Patents

Literature

136results about How to "Speed up gas flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

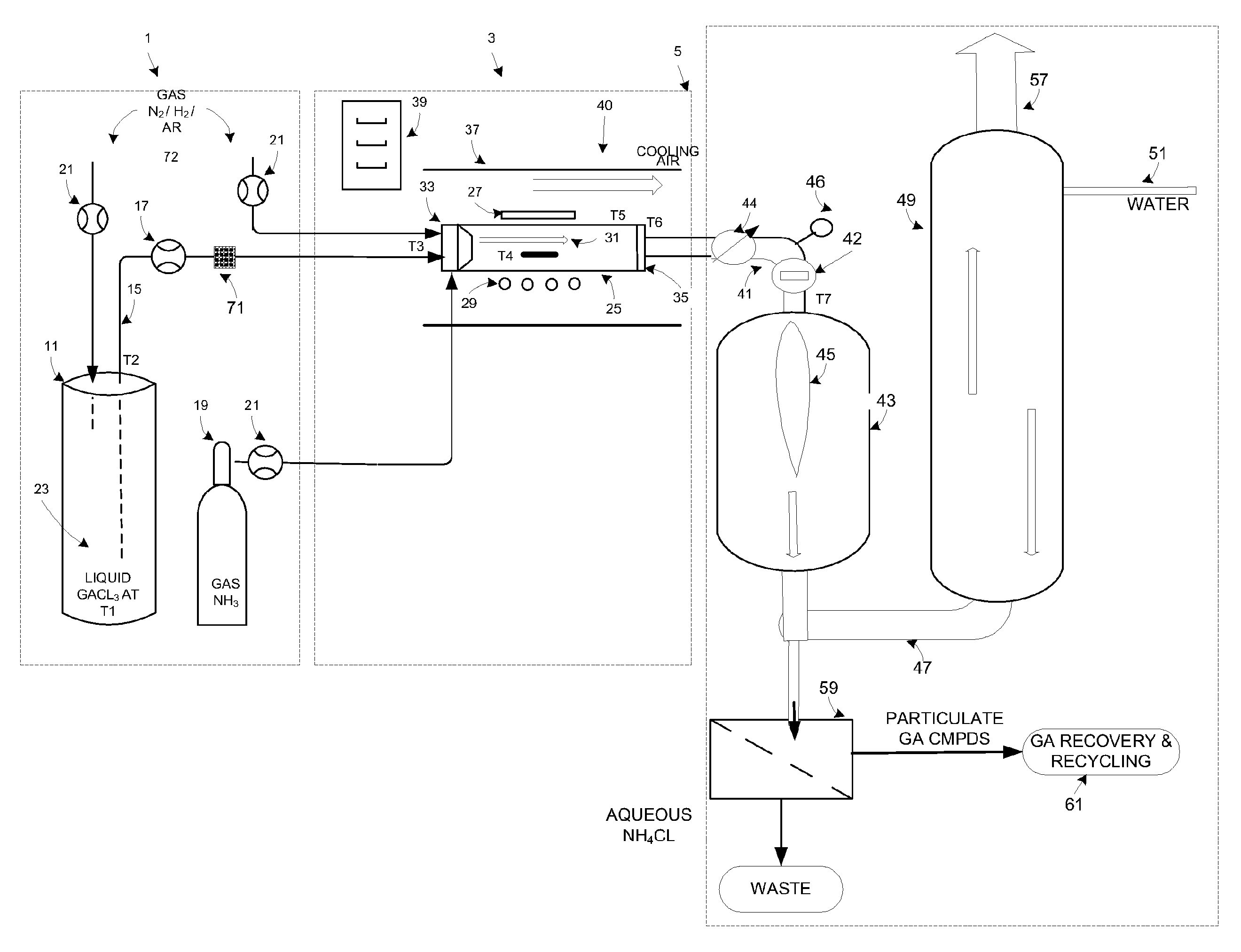

High volume delivery system for gallium trichloride

InactiveUS20090223441A1High manufacturing processEasy to prepare in large batchesPolycrystalline material growthSemiconductor/solid-state device manufacturingHigh volume manufacturingSemiconductor materials

The present invention is related to the field of semiconductor processing equipment and methods and provides, in particular, methods and equipment for the sustained, high-volume production of Group III-V compound semiconductor material suitable for fabrication of optic and electronic components, for use as substrates for epitaxial deposition, for wafers and so forth. In preferred embodiments, these methods and equipment are optimized for producing Group III-N (nitrogen) compound semiconductor wafers and specifically for producing GaN wafers. Specifically, the precursor is provided at a mass flow of at least 50 g Group III element / hour for a time of at least 48 hours to facilitate high volume manufacture of the semiconductor material. Advantageously, the mass flow of the gaseous Group III precursor is controlled to deliver the desired amount.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

