Sun-reflection heat-insulation paint and manufacturing method thereof

A technology for reflecting heat-insulating coatings and sunlight, applied in the direction of reflection/signal coatings, coatings, fibrous fillers, etc., can solve the problems that it is difficult to obtain heat insulation effects, few; etc., and achieve low cost, convenient production, and insulation Effect of heat effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

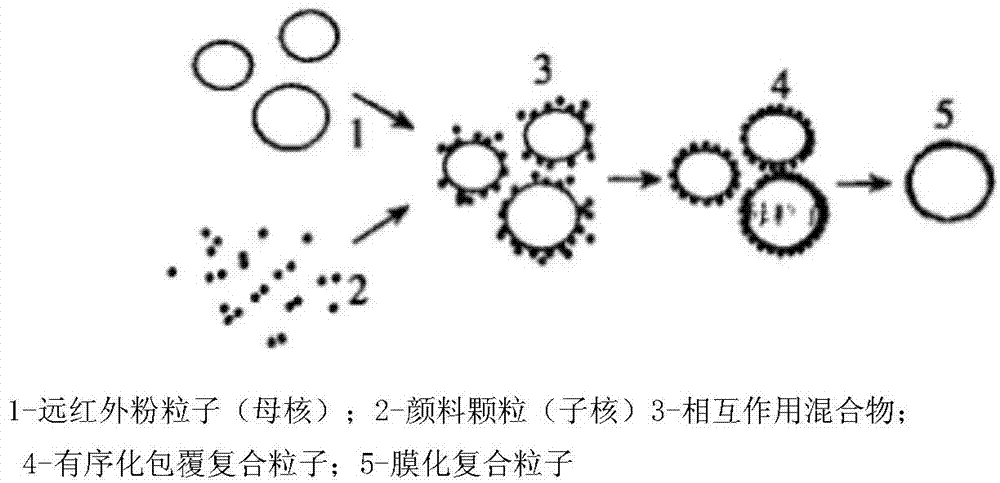

[0037] The present invention adds a special heat-insulating powder to the provided sunlight-reflecting heat-insulating coating, and coats the pigment in the coating, thereby achieving the following ideal effects:

[0038] 1. Special heat insulation powder, which significantly improves the heat insulation effect;

[0039] 2. As we all know, dark-colored objects are easy to absorb heat; after coating the pigment, the heat can be reflected, which can reduce the heat-absorbing effect of dark-colored objects, so as to achieve the purpose of heat insulation.

[0040] The auxiliary agents include preservatives, bactericides, dispersants, leveling agents, defoamers, film-forming aids, thickeners and antifreezes in sequence, and the ratio between them is recommended to be 1:1:3:2 :3:6:4:10.

[0041] The porous mineral particles are diatomite, pumice, expanded perlite, sepiolite, zeolite at least one or a mixture of two or more in any proportion; it can be a crushed natural mineral or ...

