Patents

Literature

59results about How to "Achieve continuous drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing terylene pre-tropism continuous yarn by utilizing reclaimed polyester bottle

ActiveCN101144191ALow costReduce energy consumptionMelt spinning methodsSpinning solutions preparationYarnPolyester

The present invention belongs to the fiber producing method field, in particular relates to a method which uses a reclaimed PET bottle to produce the terylene preoriented filament in particular. The present invention mainly solves the problems of the prior art that the cost of raw materials for production is high, the drying efficiency is low, and the uniformity is poor, etc., and provides a method which uses the reclaimed PET bottle to produce the terylene preoriented filament with low cost of the raw materials for production, high drying efficiency, and good uniformity. The present invention has the major steps that the bottle piece of the PET bottle is produced; the bottle piece is continuously crystallized and dried by passing through a pre-crystallizer and a drying tower; the dried bottle piece directly enters a threaded rod extrusion machine, and is melted and extruded by a spinning threaded rod; the molten polyester material is continuously filtrated by a molten mass filter with a big filtering area of one level or two levels, to enter a spinning manifold; a thread line is cooled by passing through a cross air blasting, to wind to form the preoriented filament.

Owner:浙江聚元新材料股份有限公司

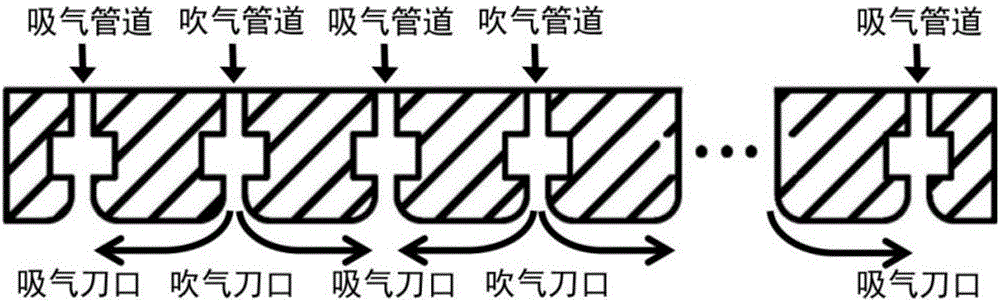

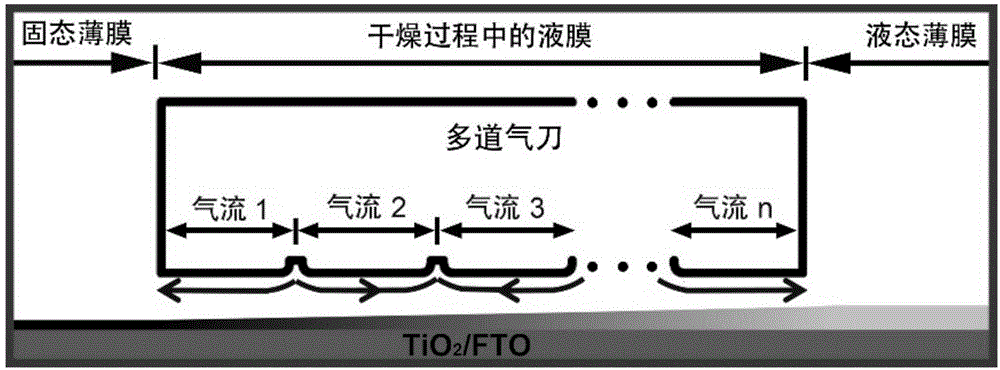

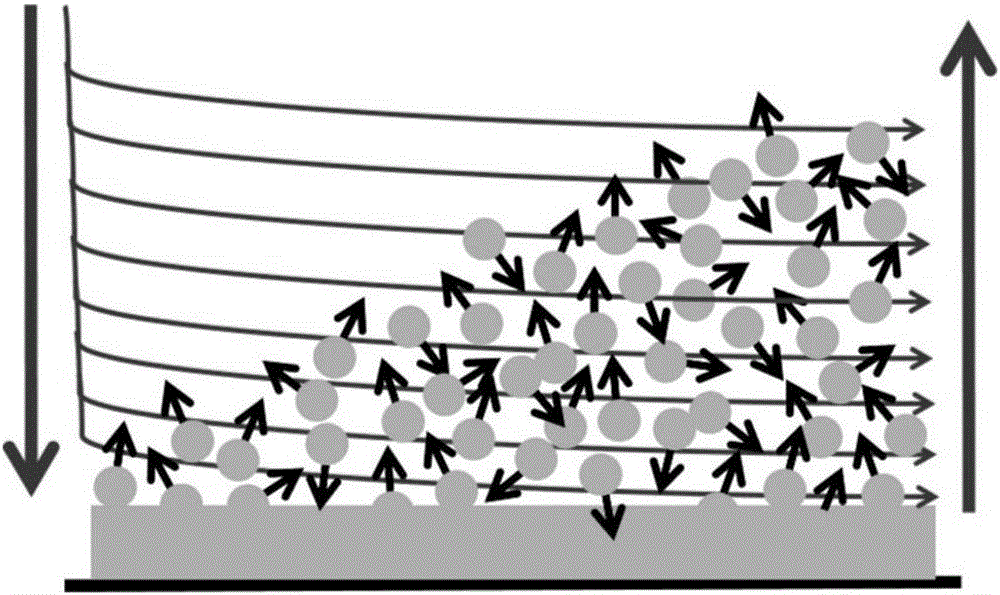

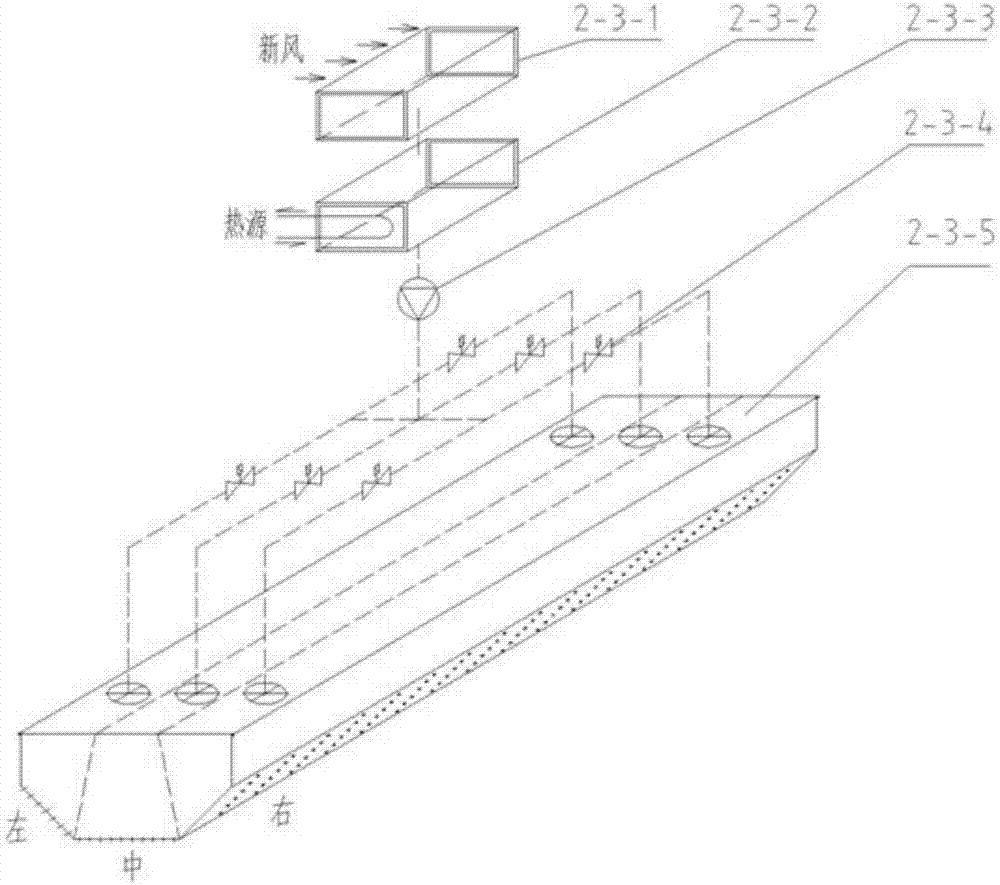

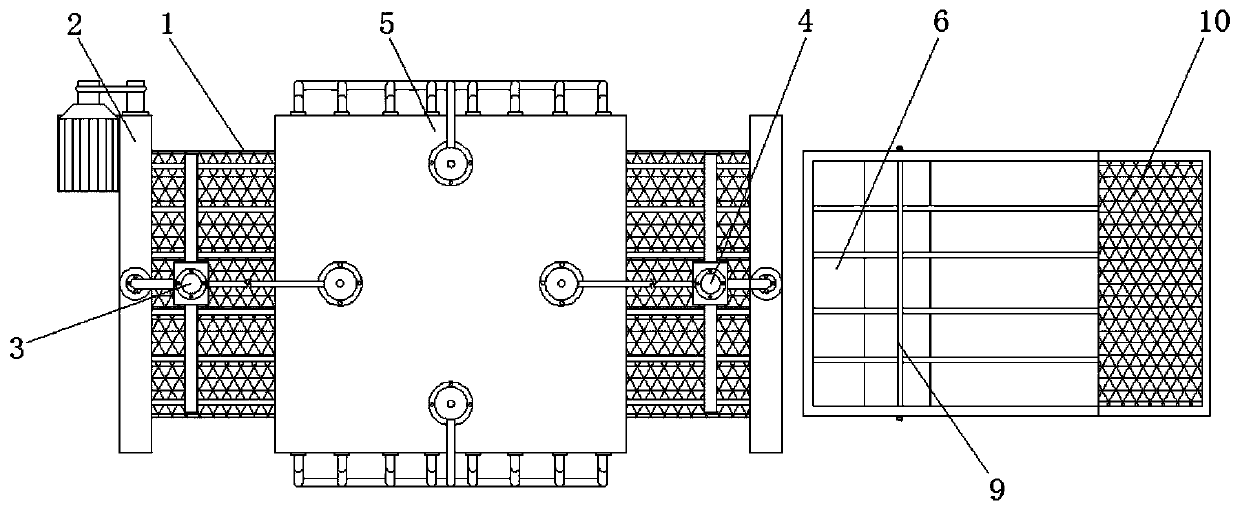

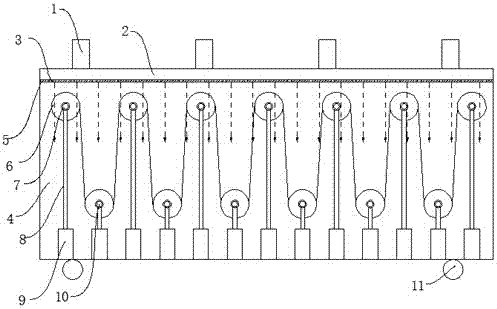

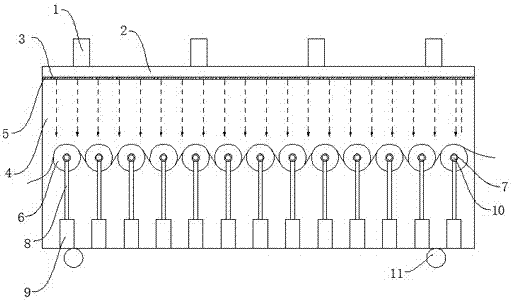

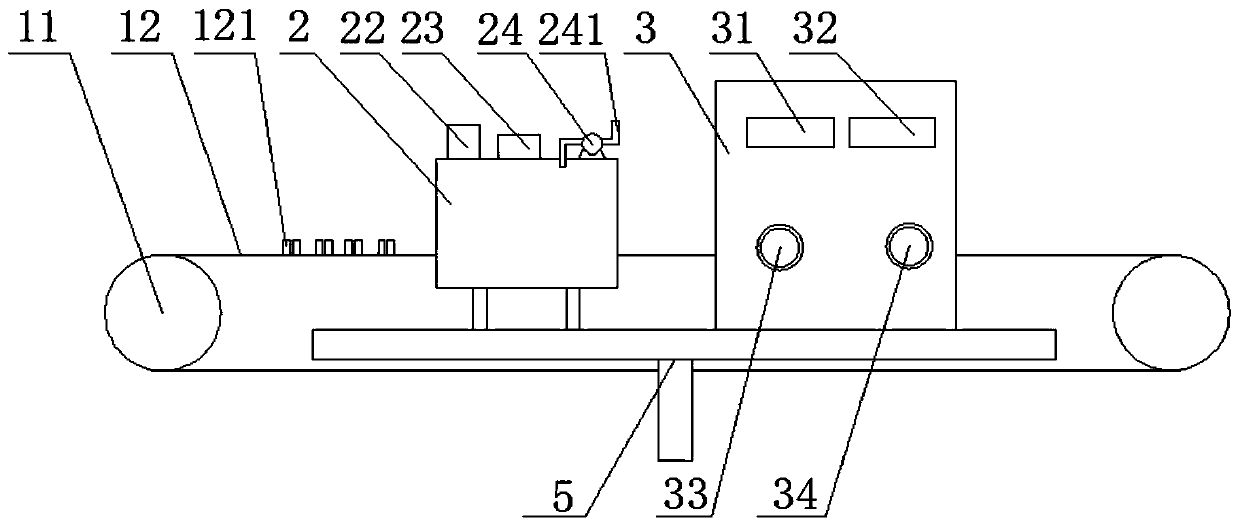

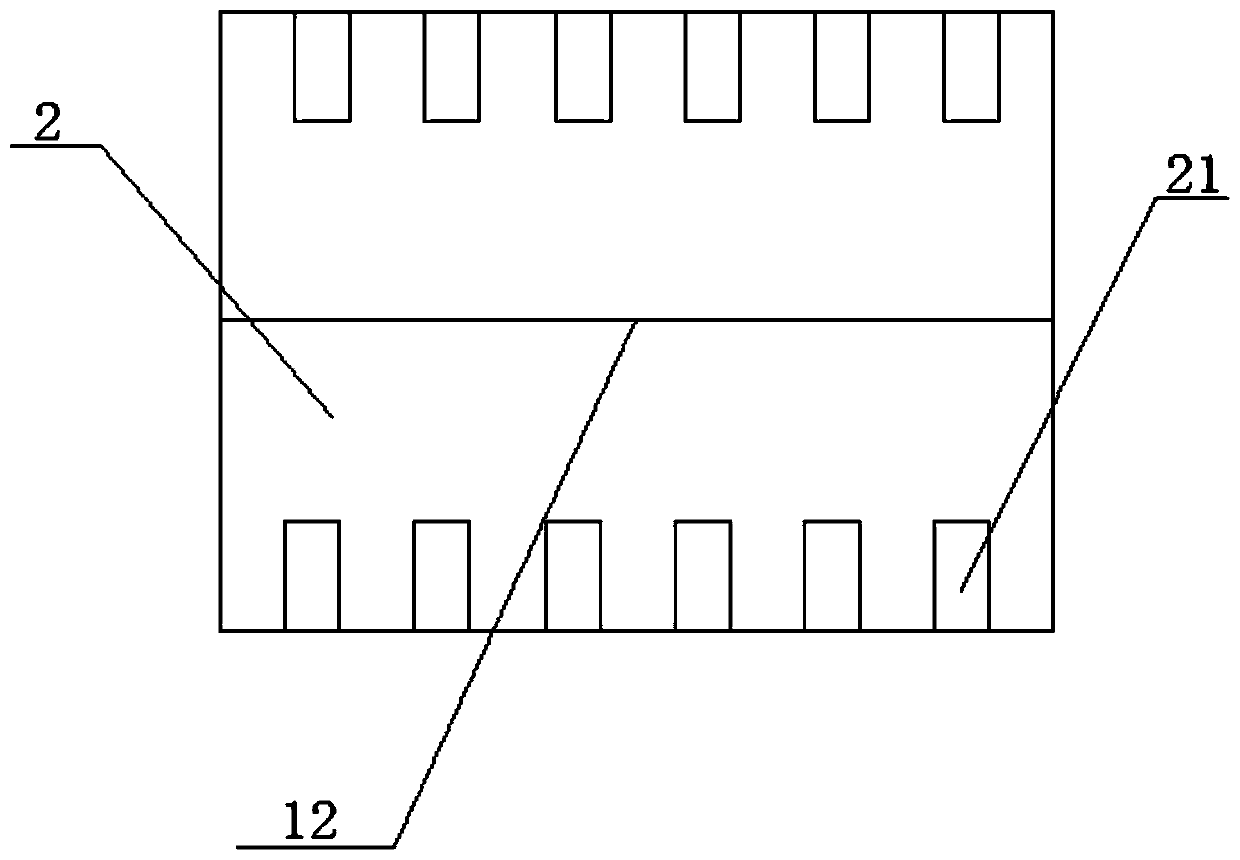

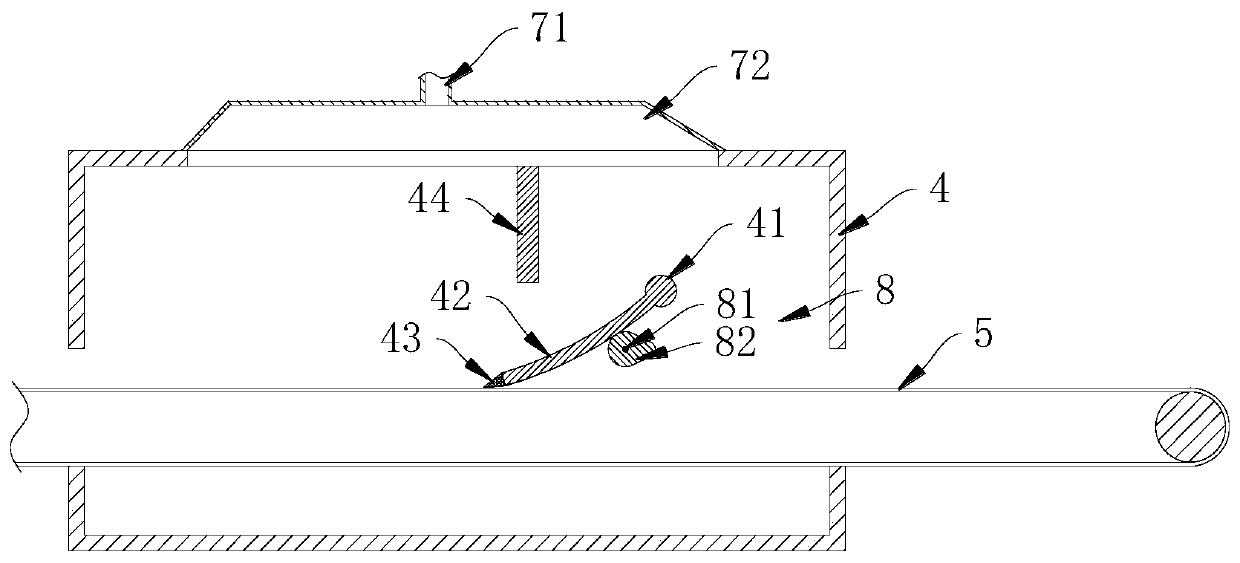

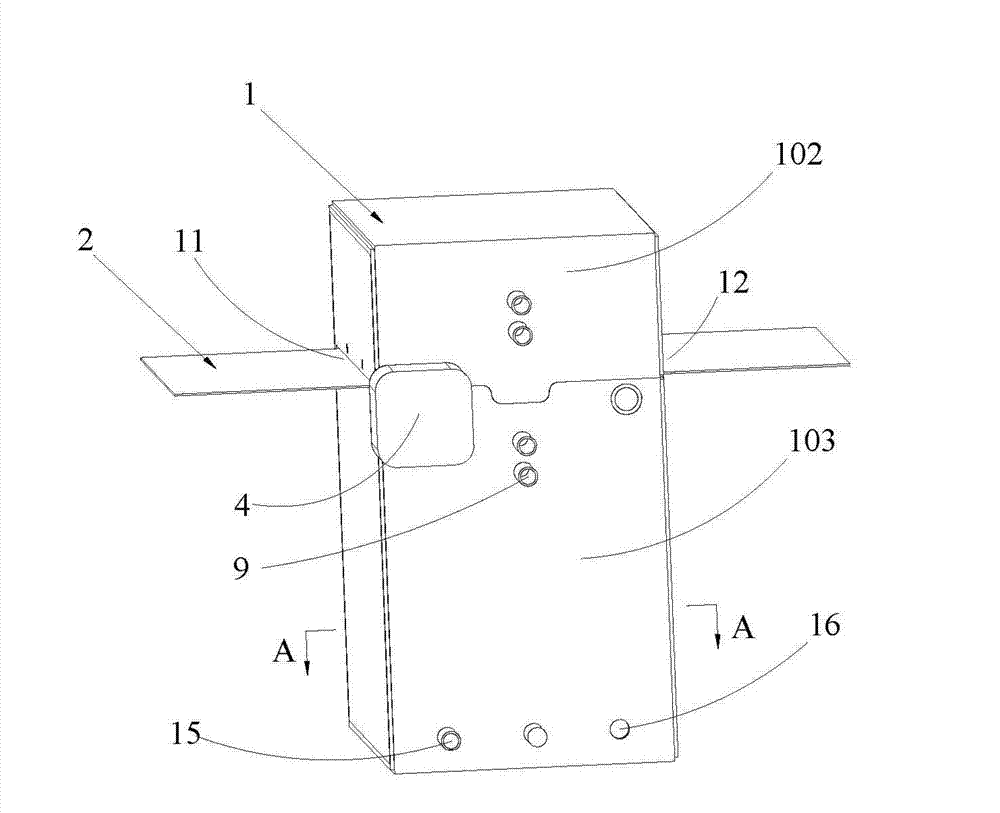

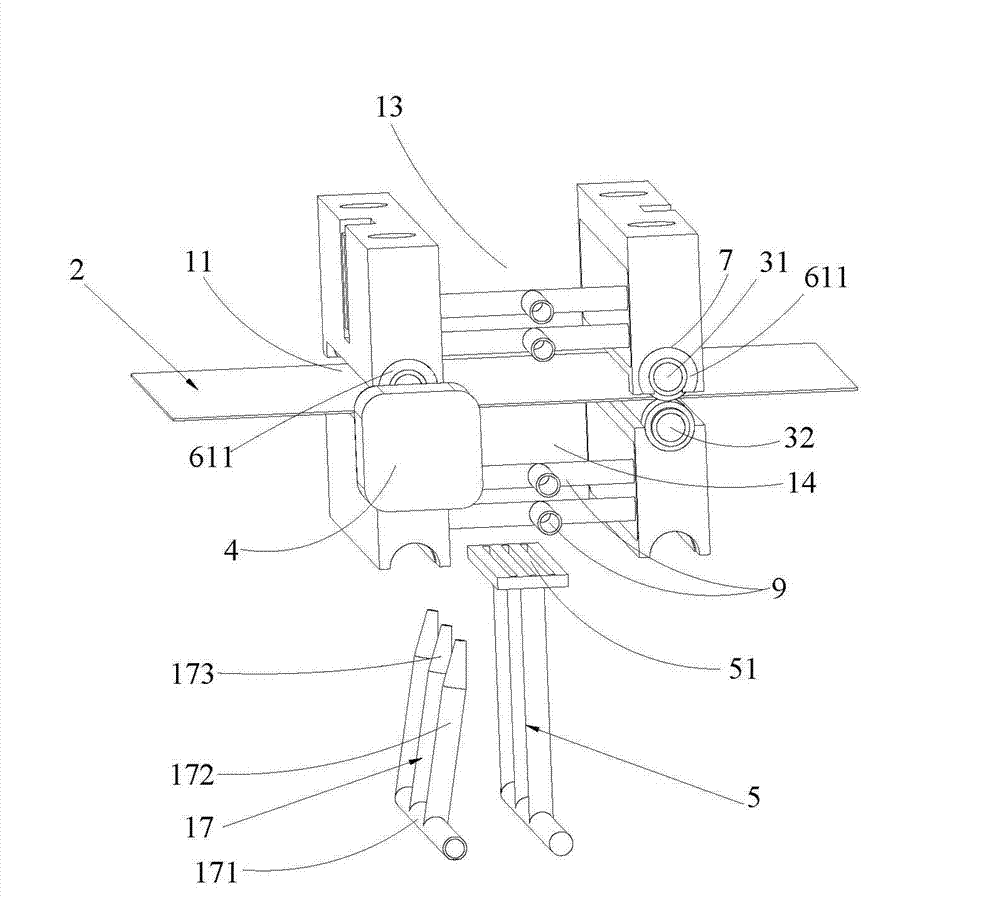

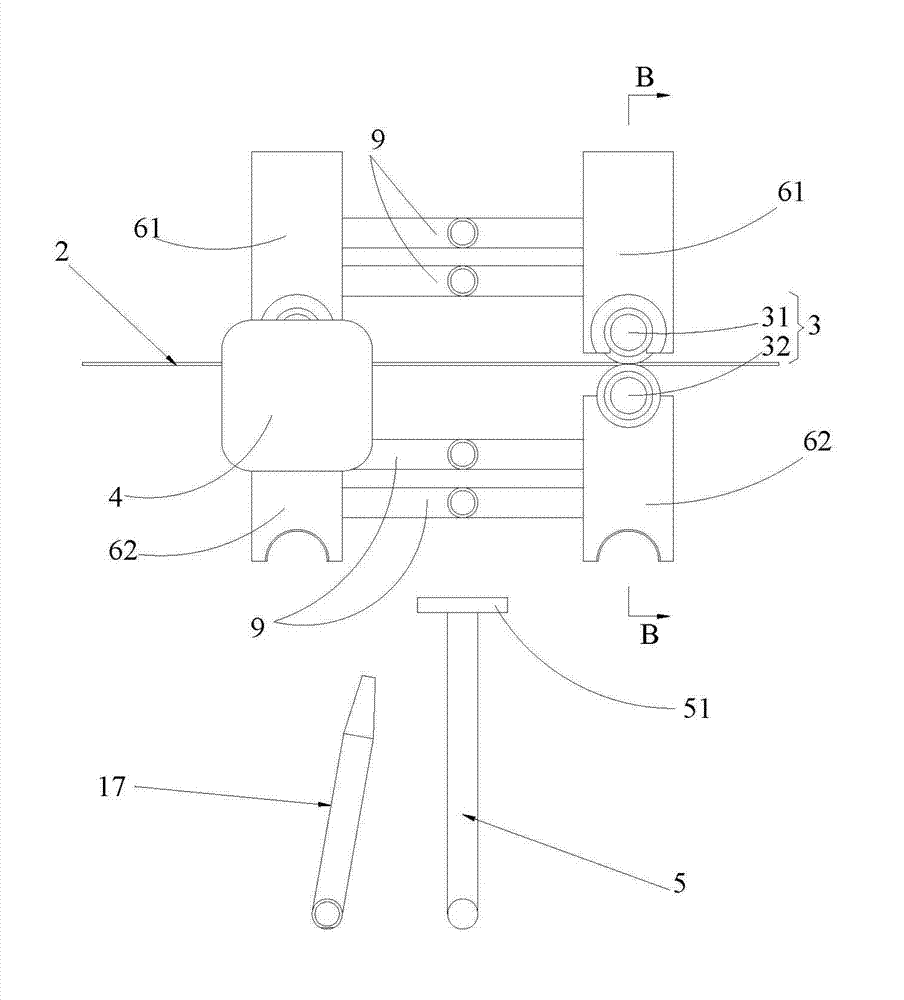

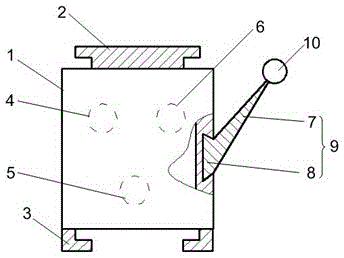

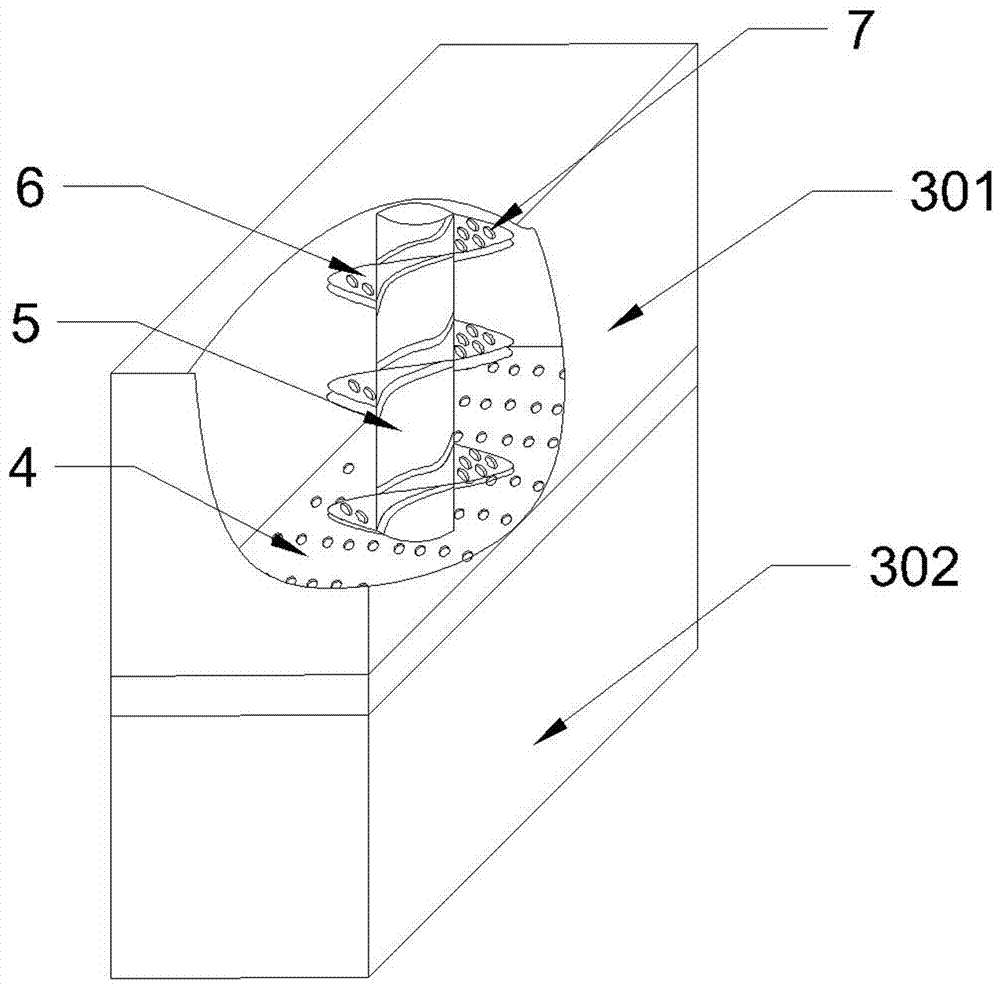

Multi-flow drying air knife and method used for preparing perovskite thin film in perovskite solar cell by using same

ActiveCN106252520AQuality improvementDry fastFinal product manufactureSolid-state devicesPerovskite solar cellEngineering

