Coffee beans automatic drying and screening device

A screening equipment and coffee bean technology, applied in the fields of sieving, food processing, solid separation, etc., can solve the problems of affecting the quality of materials and re-moisture, and achieve the effect of improving anti-corrosion and anti-bacterial properties, avoiding moisture return, and preventing leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

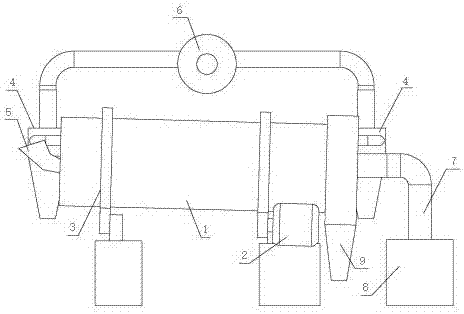

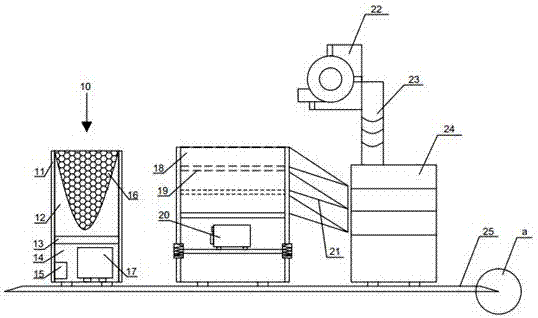

[0023] Such as Figure 1~4 As shown, a coffee bean automatic drying and screening equipment includes a drum 1, a transmission mechanism 2 connected to the outer surface of the drum 1, and a bracket part 3. The left side of the drum 1 is connected to a feed port 5, and the right side of the drum 1 is connected to a Outlet 9, the right side of the drum 1 is connected to the hot air stove 8 through the air guide pipe 7, the two sides of the drum 1 are connected to the dust collector 4, and the dust collector 4 is connected to the frequency conversion fan 6, and there is a screening box directly below the outlet 9 18. There is a dust collection box 10 on the left side of the screening box 18, and a charging box 24 on the right side of the screening box 18. This device uses a hot air stove 8 to supply air to the drum 1 to achieve the purpose of drying coffee beans, and the hot air The portable dust is discharged, which not only makes the air circulate in the drum 1, accelerates the...

Embodiment 2

[0033] Such as Figure 1~4 As shown, a kind of coffee bean automatic drying and screening equipment, in actual work, pour coffee beans into the feed port 5, start the transmission mechanism 2, make it drive the drum 1 to roll, turn on the hot blast stove 8 and the frequency conversion fan 6, and pass The air guide pipe 7 blows hot air to the inside of the drum 1, and the coffee beans are tossed under the lifting plate on the inner wall of the drum 1, and at the same time contact with the hot air, the coffee beans are quickly dried, and the frequency conversion fan 6 can effectively control the air speed of the hot blast stove 8, In order to reduce energy consumption, the air outlets of the dust collectors 4 at both ends of the drum 1 are connected to each other, and the frequency conversion fan 6 is installed at the air outlets of the two dust collectors 4, so that the hot air can pass through the dust collectors 4 when discharged from both ends of the drum 1, thereby The dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com