Embodiment 1

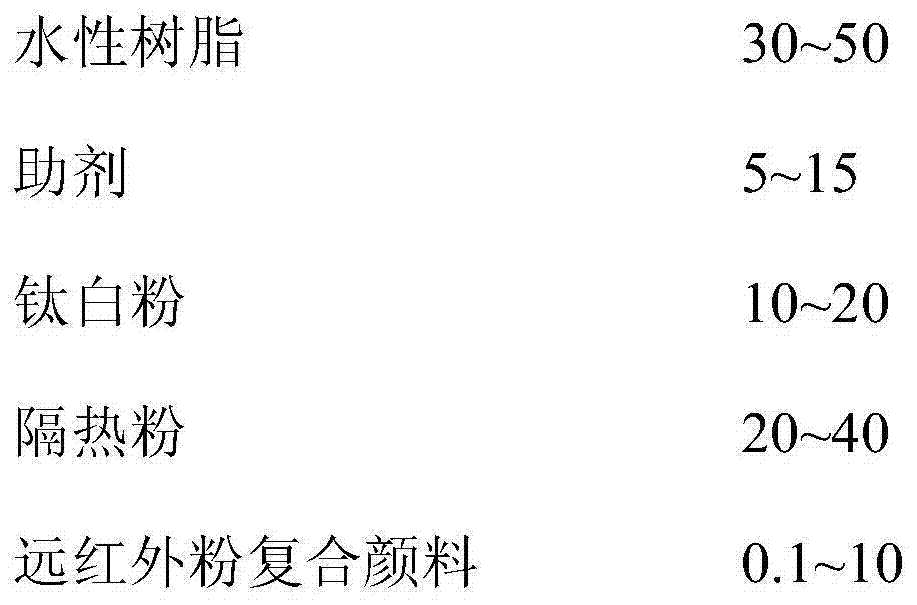

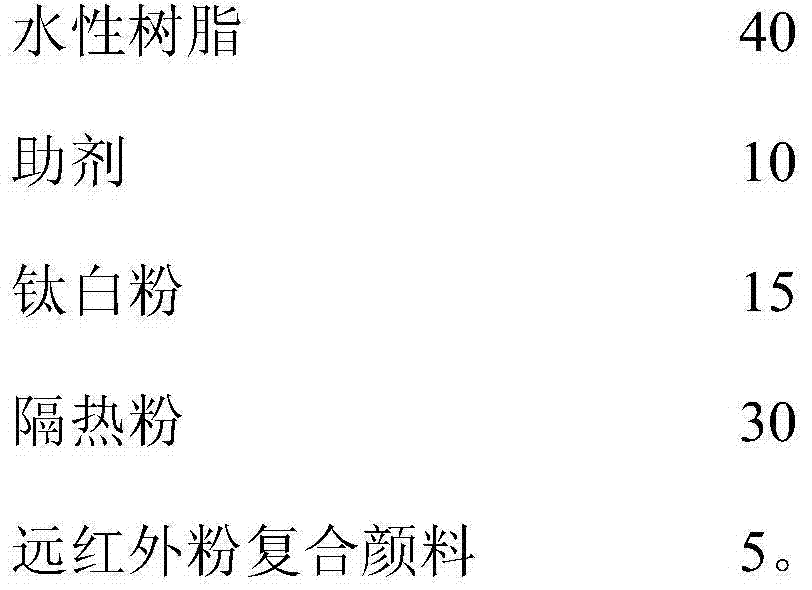

[0045] A kind of sunlight reflective heat-insulating coating, the composition that comprises and parts by weight are as follows:

[0046] Pure acrylic emulsion 30, additive 5, rutile titanium dioxide 20, heat insulating powder 40, far-infrared powder composite pigment 2;

[0047] The auxiliary agents include 0.1 preservative, 0.1 bactericide, 0.3 dispersant, 0.2 leveling agent, 0.3 defoamer, 0.6 film-forming aid, 0.4 thickener and 1 antifreeze;

[0048] The preparation method of the solar reflective heat-insulating paint is as follows: mixing and stirring the water-based resin, additives, titanium dioxide, heat-insulating powder and far-infrared powder composite pigments according to the set ratio and evenly.

[0049] The preparation method of described thermal insulation powder is:

[0050] a) After mixing expanded perlite, KH560, polyethylene glycol 200, deionized water and absolute ethanol in a mass ratio of 10:6:1:60:100, ultrasonically disperse for 30 minutes;

[0051] ...

Embodiment 2

[0059] A kind of sunlight reflective heat-insulating coating, the composition that comprises and parts by weight are as follows:

[0060] Fluorocarbon resin emulsion 50, auxiliary agent 15, rutile titanium dioxide 10, heat insulating powder 20, far-infrared powder composite pigment 10;

[0061] Among the auxiliary agents, 0.1 of preservative, 0.1 of bactericide, 0.3 of dispersant, 0.2 of leveling agent, 0.3 of defoamer, 0.6 of film-forming aid, 0.4 of thickener and 1 of antifreeze.

[0062] The preparation method of the solar reflective heat-insulating paint is as follows: mixing and stirring the water-based resin, additives, titanium dioxide, heat-insulating powder and far-infrared powder composite pigments according to the set ratio and evenly.

[0063] The preparation method of described thermal insulation powder is:

[0064] a) After mixing diatomaceous earth, KH550, polyethylene glycol 200, deionized water and absolute ethanol in a mass ratio of 10:7:2:50:100, ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com