The invention provides a multi-flow drying air knife and a method used for preparing a perovskite thin film in a perovskite solar cell by using the same. A perovskite liquid film coated on the surface of a substrate is arranged under the multi-flow drying air knife, wherein several blowing passages and suction passages are alternatively arranged at intervals. Dilution airflow blown out by the blowing passages absorbs a solvent component when flowing through the surface of the perovskite liquid film to realize liquid film drying. The airflow leaves the liquid surface, enters the multi-flow drying air knife through the suction passages, and flows out. The solvent component in a solution is rapidly evaporated. The high-quality perovskite thin film in the perovskite solar cell is prepared by controlling the conditions of a drying process. According to the invention, the perovskite thin film with uniform and compact structure is acquired; leakage current caused by perovskite thin film holes is avoided, which is favorable for the preparation of the solar cell which has the advantages of high efficiency and large area; and the multi-flow drying air knife and the method have the advantages of simple operation, easy operation, low cost, high repeated accuracy, easy industrialization, continuous production and so on.

Owner:杨冠军

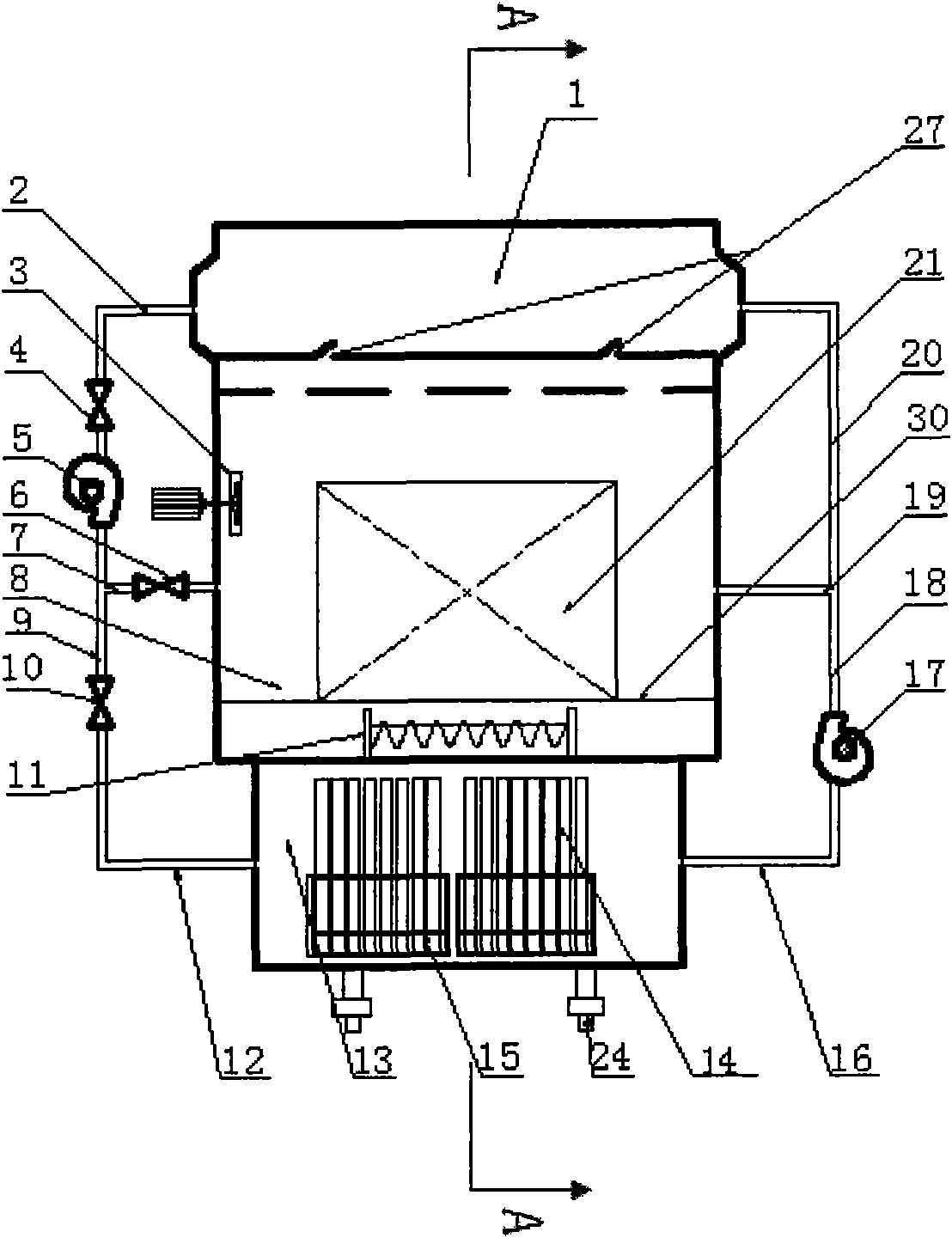

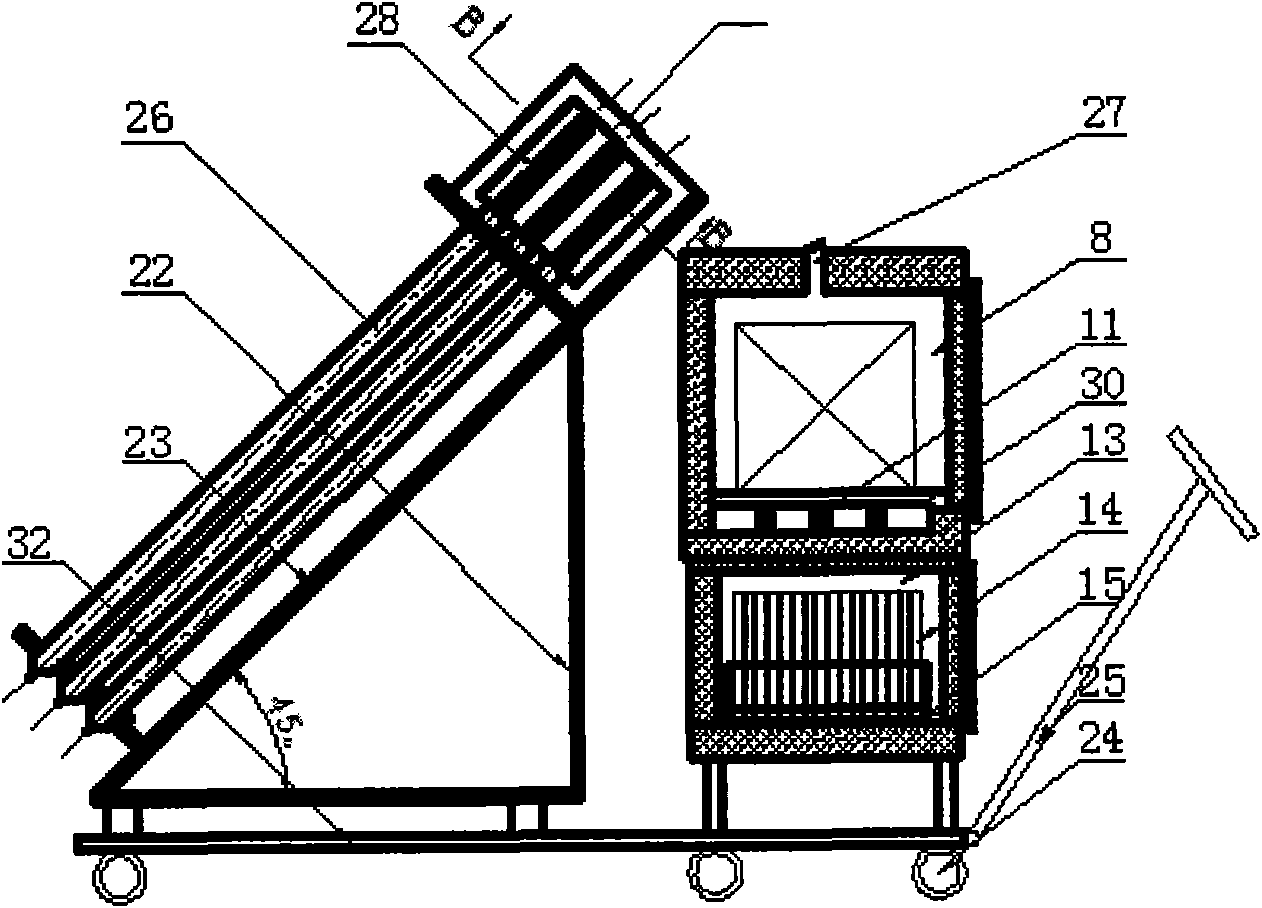

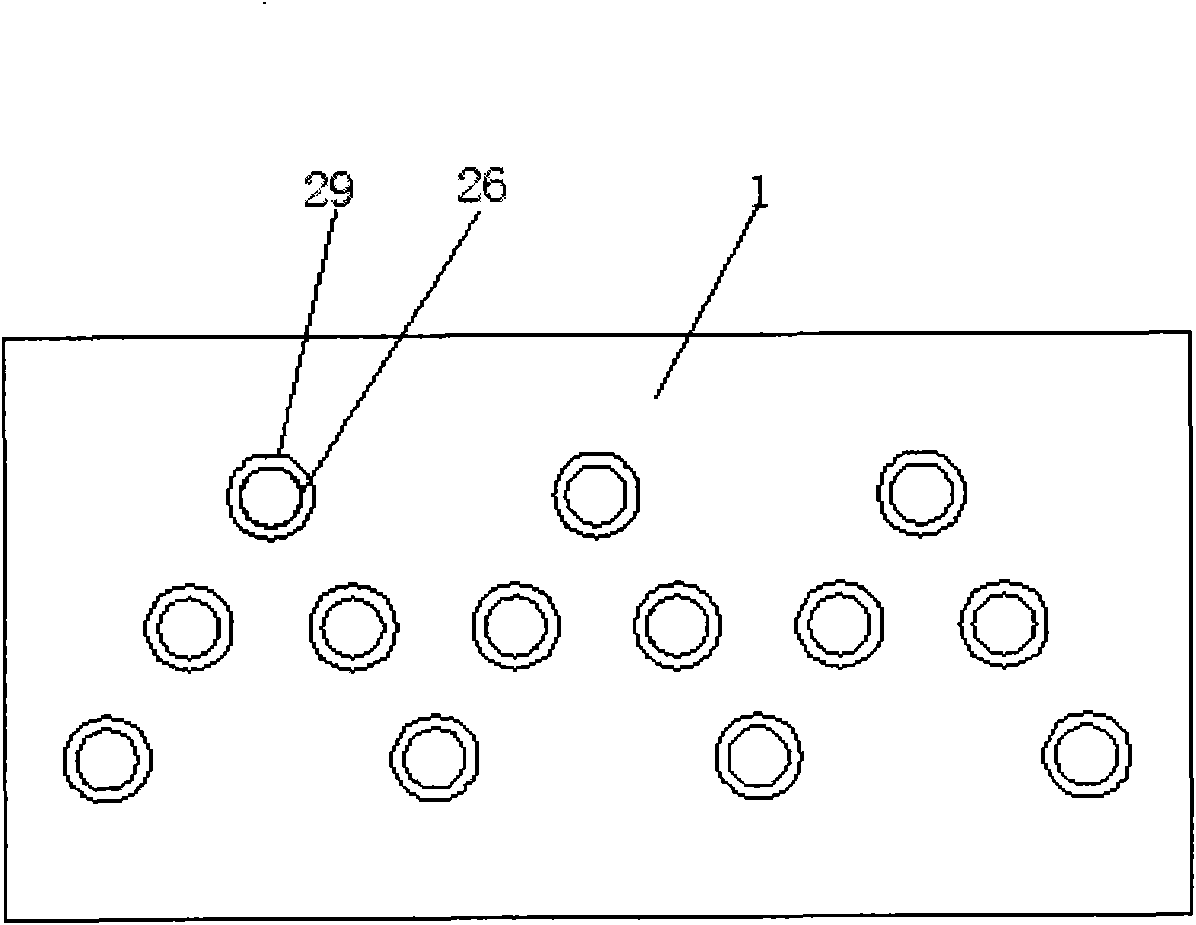

Drying method by using solar energy and device thereof

ActiveCN101776377AImprove drying efficiencyQuality improvementDrying solid materials with heatSolar heat devicesSolar dryingSolar energy conversion efficiency

The present invention discloses a wood drying method by using solar energy, comprising the steps of: putting the wood to be dried in a drying cabinet (8); supplying heat to the drying cabinet; and stopping the supply of heat when the temperature T2 of the drying cabinet (8) is higher than the setting drying temperature of the wood to dry the wood under the setting drying temperature. The movable drying device by using solar energy has stable running, constant drying temperature and continuous drying function with lower power consumption, higher solar energy conversion efficiency and good drying quality, thereby reducing the drying cost.

