Thermal-resistant and flame-retardant membrane and preparation method thereof, and applications

A diaphragm and heat-resistant technology, applied in the field of electrochemistry, can solve problems such as battery thermal runaway, battery exothermic side reactions, and accelerated battery heat accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

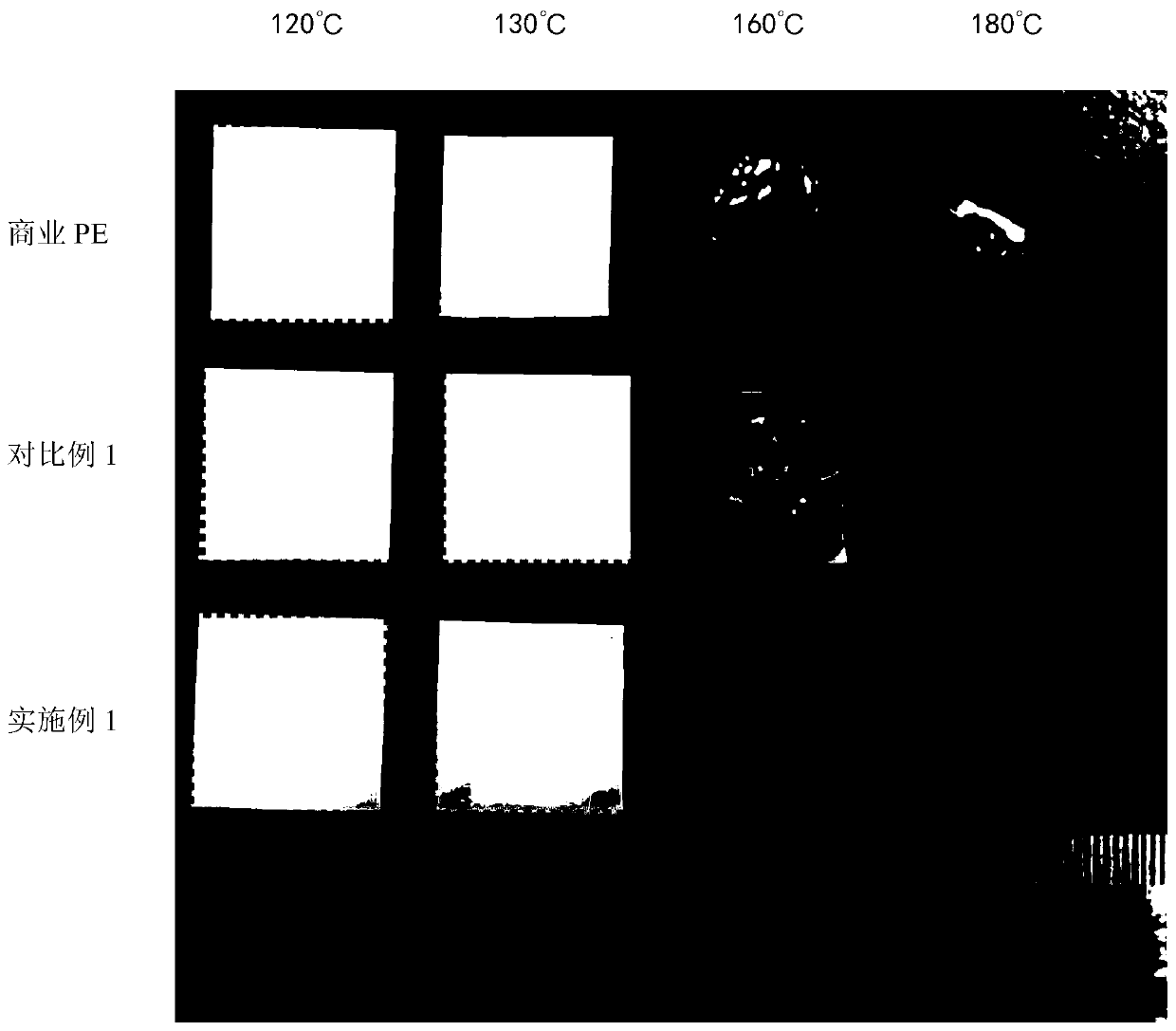

Embodiment 1

[0049] A heat-resistant and flame-retardant diaphragm of this embodiment and a preparation method thereof include the following steps:

[0050] (1) 95 parts by mass of zinc borate powder with a particle diameter of about 600nm, 3 parts by mass of styrene-butadiene rubber, 2 parts by mass of sodium carboxymethyl cellulose, solvent ethanol solution, the volume ratio of water and ethanol in the ethanol solution 1:1, formulated as a flame retardant slurry with a solid content of 10%, coated on the surface of a single layer of microporous commercial polyethylene (PE) diaphragm, dried to remove the solvent, and then coated with flame retardant function Coated diaphragm;

[0051] (2) Dip the above diaphragm coated with a flame-retardant functional coating layer in a 30 g / L polyimide N-methylpyrrolidone solution, dry it, and remove the solvent to obtain a heat-resistant and flame-retardant diaphragm.

[0052] The heat-resistant and flame-retardant diaphragm prepared in this embodimen...

