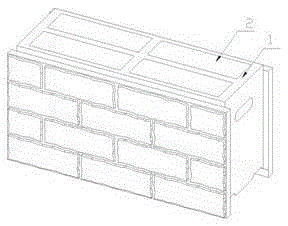

a block

A block and skeleton technology, applied in the direction of sustainable waste treatment, solid waste management, application, etc., can solve the problems of adverse effects of frost resistance and durability of walls, reduced wall thermal insulation performance, poor thermal insulation performance, etc. , to achieve superior thermal insulation performance, enhanced thermal insulation effect, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] First prepare the mineral powder, and grind the limestone through a 100-mesh sieve with a pulverizer to obtain the limestone mineral powder.

[0022] Then weigh the materials that make up the skeleton according to the following percentages by weight: 25% cement, 45% fly ash ceramsite with a particle size not greater than 10mm, 10% basalt material with a particle size not greater than 10mm, 9% of the above-mentioned limestone mineral powder, 10% of woody plant fiber and 1% of admixture; put the above-mentioned materials weighed into a mixer, add water and stir evenly to form a skeleton mixture, which is ready for use.

[0023] Then take by weighing the following weight percent materials that form the core: 25% of cement, 45% of polystyrene lightweight particle filler, 25% of limestone mineral powder and 5% of n-pentane blowing agent; Put it into a blender, add water and stir evenly to form a core mixture, set aside.

[0024] Finally, the skeleton mixture and the core mi...

Embodiment 2

[0026] First prepare the mineral powder, and grind the calcium carbide through a 200-mesh sieve with a mill to obtain the calcium carbide mineral powder.

[0027] Then weigh the materials that make up the skeleton according to the following weight percentages: 32% cement, 28% spontaneous combustion coal gangue with a particle size not greater than 10mm, 15% basalt rock with a particle size not greater than 10mm, 12% calcium carbide powder, and 11% plant fiber. % and admixture 2%; put the above-mentioned materials weighed into a mixer and stir evenly to form a skeleton mixture for use.

[0028] Then take the following weight percent materials that form the core: 45% of cement, 25% of EPS granules, 15% of calcium carbide powder and 15% of trichlorofluoromethane blowing agent; Evenly, form a core mixture, set aside.

[0029] Finally, the skeleton mixture and the core mixture are respectively injected into the corresponding cavity of the mould, and then formed, and then the block...

Embodiment 3

[0031] First prepare the mineral powder, and grind the limestone through a 200-mesh sieve with a pulverizer to obtain the limestone mineral powder.

[0032] Then weigh the materials that make up the skeleton according to the following weight percentages: 36% of cement, 30% of porous sintered material with a particle size of no more than 10mm, 11.5% of basalt rock with a particle size of no more than 10mm, 8% of the above-mentioned limestone mineral powder, and 13% of plant fiber and admixture 1.5%; put the above-mentioned materials weighed into a mixer, add water and stir evenly to form a skeleton mixture, which is ready for use.

[0033] Then take by weighing the following weight percent materials that form the core: 45% of cement, 25% of polystyrene lightweight particle filler, 20% of the above-mentioned limestone mineral powder and 10% of tetrafluoroethylene dichloride blowing agent; Put the above-mentioned materials into a mixer and add water to stir evenly to form a core ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com