Owner:潍坊恒远新材料科技有限公司

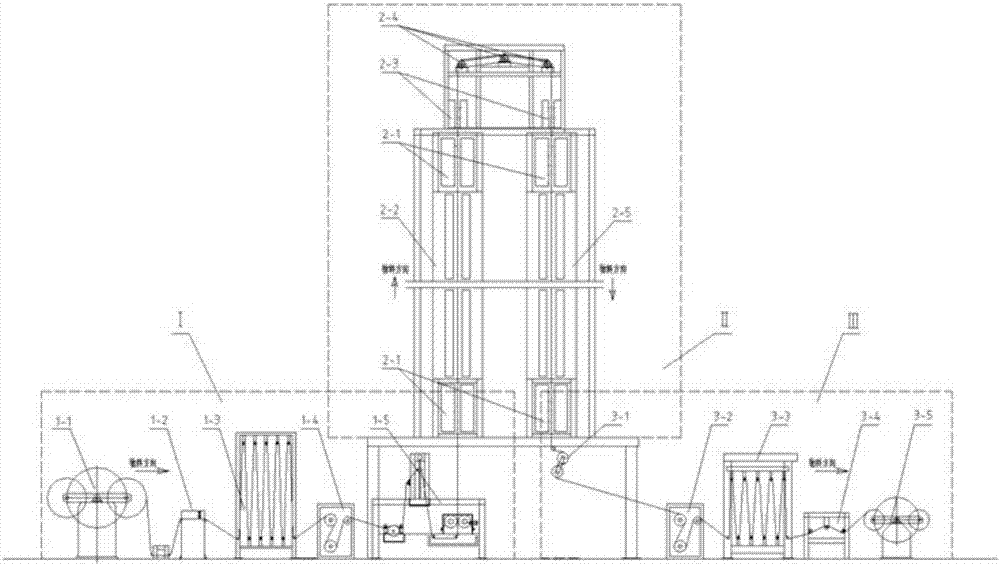

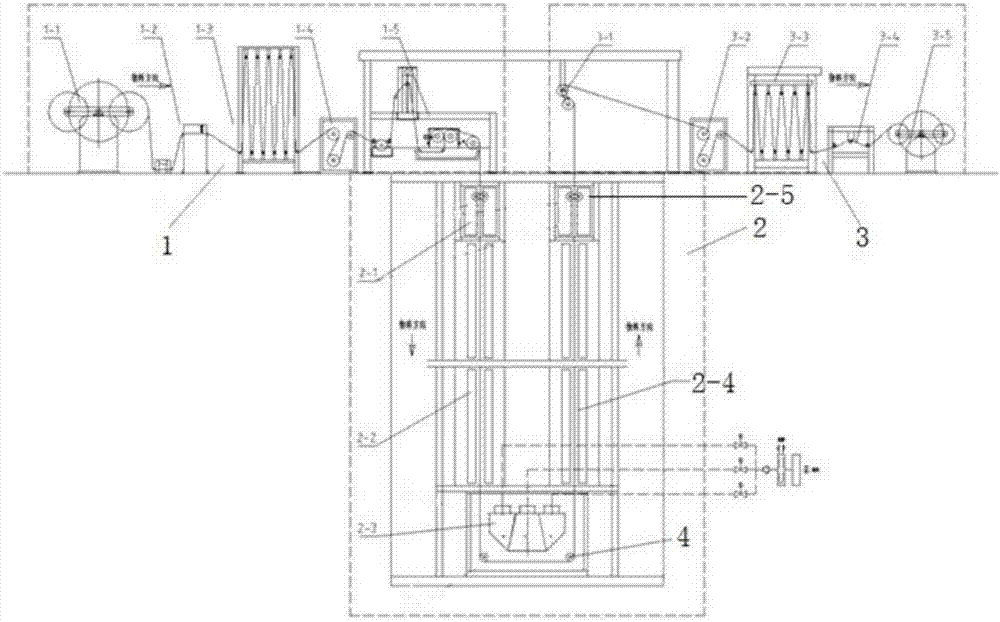

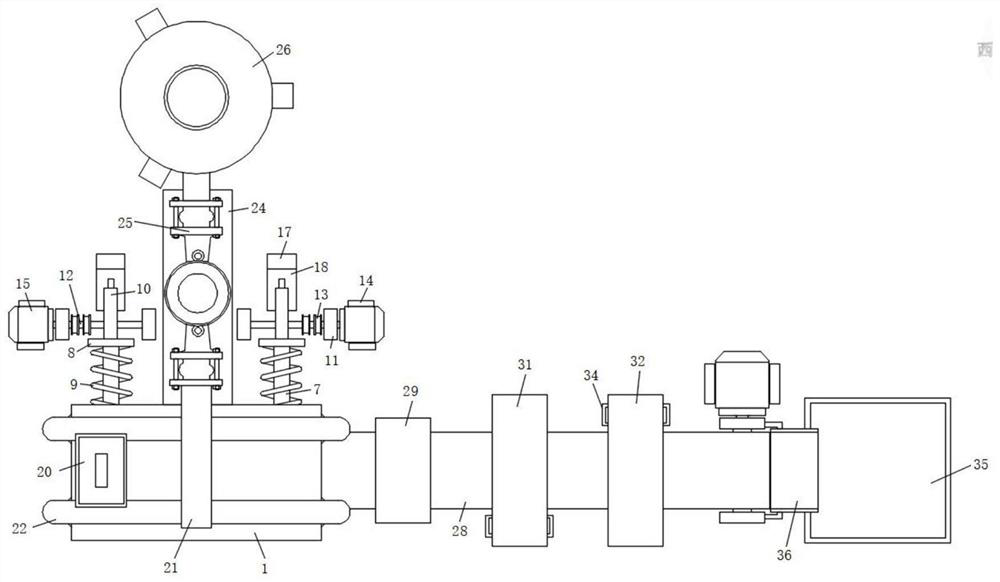

Vertical gluing machine

ActiveCN107051818AReduce running traction tensionImprove warpage and other related issuesPretreated surfacesCoatingsSlant angleEngineering

The invention discloses a vertical gluing machine. The vertical gluing machine comprises front segment equipment, a drying unit and rear segment equipment all of which are sequentially connected. The drying unit is arranged below the front segment equipment and the rear segment equipment. A plurality of edge guiding mechanisms are arranged in the drying unit in the running directions of materials. According to the vertical gluing machine, the reheating process after cooling and guiding is not needed, the energy sources are saved, and the working efficiency is improved. According to the vertical gluing machine, the wind pressure is adjusted according to production states and material properties, the traction tension of material running is reduced, and the problem that warping of a copper-clad plate is increased as the weft slant angles of woven materials are increased by increased tension is solved. Meanwhile, the edge guiding mechanisms and a steering device are arranged, material tension can be stably controlled in the drying unit, and the problems of material floating, swinging, off tracking and wall hanging can be solved.

Owner:SHAANXI SHENGYI TECH

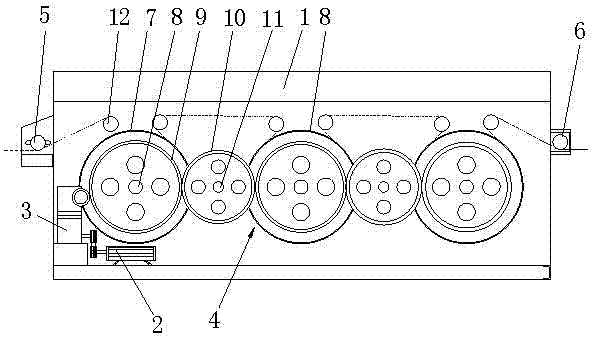

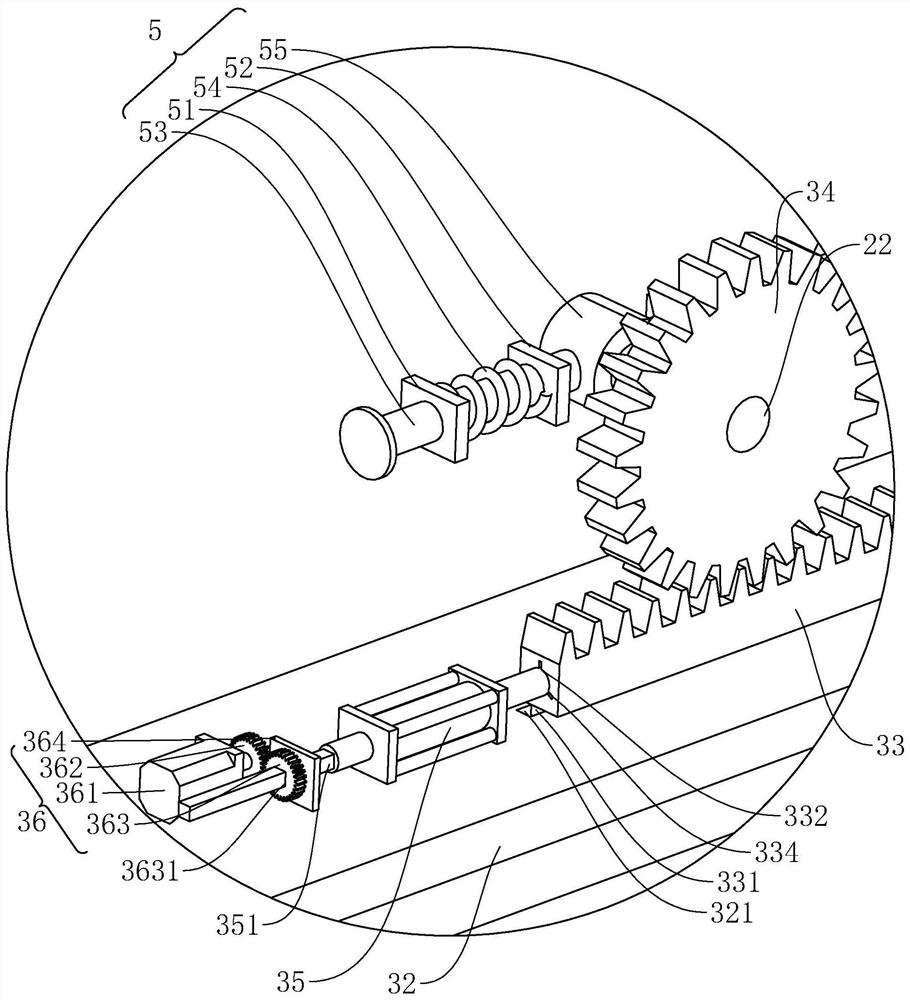

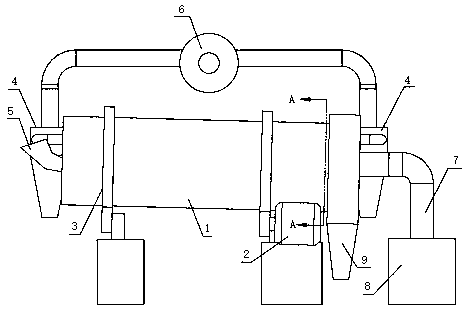

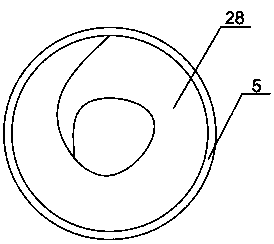

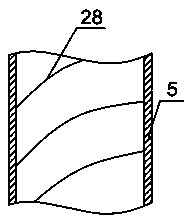

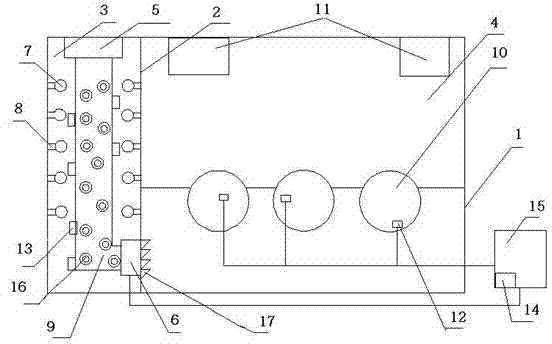

Drum-type drying device of cloth

InactiveCN103088613ASimple structureAchieve continuous dryingIroning machinesTextiles and paperGear wheelEngineering

The invention relates to a drum-type dying device of cloth. The drum-type drying device of the cloth comprises a machine body, a power device, a transmission device and a drum device, wherein the power device drives the transmission device to rotate. The drum-type drying device of the cloth is characterized in that one end of the machine body is provided with a feeding guide roller, and the other end of the machine body is provided with a discharging guide roller, the drum device comprises drum bodies and rotating shafts, the drum bodies are fixedly connected with the rotating shafts, the number of the drum bodies is three, the number of the rotating shafts is three, a transmission large gear wheel is arranged at one side of each rotating shaft, and the transmission device drives the transmission large gear close to the feeding guide roller to rotate. The cloth enters from the feeding guide roller, winds the surfaces of the drum bodies by means of transmission guide rollers, heating tubes in the drum bodies heat the air and transmit heat to the surfaces of the drum bodies, and therefore the cloth is ironed and dried. The number of the drum bodies is three. Finally, cloth is discharged from the discharging guide roller and drying is finished. The drum-type drying device of the cloth is simple in structure, achieves continuous drying of the cloth and improves production efficiency.

Owner:MAXCLEAN WUXI TECH

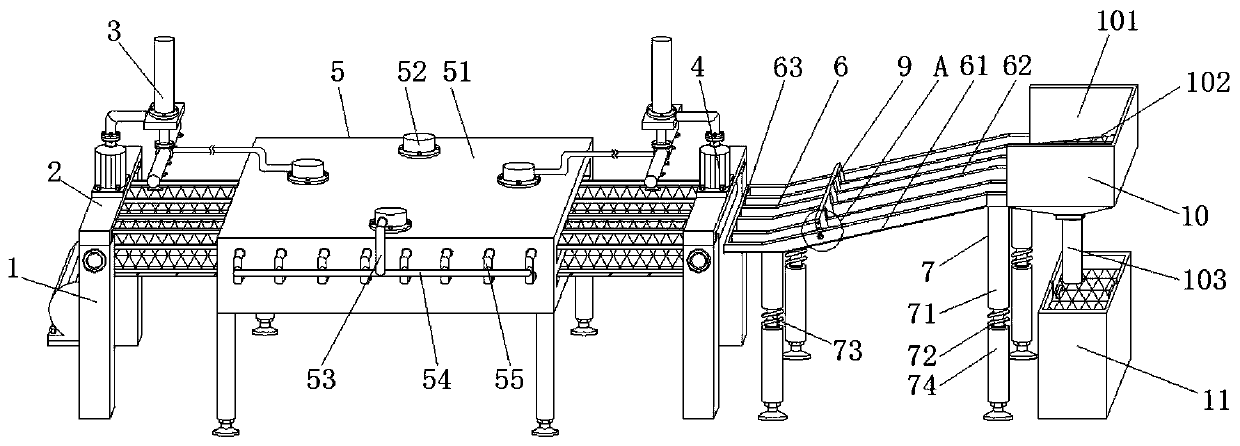

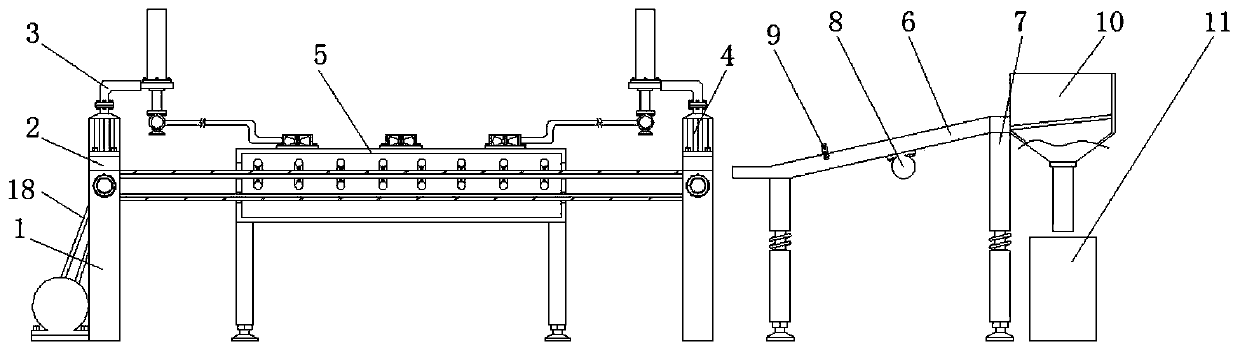

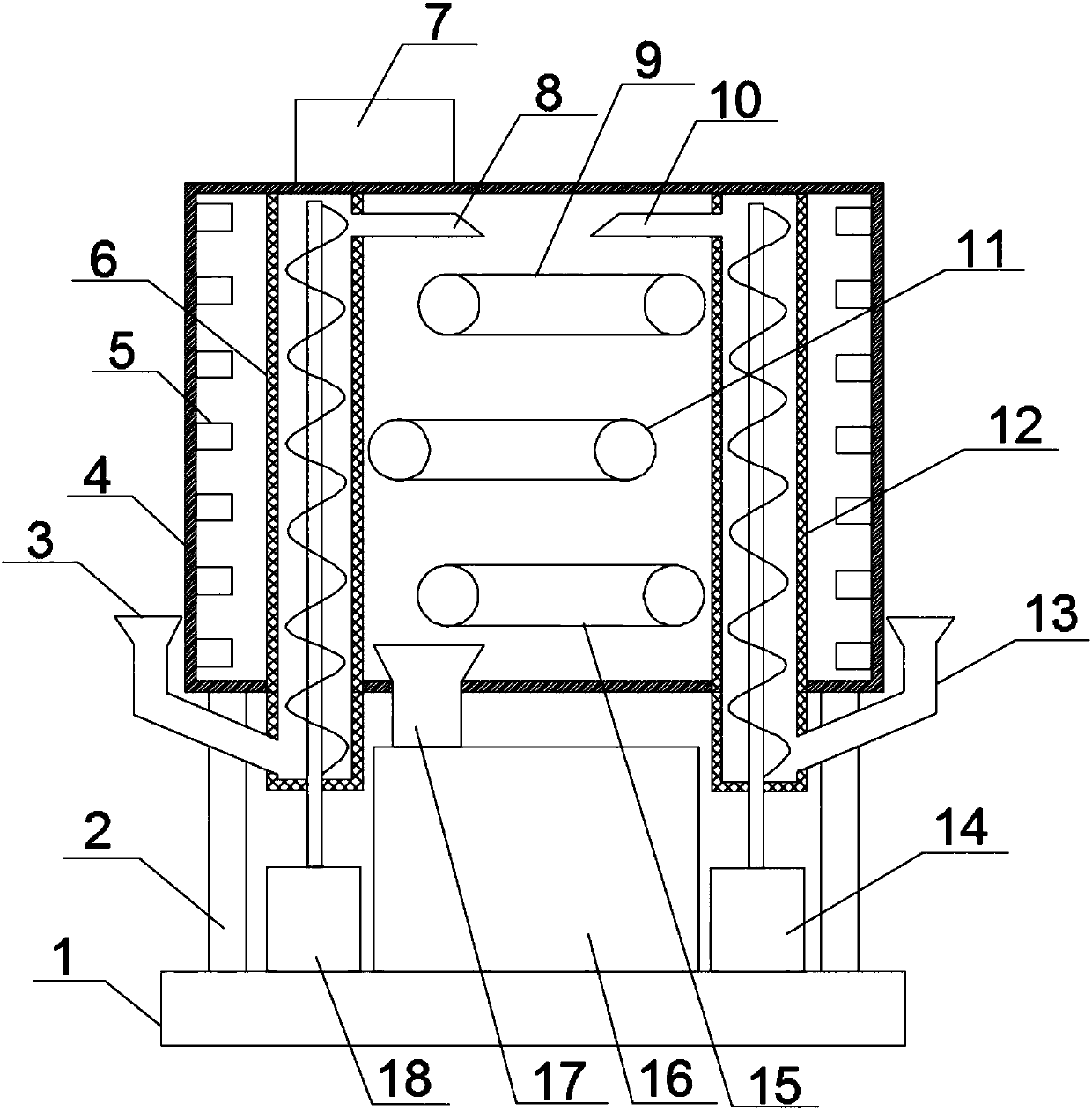

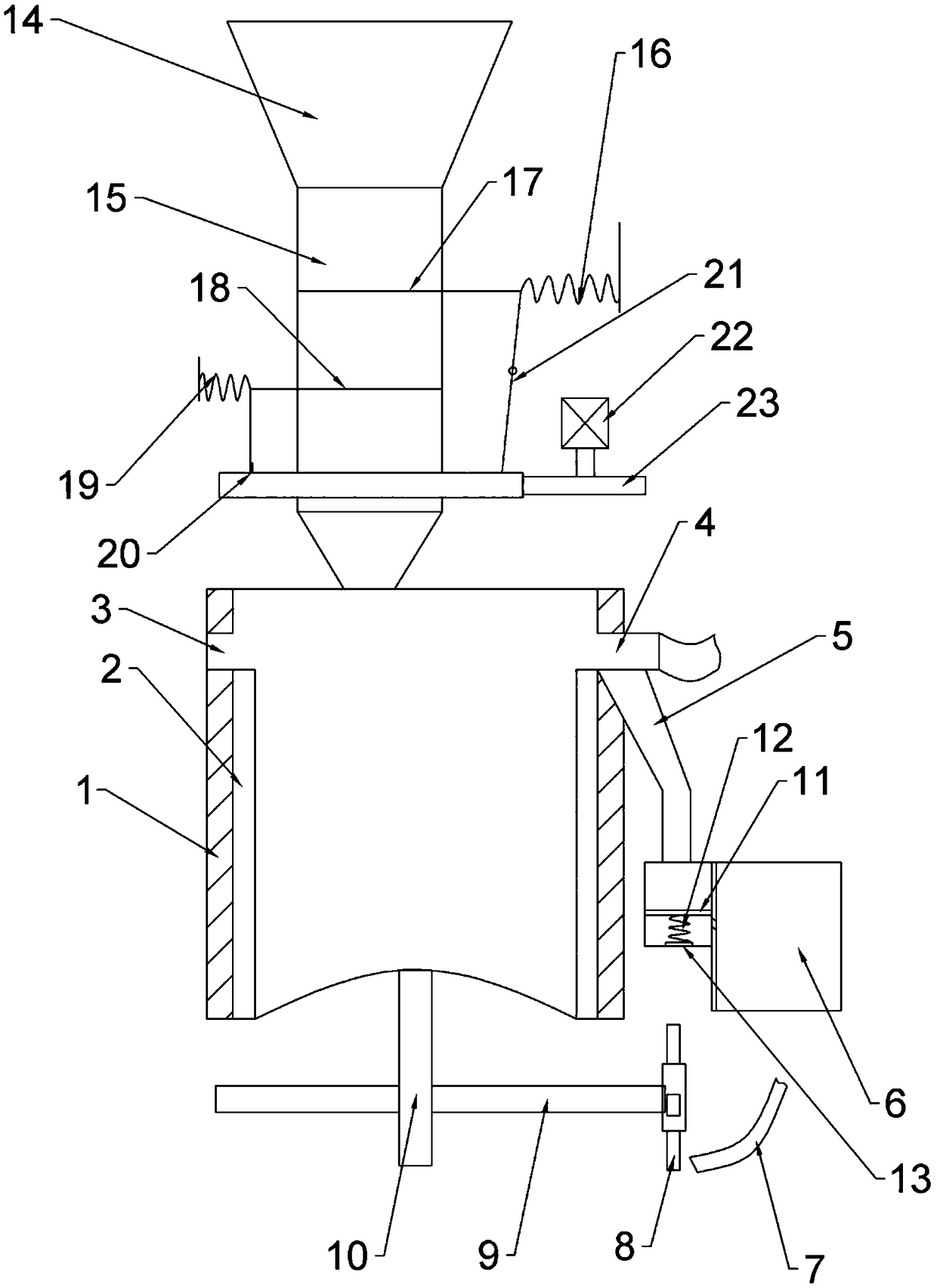

Continuous drying device used for production of silicon wafers and capable of automatically feeding and discharging

InactiveCN110487054AIncrease productivityReduce labor intensityDispersed particle filtrationDrying gas arrangementsEngineeringContinuous production

The invention discloses a continuous drying device used for the production of silicon wafers and capable of automatically feeding and discharging. The continuous drying device comprises a conveying mechanism, the upper end of the conveying mechanism is fixedly connected with support plates; the upper end of the support plate at the left end of the conveying mechanism is fixedly connected with a discharging mechanism; the upper end of the support plate at the right end of the conveying mechanism is fixedly connected with a feeding mechanism; a drying mechanism is mounted between the dischargingmechanism and the feeding mechanism; a guiding mechanism is mounted at the right end of the conveying mechanism; the lower end of the guiding mechanism is fixedly connected with support columns and avibrating motor which is located between the support columns; a quantifying mechanism is mounted at the left end of the guiding mechanism; the right end of the guiding mechanism is fixedly connectedwith a receiving mechanism; and a water purifying mechanism is positioned at the lower end of the receiving mechanism. The continuous drying device used for the production of the silicon wafers and capable of automatically feeding and discharging, achieves not only continuous feeding and discharging in the production process but also continuous production, thereby not only reducing the labor intensity but also increasing the production efficiency.