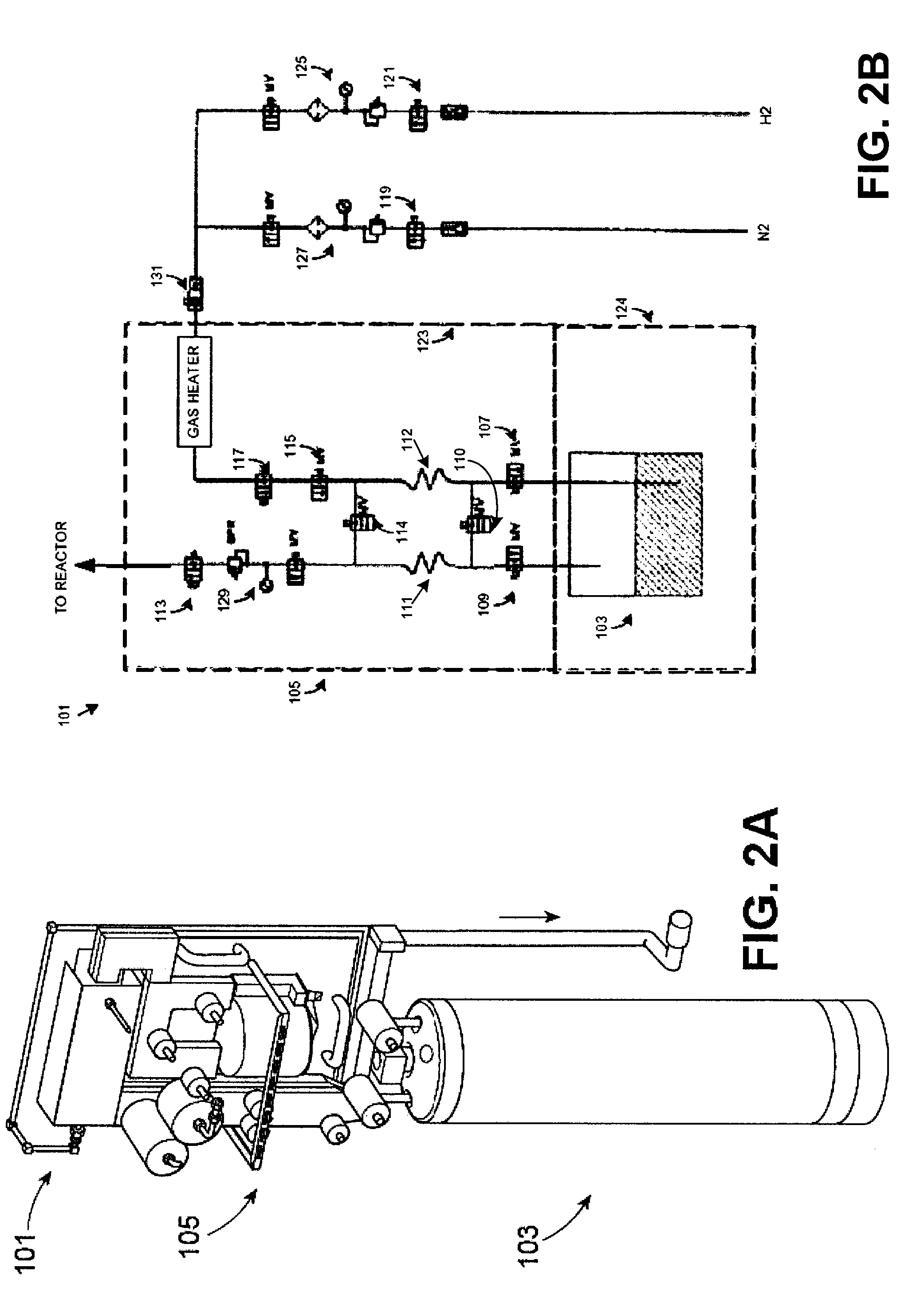

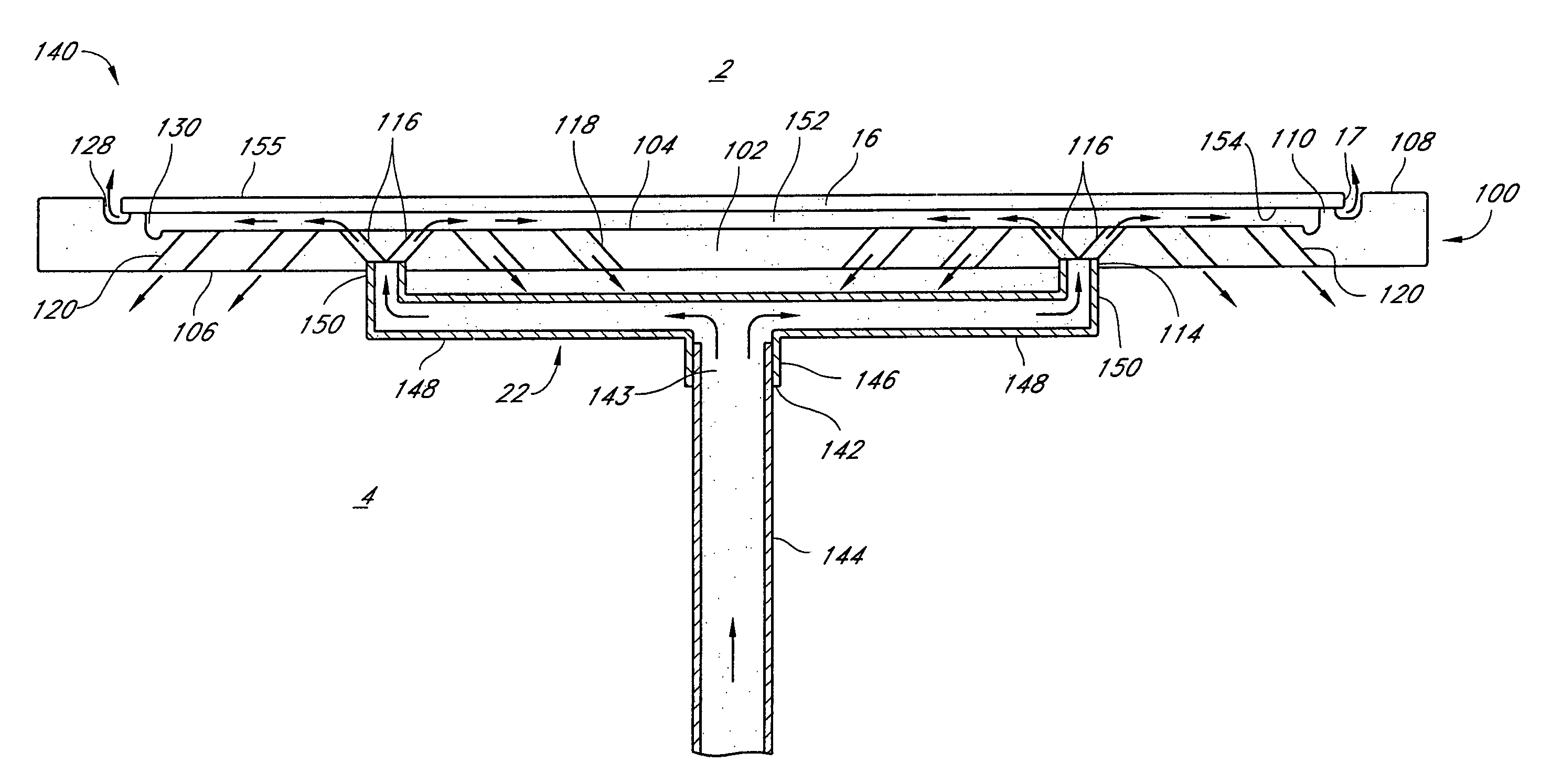

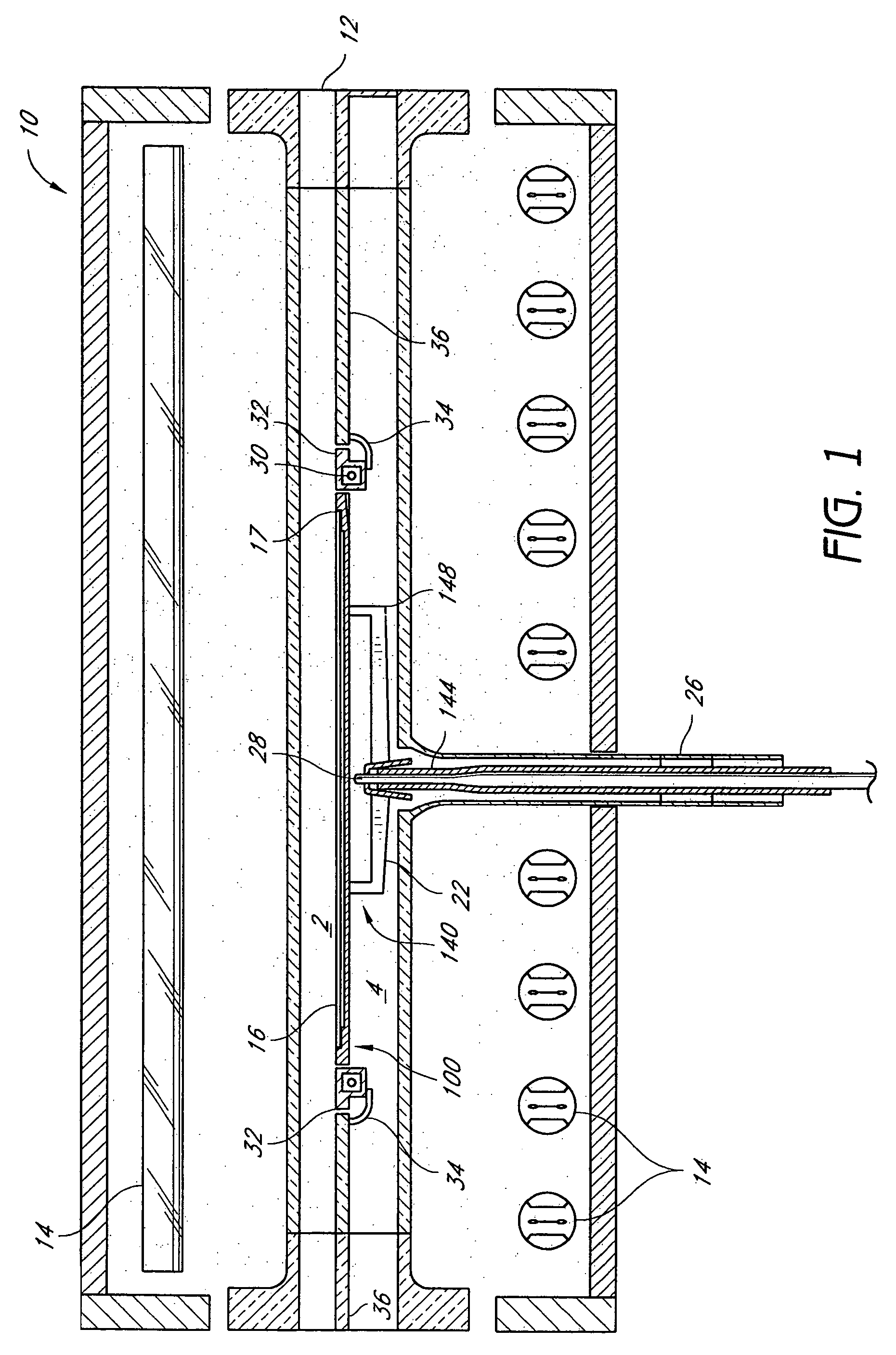

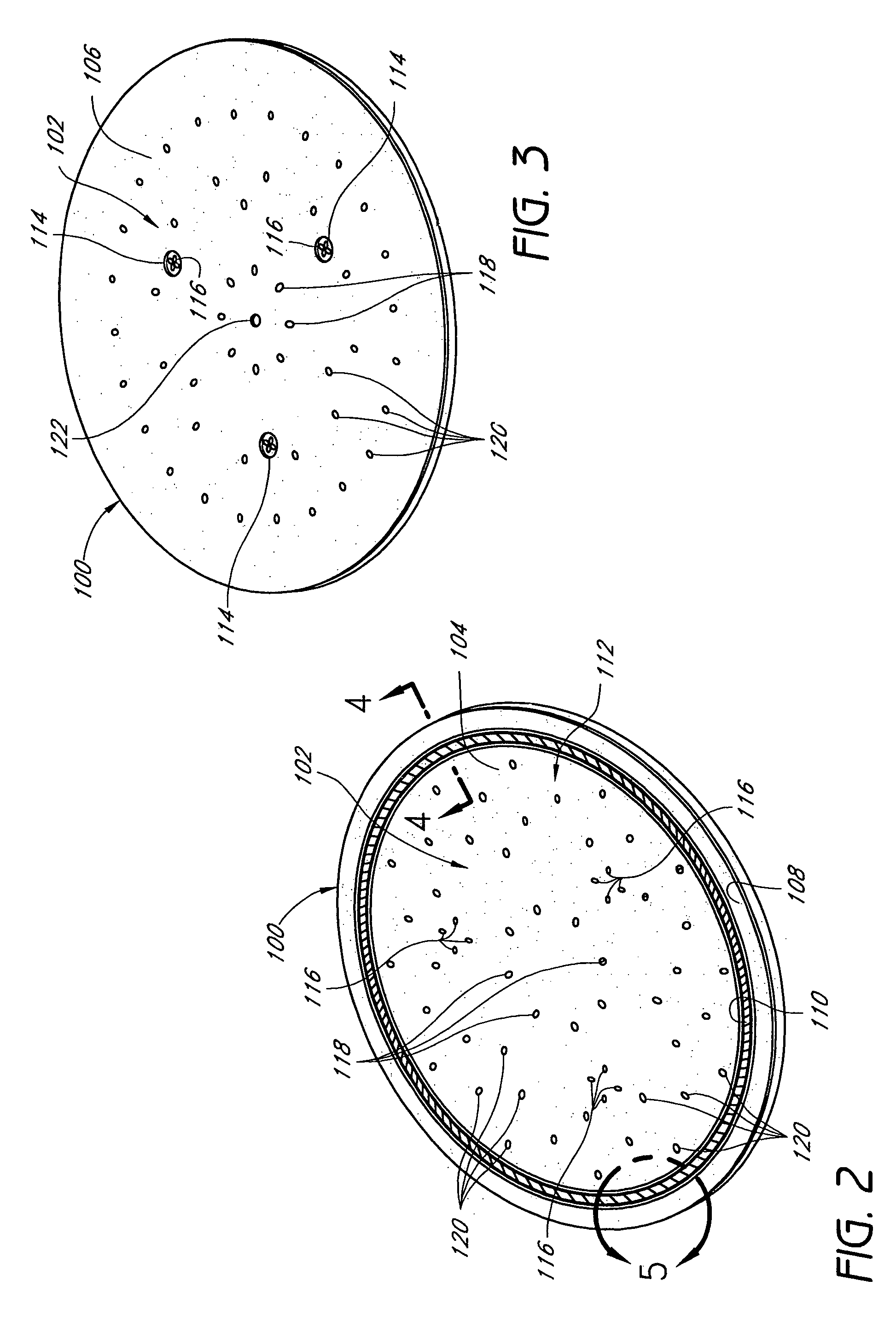

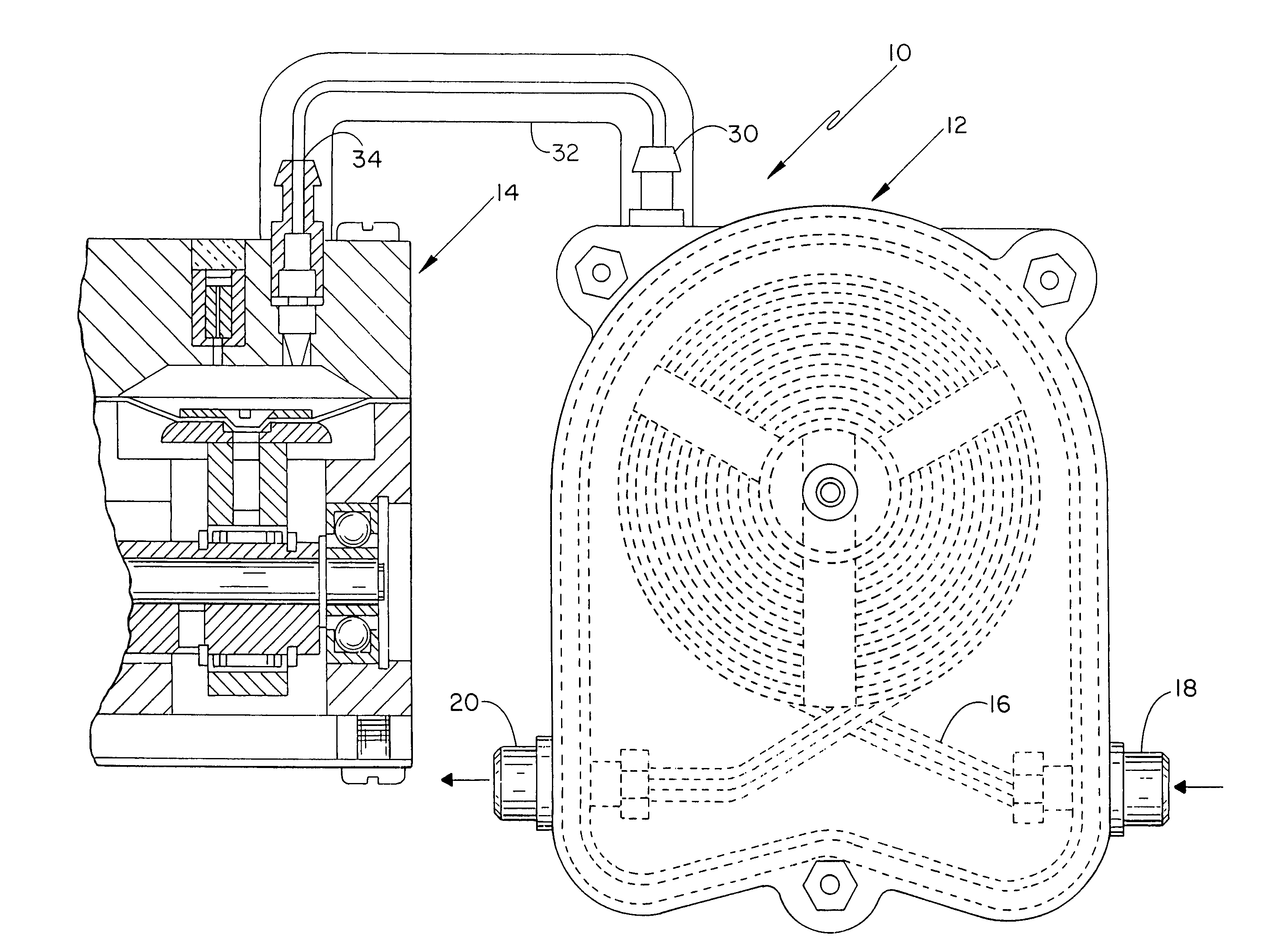

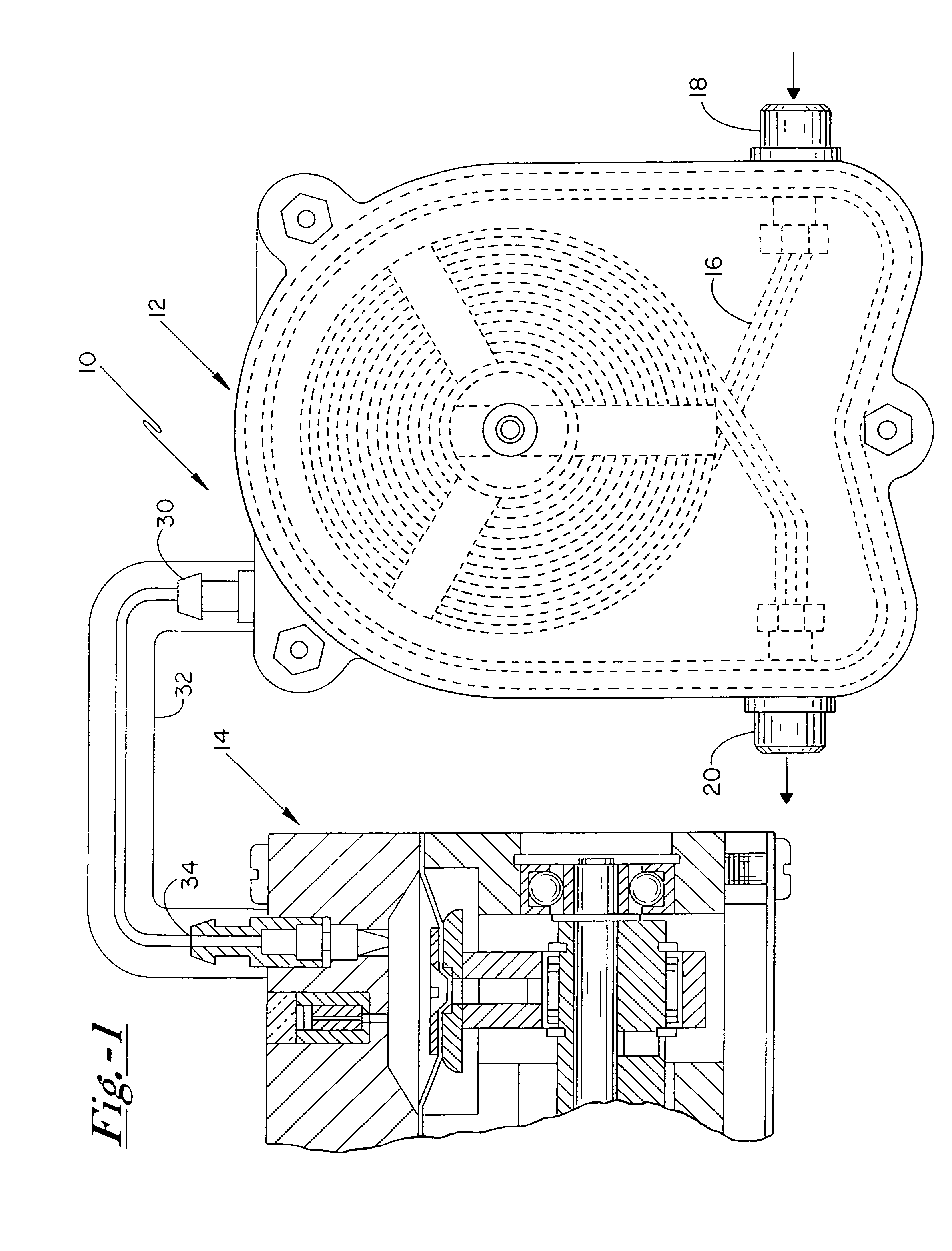

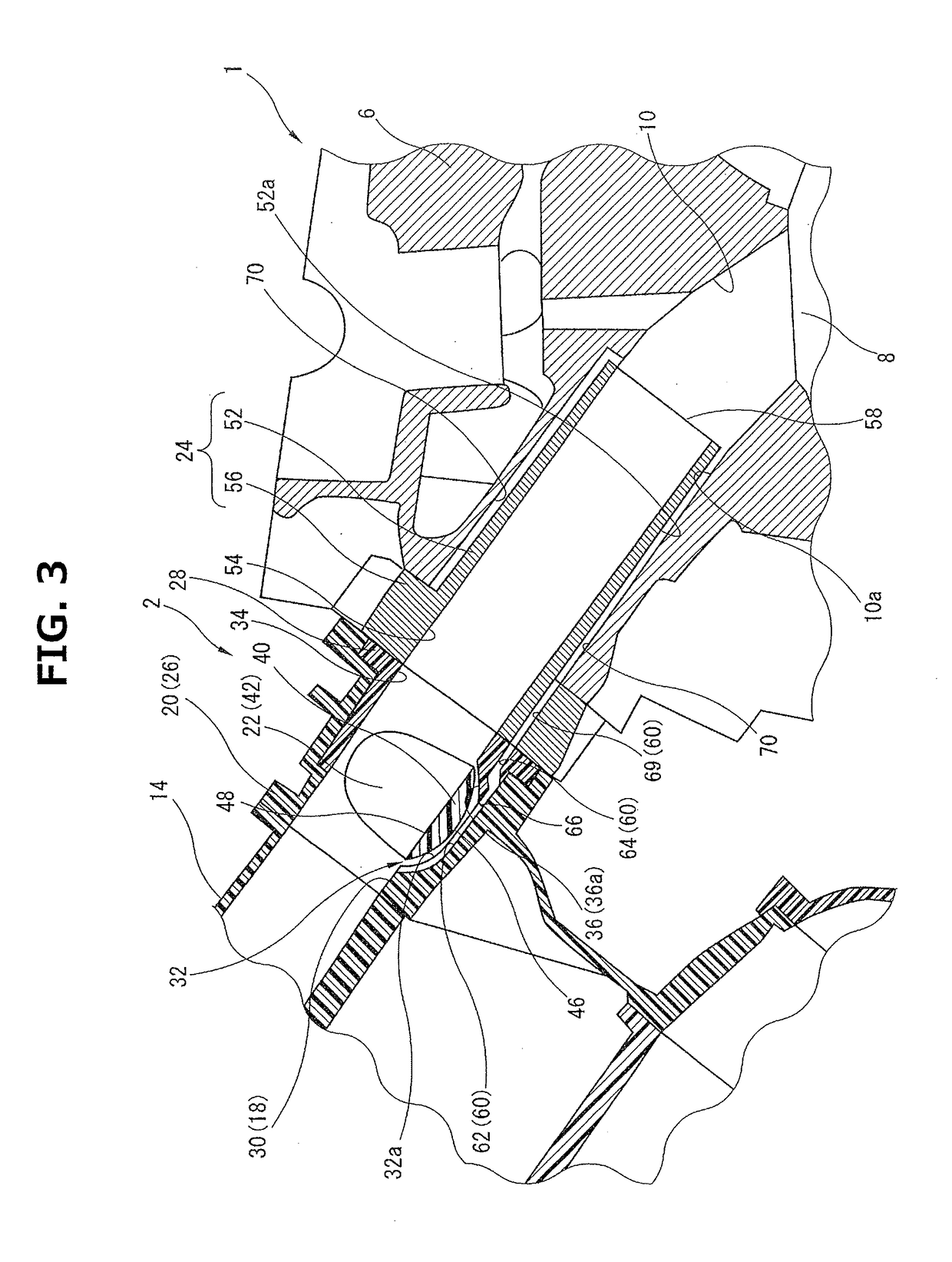

Substrate support system for reduced autodoping and backside deposition

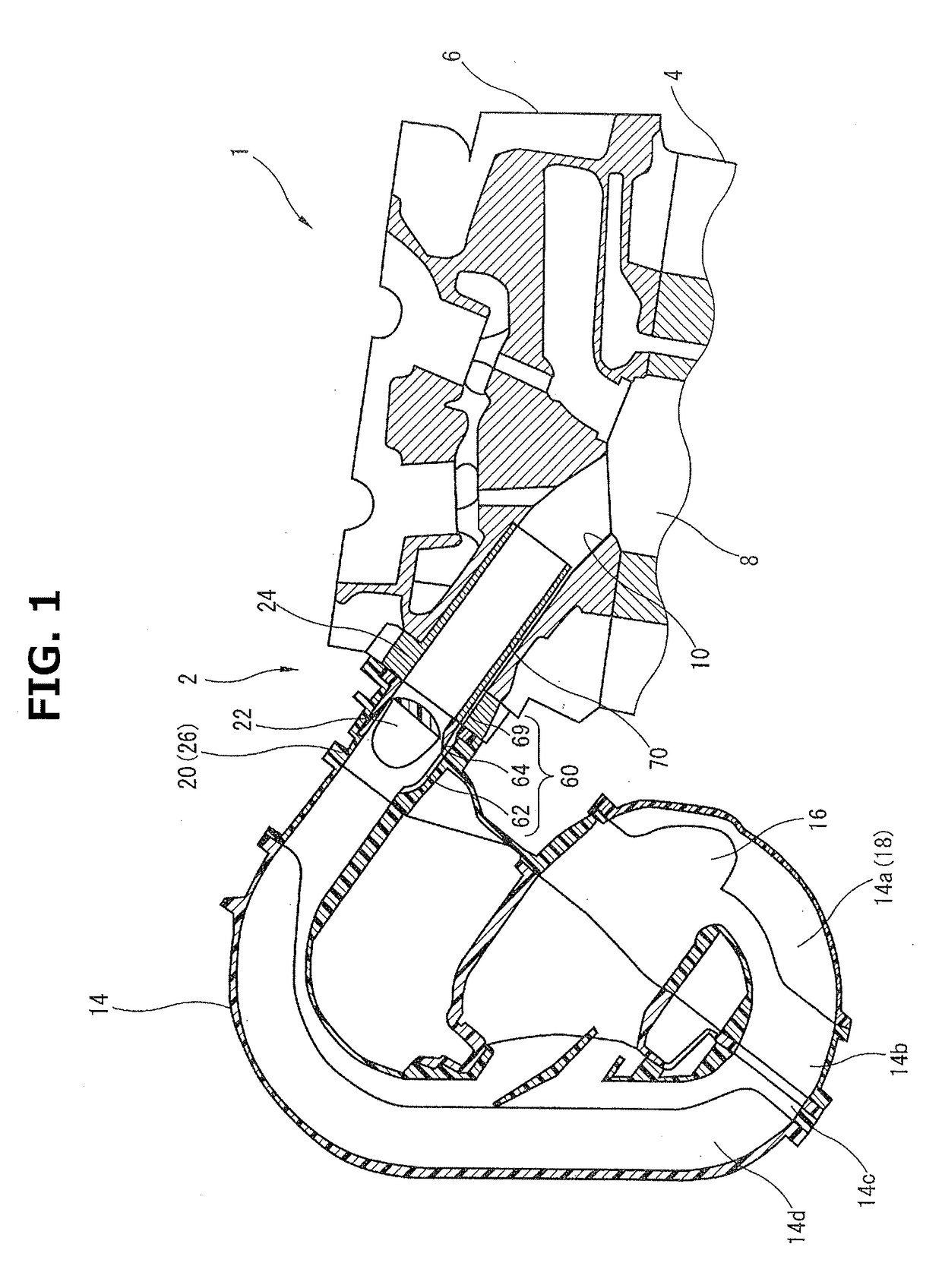

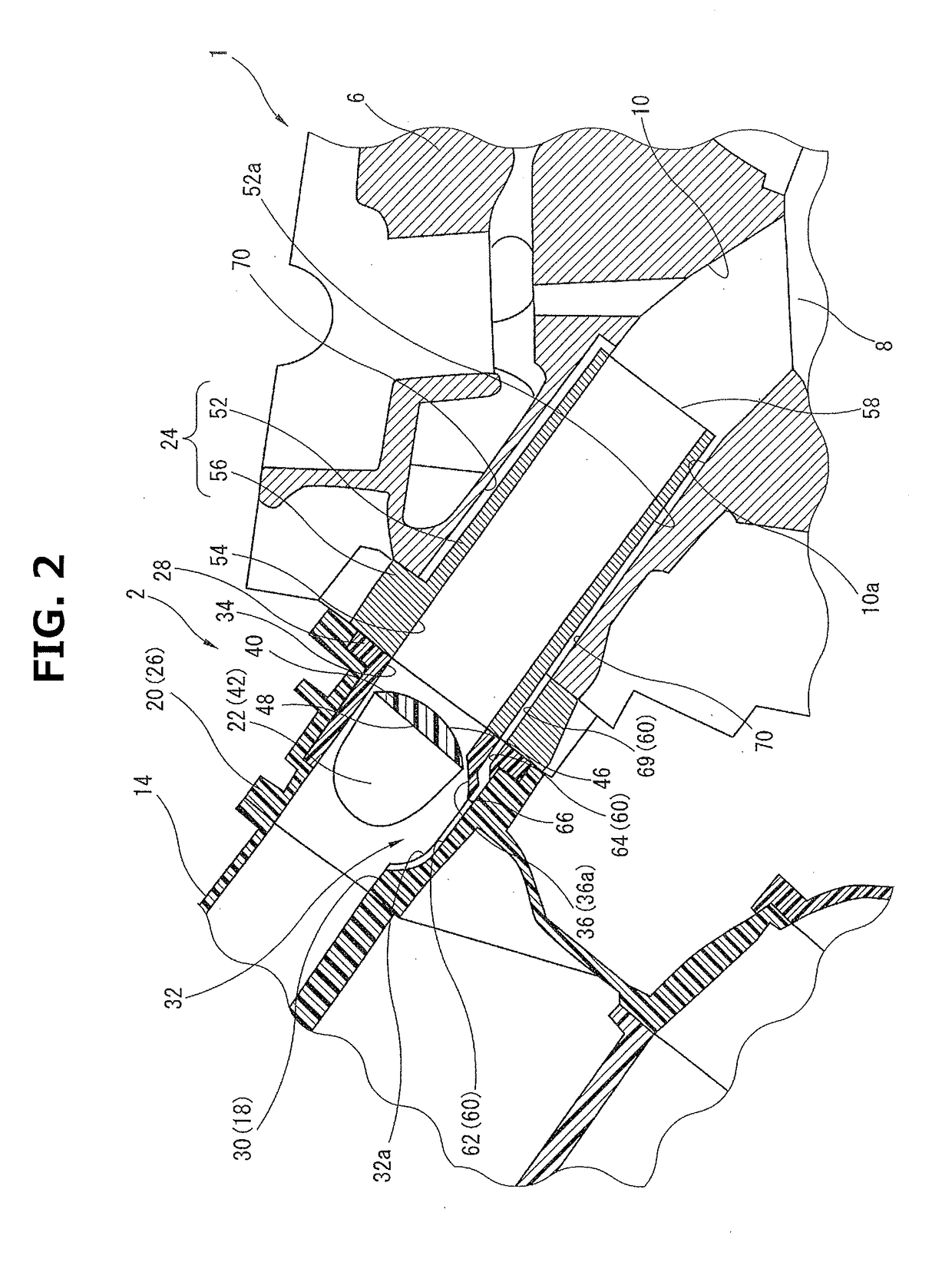

ActiveUS20050193952A1Speed up gas flowAvoid flowLiquid surface applicatorsElectric discharge tubesSupporting systemEngineering

