Preparation method and application of three-source integrated hyperbranched structure flame retardant

A structural flame retardant, hydroxyl-terminated hyperbranched technology, applied in the field of flame retardant preparation, can solve the problems of low molecular weight, weakened material mechanical properties, poor polymer compatibility, etc., achieve good fluidity, improve mechanical properties, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 Preparation of reactive "three sources in one" hyperbranched structure flame retardant

[0021] Step 1. Add the hydroxyl-terminated hyperbranched polyester and phosphoric acid into the reactor, and add the catalyst phosphotungstic acid or p-toluenesulfonic acid. The molar ratio of the hydroxyl-terminated hyperbranched polyester, phosphoric acid, and catalyst is 1:0.4:0.5 %;

[0022] Step 2, heating up to 80°C, and reacting under vacuum for 4 hours;

[0023] Step 3, wash with ethanol, after drying, dissolve in acetone;

[0024] Step 4: After adding ethylenediamine in an equimolar ratio to phosphoric acid and reacting for 30 minutes, the precipitate was obtained, washed three times with ethanol, and dried to obtain a light yellow powder, which is a reactive "three sources in one" hyperbranched structure flame retardant.

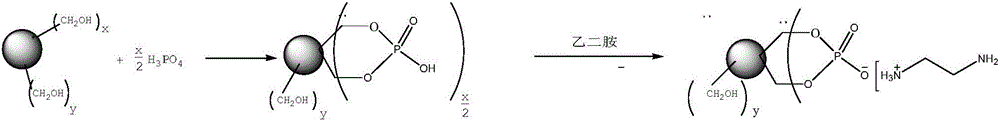

[0025] The reaction equation of the reactive "three sources in one" hyperbranched structure flame retardant is as follows:

[0026]

[0...

Embodiment 2

[0032] Example 2 Application of reactive "three sources in one" hyperbranched structure flame retardant

[0033] The reactive "three sources in one" hyperbranched structure flame retardant can be used as a chain extender or crosslinking agent in the polyurethane reaction system, becoming a reactive "three sources in one" flame retardant in the polyurethane system. The specific operation steps are as follows:

[0034] Mix partially flame-retardant modified hyperbranched polyester with polyester polyol and toluene diisocyanate in a certain proportion, add catalyst triphenylbismuth, mix well, defoam, put into mold and cure at 60°C for 2 days. Wherein, the polyester polyol of this embodiment can also be replaced with other polyols, such as polyether polyols, polybutadiene polyols and other polyurethane raw materials; toluene diisocyanate can also be other polyisocyanates.

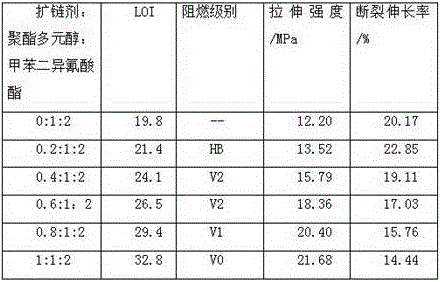

[0035] Taking the fourth-generation hydroxyl-terminated hyperbranched polyester as an example, the polyuret...

Embodiment 3

[0039] Example 3 Application of Reactive "Three Sources in One" Hyperbranched Structure Flame Retardant

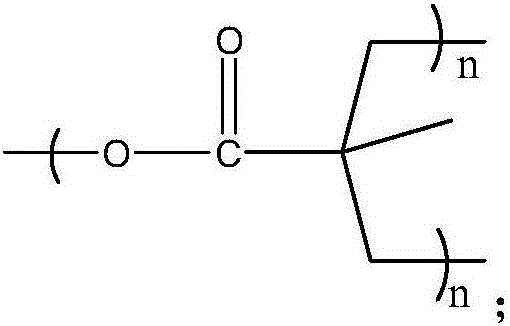

[0040] The reactive "three sources in one" hyperbranched structure flame retardant can react with monomers containing double bonds (such as acrylic acid, oleic acid, etc.), and can obtain end groups containing double bonds, which can be used as reactive type of olefin polymer materials "Three sources in one" flame retardant. Taking the modified part of acrylic acid as an example, the reaction equation is as follows:

[0041]

[0042] The specific preparation method is as follows:

[0043]The flame-retardant modification of part of the end group of the hydroxyl-terminated hyperbranched polyester is obtained to obtain a reactive "three sources in one" hyperbranched structure flame retardant. In the Boltorn type hyperbranched polyester, the hydroxyl group of the y part that does not participate in the reaction reacts with the carboxylic acid containing double bonds to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com