Owner:马鞍山致青工业设计有限公司

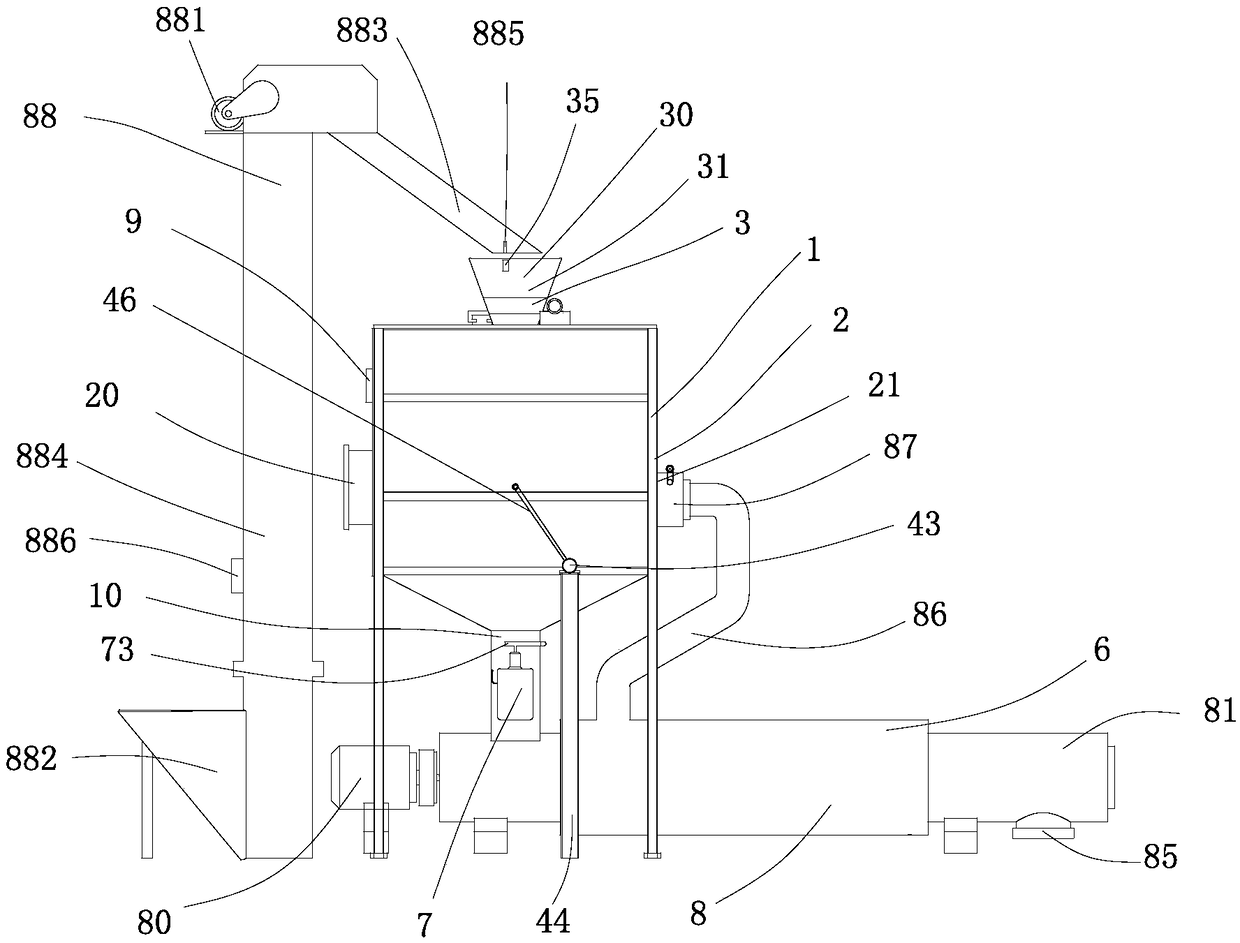

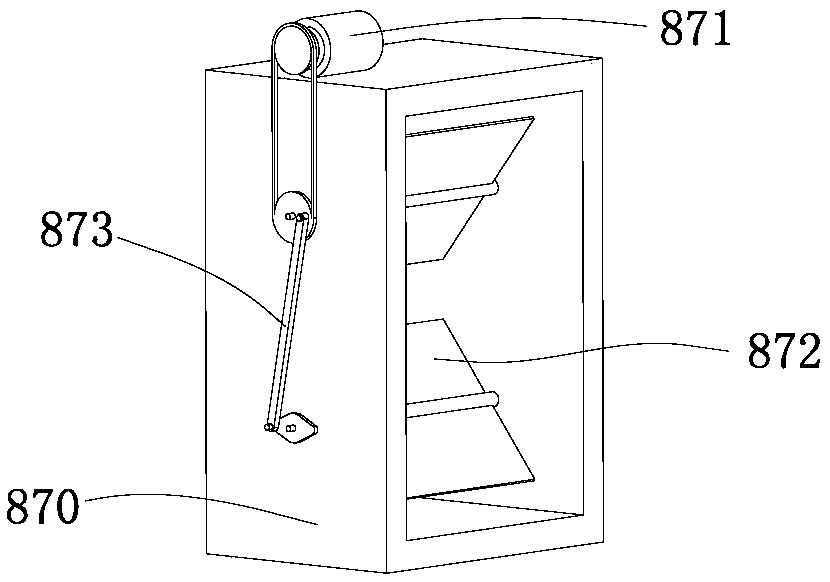

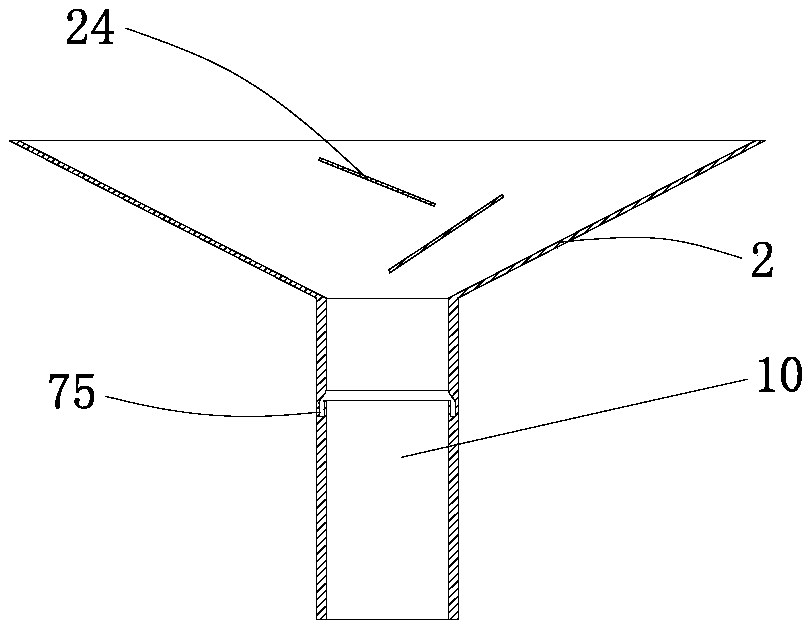

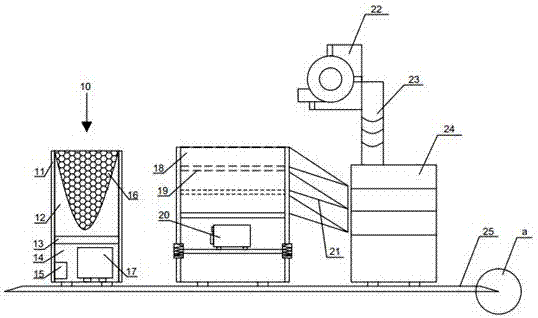

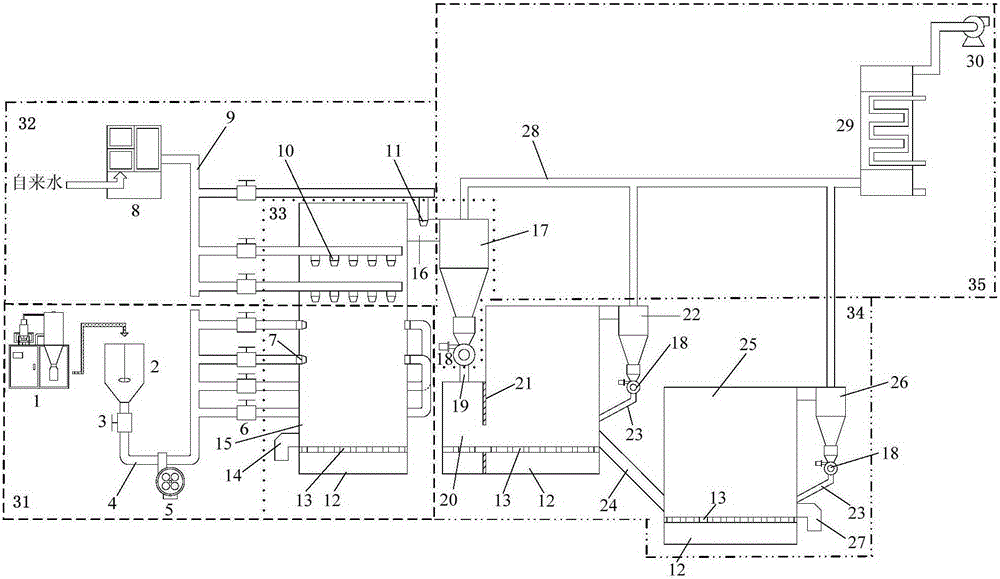

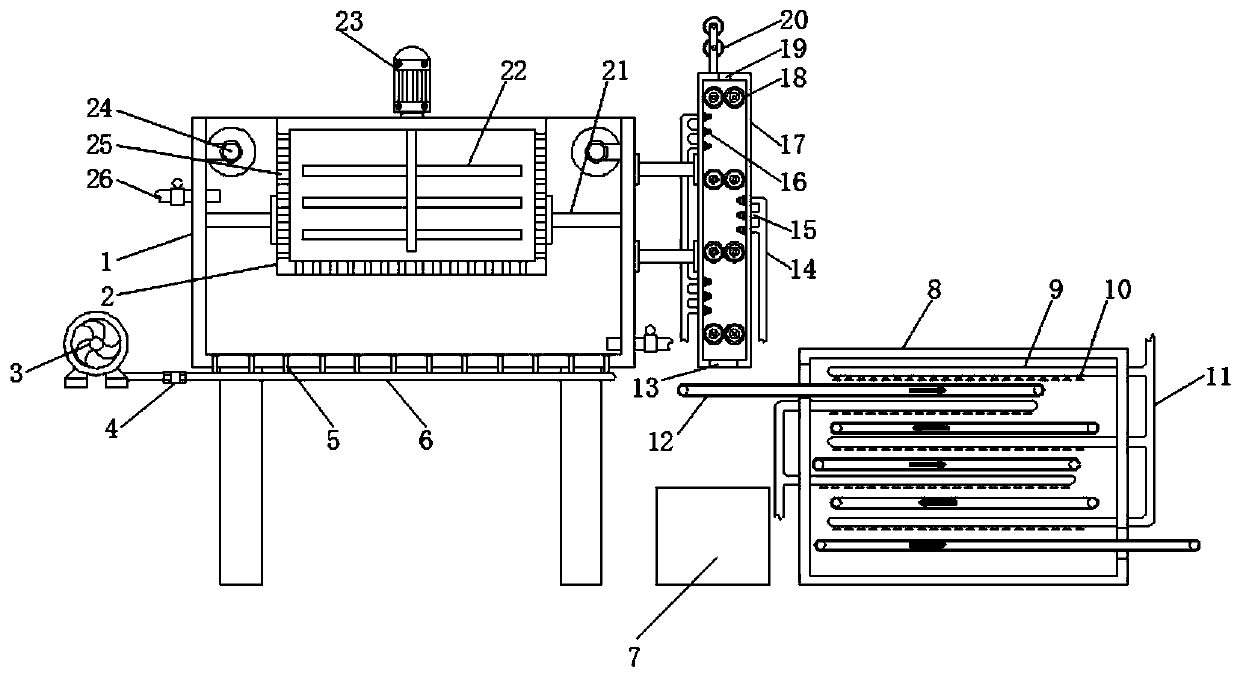

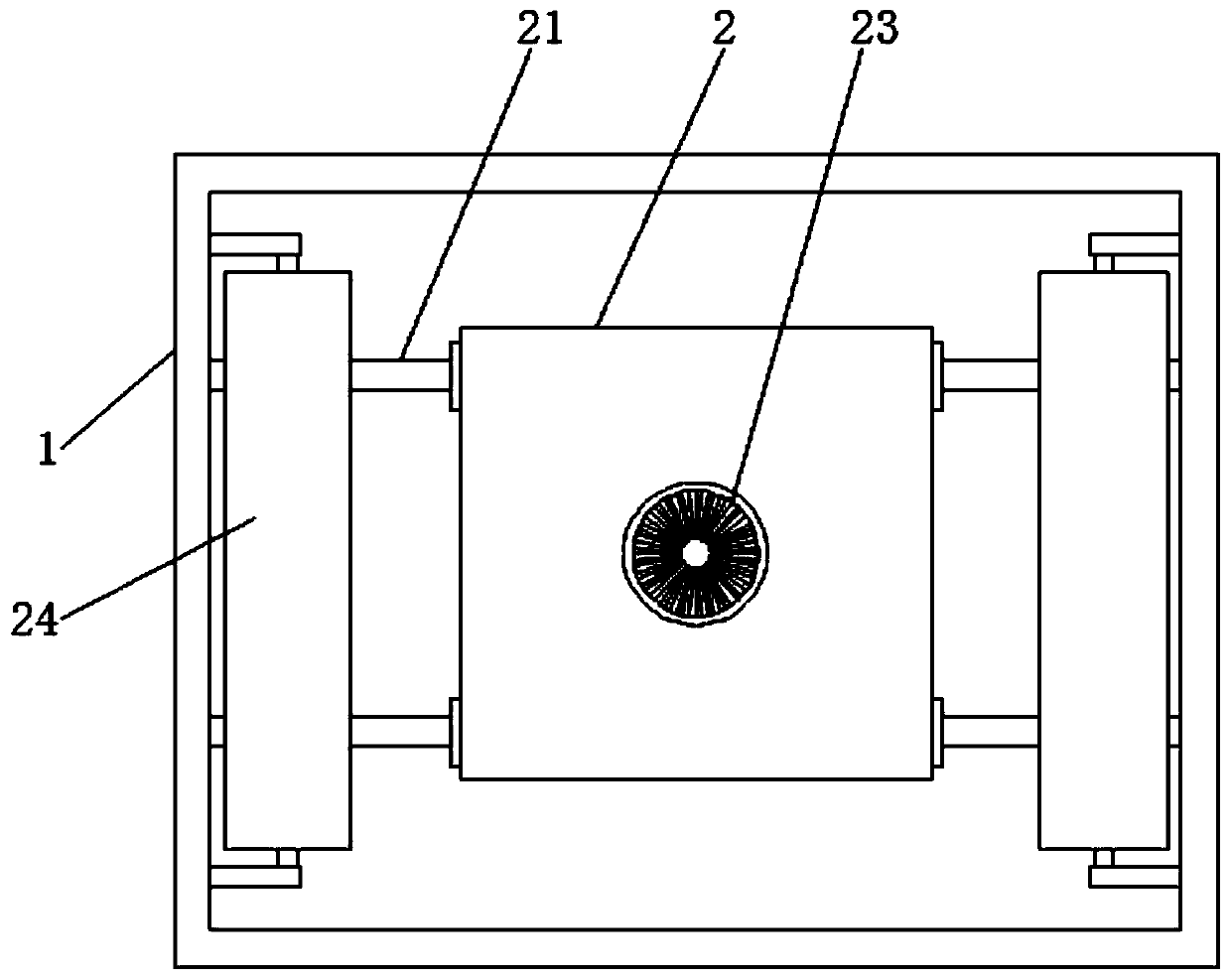

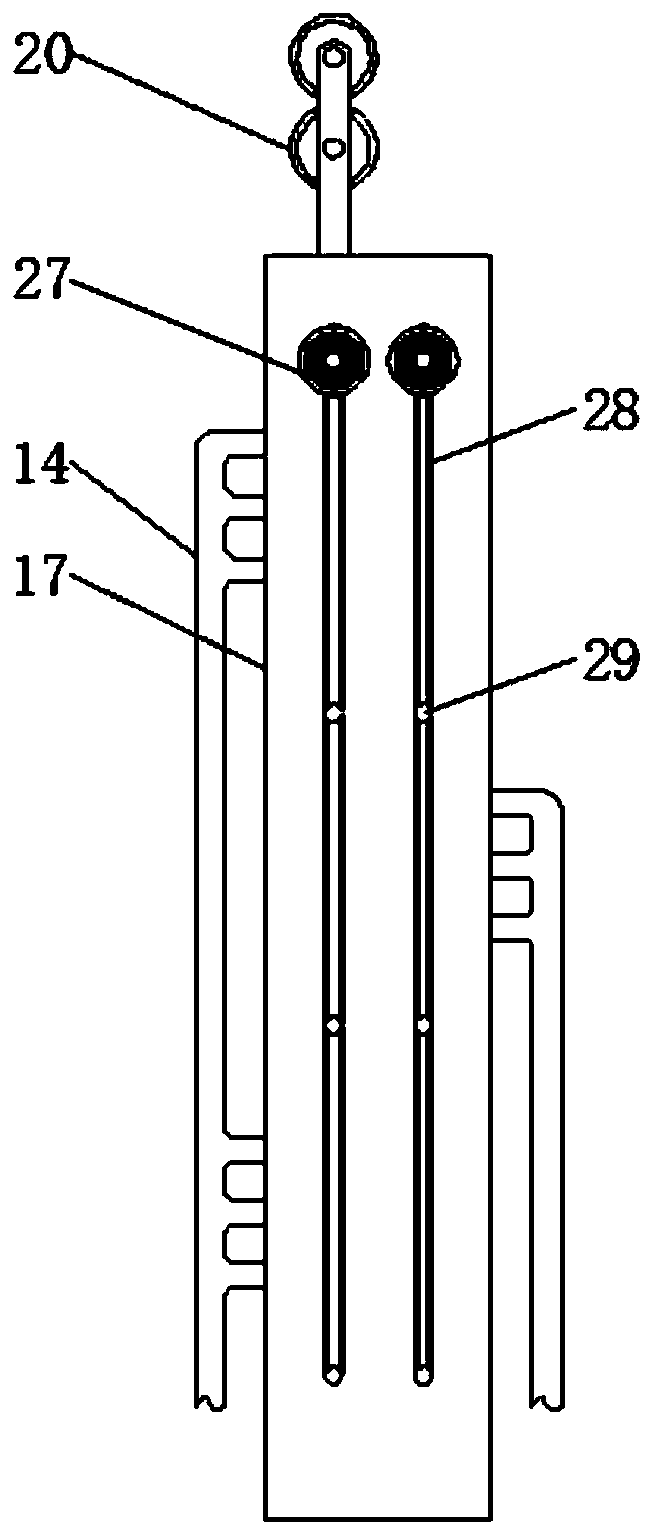

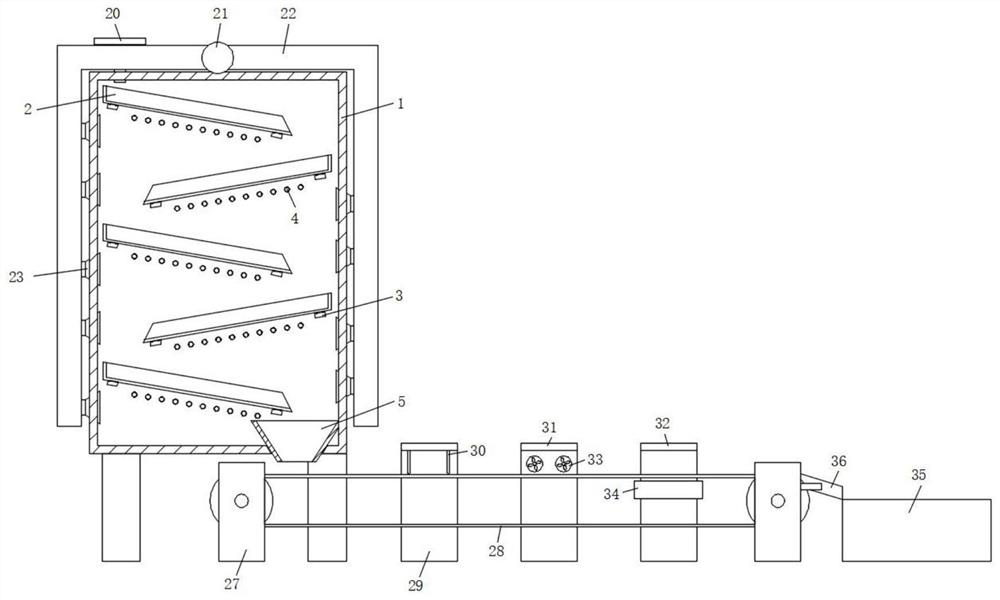

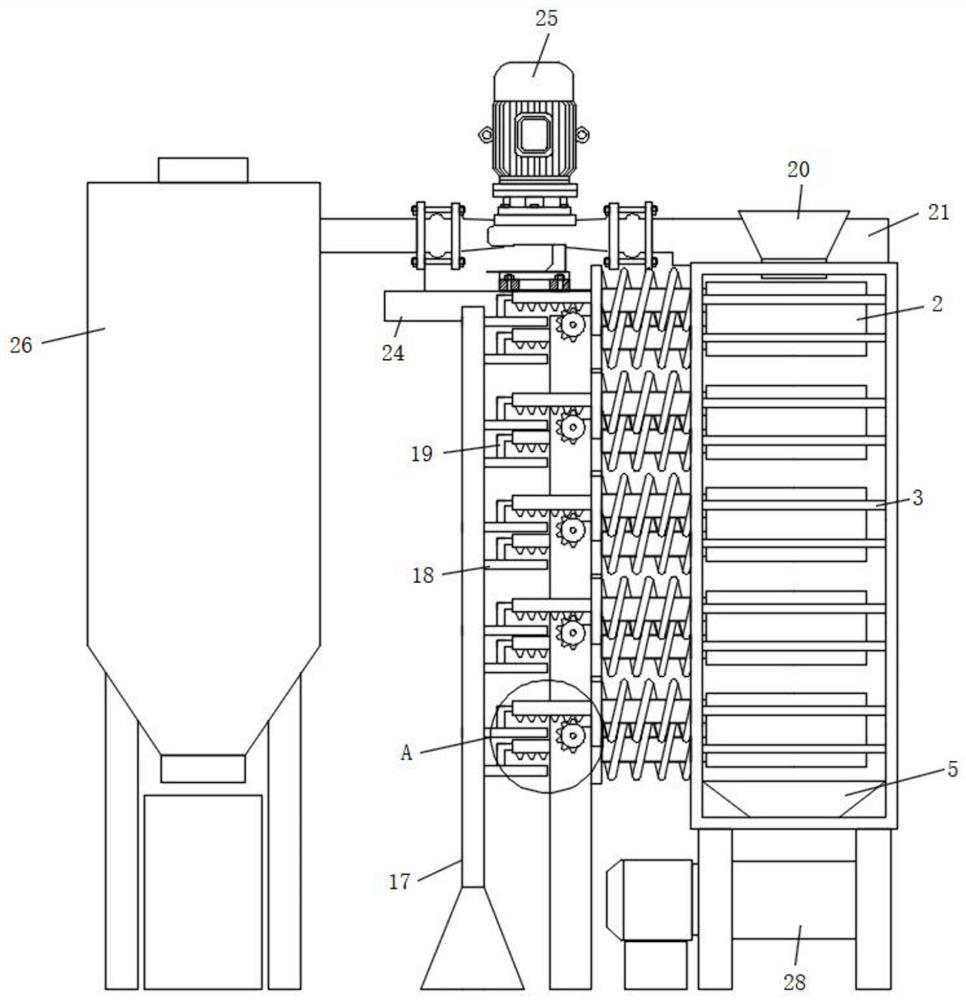

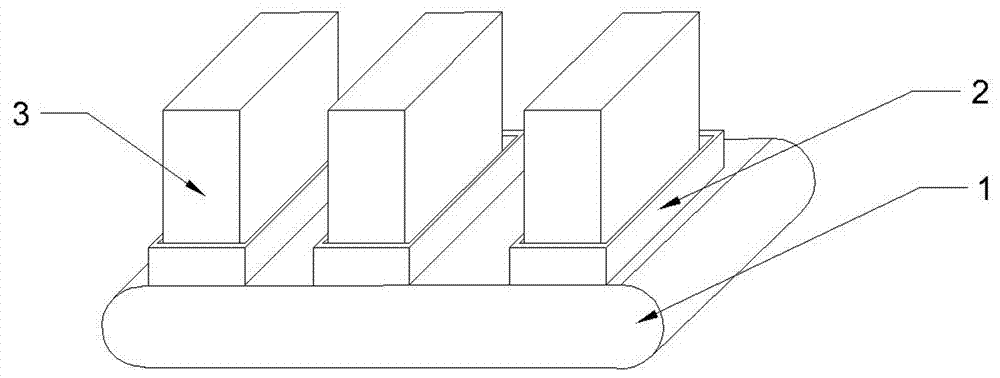

Seed drying, coating and processing integrated machine

ActiveCN109287193AImprove germination rateSave time and manpowerDrying gas arrangementsSeed coating/dressingGerminationAgricultural engineering

A seed drying, coating and processing integrated machine mainly includes a dryer, a coating machine and a controller. The dryer mainly includes a box body, a spreading mechanism, a receiving mechanismand a blanking mechanism. The coating machine mainly includes a spraying mechanism and a packing auger mechanism arranged at the lower end of the spraying mechanism. The upper end of the box body hasa strip-shaped opening, and the spreading mechanism is arranged directly above the strip-shaped opening and includes a blanking bin and a walking mechanism. The receiving mechanism mainly includes achain, a shelving plate and a sprocket group, the shelving plate is connected with the chain through a hanging arm, and a rotating damper is arranged between the shelving plate and the hanging arm. AHall sensor is arranged on the inner side of the box body, and an induction magnet is arranged on the hanging arm. The lower part of the dryer is connected with the spraying mechanism; the lower partof the spraying mechanism is connected with the packing auger mechanism, the outer side of the packing auger mechanism is provided with a heating chamber, and the heating chamber is connected with thebox body. The continuous automatic drying and coating of seeds are realized, the improvement of the germination rate and survival rate of the seeds is facilitated, and the manpower and time are saved.

Owner:卢明钗

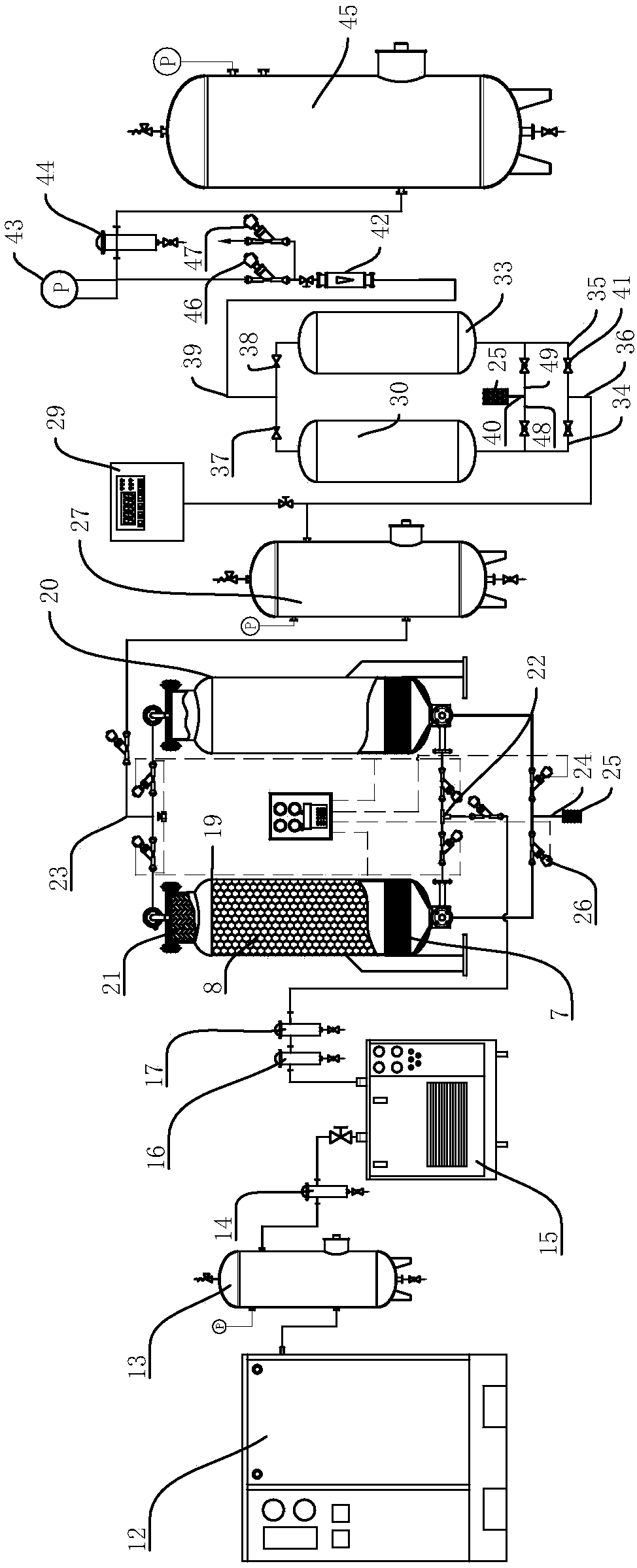

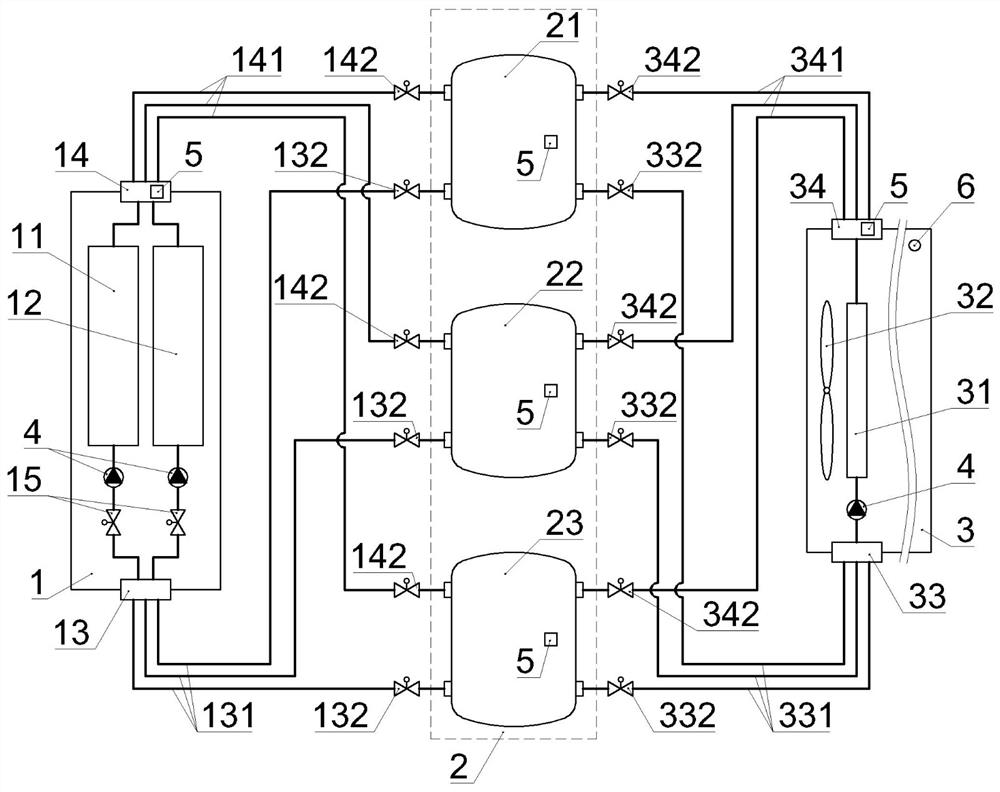

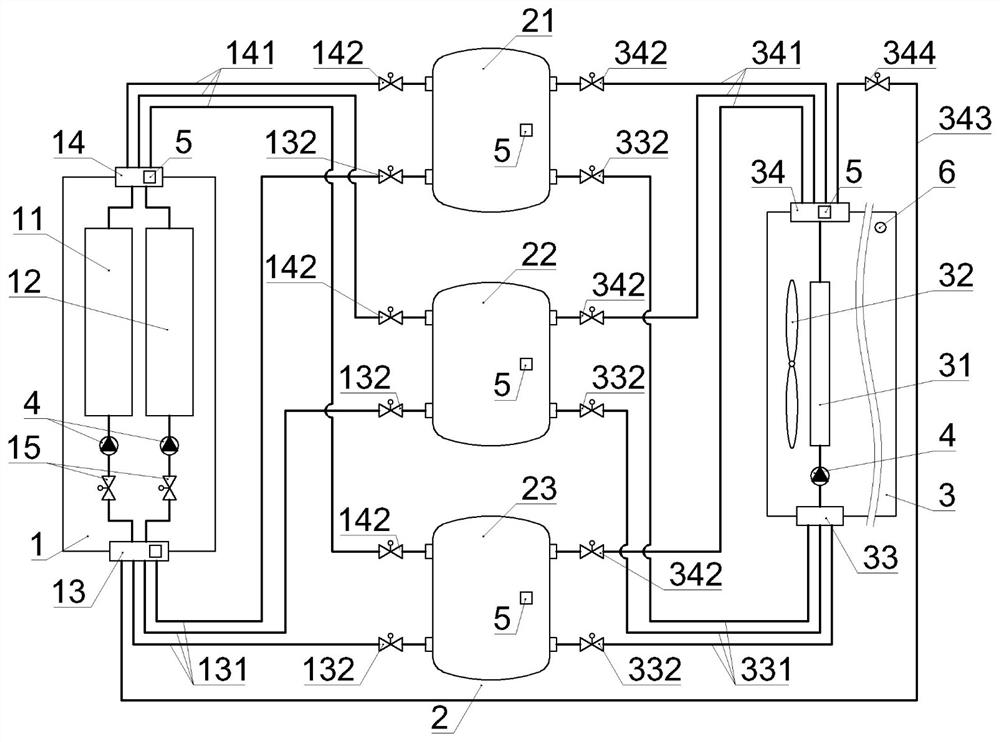

Low-dew-point PSA nitrogen generation system

PendingCN108518920ALower dew pointAchieve continuous dryingNitrogen purification/separationSolidificationBuffer tankNitrogen

The invention relates to the field of nitrogen generation systems, in particular to a low-dew-point PSA nitrogen generation system. According to the technical scheme, the low-dew-point PSA nitrogen generation system is characterized in that the low-dew-point PSA nitrogen generation system comprises an air compressor, an air buffer tank, a C-level filter, a refrigeration dryer, a T-level filter, anA-level filter, a nitrogen generation device, a nitrogen buffer tank and a nitrogen storage tank which are sequentially connected through pipelines, and further comprises a nitrogen outlet pipeline and a nitrogen discharging pipeline; the nitrogen generation device comprises a first adsorption tower and a second adsorption tower; a three-way pipe is arranged on the A-level filter, and the A-levelfilter is connected with nitrogen inlets of the first adsorption tower and the second adsorption tower through the three-way pipe; the nitrogen inlets of the first adsorption tower and the second adsorption tower