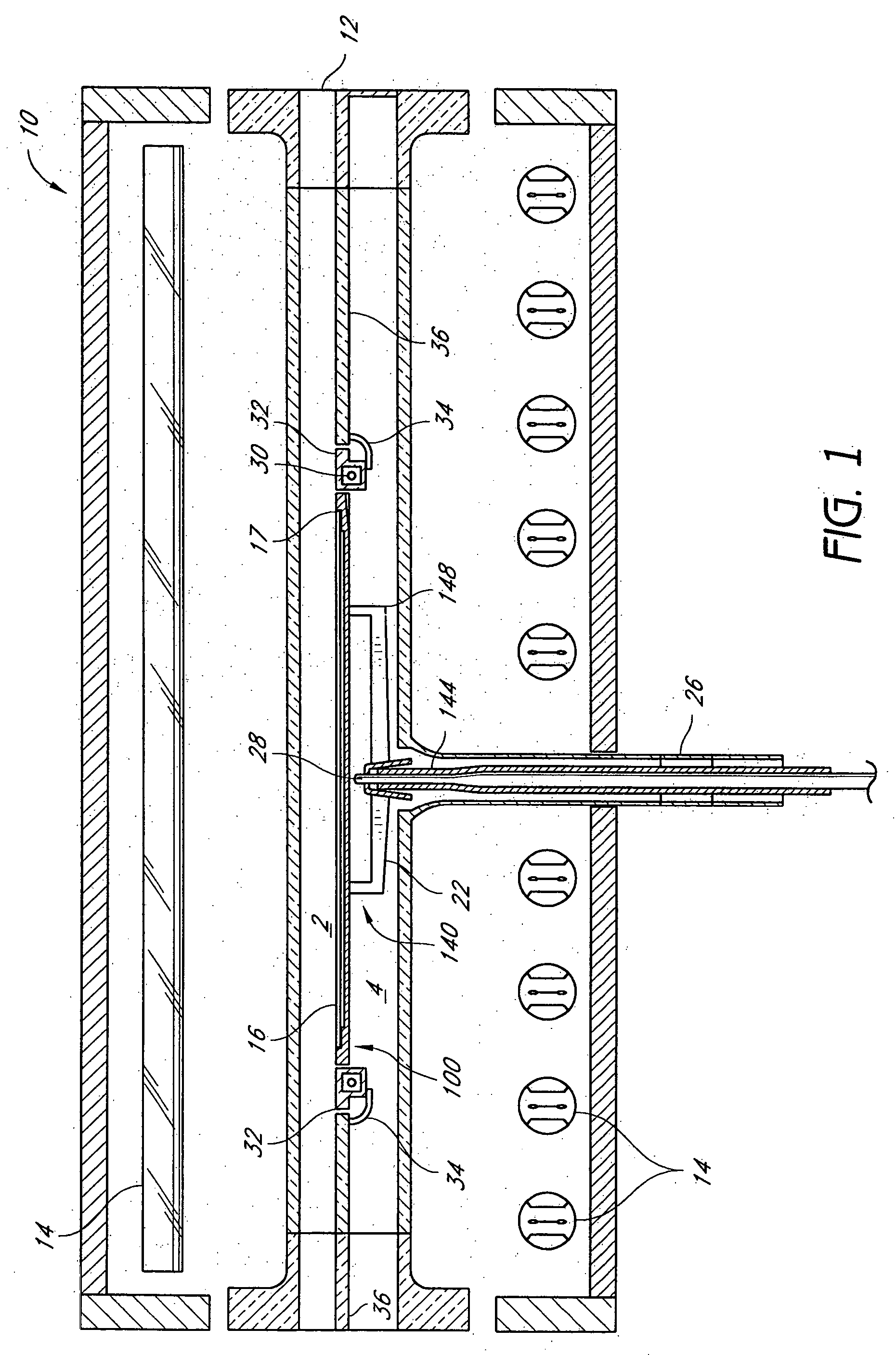

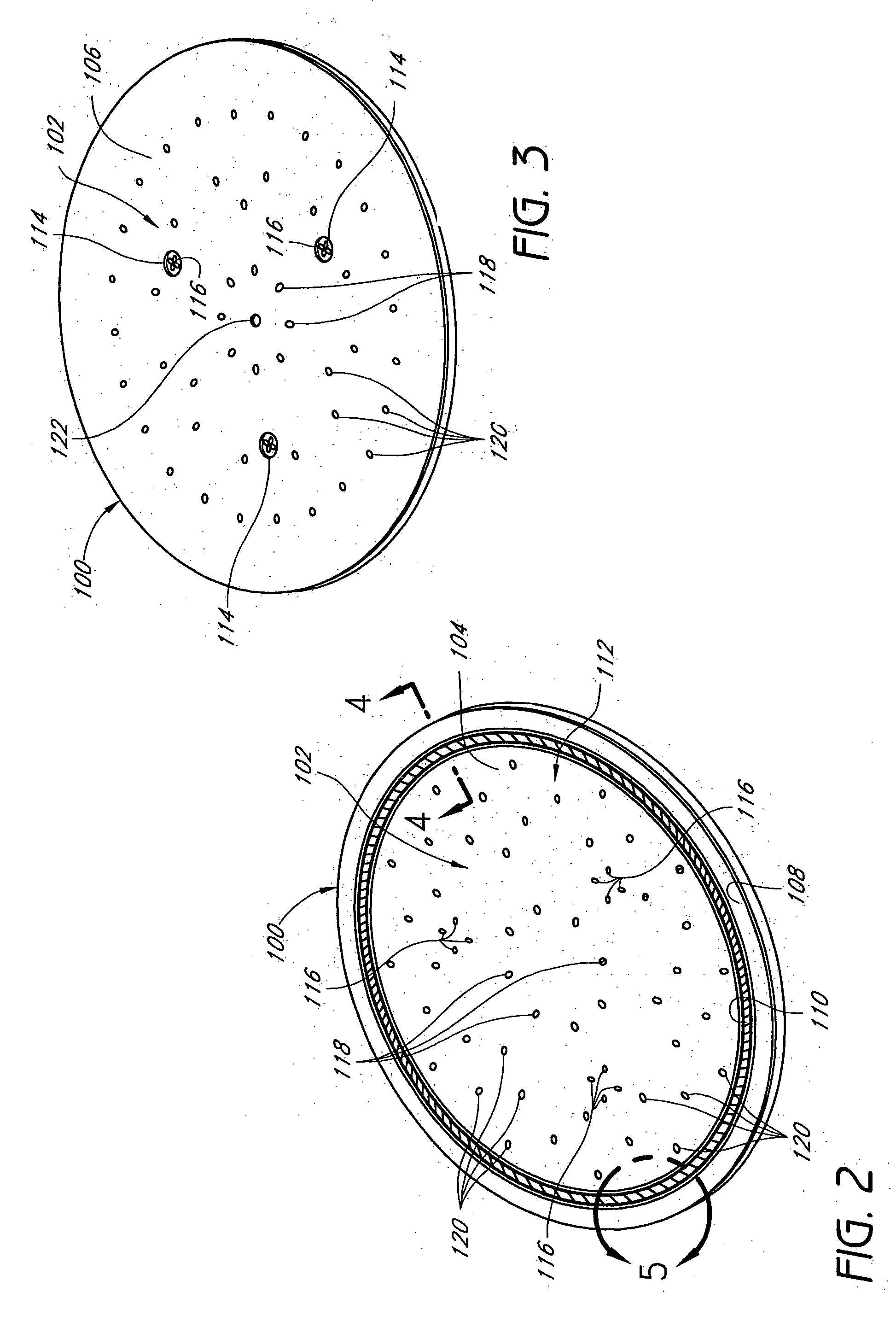

A substrate support system comprises a relatively thin circular substrate holder having a plurality of passages extending between top and bottom surfaces thereof. The substrate holder includes a single substrate support ledge or a plurality of substrate support spacer vanes configured to support a peripheral portion of the substrate backside so that a thin gap is formed between the substrate and the substrate holder. The vanes can be angled to resist backside deposition of reactant gases as the substrate holder is rotated. A hollow support member provides support to an underside of the substrate holder. The hollow support member is configured to convey gas (e.g., inert gas or cleaning gas) upward into one or more of the passages of the substrate holder. The upwardly conveyed gas flows into the gap between the substrate and the substrate holder. Depending upon the embodiment of the invention, the gas in the gap can then flow either (1) outward and upward around the substrate edge or (2) downward through passages of the substrate holder, if any, that do not lead back into the hollow support member. The gas that flows outward and upward around the substrate edge inhibits backside deposition of reactant gases above the substrate. The gas that flows downward through the passages that do not lead back to the support member advantageously inhibits autodoping by sweeping out-diffused dopant atoms away from the substrate front side. In one embodiment, the support member comprises a hollow multi-armed support spider that conveys gas into selected ones of the passages. In another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all of the passages. In yet another embodiment, the support member comprises a bowl- or cup-shaped structure that conveys gas upward into all but one or more of the passages.