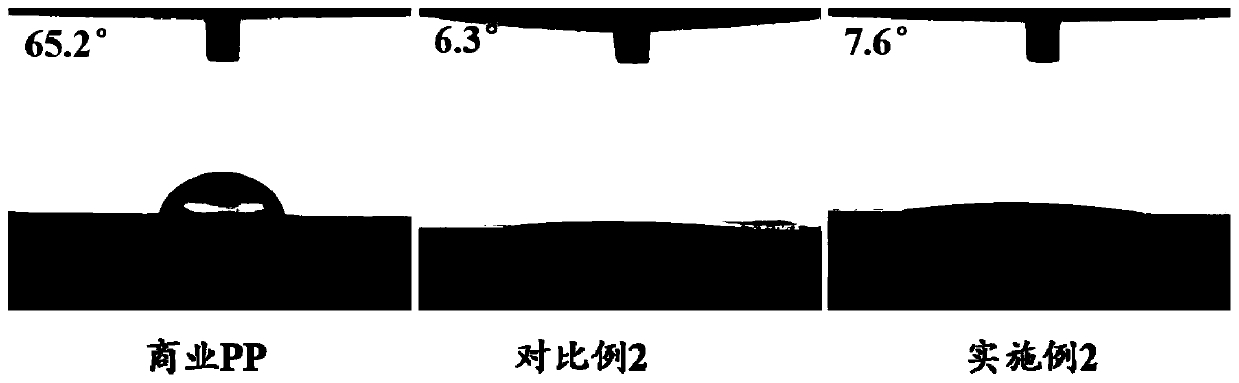

Embodiment 2

[0054] The difference between embodiment 2 and embodiment 1 is:

[0055] (1) 90 parts by mass of ammonium polyphosphate powder with a particle diameter of about 500nm, 5 parts by mass of gelatin, 2 parts by mass of polyvinyl alcohol, and the solvent is a water / isopropanol mixture with a volume ratio of 2:1 to prepare a solid The flame retardant slurry with a content of 15% is coated on the double-layer surface of a commercial polypropylene (PP) diaphragm with microporosity, and dried to remove the solvent, so as to obtain a diaphragm coated with a flame-retardant functional coating layer.

[0056] (2) Dip the above diaphragm coated with a flame-retardant functional coating layer in a 40 g / L polyarylether N,N-dimethylformamide solution, dry it, and remove the solvent to obtain a heat-resistant and flame-retardant diaphragm.

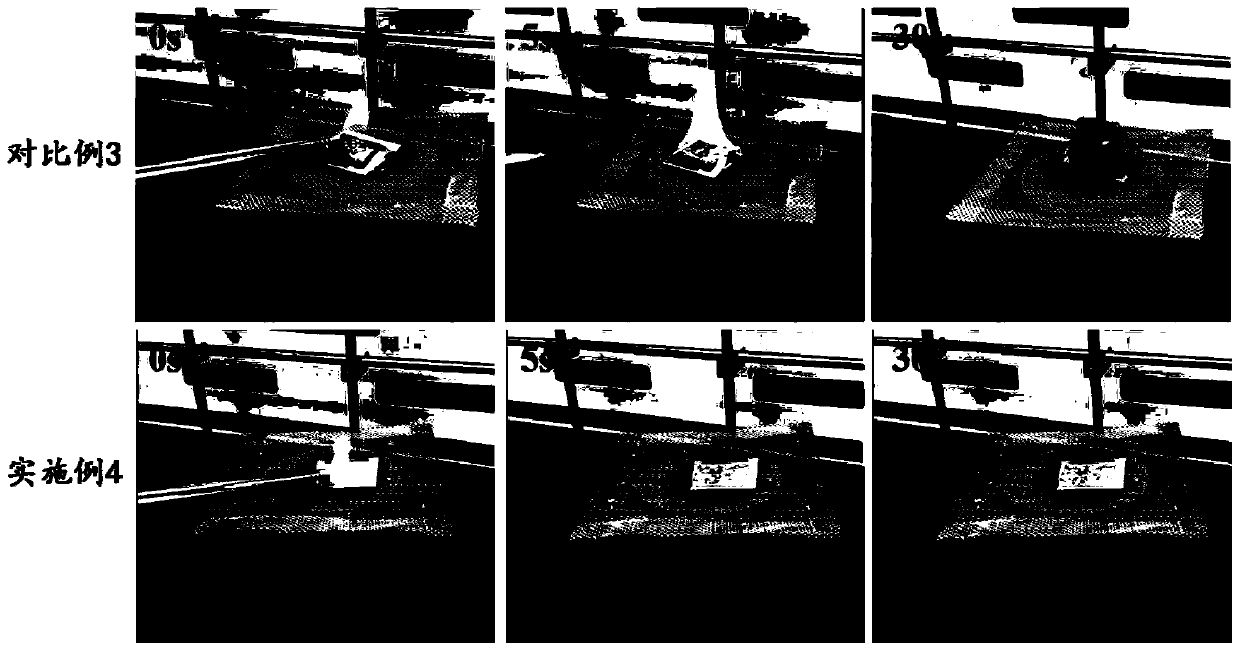

Embodiment 3

[0058] The difference between embodiment 3 and embodiment 1 is:

[0059] (1) 92 parts by mass of melamine sodium urate powder with a particle diameter of about 800nm, 8 parts by mass of polyvinylidene fluoride, using acetone as a solvent, prepare a flame retardant slurry with a solid content of 12%, and coat it on a micro Porous commercial polyacrylonitrile organic microporous membrane base material single-layer surface, drying to remove solvent, promptly obtains the membrane coated with the flame-retardant function coating layer.

[0060] (2) Spray-coat 80 g / L ethanol solution of phenolic resin on the surface of the diaphragm coated with the flame-retardant functional coating layer, dry it, and remove the solvent to obtain a heat-resistant flame-retardant diaphragm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com