are both connected to the nitrogen discharging pipeline; nitrogen outlets of the first adsorption tower and the second adsorption tower are both connected to the nitrogen outlet pipeline; a silencer is arranged on the nitrogen discharging pipeline; and a heat-free adsorption-type dryer is further connected between the nitrogen buffer tank and the nitrogen storage tank through a pipeline. The low-dew-point PSA nitrogen generation system has the advantages that the nitrogen dew point can be decreased, and the nitrogen purity can be improved.

Owner:无锡市申隆气体设备有限公司

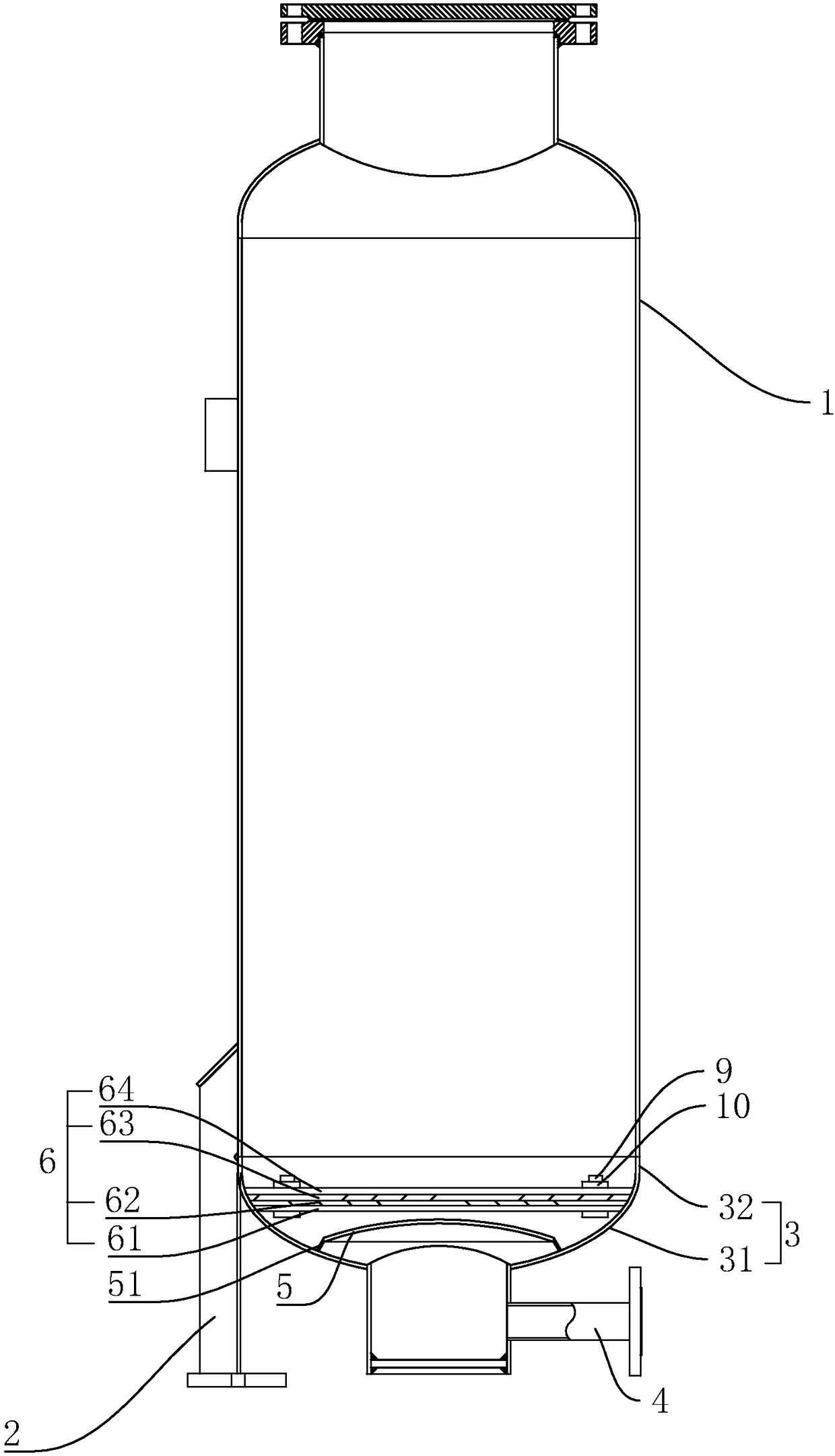

Spinning yarn drying tank

InactiveCN107024097AAchieve continuous dryingUniform temperatureDrying gas arrangementsDrying chambers/containersYarnEngineering

The invention discloses a spinning yarn drying tank, and aims to solve the problem of poor drying quality. The spinning yarn drying tank comprises a tank body, a hot air tank, a guide roller, a lifting rod and a driving device, wherein the hot air tank is mounted at the top of the tank body; a plurality of hot air inlets are formed in the top of the hot air tank; the bottom of the hot air tank adopts an air inlet plate; a plurality of vent holes for communicating the hot air tank with the tank body are formed in the air inlet plate; the guide roller is longitudinally mounted inside the tank body; lifting rods are mounted on guide roller shafts at two ends of the guide roller; the lifting rods are mounted on the driving device. Due to the guide roller, the driving device and the lifting rods of the drying tank, spinning yarns can be supported and transported, and then continuous drying of the spinning yarns is achieved; due to the plurality of the vent holes in the air inlet plate, hot air fed into the tank body can be rapidly distributed inside the tank body, then the temperature inside the tank body can be unified, and the phenomenon that the spinning yarn drying quality is poor as the temperature inside the tank body is not uniform is avoided.

Owner:长兴宝诺纺织科技有限公司

Continuous drying equipment for cherry tree seeds

A kind of continuous drying equipment for cherry tree seeds, comprising a box body, a first screw conveyor and a second screw conveyor are vertically arranged in the box, the casings of the first screw conveyor and the second screw conveyor are both It is a ventilation net, the top of which is fixed to the inner wall of the box, and the bottom end extends out of the box, and the lower end is respectively provided with a first feeding funnel and a second feeding funnel; the box is also equipped with an upper conveyor belt, a middle conveyor belt and The lower conveyor belt, the upper ends of the first screw conveyor and the second screw conveyor are respectively provided with a first discharge port and a second discharge port, and the first discharge port and the second discharge port are located above the upper conveyor belt; Evenly distributed air outlet pipes are arranged on the side wall of the box body, and the air outlet pipes are connected with the hot air blower arranged on the top of the box body. The invention combines primary drying and secondary drying, and in the process of secondary drying, small batches of seeds can be transported, the drying is uniform, the drying efficiency is high, continuous drying can be realized, and the production efficiency is high.