Owner:ASM IP HLDG BV

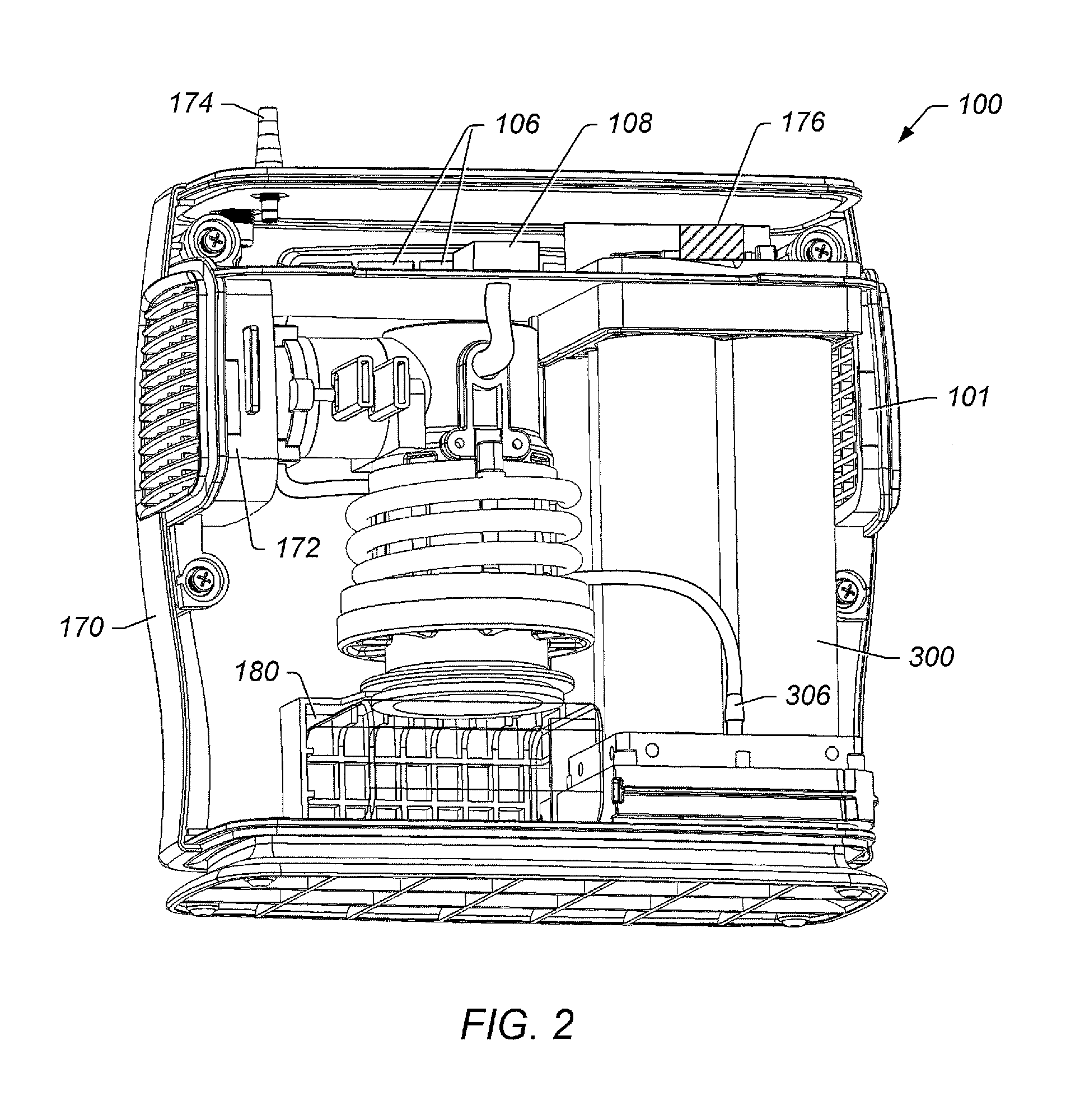

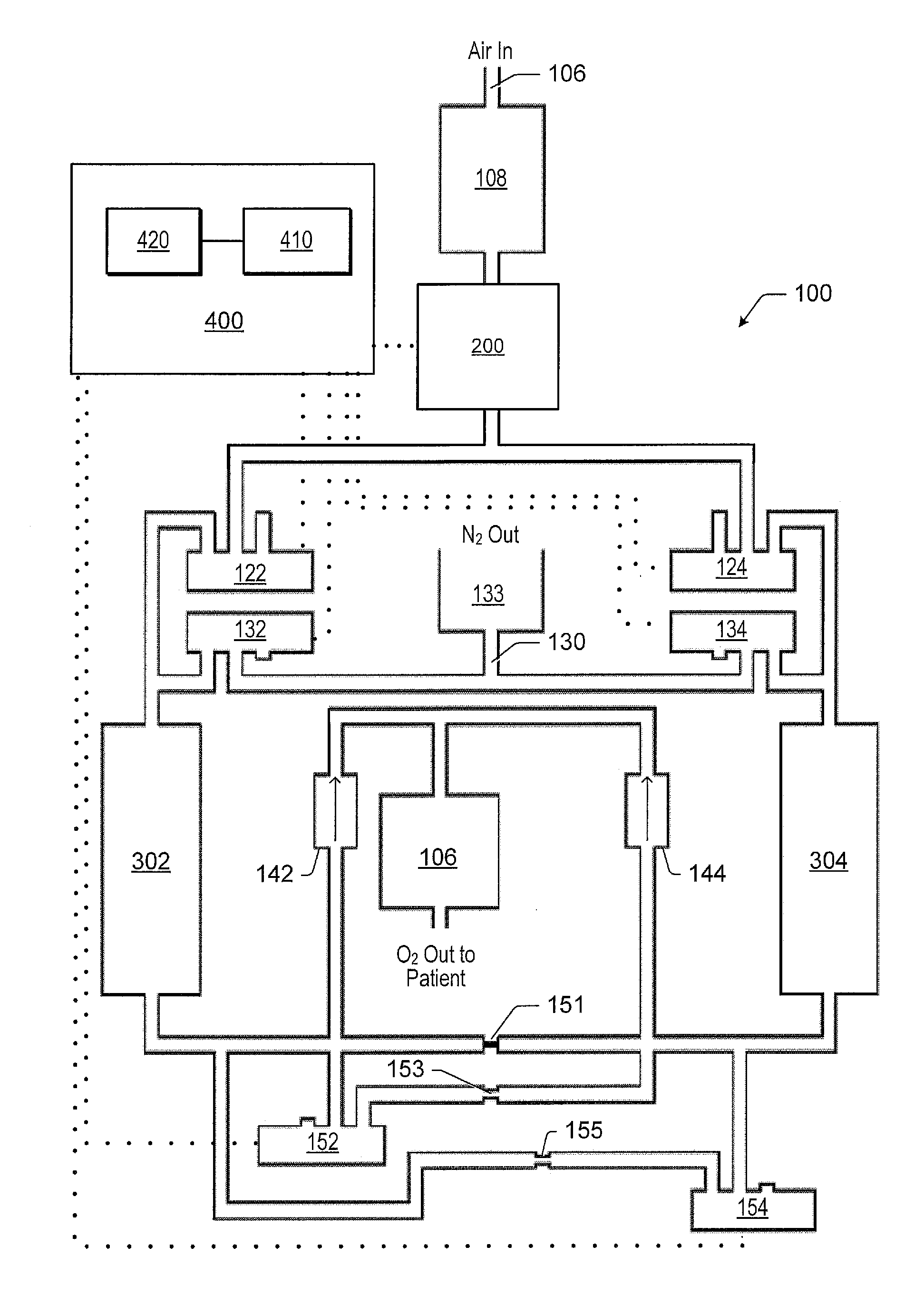

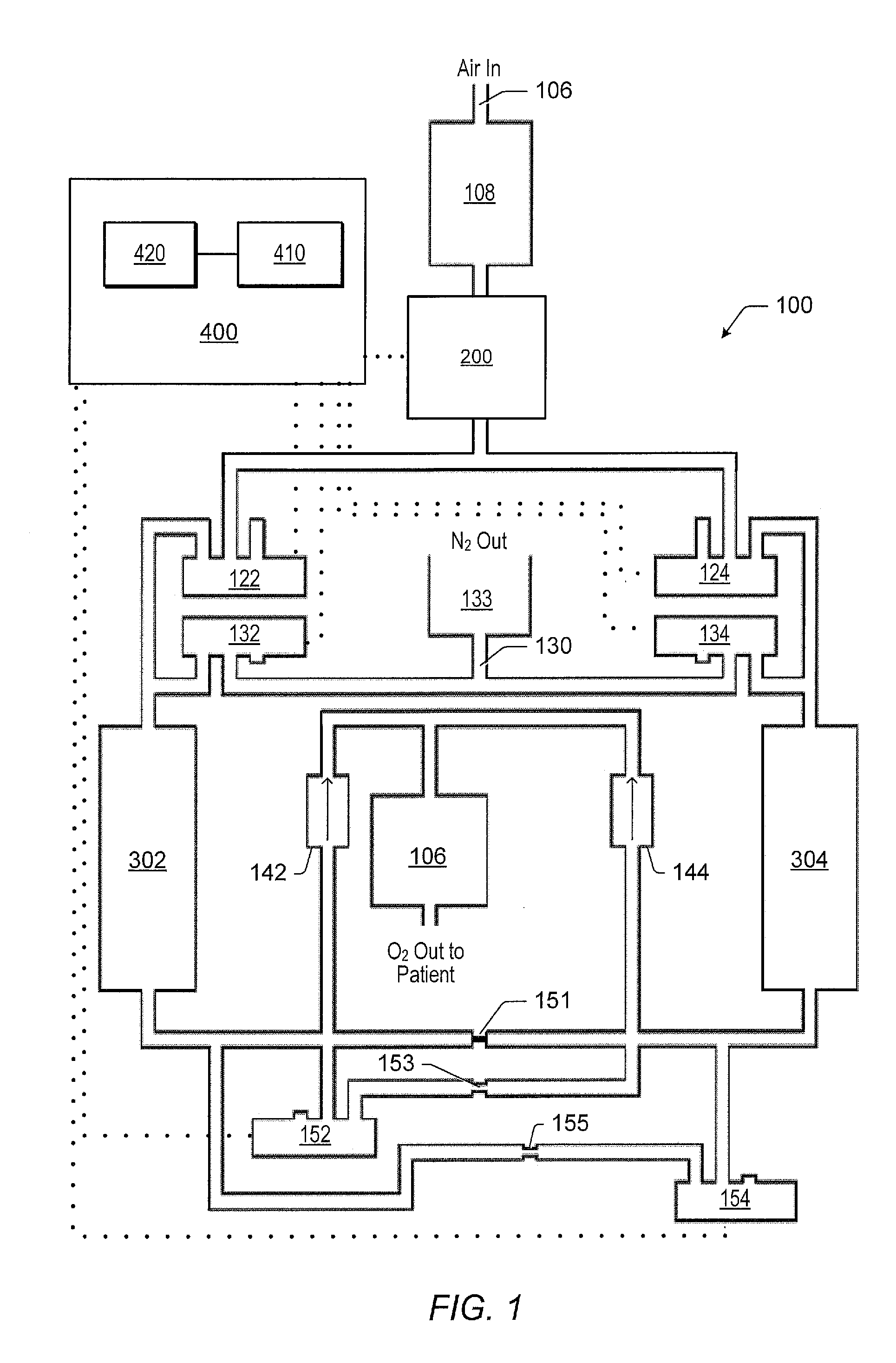

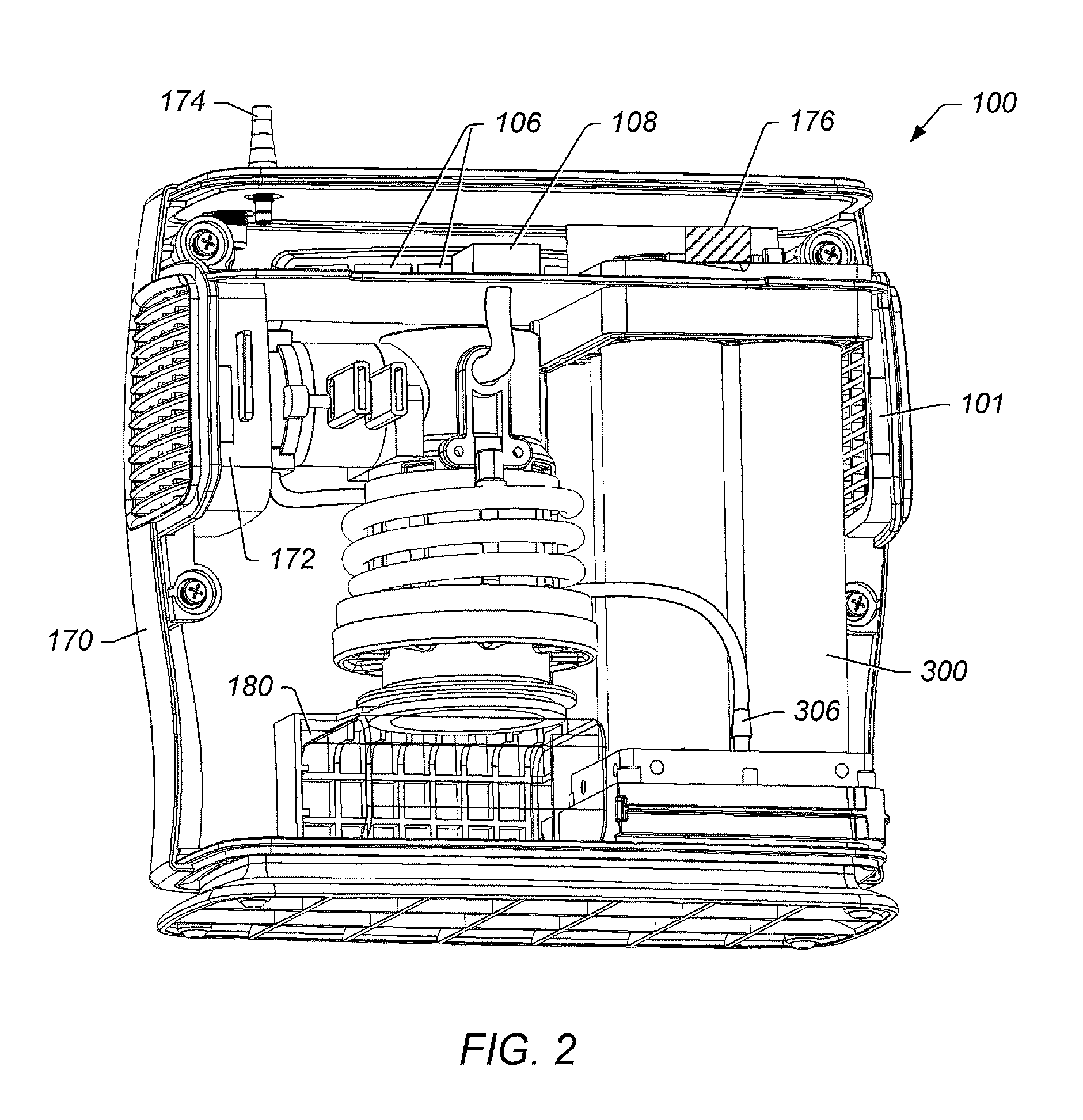

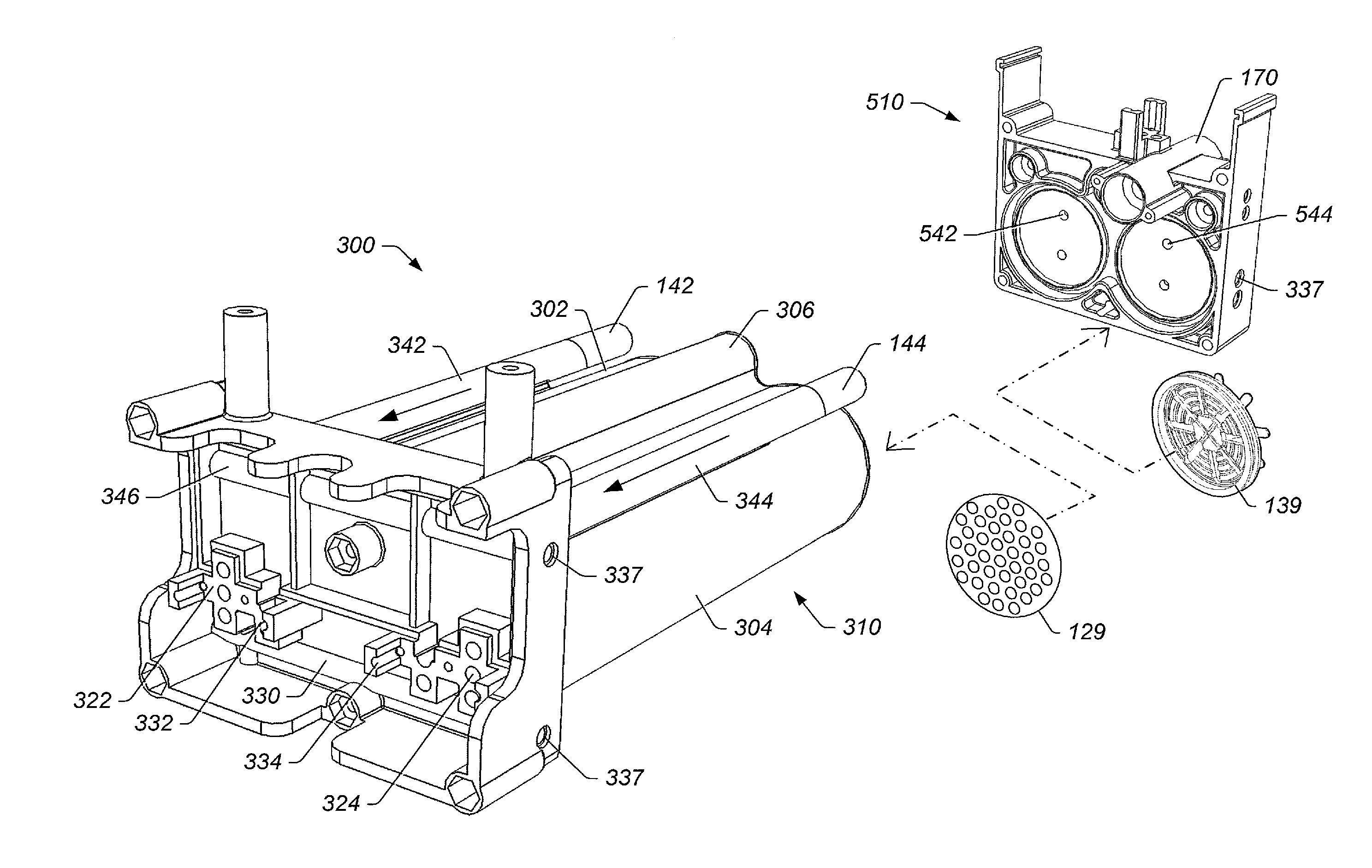

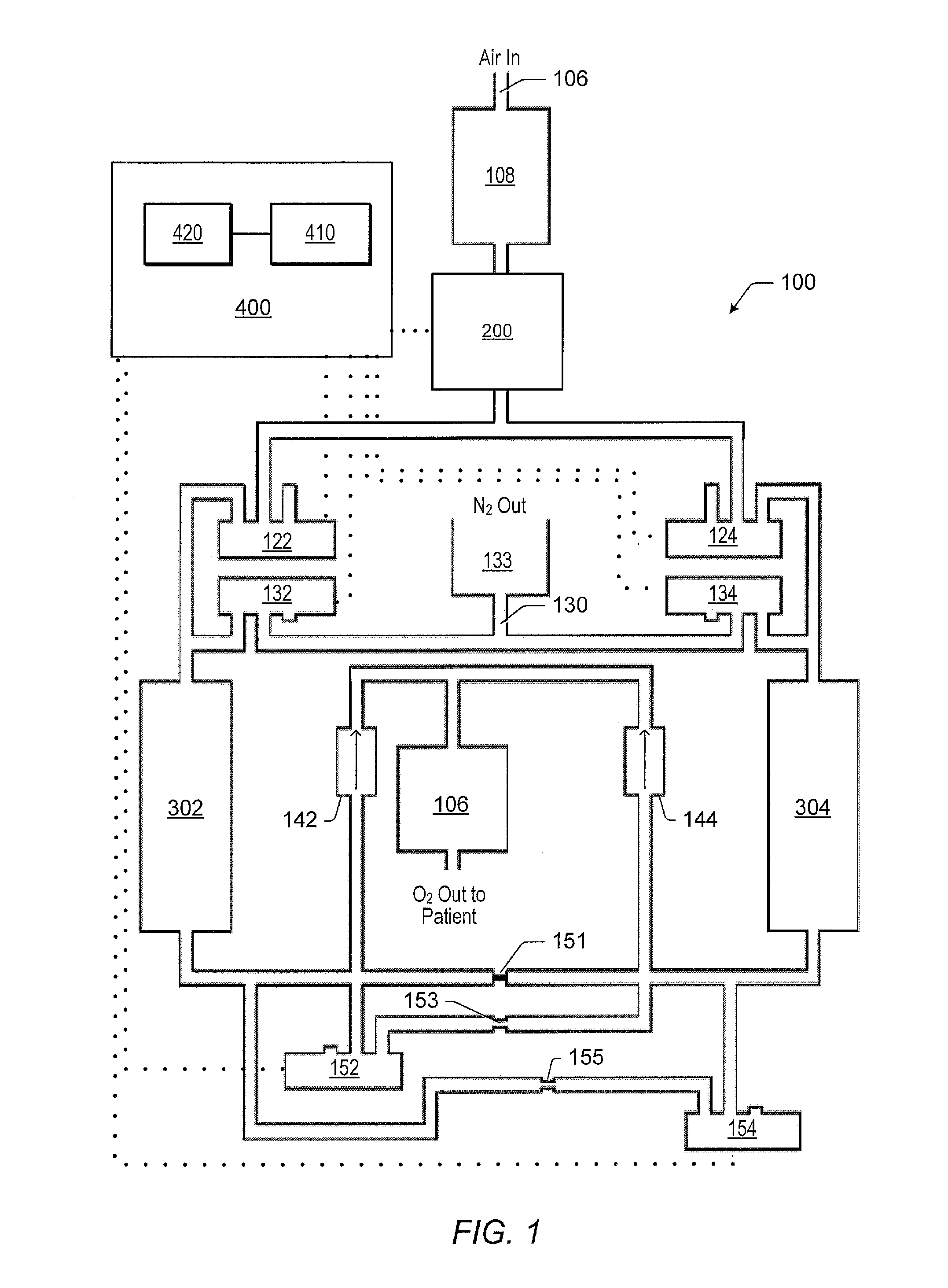

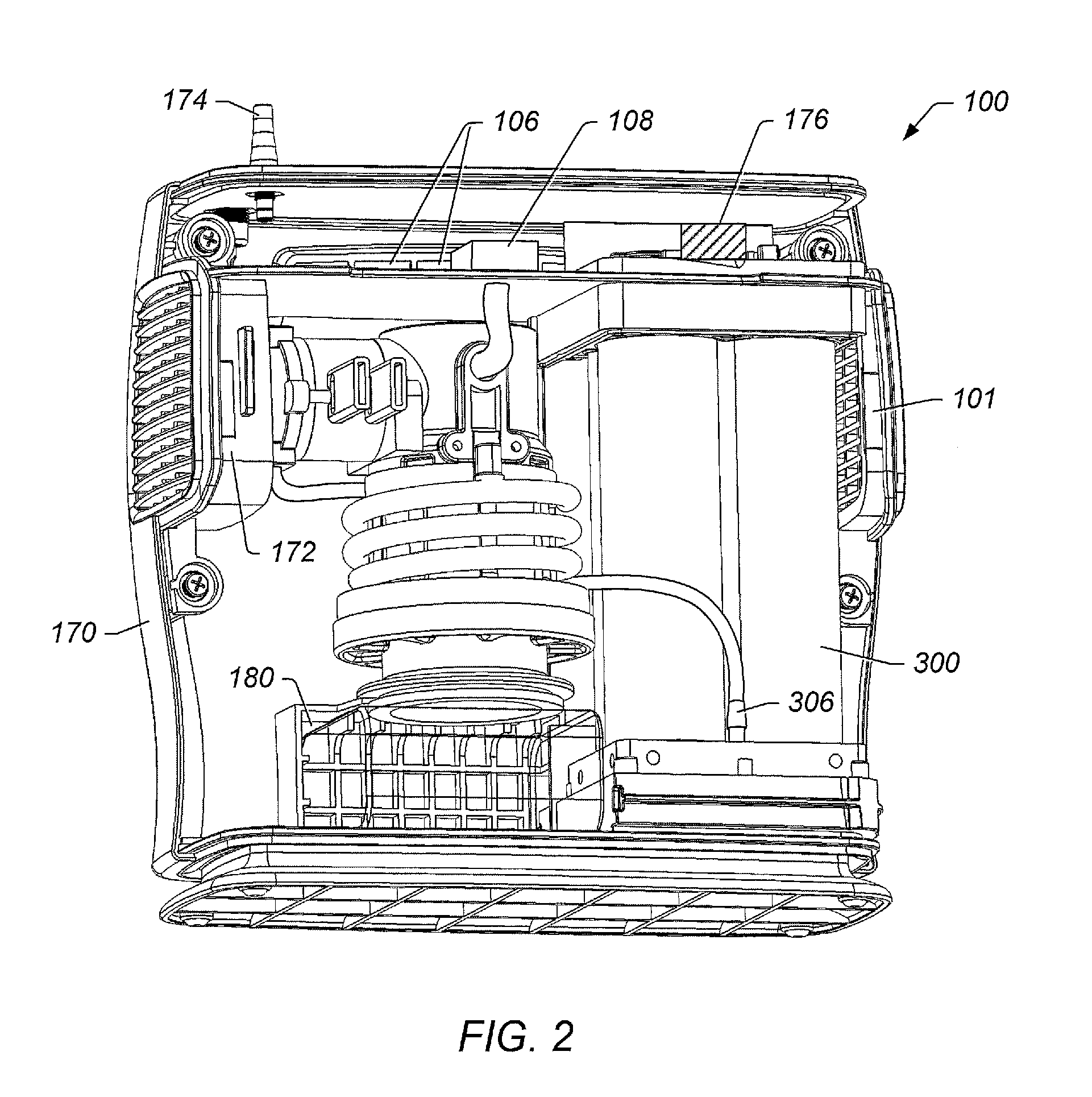

