Micropore light weight silica brick and preparation method thereof

A lightweight, silica brick technology, applied in the field of refractory materials, can solve the problems of poor heat insulation effect, high bulk density, low service temperature, etc., and achieve the effect of reducing specific gravity, small bulk density and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

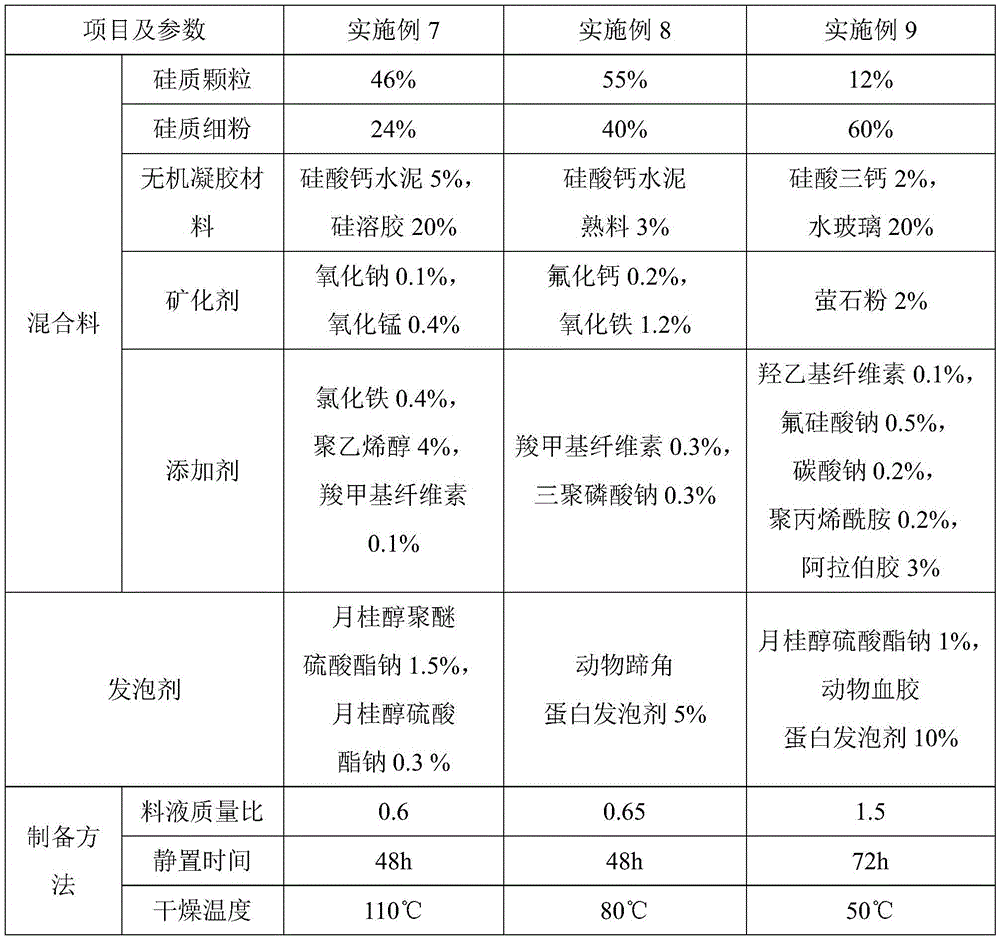

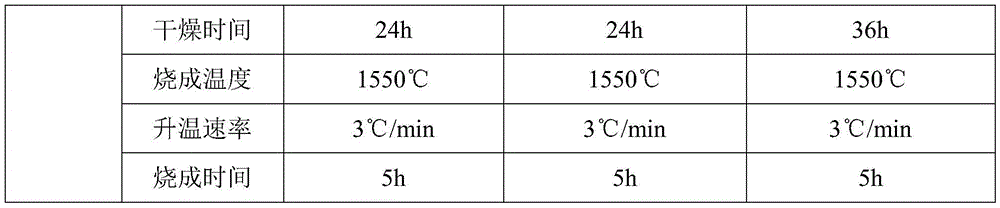

Examples

Embodiment 1

[0032] The microporous lightweight silica brick of the present embodiment is mainly made of a mixture and an animal hoof keratin foaming agent, and the consumption of the animal hoof keratin foaming agent is 9% of the mixture quality;

[0033] The mixture is made up of the following components in mass percent: 10% silica particles (SiO 2 Content is 98wt%), 58% silica fine powder (SiO 2 Content is 98wt%), 15% silicon powder (SiO 2 The content is 92wt%), 8% of calcium silicate cement, 1% of iron oxide powder, 3% of calcium oxide powder, 3% of fluorite powder, and 2% of calcium lignosulfonate.

[0034] Among them, the particle size of silica particles is 0.1-3 mm, and the particle size of silica fine powder and silicon micropowder is ≤0.075 mm; in the mixture, the mass ratio of silica particles to silica fine powder is 10:73.

[0035] The preparation method of the microporous lightweight silica brick of the present embodiment comprises the following steps:

[0036] 1) Take the...

Embodiment 2

[0042] The microporous lightweight silica brick of this embodiment is mainly made of a mixture and a tea saponin vegetable protein foaming agent, and the consumption of the tea saponin vegetable protein foaming agent is 3% of the mixture quality;

[0043] The mixture is made up of the following components in mass percent: 40% silica particles (SiO 2 Content is 99wt%), 20% silica fine powder (SiO 2 Content is 99wt%), 10% quartz powder (SiO 2 content of 99.4wt%), 10% silicon powder (SiO 2 The content is 96wt%), 10% of silica sol, 1% of iron oxide powder, 5% of milk of lime, 3.5% of fluorite powder, and 0.5% of sodium carbonate.

[0044] Among them, the particle size of silica particles is 0.1-3 mm, and the particle size of silica fine powder, quartz powder, and silicon micropowder is ≤0.075 mm; in the mixture, the mass ratio of silica particles to silica fine powder is 40:40.

[0045] The preparation method of the microporous lightweight silica brick of the present embodiment...

Embodiment 3

[0052] The microporous lightweight silica brick of this embodiment is mainly made of a mixture and a foaming agent, and the amount of the foaming agent is 3% of the mixture quality; the foaming agent is composed of the following components by mass percentage: 20% Sodium Lauryl Sulfate and 80% Sodium Ceteth Sulfate;

[0053] The mixture is made up of the following components in mass percent: 10% silica particles (SiO 2 Content is 98.5wt%), 15% waste silica brick particles (SiO 2 Content is 94.3wt%), 55% silica fine powder (SiO 2 The content is 98.5wt%), 8% calcium silicate cement, 0.5% iron oxide powder, 5% calcium oxide powder, 1% fluorite powder, 0.5% sodium tripolyphosphate, 5% gelatin.

[0054] Among them, the particle size of silica particles and waste silica brick particles is 0.1-3 mm, and the particle size of silica fine powder is ≤0.075 mm; in the mixture, the mass ratio of silica particles to silica fine powder is 25:55.

[0055] The preparation method of the micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com