Unfired clay tile and production technology thereof

A technology for firing clay and antioxidants is applied in the field of non-fired clay tiles and their preparation, which can solve the problems of heavy sintered clay tiles, unsuitable lightweight roofs, and high production costs, and achieves reduction in specific gravity, weight reduction, and improvement in strength and toughness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

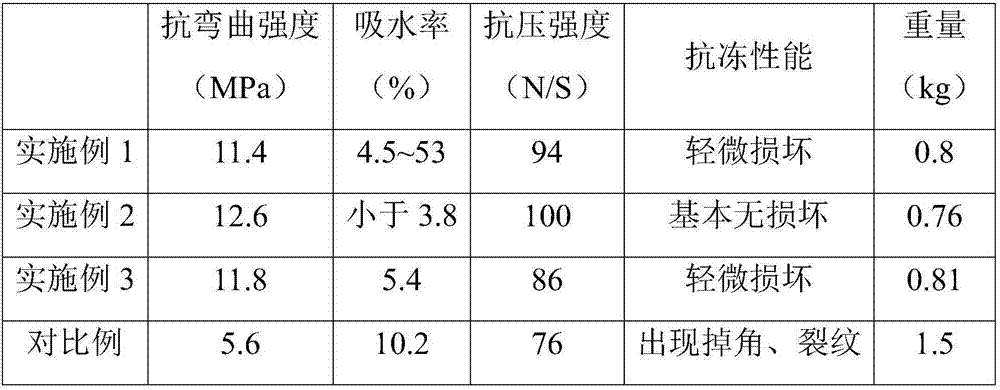

Examples

Embodiment 1

[0030] A burn-free clay tile, comprising the following components by weight:

[0031] 10 parts of natural colored sand, 15 parts of natural colored quartz, 5 parts of polyester resin, 5 parts of polystyrene resin, 8 parts of alkali-free glass fiber, 0.5 parts of zinc stearate, 1 part of steel mesh, 5 parts of light magnesium oxide And 0.05 parts of antioxidant SP.

[0032] The preparation process of the above-mentioned burn-free clay tile includes the following steps:

[0033] (1) According to the formula, mix the polyester resin and polystyrene resin in a kneader, then add zinc stearate, stir for 3 minutes, then add natural colored sand with a particle size greater than or equal to 200 meshes, and continue stirring for 8 minutes, and then Add natural colored quartz sand with a particle size greater than or equal to 100 mesh, light magnesium oxide, antioxidant SP and alkali-free glass fiber with a length of 2 cm, and continue stirring for 15 minutes;

[0034] (2) Put the product obta...

Embodiment 2

[0036] A burn-free clay tile, comprising the following components by weight:

[0037] 10 parts of natural colored sand, 10 parts of natural colored quartz sand, 3 parts of polyester resin, 2 parts of polystyrene resin, 5 parts of alkali-free glass fiber, 0.5 parts of zinc stearate, 1 part of steel wire mesh, 2 parts of light magnesium oxide Parts and 0.02 parts of antioxidant SP.

[0038] The preparation process of the above-mentioned burn-free clay tile includes the following steps:

[0039] (1) Mix the polyester resin and polystyrene resin according to the formula, place in the kneader, then add zinc stearate, stir for 3 minutes, then add natural colored sand with a particle size greater than or equal to 200 meshes, continue to stir for 5 minutes, and then Add natural colored quartz sand with a particle size greater than or equal to 100 mesh, light magnesium oxide, antioxidant SP and alkali-free glass fiber with a length of 2 cm, and continue to stir for 10 minutes;

[0040] (2) Pu...

Embodiment 3

[0042] A burn-free clay tile, comprising the following components by weight:

[0043] 15 parts of natural colored sand, 15 parts of natural colored quartz sand, 5 parts of polyester resin, 5 parts of polystyrene resin, 8 parts of alkali-free glass fiber, 0.8 parts of zinc stearate, 1 part of steel wire mesh, 5 parts of light magnesium oxide Parts and antioxidant SP 0.05 parts.

[0044] The preparation process of the above-mentioned burn-free clay tile includes the following steps:

[0045] (1) Mix the polyester resin and polystyrene resin according to the formula, put them in the kneader, then add zinc stearate, stir for 3 minutes, then add natural colored sand with a particle size greater than or equal to 200 meshes, continue to stir for 6 minutes, and then Add natural colored quartz sand with a particle size greater than or equal to 100 mesh, light magnesium oxide, antioxidant SP and alkali-free glass fiber with a length of 2 cm, and continue stirring for 12 minutes;

[0046] (2) P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com