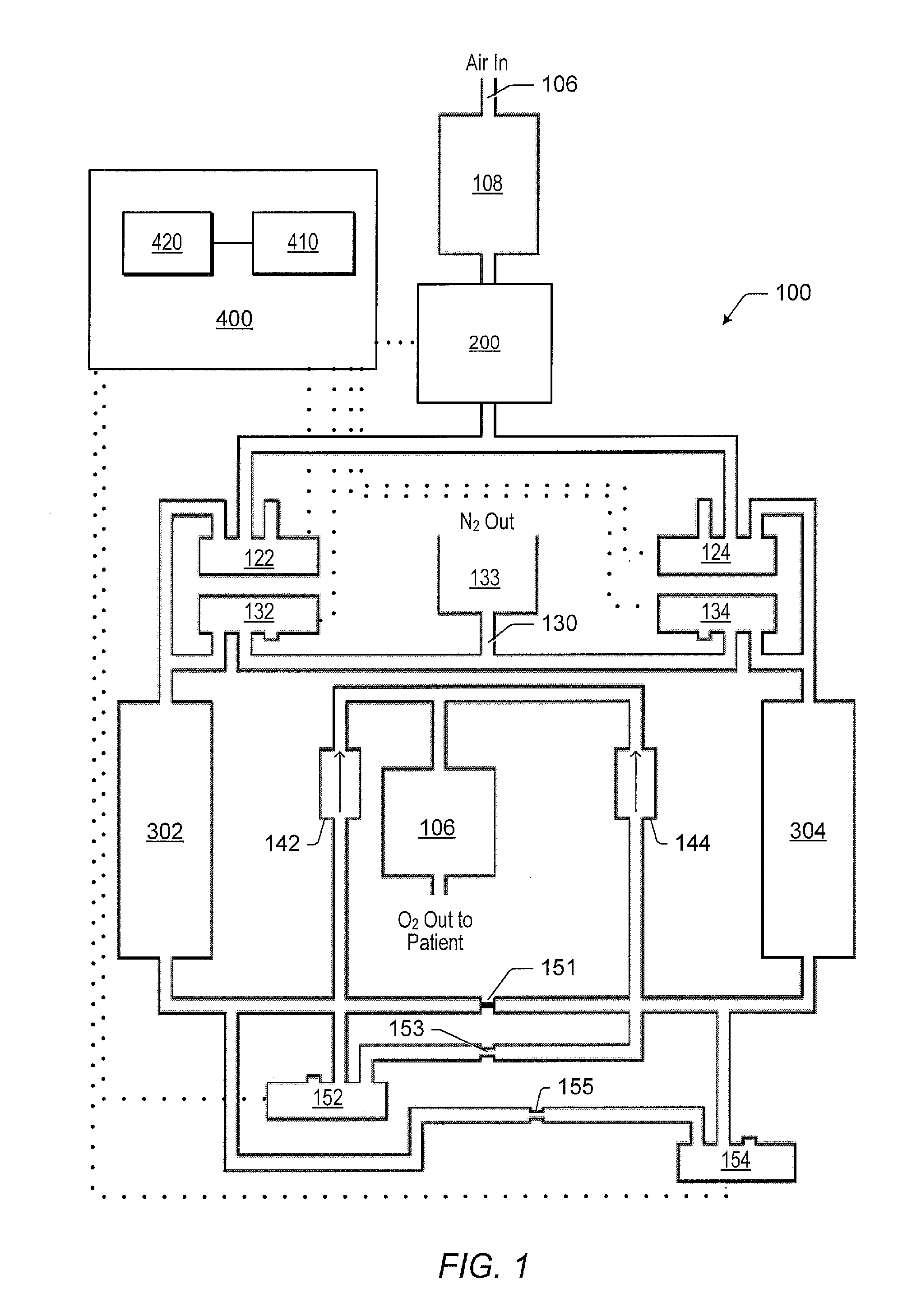

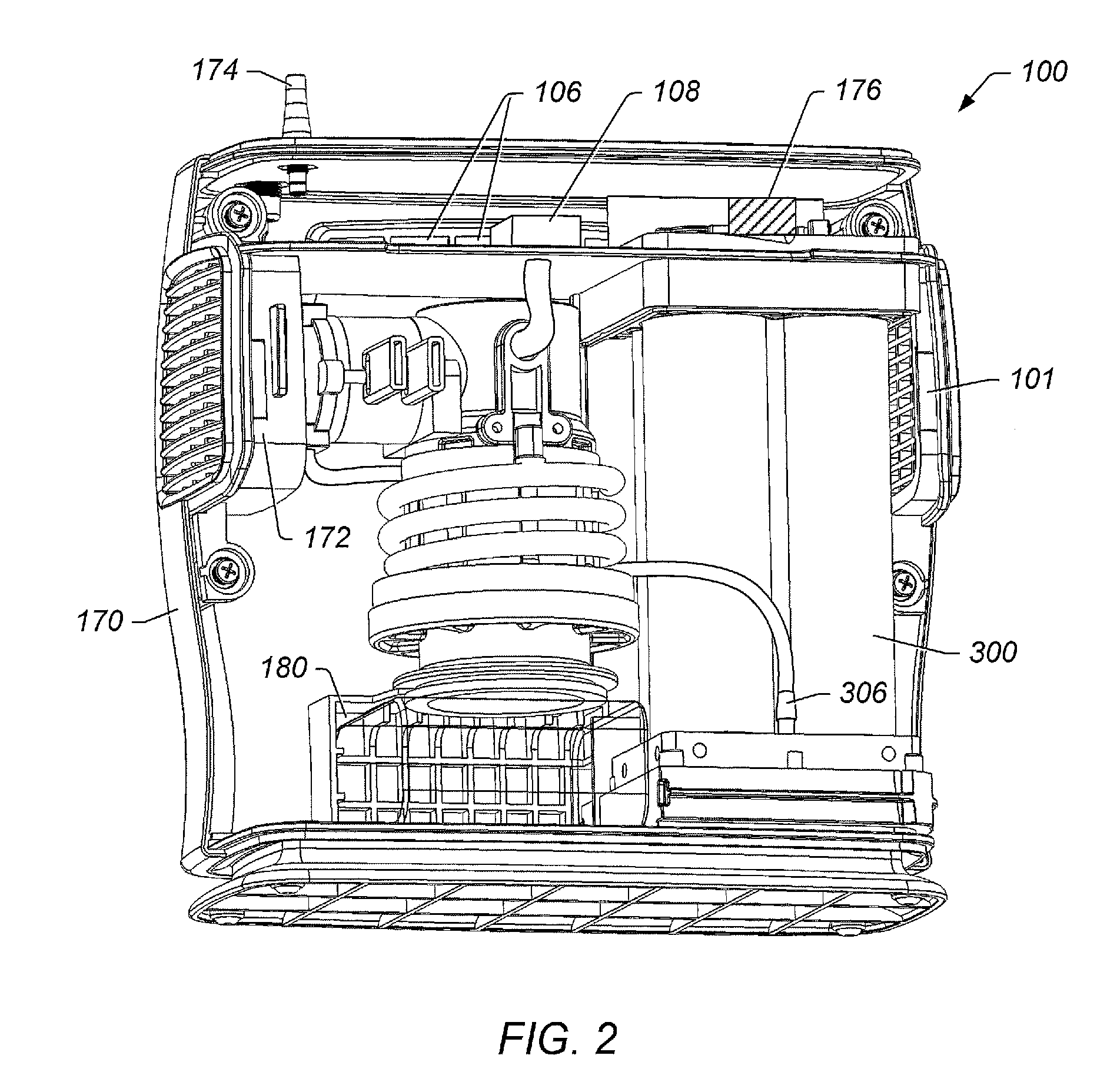

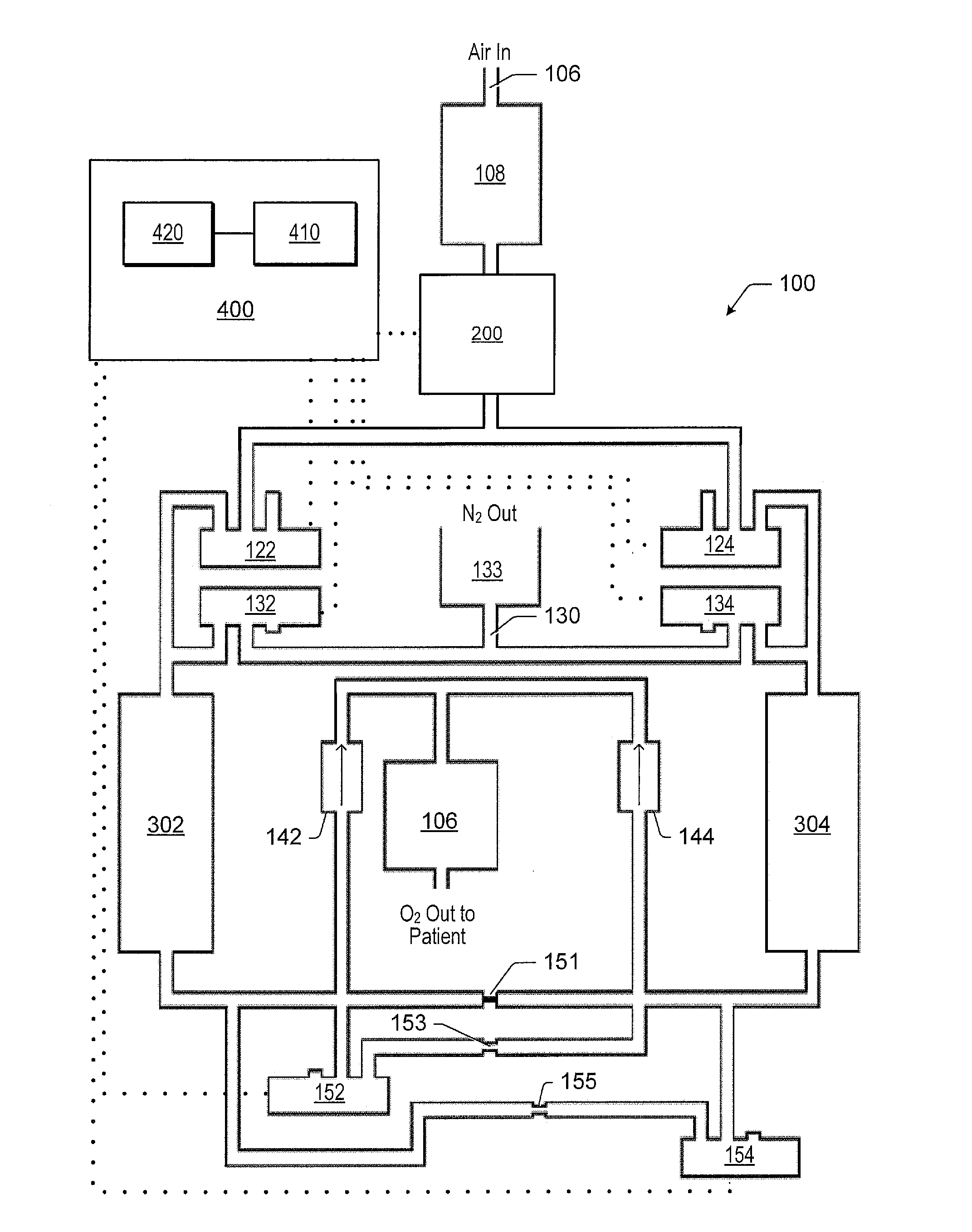

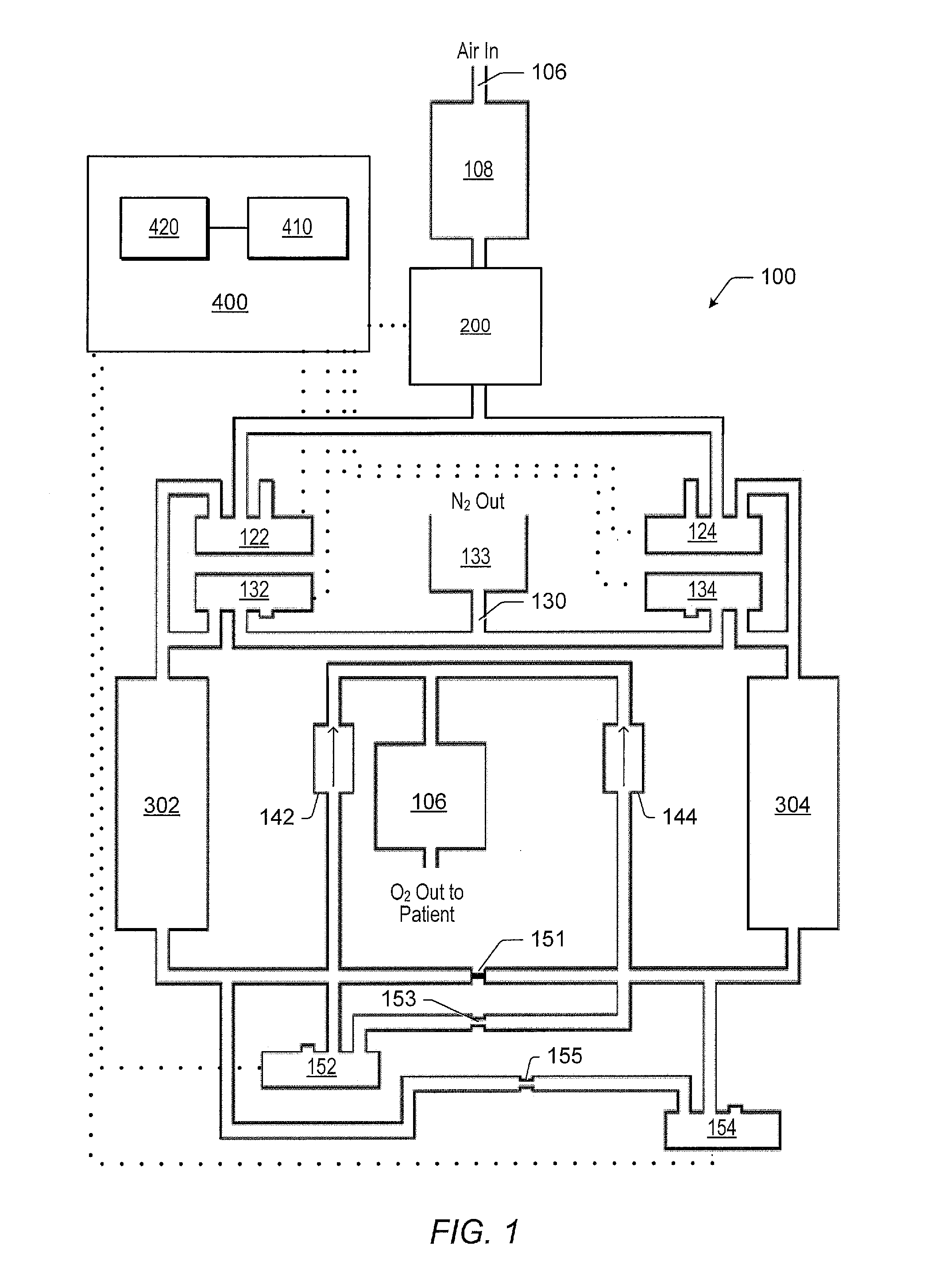

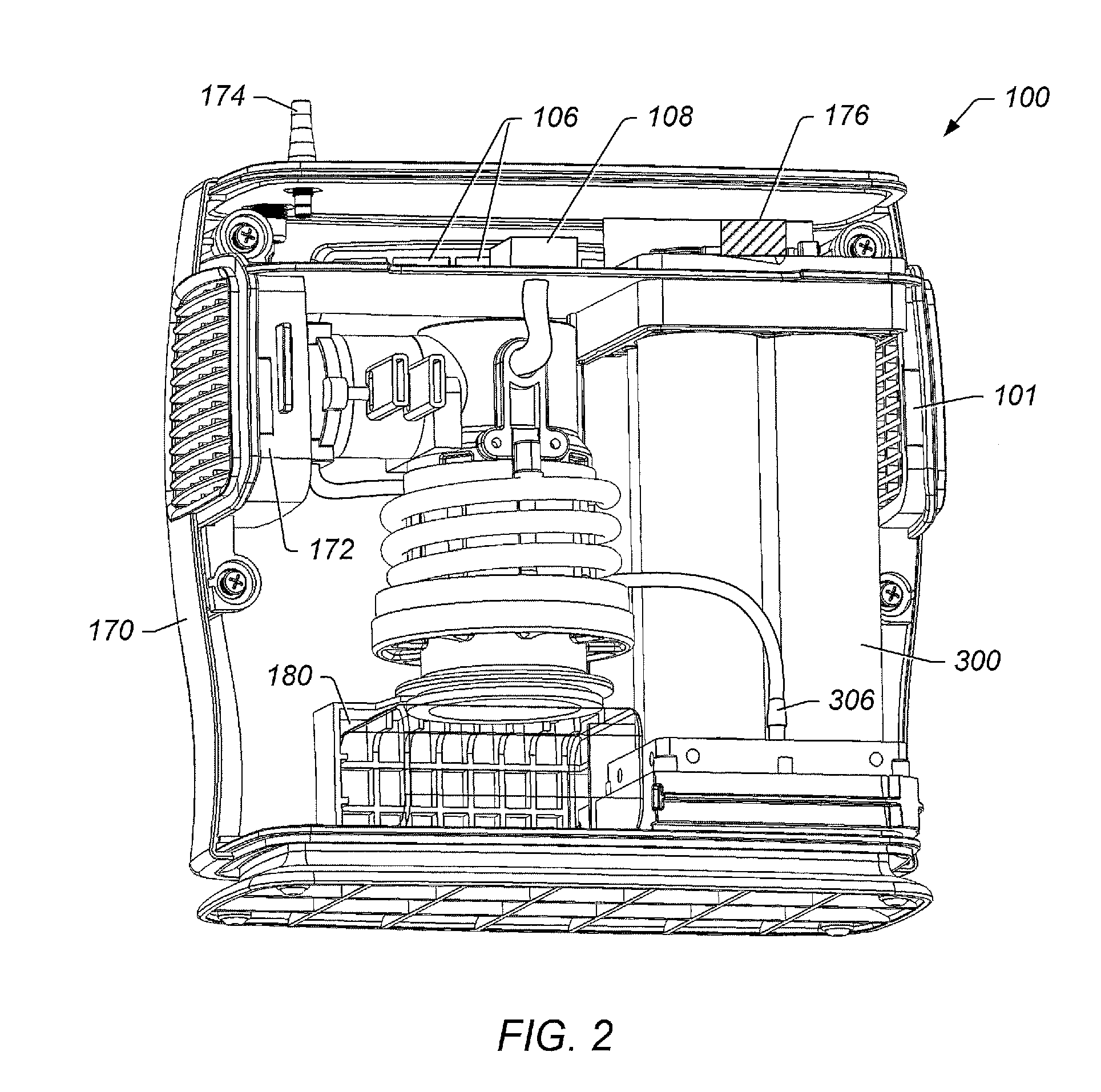

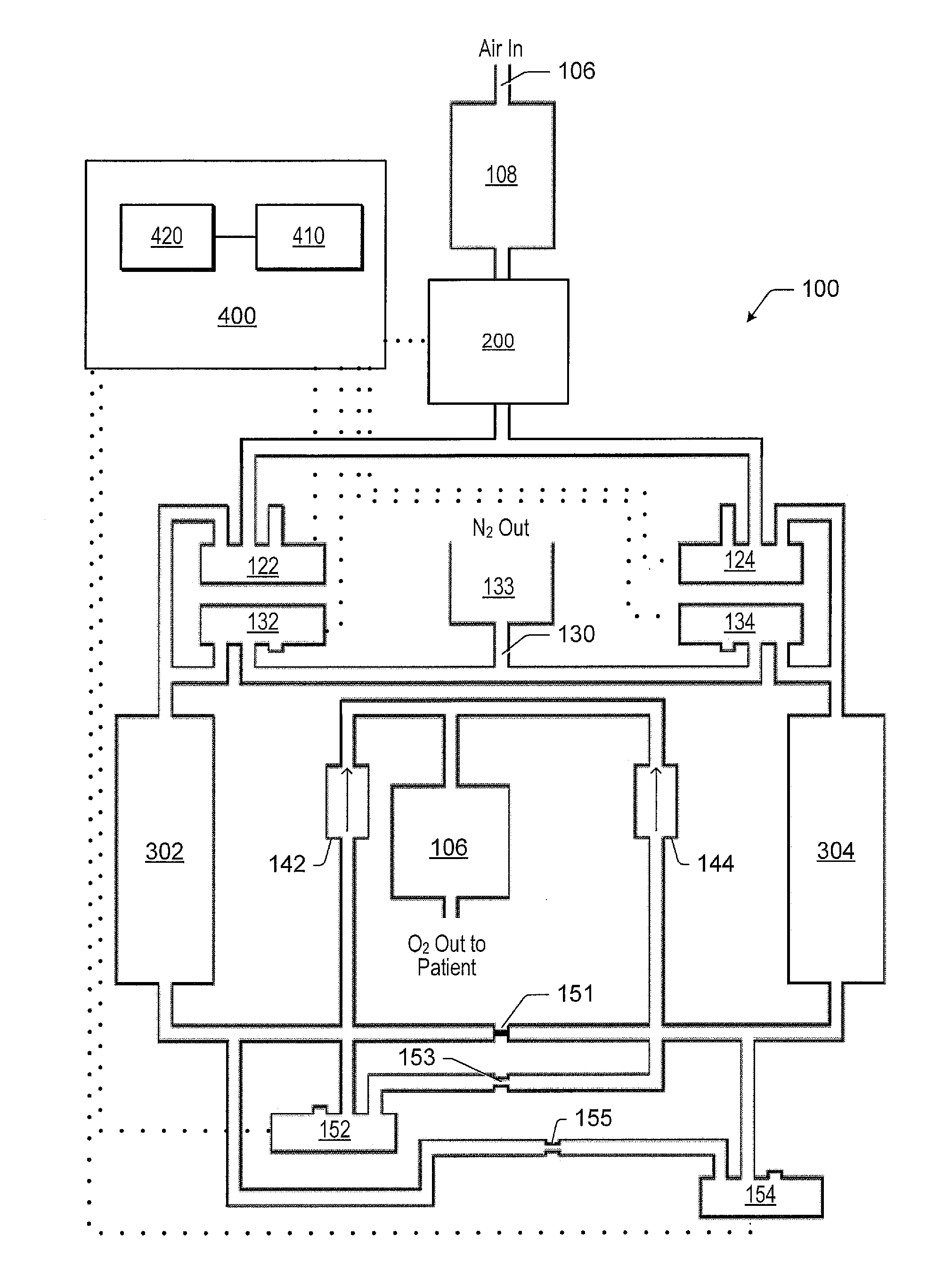

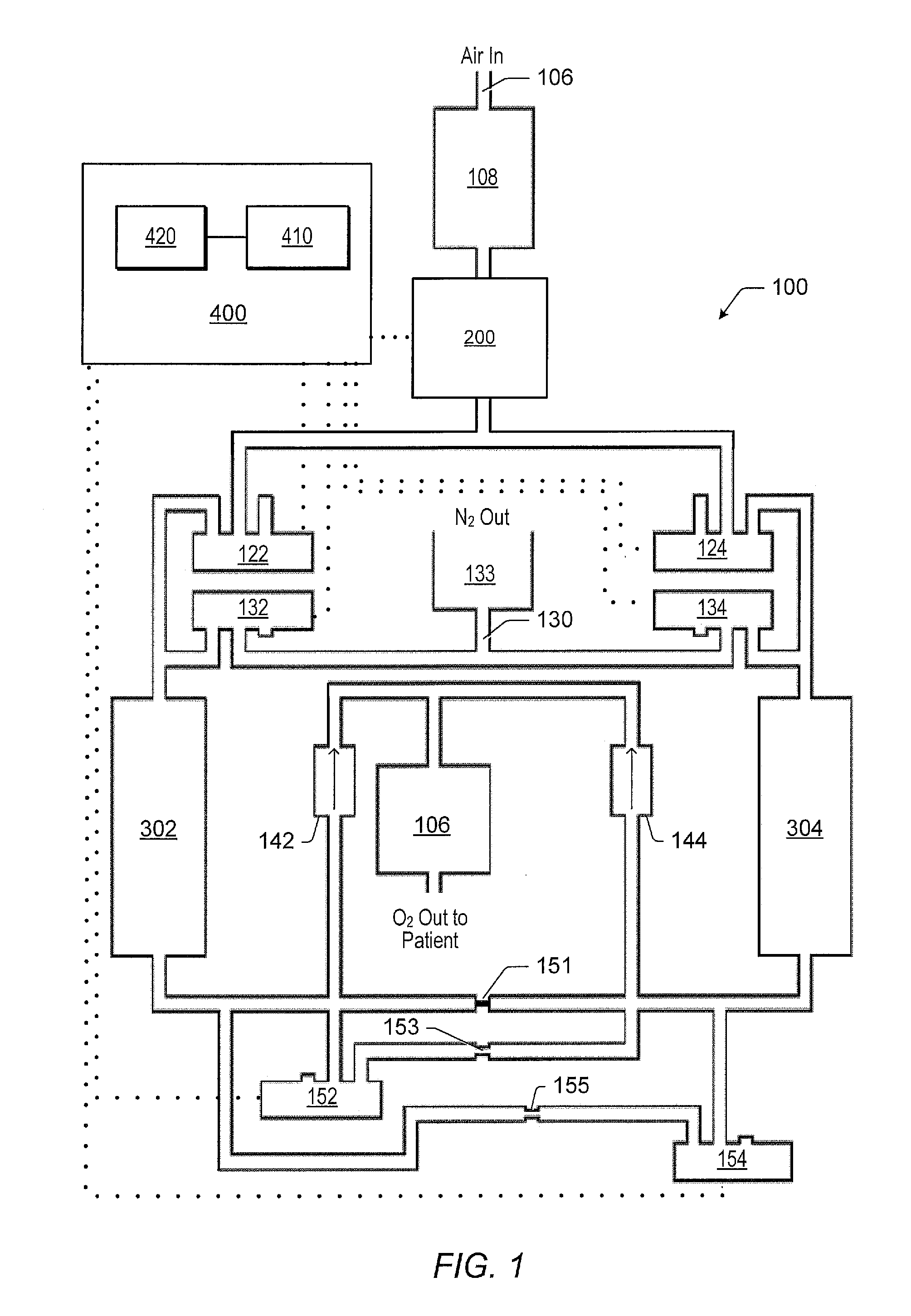

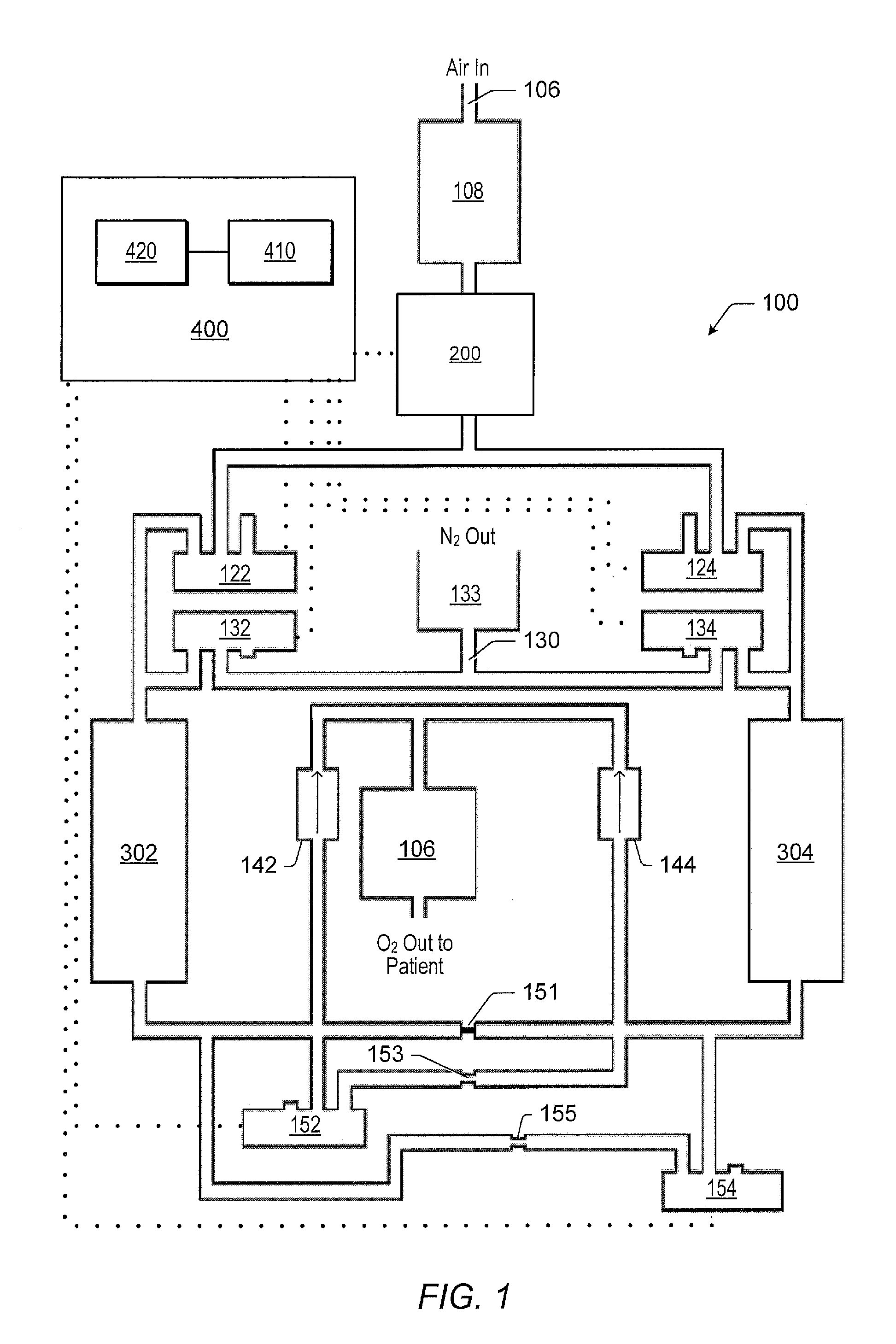