Owner:SICHUAN GUANTENG TECH CO LTD

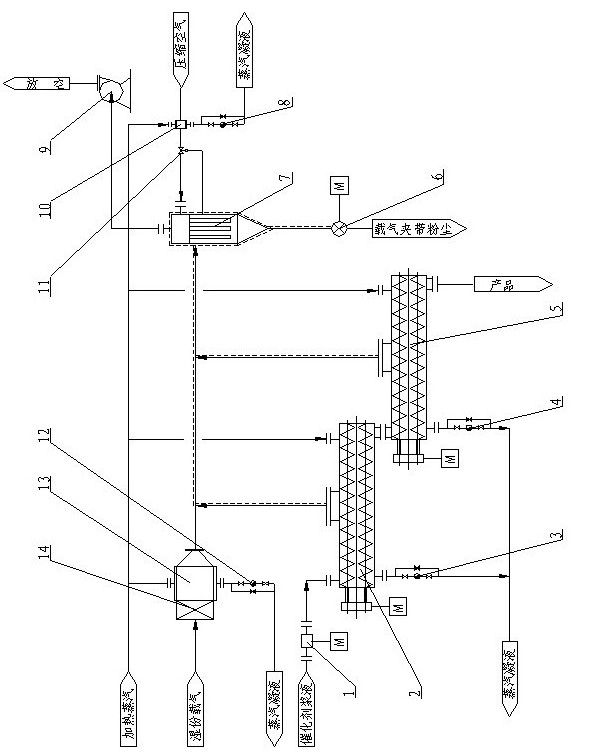

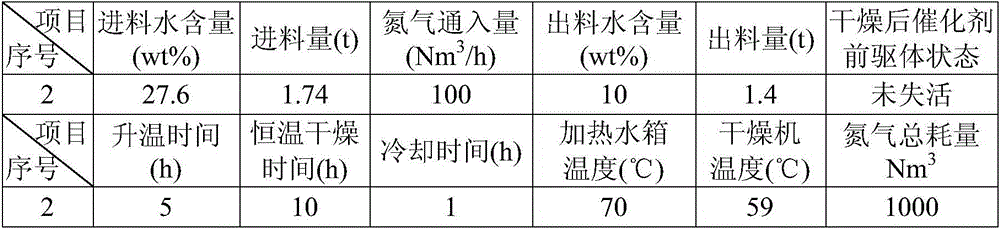

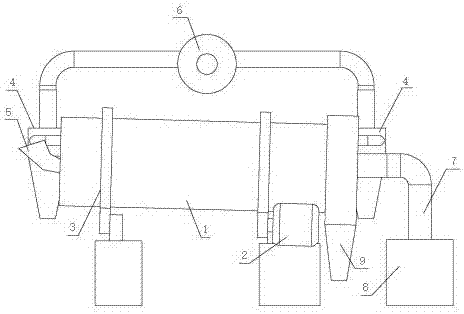

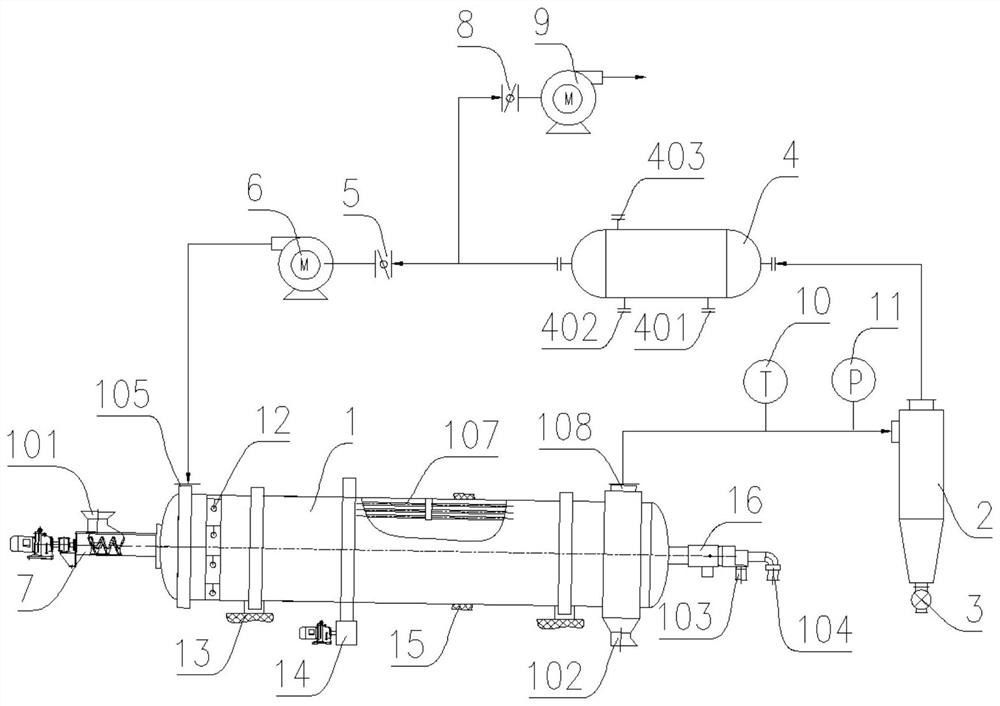

Continuous drying process and equipment for cyclohexanone oximation catalyst

InactiveCN102538426AMeet the requirements of continuous drying processSolve high humidityDrying gas arrangementsDrying solid materialsPtru catalystAir filter

The invention provides a continuous drying process and equipment for a cyclohexanone oximation catalyst, which solve the material viscosity problem and realize the process course of continuous and clean drying of a slurry liquid material. The invention provides matching equipment of the drying process at the same time. The process course comprises the following steps of: adding catalyst slurry from a material inlet of a primary blade dryer through a feed pump; heating, drying and solidifying the slurry material in the process of conveying to a material outlet of the dryer, and then entering a secondary blade dryer; and continuously heating the material in the secondary blade dryer, and drying until reaching the water content required by the process to obtain a catalyst product, wherein dust impurities of a carrier gas are filtered via an air filter, the carrier gas is heated via an air heater and mixed with water vapor which is evaporated from the primary and secondary blade dryers, then a mixture is introduced to a dust catcher so as to catch catalyst dusts carried by the evaporated water vapor in the drying process, and the dedusted and purified mixed gas is discharged via a draught fan.

Owner:NANJING TIANHUA CHEM ENG

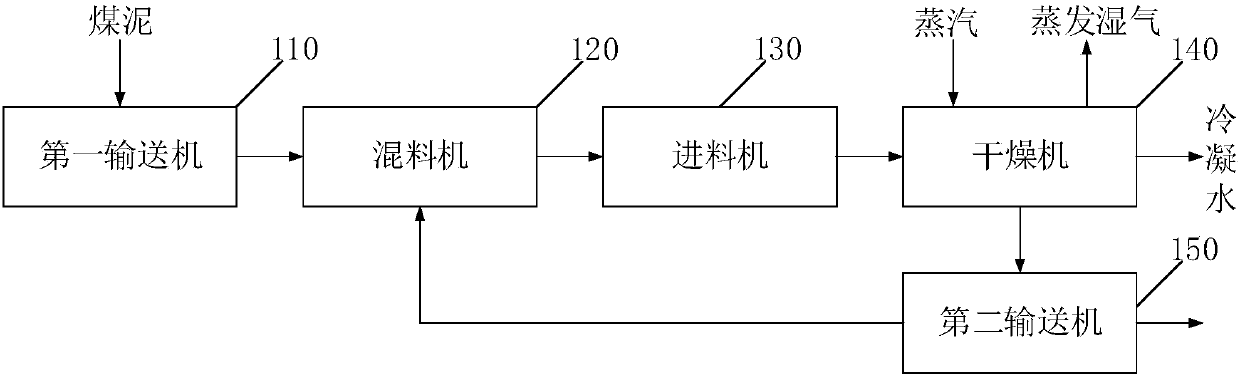

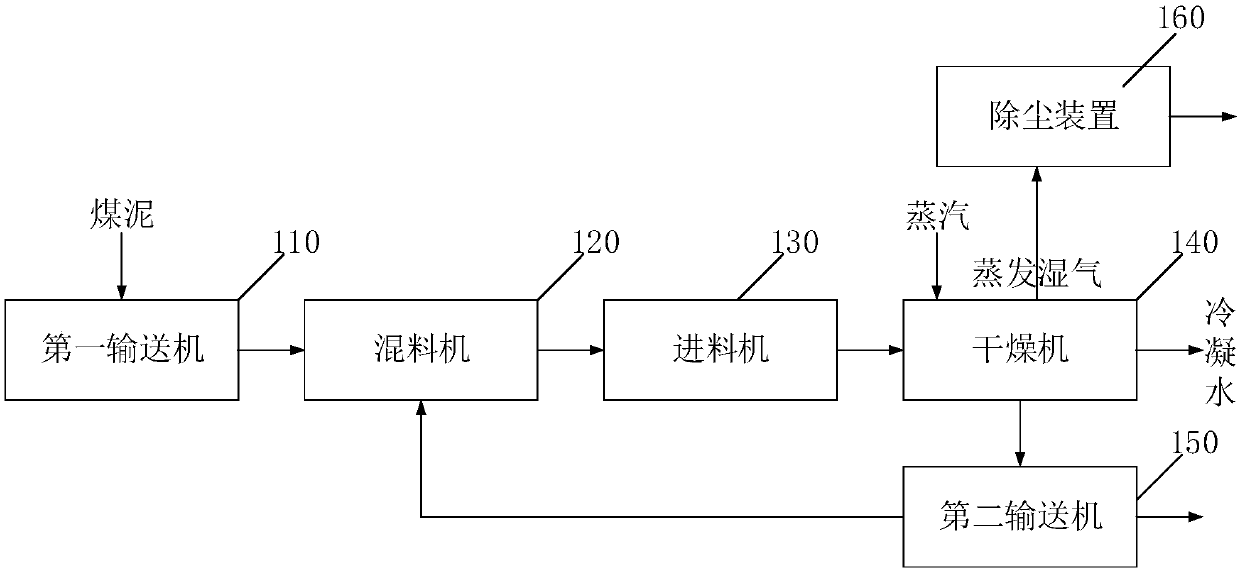

Coal slime indirect drying system

ActiveCN107940937AReduce viscosityReduce bondingDrying machines with non-progressive movementsDrying solid materialsBLENDER/MIXERThermodynamics

The invention provides a coal slime indirect drying system. The coal slime indirect drying system comprises a first conveyor, a blender mixer, a feeding machine, a dryer and a second conveyor. The output end of the first conveyor is connected with the first input end of the blender mixer. The output end of the blender mixer is connected with the feeding end of the dryer through the feeding machine. The discharging end of the dryer is connected with the input end of the second conveyor. The first output end of the second conveyor is connected with the second input end of the blender mixer. Thesecond output end of the blender mixer is used for outputting dried coal slime. The blender mixer is used for mixing the coal slime provided by the first conveyor and the second conveyor and conveyingthe coal slime to the dryer through the feeding machine. The dryer can make the coal slime slowly overturn, and meanwhile, the coal slime is heated and dried indirectly by using steam. By means of the coal slime indirect drying system, the environmental pollution in the drying process can be reduced, the drying efficiency is improved, and the energy consumption is reduced.

Owner:光大清洁技术股份有限公司

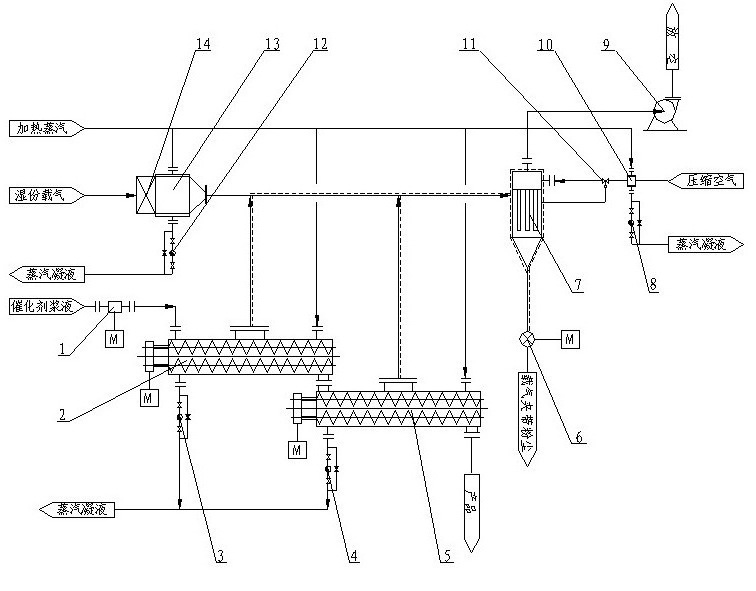

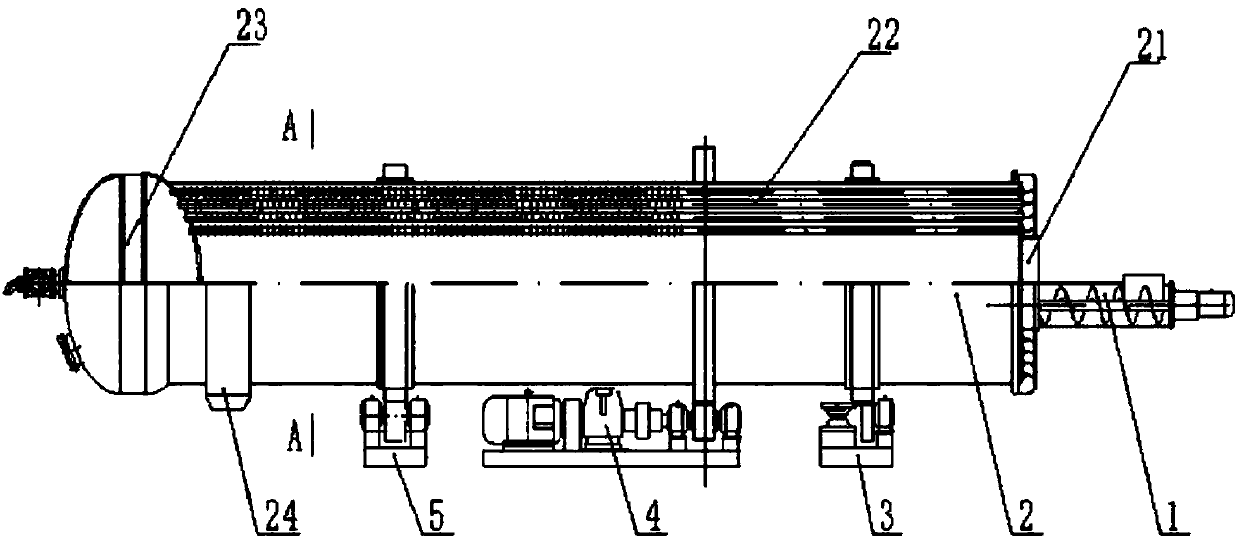

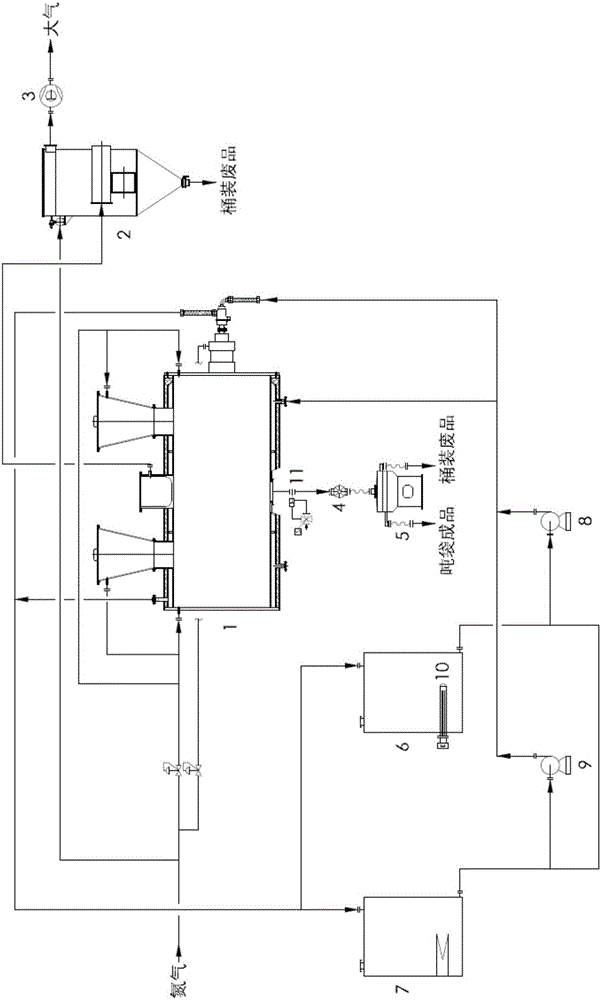

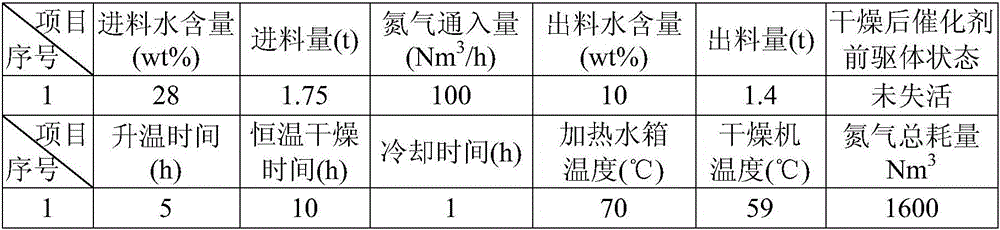

Catalyst precursor industrial drying method capable of being easily influenced by temperature and oxygen and system thereof

InactiveCN106352683ADo not decomposeImprove liquidityDrying gas arrangementsDrying machines with non-progressive movementsSpontaneous combustionDecomposition

The invention provides a catalyst precursor industrial drying method capable of being easily influenced by temperature and oxygen and a system thereof. The method comprises the steps that a catalyst precursor is dried by a drying machine; circulation hot water is introduced into blades, a shaft and a jacket of the drying machine for providing heat sources; nitrogen gas continuously passes through a cavity of the drying machine, so that effects of protecting gas and carrying the moisture are achieved; the nitrogen gas carries out the moisture and then enters a filter; catalyst dust is filtered and is pumped out by a draught fan to be discharged; the dried catalyst precursor is cooled and sieved to obtain a product. The system comprises the drying machine, the filter, the draught fan, a rotary feeder, a vibration sieve, a heating water tank, a cooling water tank, a heating water pump, a cooling water pump and an electric heater. The drying method provided by the invention has the advantages that the catalyst precursor is uniformly and stably dried in inert environment at low temperature; the catalyst precursor can be effectively prevented from spontaneous combustion, decomposition and inactivation in the drying process; the dried catalyst precursor has good flowability.

Owner:BEIJING PETROCHEM ENG

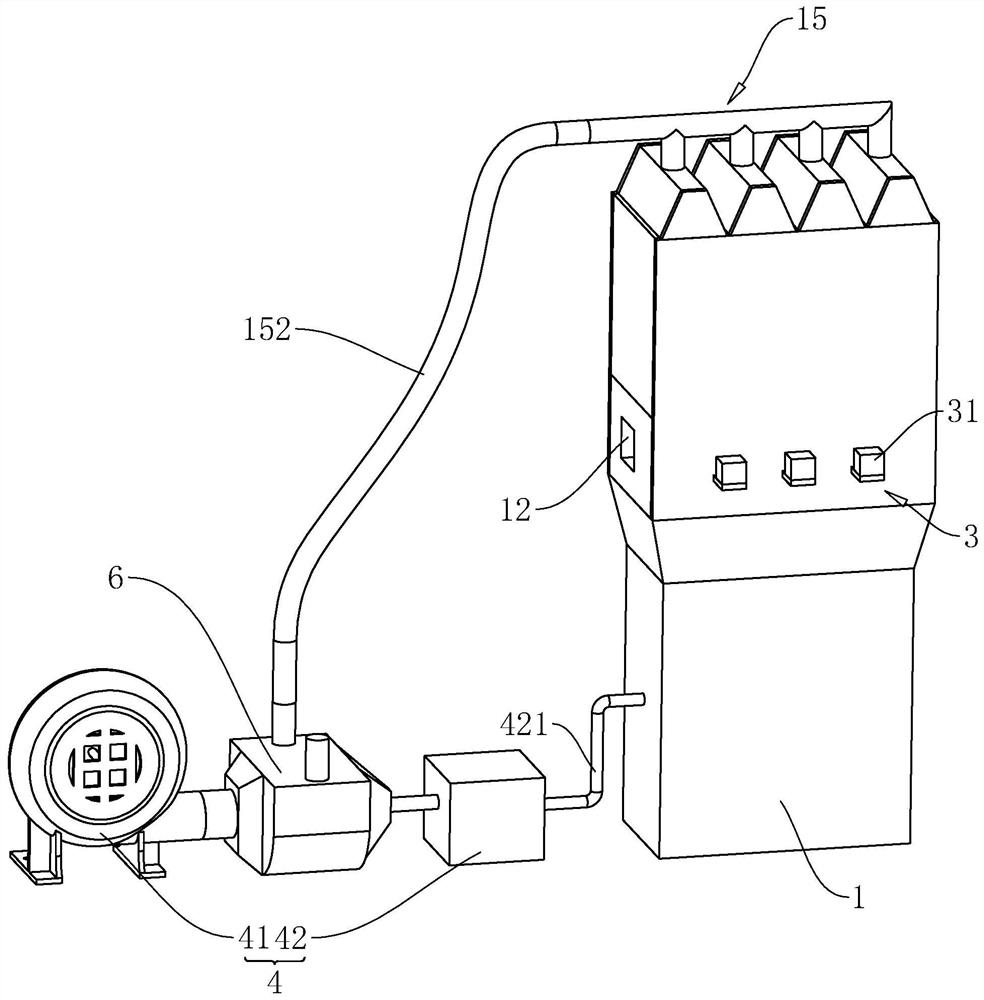

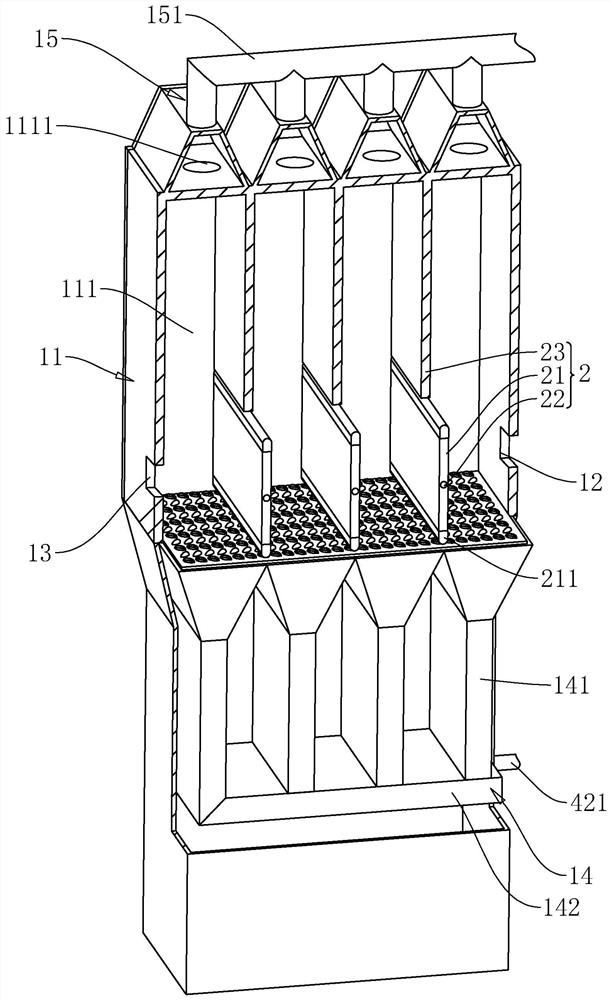

Energy-saving multi-chamber continuous drying boiling dryer

ActiveCN113494838AAchieve continuous dryingSame drynessDrying solid materials with heatDrying gas arrangementsProcess engineeringMechanical engineering

The invention relates to the field of drying equipment, in particular to an energy-saving multi-chamber continuous drying boiling dryer. The dryer comprises a boiling dryer body, a drying cavity used for drying materials is formed in the boiling dryer body, a feeding port and a discharging port are formed in the boiling dryer body, and a partition device is arranged in the drying cavity. The drying cavity is divided into a plurality of drying sub-cavities by the partition device, the feeding port and the discharging port are communicated with the different drying sub-cavities, and a driving device for driving the partition device to be opened and closed is further arranged on the boiling dryer body. The dryer has the effects that continuous drying of the materials is achieved, the drying efficiency is improved, and meanwhile the drying degrees of all batches of the materials output by the boiling dryer body are the same.

