Technology for flame-retardant and water-proof coating of fabric

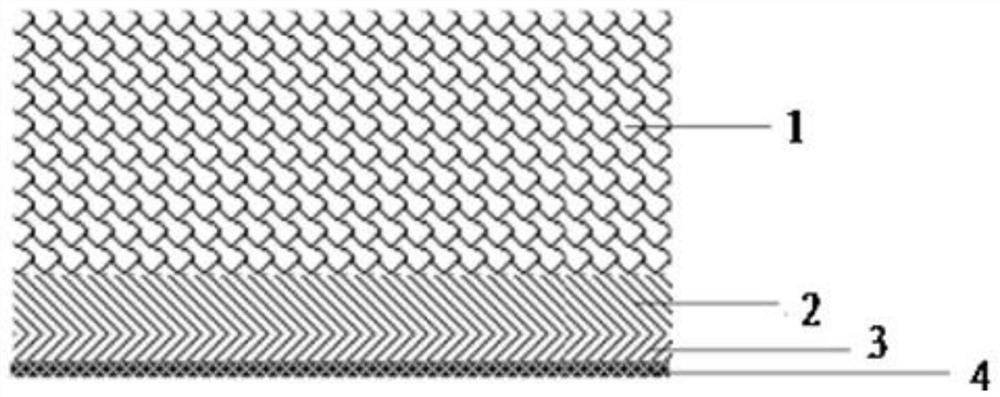

A waterproof coating and fabric technology, applied in fabric surface trimming, textiles and papermaking, etc., can solve the problems of poor synergy of waterproof performance, reduced fabric strength, unstable flame retardant effect, etc., to achieve good flame retardant effect and reduce strength loss , good penetration and binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

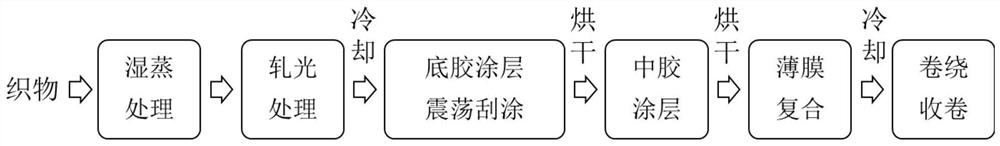

[0046] 1. Using the leading cloth, the linear density of the package after printing, washing and shaping is 650dtex, and the square meter weight is 243g / m 2 The high-strength polyamide 66 air-changing yarn plain weave fabric is placed on the fabric conveying mechanism, unwound, and wet-steamed through a high-temperature and high-humidity steamer. The hot and humid steam is supersaturated steam at a temperature of 110°C; the pressure is 1.1bar, and then Put the reverse side of the fabric flat on the surface of the high-temperature hollow smooth chrome-plated metal roller, and pass it directly under the action of tension. The tension is 110N, and the temperature of the metal roller surface is 150°C. Cooling, the cooling temperature is normal temperature;

[0047] 2. Transfer the calendered and cooled fabric to the primer coating mechanism through guide rollers, and mix 100 parts by weight of polyurethane glue, 90 parts of flame retardant decabromodiphenylethane, 30 parts of flam...

Embodiment 2

[0053] 1. Using the leading cloth, the linear density of the printed, washed and shaped package is 1000dtex, and the square meter weight is 315g / m 2 The high-strength polyester air-change yarn plain weave fabric is placed on the fabric conveying mechanism, unwound, and steamed through a high-temperature and high-humidity steam drum. The temperature of the steam is 120°C; The surface of the hollow smooth chrome-plated metal drum passes directly under the action of tension, the tension is 150N, and the temperature of the metal drum surface is 160°C to obtain a fabric with a flat and smooth reverse side, and then the fabric is cooled by the cooling drum, and the cooling temperature is normal temperature.

[0054] 2. Transfer the calendered and cooled fabric to the primer coating mechanism through guide rollers, and mix 100 parts by weight of polyurethane glue, 90 parts of flame retardant decabromodiphenylethane, 30 parts of flame retardant Antimony, 3 parts of bridging agent mela...

Embodiment 3

[0060] 1. Using the leading cloth, the linear density of the printed and washed package is 500dtex, and the square meter weight is 202g / m 2 The high-strength polyamide 6 air-changing yarn plain weave fabric is placed on the fabric conveying mechanism, unwound, and under the control of a certain tension, it is wet-steamed through a high-temperature and high-humidity steamer. The hot and humid steam is saturated steam at a temperature of 110°C; the pressure 1.1 bar, and then the reverse side of the fabric is flatly attached to the surface of the high-temperature hollow smooth chrome-plated metal roller, and it passes directly under the action of tension. The fabric is cooled by the cooling drum, and the cooling temperature is normal temperature.

[0061] 2. Transfer the calendered and cooled fabric to the primer coating mechanism through guide rollers, and mix 100 parts by weight of polyurethane glue, 90 parts of flame retardant decabromodiphenylethane, 30 parts of flame retarda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com