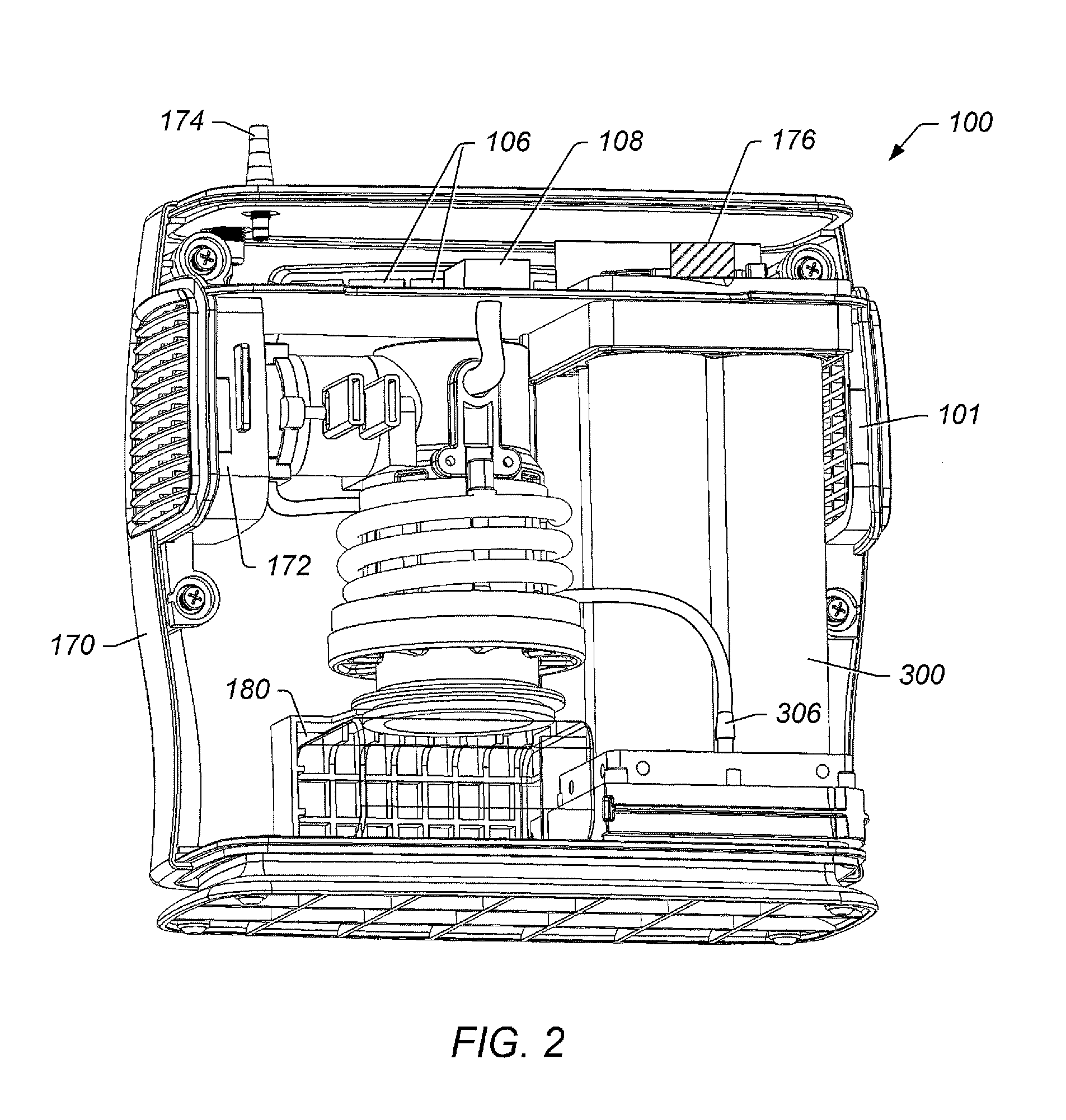

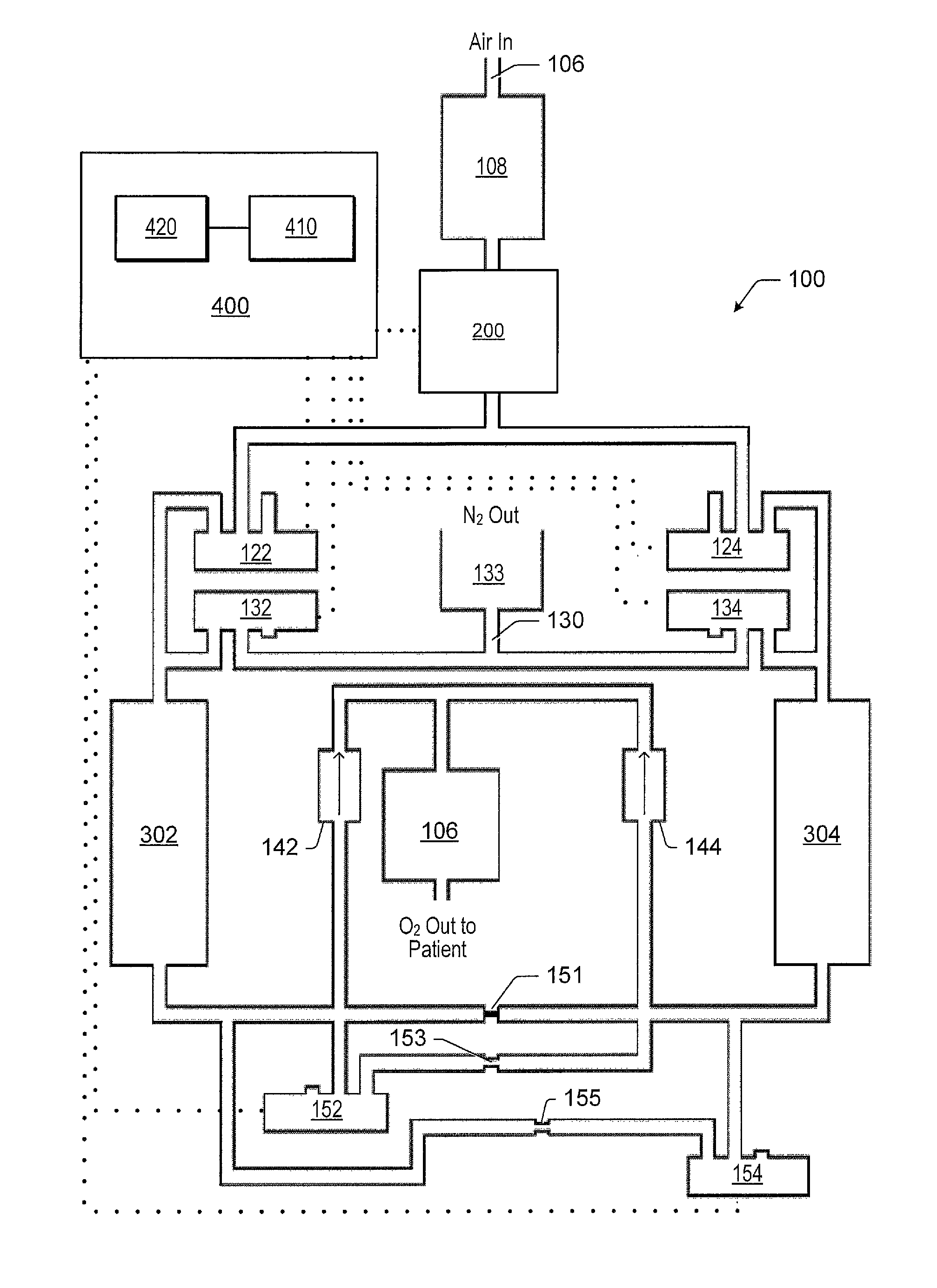

Power management systems and methods for use in an oxygen concentrator

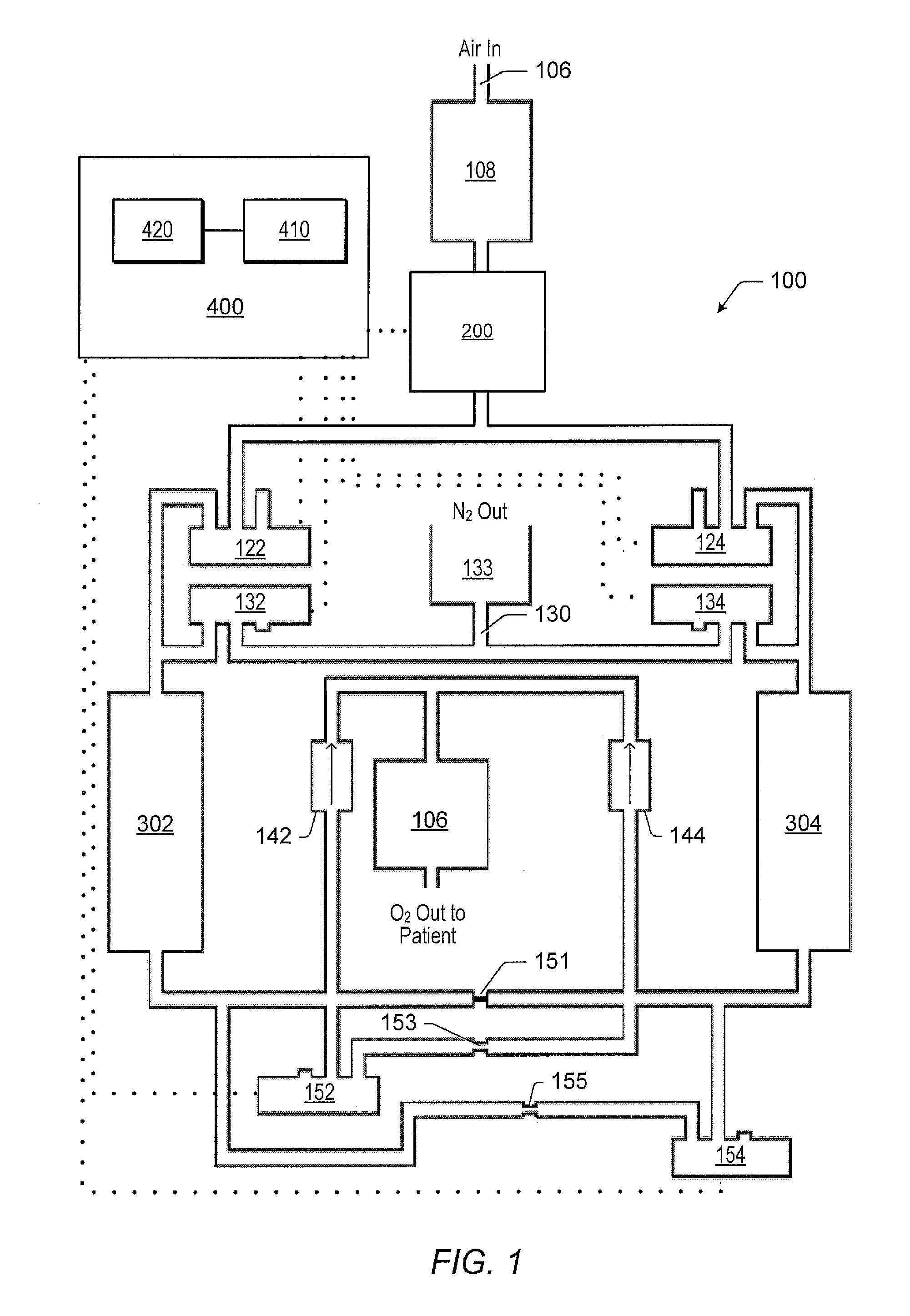

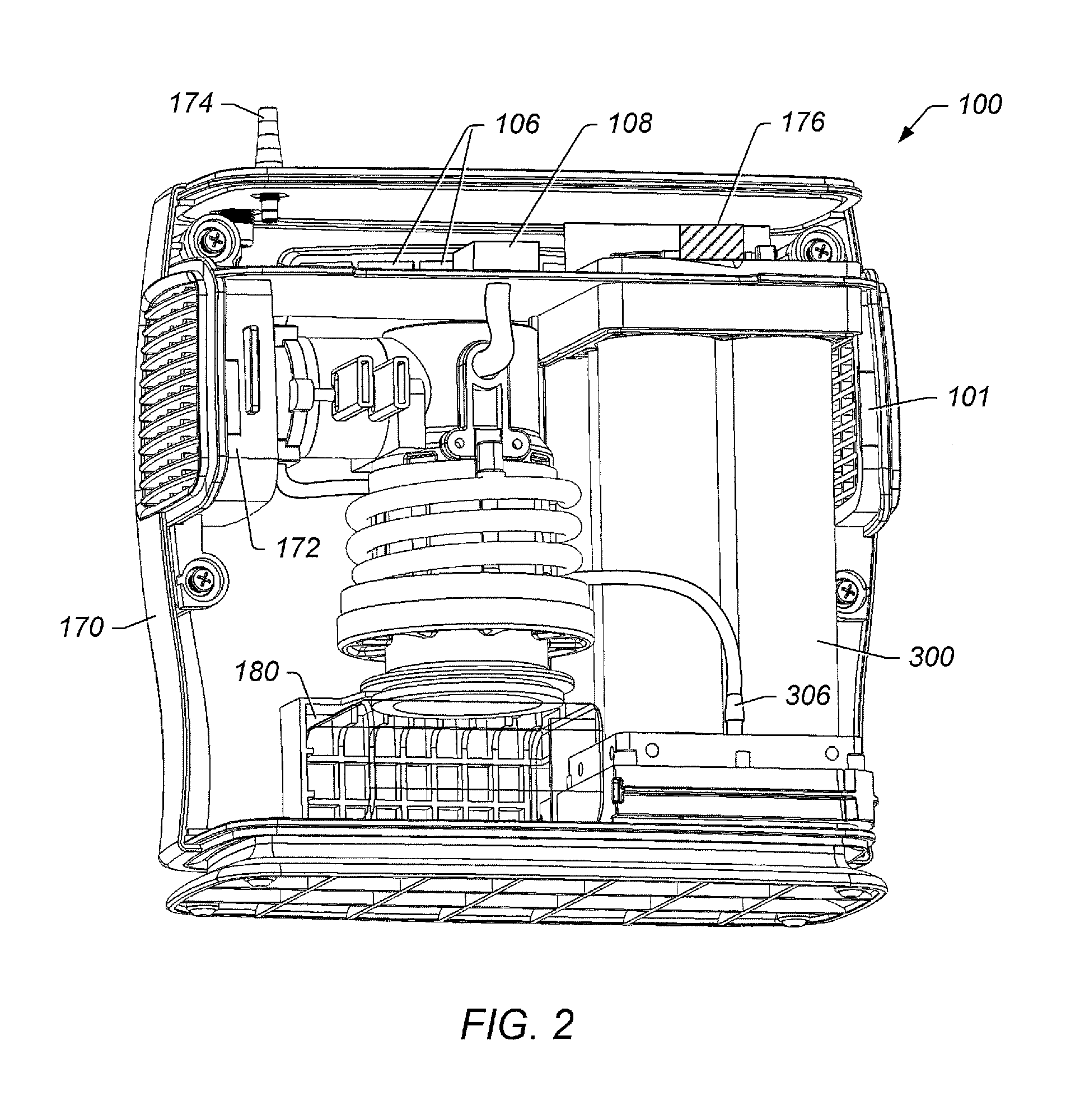

ActiveUS20120055340A1Speed up gas