Owner:常州市润邦干燥设备科技有限公司

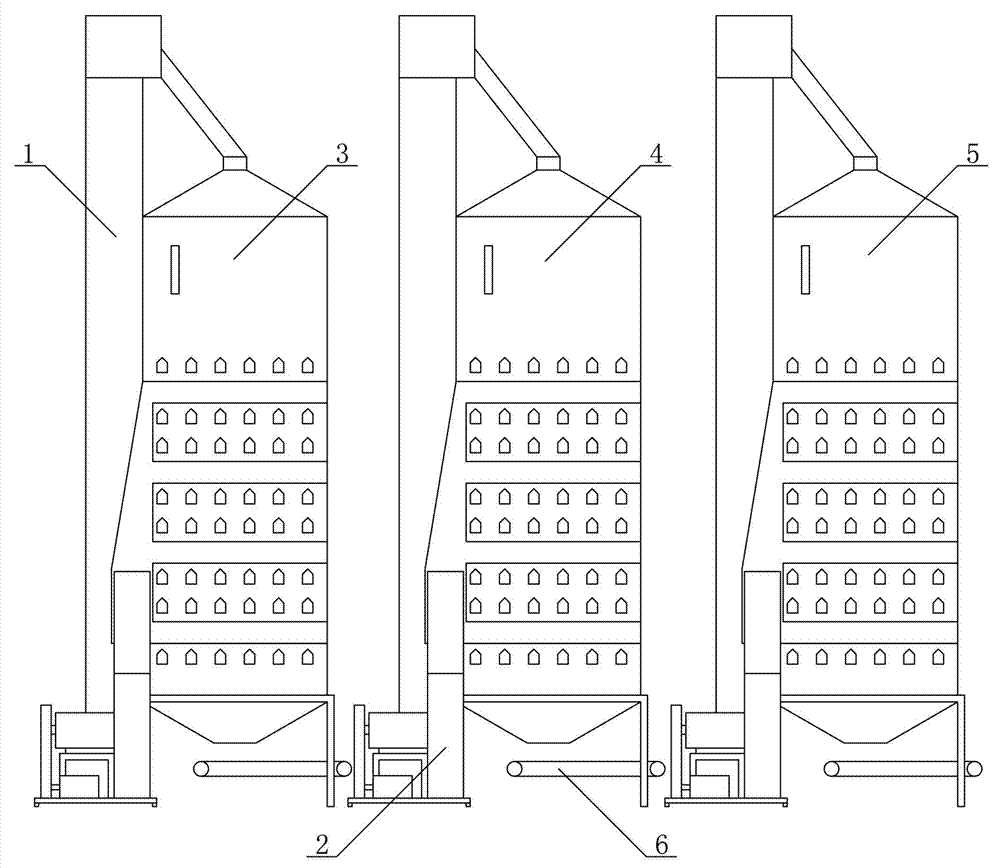

Multiple-tower continuous dryer

InactiveCN103478246AGuaranteed drying timeWon't burn outSeed preservation by dryingProcess engineeringDrying time

The invention provides a multiple-tower continuous dryer, comprising at least two stages of drying tower mechanisms and a hot air generating and conveying mechanism for providing drying gas for each drying tower mechanism. Each stage of drying tower mechanism comprises a drying tower and an elevator for conveying grains to the corresponding drying tower; and a grain input terminal of a lower stage of elevator is arranged corresponding to the grain output terminal of an upper stage of elevator, so as to conveniently convey the dried grains in an upper stage of drying tower to a lower stage of drying tower. The multiple-tower continuous dryer has the advantages of scientific design, sufficient drying time, low cost, grading temperature supply, good drying effect and high drying efficiency.

Owner:李保安

Coffee beans automatic drying and screening device

InactiveCN107495429ADry fastPrevent leakageSievingGas current separationPulp and paper industryHot blast

The present invention provides a coffee bean automatic drying and screening device. The coffee bean automatic drying and screening device comprises a roller, and a transmission mechanism and a bracket part connected with an outer surface of the roller. A material inlet is connected with a left side of the roller, a material outlet is connected with a right side of the roller, a hot blast stove is connected with the right side of the roller via an air guide pipe, two dust removers are connected with two sides of the roller and both connected with a variable frequency fan, a screening box is arranged right below the material outlet, a dust collection box is arranged at a left side of the screening box, and a material loading box is arranged at a right side of the screening box. By using the hot blast stove to blow air into the roller, a purpose of drying coffee beans is achieved and the hot air can also carry away dust, so that air in the roller circulates, the drying of the coffee beans is accelerated and a dust concentration within the roller is also reduced. The coffee bean automatic drying and screening device ensures a smooth operation of the roller, can also conduct the automatic screening after the drying is completed, reduces labor costs and improves a use value.

Owner:兰溪市奥而特农业科技有限公司

Efficient dryer facilitating fertilizer forming

InactiveCN107677070ADry fastAvoid cloggingSievingManure dryingFrequency conversionAgricultural engineering

The invention provides an efficient dryer facilitating fertilizer forming. The efficient dryer facilitating fertilizer forming comprises an obliquely arranged roller, a transmission mechanism connected with the outer surface of the roller and a bracket part. A feeding port is connected with the left side of the roller, a discharging port is connected with the right side of the roller, a hot blastheater is connected with the right side of the roller through a wind guide pipe, and dust removers are connected with the two sides of the roller; and the dust removers are both connected with a frequency conversion fan, a screening box is arranged over the discharging port, a dust collecting box is arranged on the left side of the screening box, and a charging box is arranged on the right side ofthe screening box. According to the efficient dryer facilitating fertilizer forming, the drying effect is good, fertilizer drying is even, dust removing can be conducted in the drying process and after drying is conducted, the fertilizer quality is obviously improved, cooling screening can be integrally achieved after drying is completed, the labor cost is reduced, and the market prospect of thedryer is promoted.

Owner:浦江县元寿农业科技有限公司

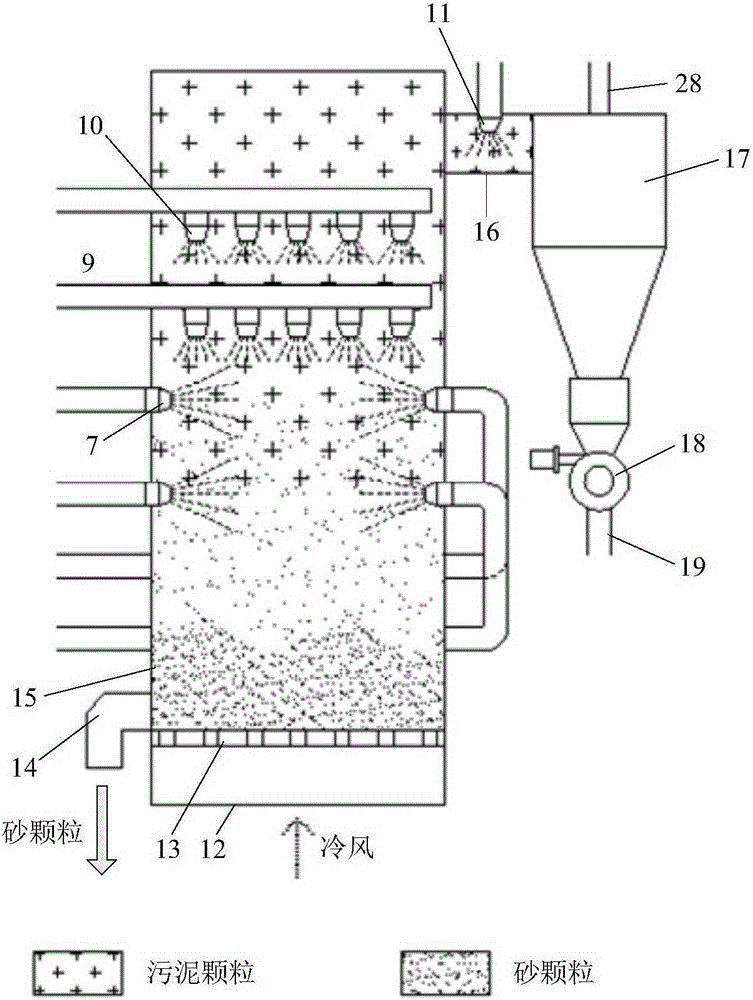

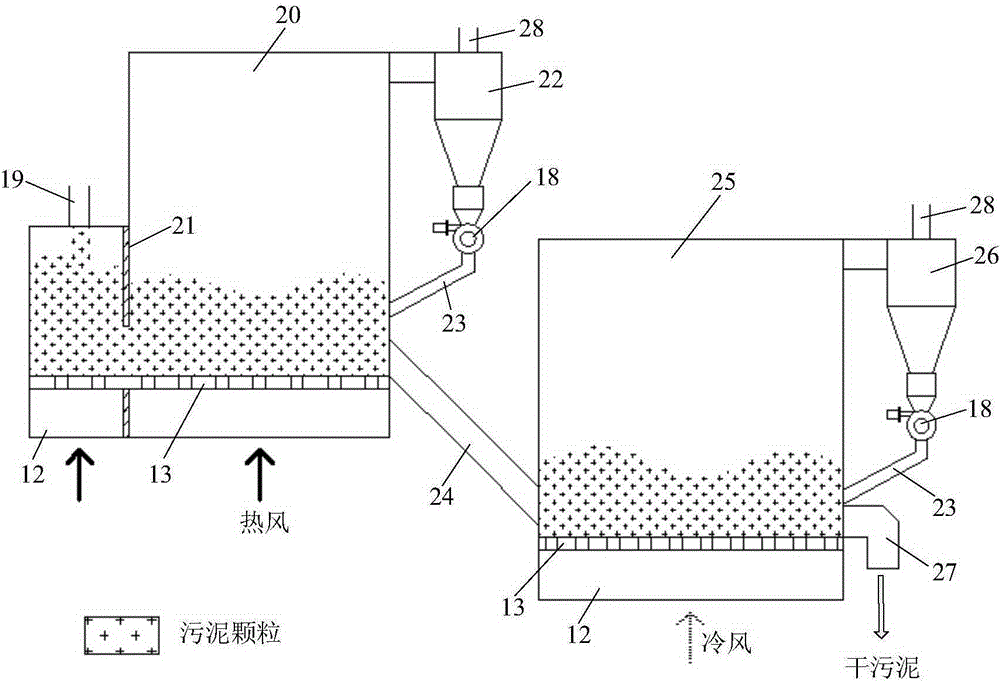

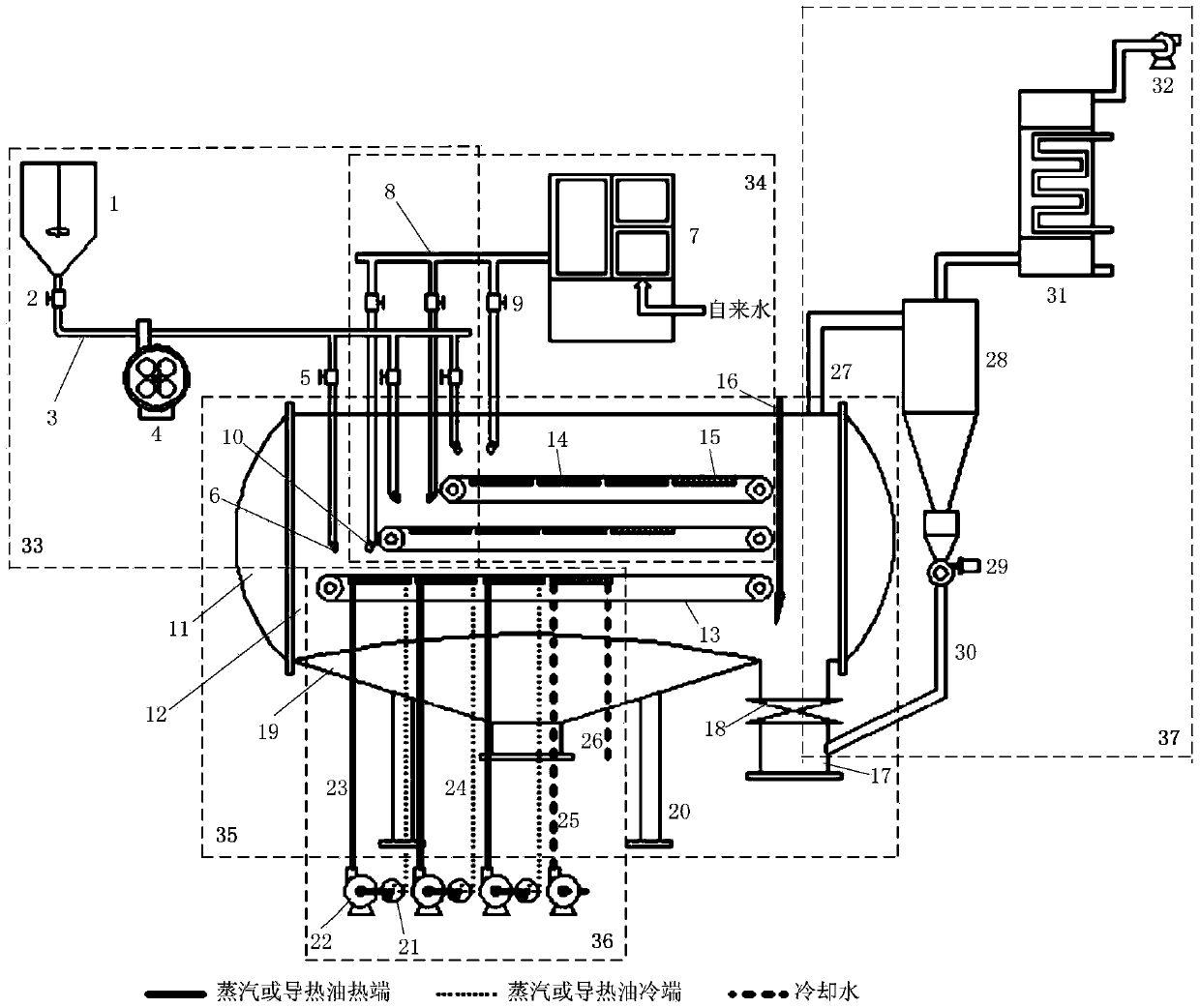

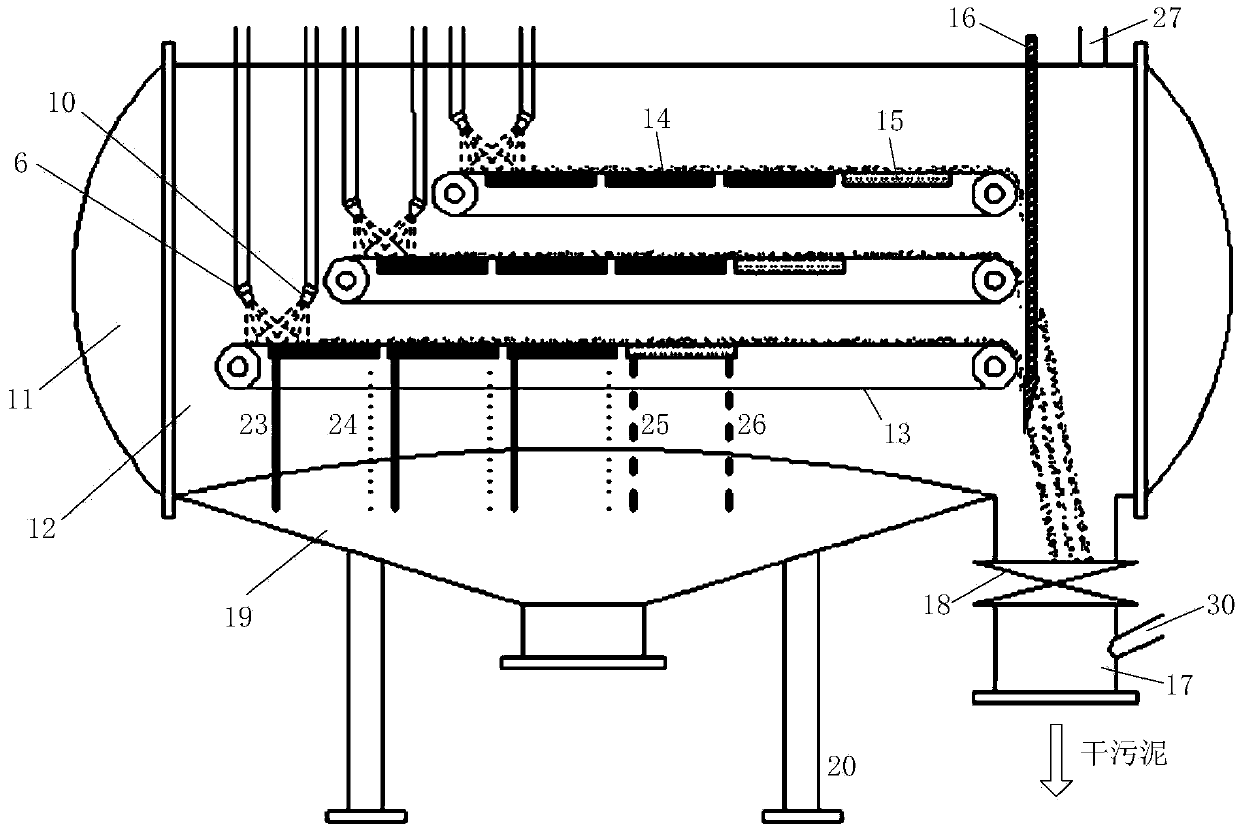

Sludge comprehensive treatment system and method

ActiveCN105347645AFully deodorizedFully drySludge treatment by de-watering/drying/thickeningDispersed particle separationFluidized bed dryingSludge

The invention discloses a sludge comprehensive treatment system and method and belongs to the technical field of sludge treatment. The system comprises a sludge crushing, conveying and spraying device, a plant liquid conveying and spraying device, a fluidized bed sand particle removal and deodorizing device, a fluidized bed drying and cooling device and a tail gas treatment device. Through the sludge crushing, conveying and spraying device, sand particle-containing sludge forms liquid drops with sizes of 150-200 microns, the mixed liquid drops are uniformly sprayed into the fluidized bed sand particle removal and deodorizing device, and through adjustment of a fluidization air rate, sand particles with sizes of 200 microns or less are removed from wet sludge. The sludge comprehensive treatment system and method solve the problems that sludge with high sand content causes problems in a sludge anhydration burning system and equipment wear, reduces enterprise operation and maintenance costs, prevents odor in a region of the sludge anhydration burning engineering project, reduces capital investment of odor guidance and removal, realizes sludge continuous drying and has a good engineering application prospect.

Owner:TSINGHUA UNIV

Continuous drying device used for automatic circuit board production line

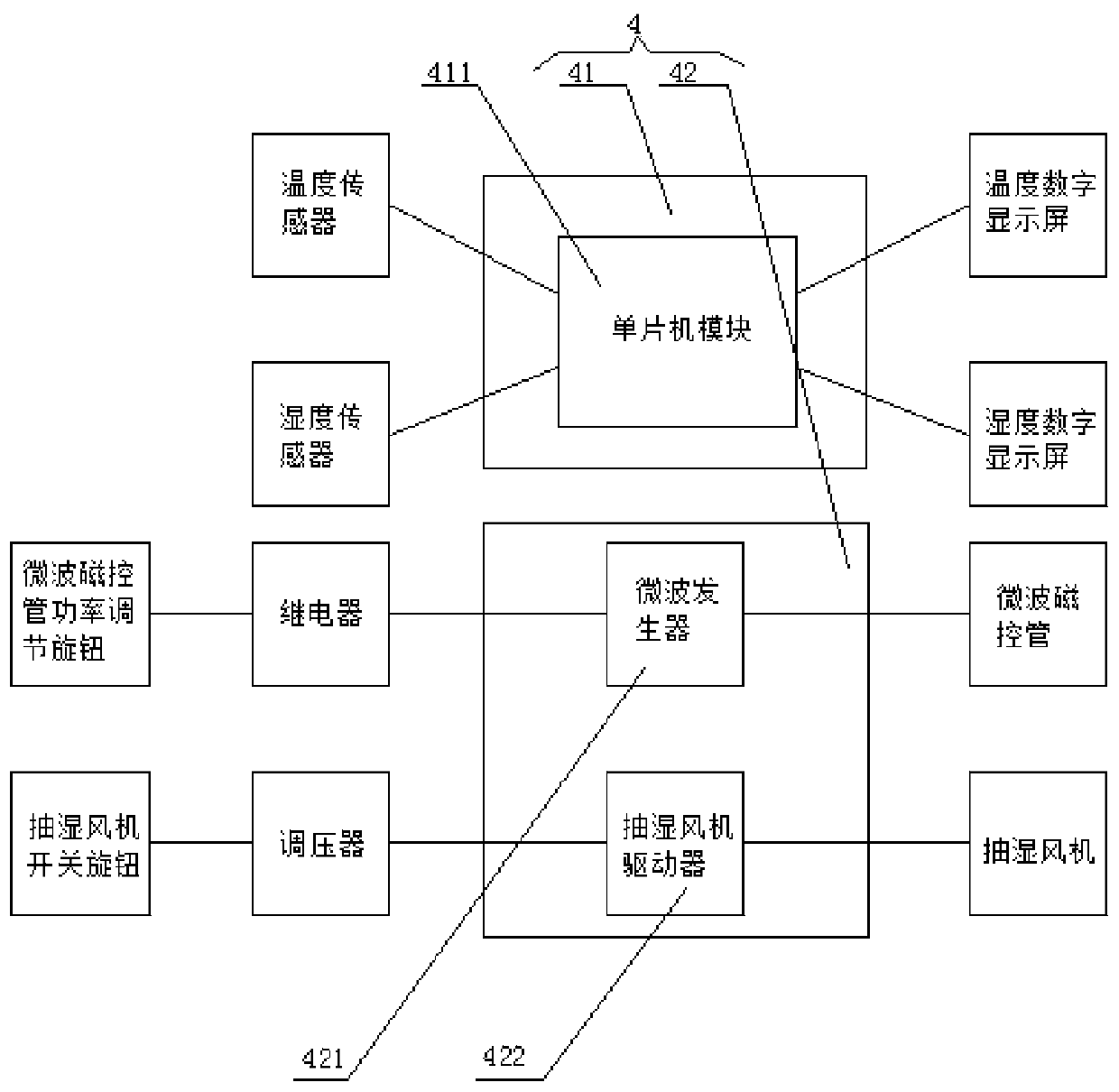

InactiveCN109827411AImprove heat utilizationImprove drying efficiencyDrying solid materials with heatDrying machines with progressive movementsEngineeringMicrowave

The invention discloses a continuous drying device used for an automatic circuit board production line, and relates to the technical field of circuit board drying. The device comprises a conveying device and a drying device; the drying device is arranged on the conveying device, the conveying device comprises two belt wheels, a conveying belt surrounding the two belt wheels is arranged outside thetwo belt wheels, the drying device comprises a drying box, multiple micro wave magnetrons are arranged in the drying box, a temperature sensor, a humidity sensor and a dehumidification fan are arranged on the upper end of the drying box in sequence, an air inlet of the dehumidification fan communicates with the interior of the drying box through an exhaust pipeline, the conveying belt penetratesthrough the interior of the drying box, a circuit board is placed between two fixed plates and penetrates through the drying box through the conveying belt, microwaves generated by heating of the micro wave magnetrons in the drying box are used for drying the circuit board, the heat energy use rate is improved, the drying efficiency is improved, and continuous drying is achieved.

