Continuous drying process and equipment for cyclohexanone oximation catalyst

A drying process and drying equipment technology, used in complete sets of equipment, continuous drying, high-efficiency drying, and cleaning fields, can solve the problems of high labor intensity, low processing capacity, poor on-site environment, etc., to reduce labor intensity, meet recycling efficiency, pollution small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

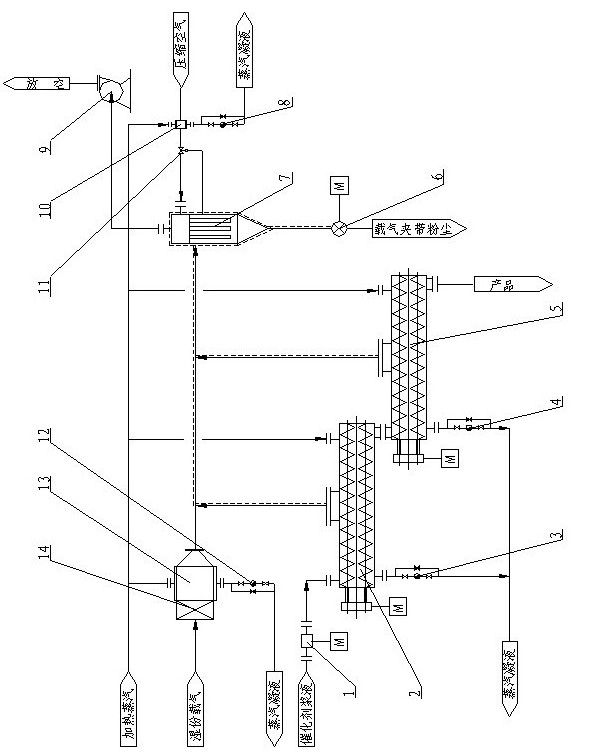

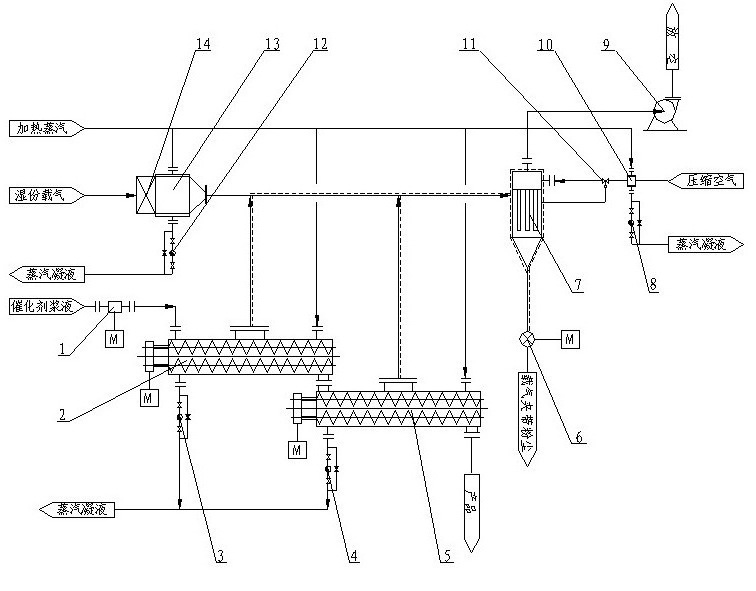

[0026] Below in conjunction with accompanying drawing, the present invention will be further described:

[0027] Such as figure 1 As shown, the continuous drying equipment of the present invention comprises a feed pump 1, two paddle dryers, an air filter 13, a finned tube heater 14, a bag filter 7, a Compressed air heater 10, a fan 9.

[0028] The material pipeline is connected with the feed pump 1, the first-stage paddle dryer 2, and the second-stage paddle dryer 5 in sequence.

[0029] The carrier gas pipeline is connected in sequence with the air filter 13, the finned tube air heater 14 shell side, the gas outlet of the primary paddle dryer 2, the gas outlet of the secondary paddle dryer 5, the bag filter 7, and the fan 9 .

[0030] The heating steam is used as the heating heat source, which is respectively fed into the 14 tubes of the finned tube air heater, the first-stage paddle dryer with 2 paddle shafts and jackets, the second-stage paddle dryer with 5 paddle shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com