flowRespiratorsOxygen/ozone/oxide/hydroxideEngineeringControl circuit

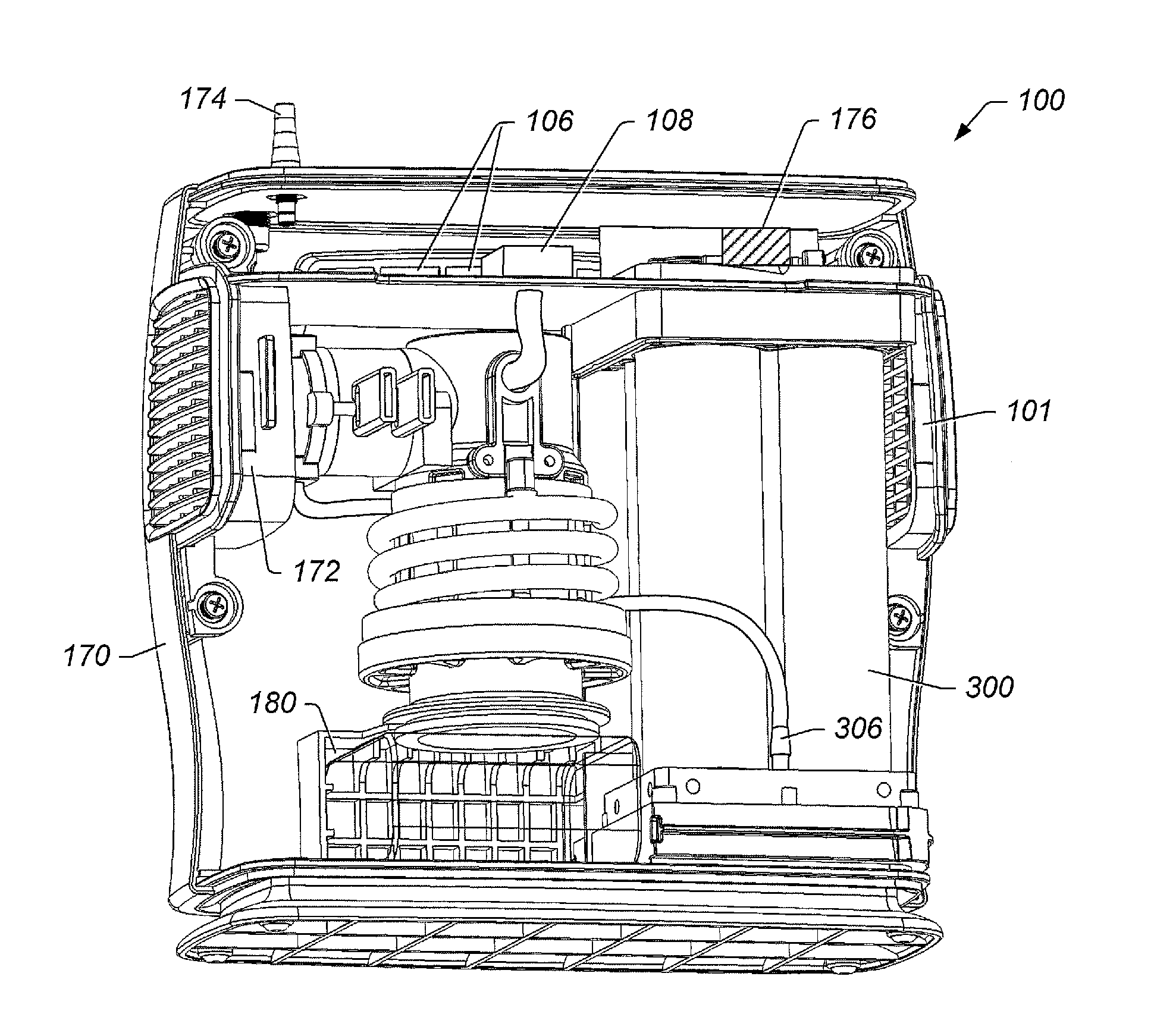

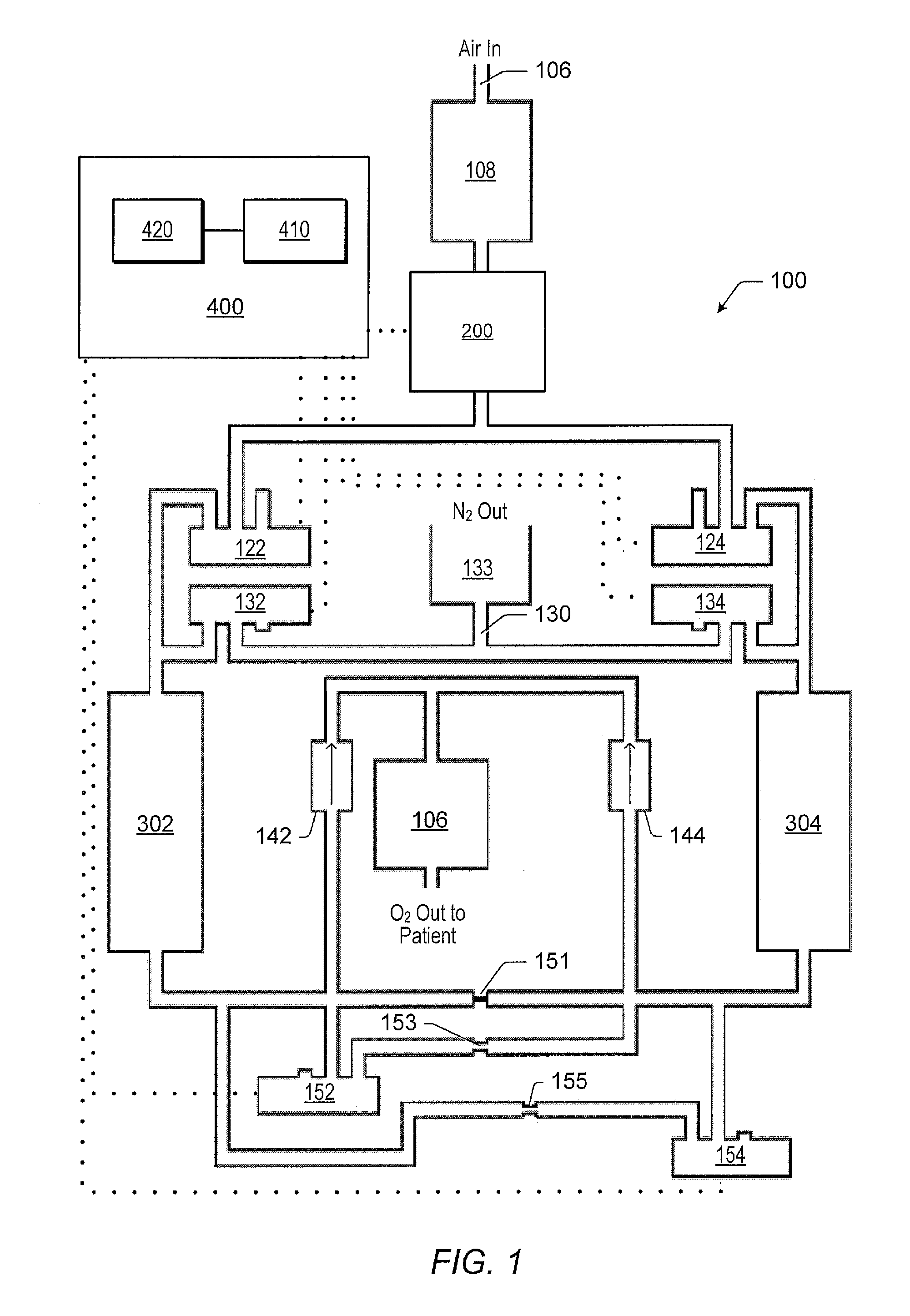

Described herein are various embodiments of an oxygen concentrator system In some embodiment, an oxygen concentrator system includes improved charging and battery control circuits.