Owner:JINGDEZHEN HONGYI ELECTRONICS TECH CO LTD

Device and method for heating and drying household garbage through steam with gas circulation

PendingCN113137612ADry fastReduce cloggingDispersed particle separationDrying gas arrangementsThermodynamicsEngineering

The invention provides a device for heating and drying household garbage through steam with gas circulation. The device comprises a steam heating pipe type rotary cylinder dryer which is cylindrical, the left end of the steam heating pipe type rotary cylinder dryer is a feeding end, the right end of the steam heating pipe type rotary cylinder dryer is a discharging end, a feeding device is installed at the feeding end of the steam heating pipe type rotary cylinder dryer, the steam heating pipe type rotary cylinder dryer is obliquely mounted, a certain included angle is formed between the steam heating pipe type rotary cylinder dryer and the horizontal plane, the side of the feeding end is high, and the discharging end is low; a garbage feeding hole is formed in the feeding device; and a circulating gas inlet is further formed in the steam heating pipe type rotary cylinder dryer, a hammering device is arranged outside a cylinder body of the steam heating pipe type rotary cylinder dryer, heating pipes are arranged in the cylinder body, a garbage discharging outlet is formed in the lower portion of the discharging end of the steam heating pipe type rotary cylinder dryer, a circulating gas outlet is formed in the upper portion of the discharging end, and a steam distribution joint, a steam inlet and a steam outlet are formed in the center of the right end of the cylinder body of the steam heating pipe type rotary cylinder dryer.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Soft magnetic ferrite magnetic core sintering furnace heat energy recycling device

ActiveCN111504060ARealize the collectionReduce wasteCharge composition/stateCharge treatment typeSoft magnetFerrite (magnet)

The invention relates to the field of soft magnet ferrite, and discloses a soft magnetic ferrite magnetic core sintering furnace heat energy recycling device. The device comprises a preheating segmentfurnace body, a sintering segment furnace body, a cooling segment furnace body, a drying segment furnace body and a conveying mesh belt, a supporting base is mounted on the cooling segment furnace body, a conveying pipe is horizontally mounted on the supporting base, a smoke discharging pipe communicating with one end of the conveying pipe is arranged on the preheating segment furnace body and the sintering segment furnace body, the end, deviating from the smoke discharging pipe, of the conveying pipe is provided with a filter mechanism, an exhaust pipe is mounted on the filter mechanism, anair cover is mounted on the drying segment furnace body, the upper end of the air cover communicates with the exhaust pipe, and the device has the advantages that through the efficient heat energy recycling device, heat collection of the preheating segment and the sintering segment can be achieved, heat is transmitted into the drying segment furnace body, recycled heat energy can dry the finishedproducts in the drying segment furnace body, heat energy effective recycling is achieved, and the effect of reducing the resource waste can be achieved.

Owner:湖北华磁电子科技有限公司

Pearl fiber cleaning and drying device

PendingCN111074447AFast cleaningSpeed up gas flowSucessive textile treatmentsLiquid/gas/vapor removal by gas jetsProcess engineeringEnvironmental geology

The invention discloses a pearl fiber cleaning and drying device. The pearl fiber cleaning and drying device comprises a cleaning box and a flushing box, wherein the interior of the cleaning box is fixedly connected with a stirring box through a supporting rod. According to the pearl fiber cleaning and drying device, firstly, the cleaning box and the flushing box are adopted; a stirring motor drives a stirring paddle to stir a cleaning liquid in the cleaning box, and flow of the cleaning liquid is accelerated, thereby accelerating the cleaning liquid to pass through pearl fibers and further speeding up the cleaning process; meanwhile, the cleaning box is inflated with a large amount of gas though an air blower, so that the cleaning liquid is full of bubbles, the air flow is accelerated, bubble breaking can shake off fine dust on the surfaces of the pearl fibers, the cleaning efficiency of the pearl fibers is greatly improved, the cleaned pearl fibers are conveyed through a conveying roller and gradually enter the flushing box; and a spray head on the side wall of the flushing box sprays water, and the pearl fibers are washed, so that the cleaning liquid on the surfaces of the pearlfibers is washed off, the cleaning degree of the pearl fibers is further improved, and the finished product quality of the pearl fibers is greatly improved.

Owner:浙江大通轻纺有限公司

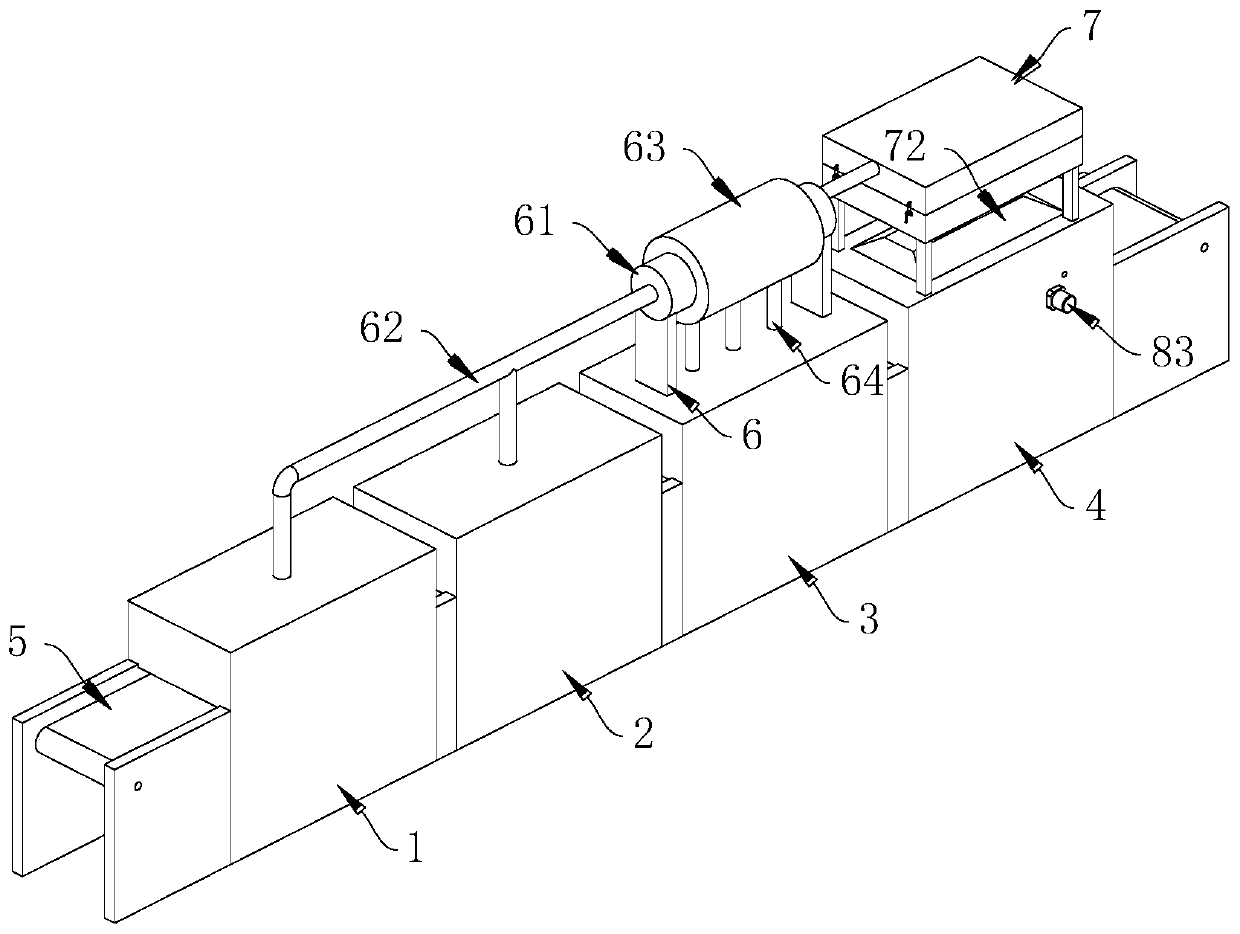

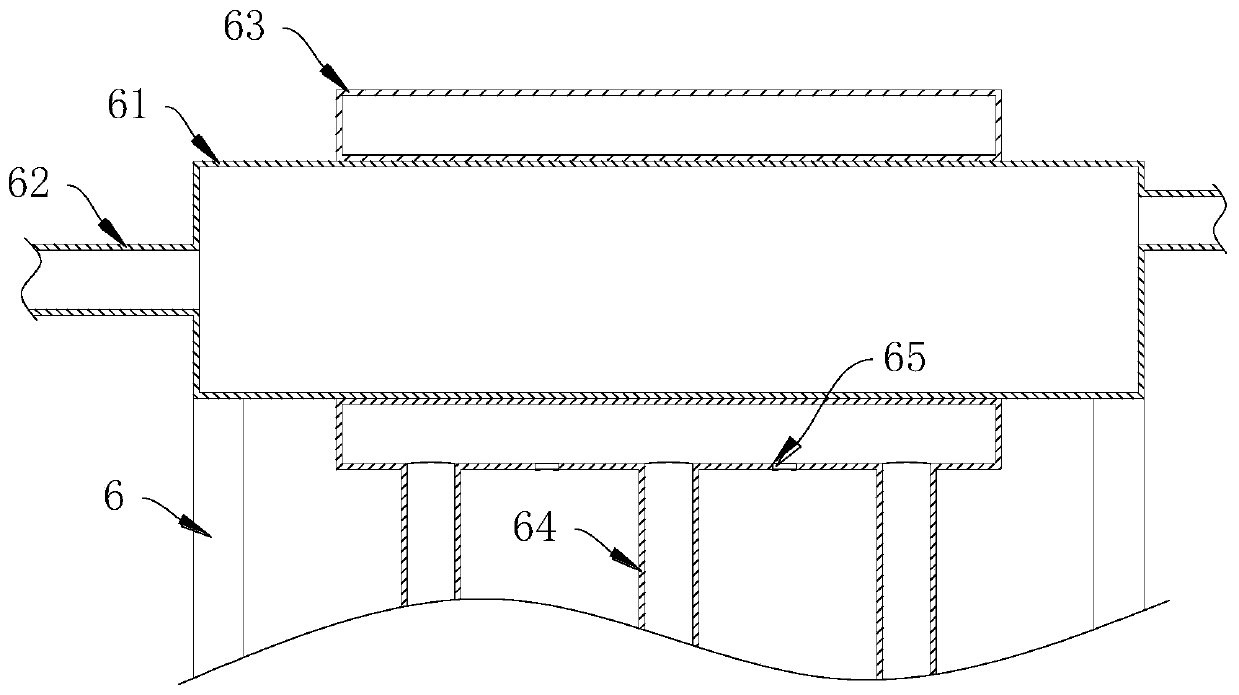

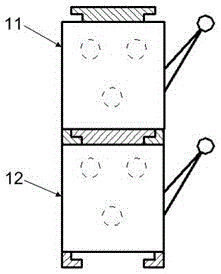

Continuous drying module for use in semiconductor integrated manufacturing production line

InactiveCN103050426AContinuous dryingAchieving a modular designSemiconductor/solid-state device manufacturingSemiconductorModular design

The invention relates to the field of semiconductor integrated manufacturing, in particular to a continuous drying module for use in a semiconductor integrated manufacturing production line. The invention provides a continuous drying module for use in a semiconductor integrated manufacturing production line. Both sides of a shell are provided with an inlet and an outlet through which a conveying belt passes, and drum groups for dynamically clamping the conveying belt are arranged at the inlet and the outlet, so that the effect of dynamically sealing the shell and the conveying belt is achieved when the conveying belt passes through the shell from the inlet and the outlet. Due to the adoption of the continuous drying module provided by the invention, a continuous drying function on a photosemiconductor substrate can be realized, and the quality of a gas in the shell can be controlled in real time in a drying process; and meanwhile, a modular design of a drying process in the semiconductor integrated manufacturing production line is realized.

Owner:王奉瑾

Drying device for processing trichosanthes kirilowii maxim seeds

InactiveCN113498869AEvenly heatedImprove drying efficiencyGas current separationFood treatmentTrichosanthes kirilowiiEngineering

The invention discloses a drying device for processing trichosanthes kirilowii maxim seeds. The drying device comprises a drying box body. Supporting legs are fixed to the four corners of the bottom face of the drying box body. A shaking disc is arranged in the drying box body, and supporting strips are arranged on the two sides of the lower end of the shaking disc; rolling grooves are formed in the top surfaces of the supporting strips; balls are further installed on the bottom face of the shaking disc. The balls are connected into the rolling grooves in a rolling mode. A heating pipe is further arranged on the lower side of the shaking disc; one side of the bottom surface of the drying box body is in through connection with a discharging vessel; push rods are fixed to the two sides of the rear end face of the shaking disc. Limiting plates are fixed to the side walls of the rear ends of the push rods. Reset springs are fixed to the ends, close to the drying box body, of the limiting plates. Racks are fixed to the center positions of the rear end faces of the limiting plates. The invention is reasonable in design, stable in device operation, uniform in trichosanthes kirilowii maxim seeds heating and high in drying efficiency, light impurities can be adsorbed and removed while stir-frying is conducted, and therefore the stir-frying quality of trichosanthes kirilowii maxim seeds is greatly improved.

Owner:QIANSHAN YOUYU TRICHOSANTHES KIRILOWII MAXIM DEV CO LTD

Combined oven used in printing and dyeing industry

InactiveCN106322958ASmall footprintEasy to disassembleDrying chambers/containersDrying machines with progressive movementsDyeingMetallic Lead

The invention discloses a combined oven used in the printing and dyeing industry. The combined oven comprises an oven body with the two opposite sides provided with a feeding port and a discharging port correspondingly. A T-shaped sliding block is formed at the top of the oven body, and a lead groove matched with the sliding block is formed in the bottom of the oven body. A first guiding roller, a second guiding roller and a third guiding roller in the oven body are arranged in a triangular manner. An auxiliary frame is arranged at the position of the side wall where the feeding port of the oven body is located. An auxiliary guiding roller is arranged at the free end of the auxiliary frame. According to the oven, the occupied area of the oven is reduced through the combination, continuous drying of multiple ovens can be achieved through auxiliary guiding rollers, and expanded application of the multiple small-volume ovens is achieved. Through the inserting and pulling type auxiliary frame, the auxiliary guiding roller is convenient to detach. The combined oven is high in expandability and applicability.

Owner:天津朗福服饰有限公司

Sichuan pepper drying device

InactiveCN108645126AAchieve continuous dryingImprove drying efficiencyDrying gas arrangementsDrying solid materialsSlide plateEngineering

The invention belongs to the field of Sichuan pepper processing devices, and particularly discloses a Sichuan pepper drying device. The Sichuan pepper drying device comprises a rack, a fan blade, a rotating shaft and a feeding pipe, a shell and a feeding bin are arranged on the rack, a heating part is arranged on the side wall of the shell, an elastic bag layer is arranged at the lower portion ofthe shell, the elastic bag layer and the upper portion of the shell form a drying cavity, the upper portion of the shell is provided with an air inlet and an air outlet, the air outlet is opposite tothe air inlet and is provided with a screen, a discharging opening is formed in the upper portion of the shell, and the air outlet communicates with an air pipe; the air outlet end of the air pipe isopposite to the fan blade, the fan blade is coaxially and fixedly connected with the rotating shaft, the rotating shaft is rotationally connected with the rack, the rotating shaft is provided with a cam, and the cam abuts against the elastic bag layer; and a feeding opening is formed in the upper end of the shell and communicates with the feeding bin through the feeding pipe, the feeding pipe is provided with a feeding control structure for controlling the feeding quantity, a collecting bin is arranged below the discharging opening, a sliding plate is in sliding connection with the interior ofthe collecting bin, an elastic piece is arranged below the sliding plate, and a switch capable of controlling the feeding control structure is arranged below the elastic piece. By means of the device, Sichuan pepper continuous drying can be achieved, and the drying efficiency is better.

Owner:重庆市江津区丰源花椒有限公司

Pharmaceutical drier

InactiveCN103697677AReduce thermal decompositionQuality improvementDrying gas arrangementsDrying solid materialsElectric heatingThermal decomposition

The invention discloses a pharmaceutical drier, comprising a shell, wherein the internal of the shell is divided into a hot air chamber and a drying chamber by a partition, the lower part of the partition is provided with a hot air blower blowing from the hot air chamber to the drying chamber, the top of the hot air chamber is provided with an intake fan, a plurality of material conveying troughs are arranged in the drying chamber, a spiral conveyer is mounted in the material conveying trough, the top of the drying chamber is provided with a dehumidifying fan, metal pendants are uniformly distributed on the inner wall of the hot air chamber, electric heating pipes are fixed on the metal pendants in a hanging manner, the electric heating pipes are uniformly distributed and provided with heating surfaces facing the material conveying troughs, and the hot air chamber is further provided with a temperature sensor and a electric heating pipe power regulating device. According to the pharmaceutical drier, the material can be continuously dried, so that the drying effect is improved, thermal decomposition of effective constituents in the material is reduced, and the quality of finished product is improved.

Owner:GUANGXI NANNING BAIHUI PHARMA GRP

Drying device for green tea

InactiveCN107410537AAchieve the purpose of separationAchieve continuous dryingPre-extraction tea treatmentElectric machineryEpigallo-catechin gallate

The invention discloses a drying device for green tea. The drying device comprises a drying chamber and a conveyor belt in the drying chamber, wherein clamping grooves are connected to the surface of the conveyor belt; drying boxes are fit in the clamping grooves in an embedding manner; the drying device further comprises screening mechanisms; each of the screening mechanisms comprises a screen mesh and a rotating shaft; the screen meshes are arranged in the middles of the drying boxes; the screen meshes are parallel with the bottom surfaces of the drying boxes; each of the screen mesh divides the corresponding drying box into a material containing box and a residue containing box; a vibrator is connected to the corresponding screen mess; the rotating shaft is perpendicular to the corresponding screen mesh; the rotating shaft and the screen mesh are connected in a rotating manner through a bearing; helical blades are arranged on the rotating shaft; an electric motor which drives the rotating shaft to rotate is connected to the corresponding rotating shaft; the green tea is in contact and rubs with each other, and crisp edges of the green tea are knocked down during the rubbing process; the edges which are knocked down fall off through the gap of a green tea leaf pile and fall onto the surface of the corresponding screen mesh; because the vibrator is connected to the corresponding screen mesh and drives the corresponding screen mesh to vibrate, the edges fall off through the apertures of the screen meshes and fall into the residue containing boxes; and the crisp edges produced during the drying process of the green tea leaves are separated from the green tea during the drying process of the green tea.

Owner:务川自治县雾青茶业有限公司

Sludge drying, deodorizing and conveying integrated device

ActiveCN105366908AImprove fluidity and homogeneityReasonable liquiditySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesExhaust gasTransfer mode

The invention provides a sludge drying, deodorizing and conveying integrated device. The device mainly comprises a wet sludge conveying and spraying device, a plant liquid conveying and spraying device, a sludge drying, deodorizing and conveying machine body, a heating / cooling medium conveying loop and a tail gas treatment device. A plurality of non-stick crawler belts are adopted for the sludge drying, deodorizing and conveying machine body and are made to be arranged in a machine shell in the longitudinal direction, and a wet sludge atomizing nozzle and a plant liquid atomizing nozzle which flush against each other are arranged at the starting end of each crawler belt; the wet sludge atomizing nozzles are utilized to atomize wet sludge, the plant liquid atomizing nozzles are utilized to atomize plant liquid, and the wet sludge atomizing nozzles and the plant liquid atomizing nozzles are made to be fully mixed to conduct deodorization. The sludge is dried to the required degree in a contact heat transfer mode through heating plates which are tightly attached to the non-stick crawler belts, and then the sludge is cooled to the required temperature through cooling plates which are tightly attached to the non-stick crawler belts. By means of the sludge drying, deodorizing and conveying integrated device, the problem that bad smell is spread all over a field area of a sludge drying incineration engineering project can be solved, and continuous drying and conveying of the sludge can be achieved.

Owner:TSINGHUA UNIV

Multi-heat-source tobacco drying system

PendingCN114322469AAchieve continuous dryingSave energyTobacco preparationDrying solid materialsWater circulationSolar thermal collector

The invention discloses a multi-heat-source tobacco drying system which comprises a multi-heat-source heating device, a heat storage water tank and a drying room. The multi-heat-source heating device comprises a solar heat collector and an air source heat pump which are arranged in parallel, the one or more heat storage water tanks are connected with the multi-heat-source heating device through heat preservation pipelines, and energy storage water in the heat storage water tanks is heated through the multi-heat-source heating device; heat dissipation coil pipes and fans are arranged in the one or more drying rooms, the heat dissipation coil pipes are connected with the heat storage water tank through heat preservation pipelines, heat is released through energy storage water introduced into the heat storage water tank, the fans are used for driving air in the drying rooms to pass through the heat dissipation coil pipes, and water pumps for driving the energy storage water to circulate are arranged on the heat preservation pipelines. Solar energy can be fully used for drying operation, the air source heat pump is used as a supplementary heat source when the solar energy is insufficient, and the technical problem that in the prior art, solar energy is used as a heat source for drying operation, and the drying operation cannot be continuous due to the influence of sunshine duration is solved.

Owner:中船双瑞(洛阳)特种装备股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com