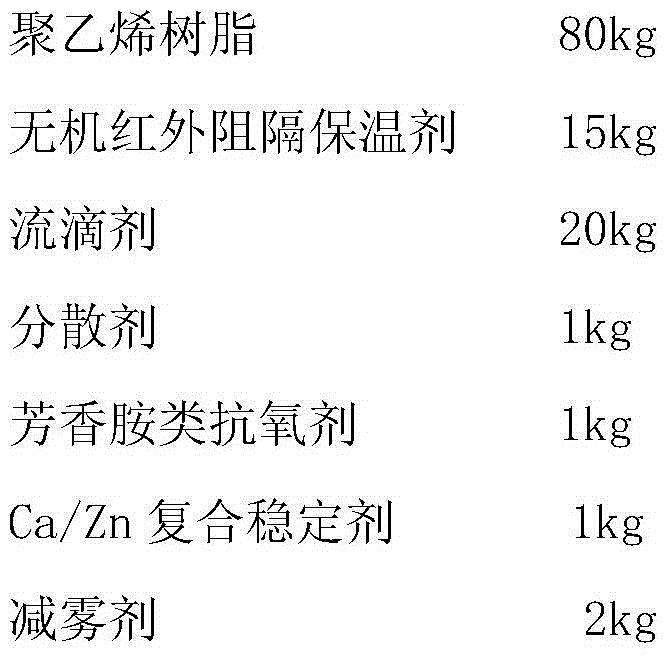

Embodiment 1

[0015]

[0016] Firstly, the above-mentioned raw materials in parts by weight were added to the mixer and stirred for 30 minutes, and the temperature of the mixer was kept at 95°C. Then, the homogeneously mixed material was added to a storage tank at 90° C. and allowed to stand for 30 minutes. Finally, the film was formed by dip coating with a coating machine, and the dip coating temperature was controlled at 80 °C.

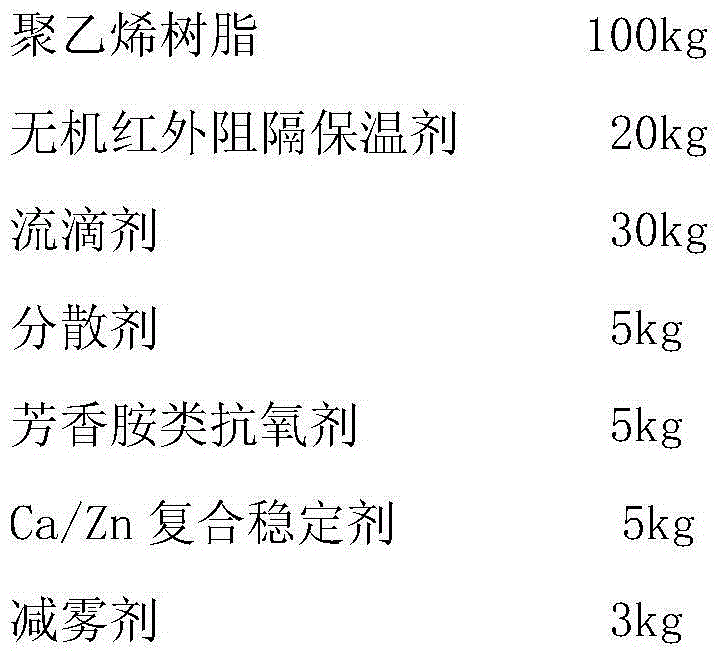

Embodiment 2

[0018]

[0019] Firstly, the above-mentioned raw materials in parts by weight were added to the mixer and stirred for 30 minutes, and the temperature of the mixer was kept at 95°C. Then, the homogeneously mixed material was added to a storage tank at 90° C. and allowed to stand for 30 minutes. Finally, the film was formed by dip coating with a coating machine, and the dip coating temperature was controlled at 80 °C.

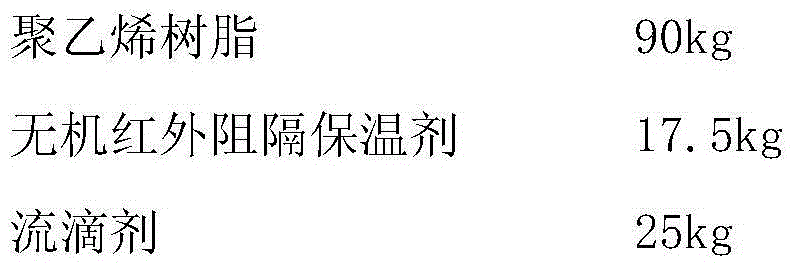

Embodiment 3

[0021]

[0022]

[0023] Firstly, the above-mentioned raw materials in parts by weight were added to the mixer and stirred for 30 minutes, and the temperature of the mixer was kept at 95°C. Then, the homogeneously mixed material was added to a storage tank at 90° C. and allowed to stand for 30 minutes. Finally, a coating machine was used to form a film by dip coating, and the dip coating temperature was controlled at 80°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com