Owner:INOVA LABS INC

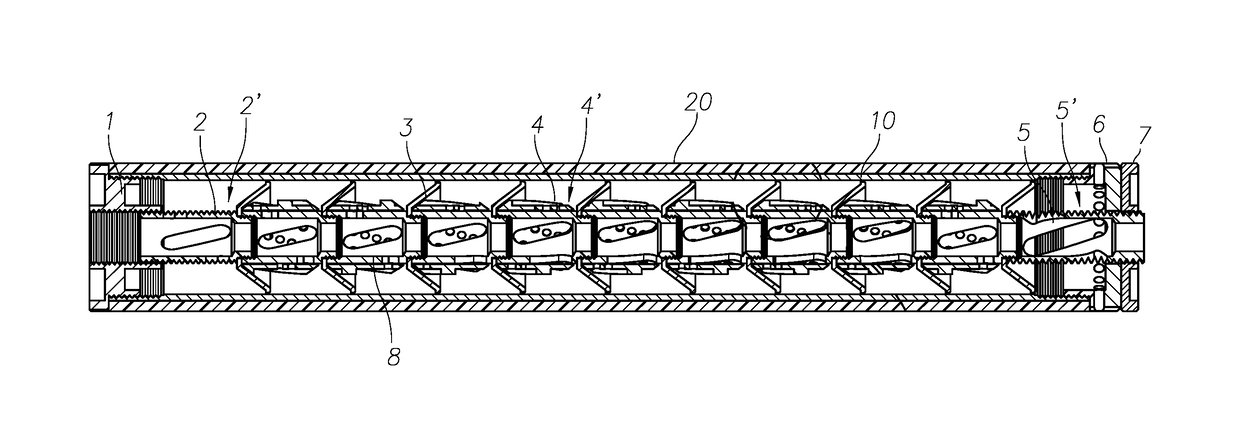

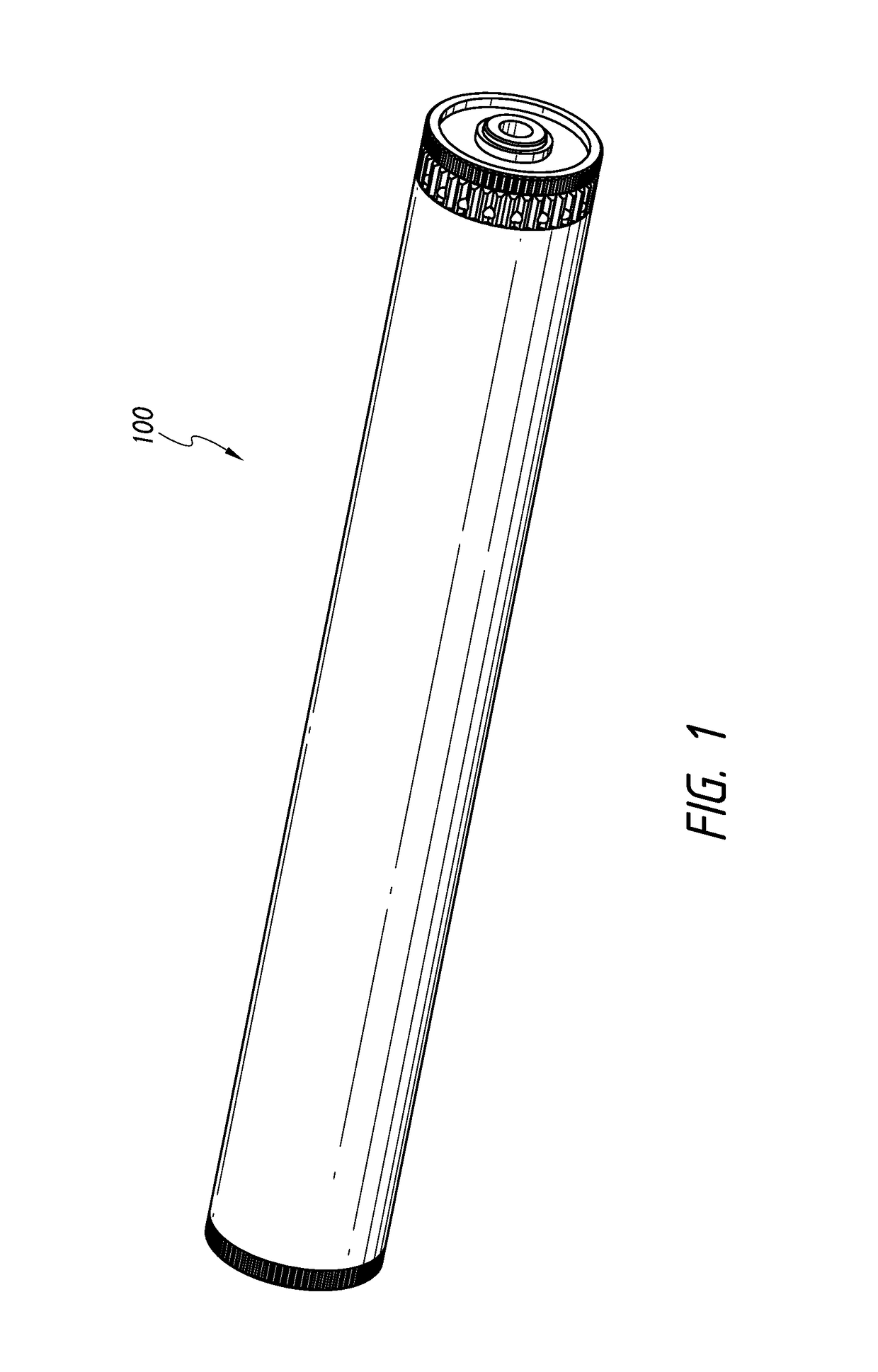

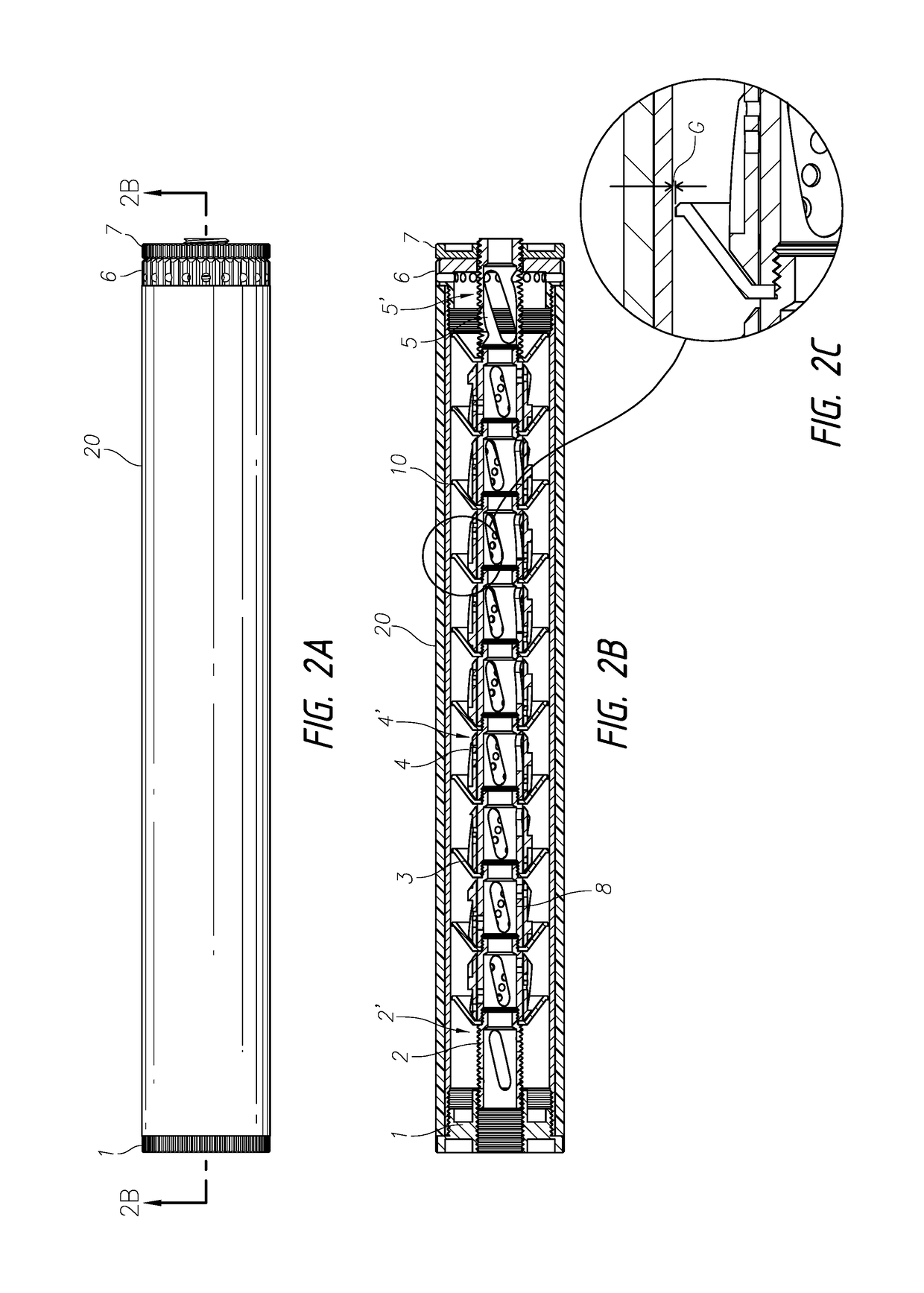

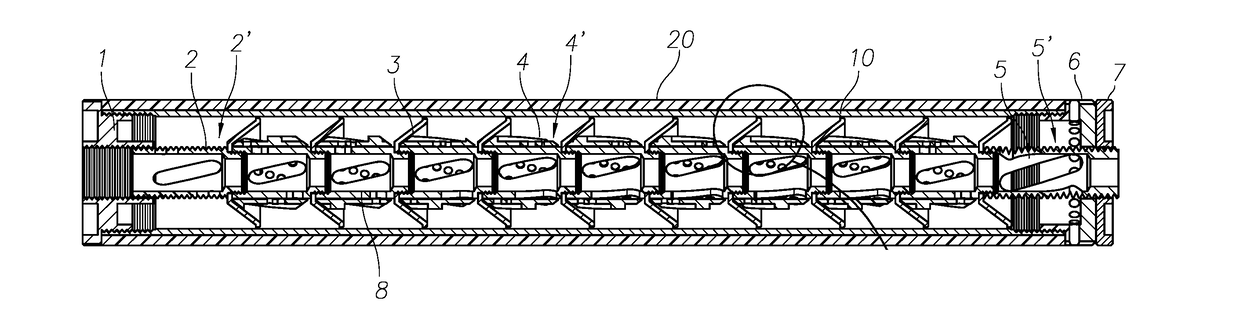

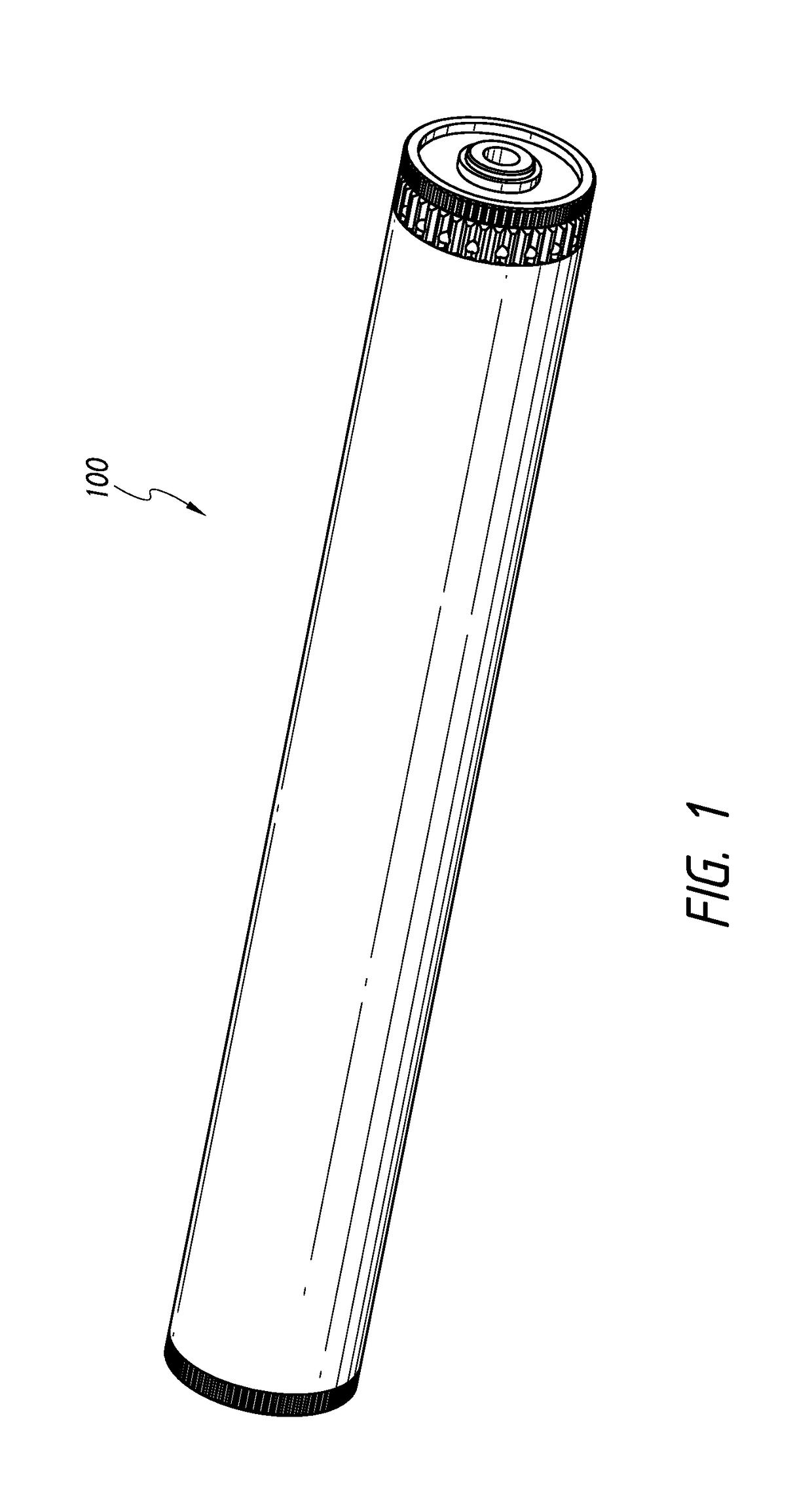

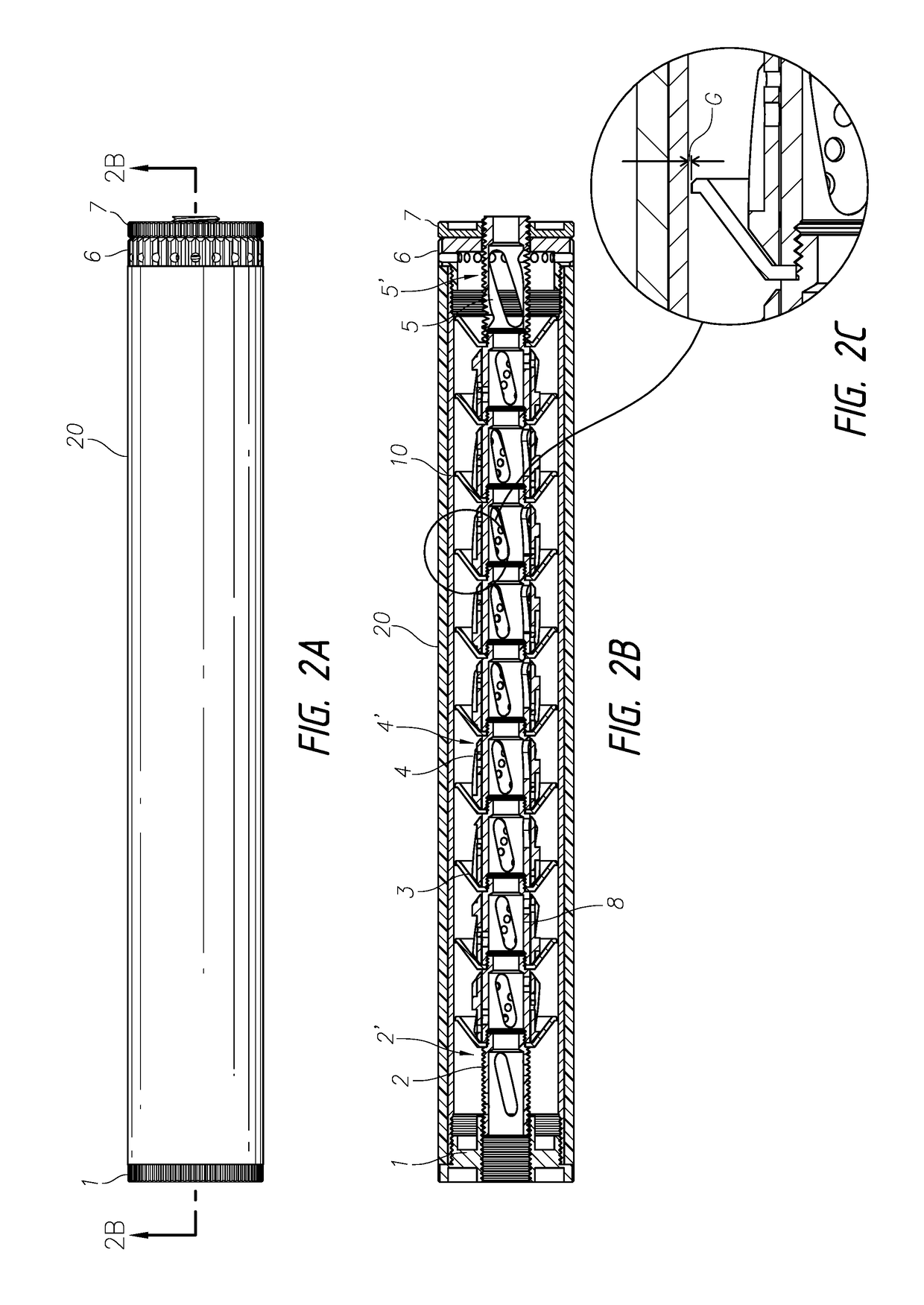

Modular gun silencer

InactiveUS9933224B2Easy to assembleReduce manufacturing costMuzzle attachmentCarbon fibersEngineering

A modular silencer includes an outer tube and a plurality of chamber separators suspended through a tensile force within a bore of the outer tube and defining chambers between each pair of chamber separators in the silencer. An outer edge of the chamber separators is spaced apart from an inner surface of the tube to allow gas equalization between the chambers. A plurality of tube portions separate the chamber separators from each other and from the proximal and distal ends of the silencer assembly. The tube portions define a continuous center tube suspended in tension within the outer tube and through which the projectile travels. The tube portions have can have angled openings through which gas discharge exits into the chambers. Rotatable sleeves can be disposed over the tube portions to further disrupt gas flow and dissipate heat and sound. A carbon fiber sleeve can be disposed over the outer tube to inhibit burn injuries from contacting the silencer.

Owner:MAD MINUTE IP HOLDCO INC

Oxygen concentrator apparatus configured for high altitude use

InactiveUS20120055477A1Facilitate gas flowSpeed up gas flowOxygen/ozone/oxide/hydroxideGas treatmentOxygen concentratorEngineering

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, an oxygen concentrator system includes a controller that compensates for the ambient pressure.

Owner:INOVA LABS INC

Shutdown system and method for an oxygen concentrator

InactiveUS20120055483A1Speed up gas flowGas treatmentDispersed particle filtrationOxygen concentratorEngineering

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, an oxygen concentrator system may be shutdown such that the canisters are pressurized to a pressure greater than ambient pressure.

Owner:INOVA LABS INC

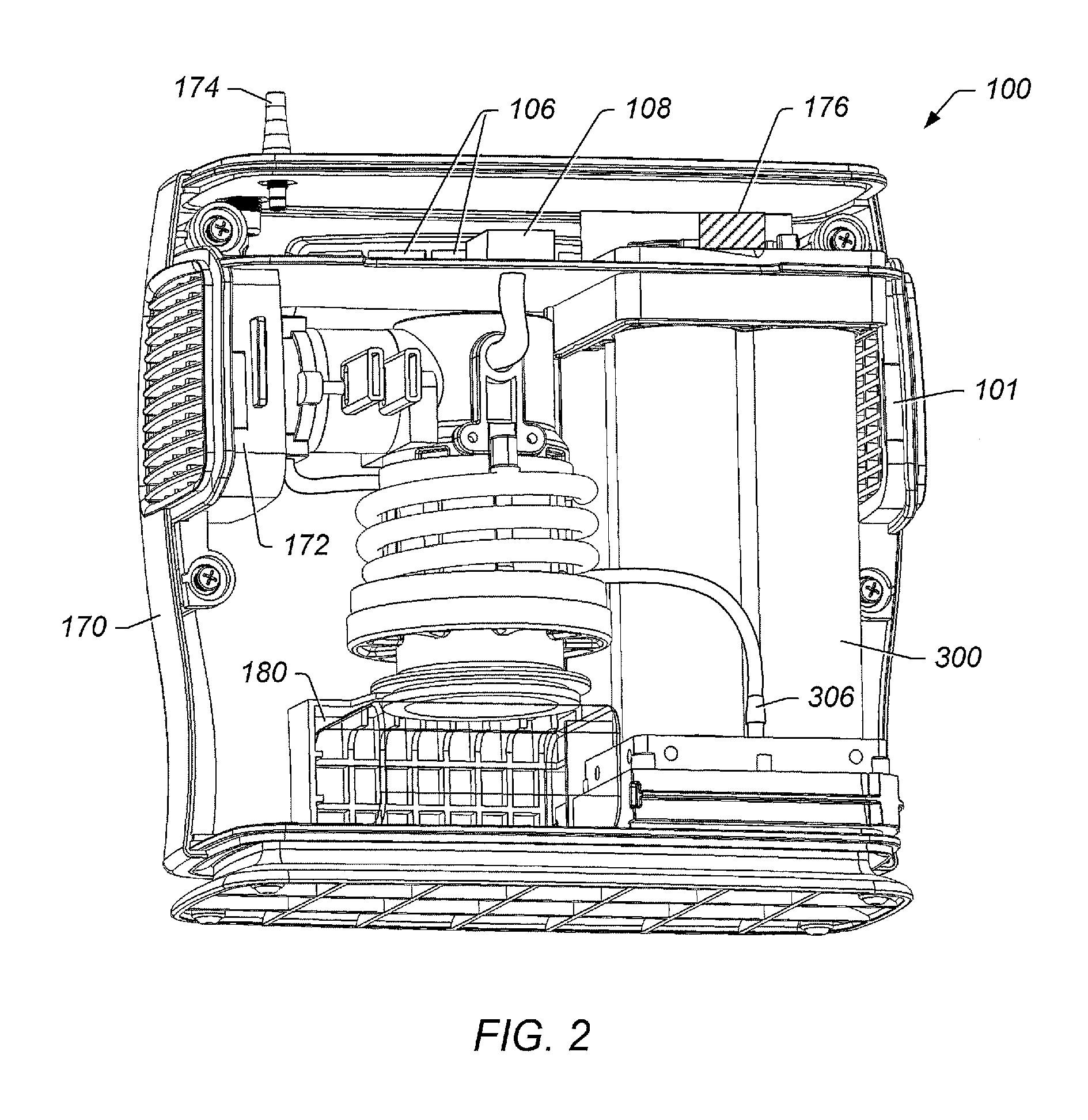

Oxygen concentrator heat management system and method

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, oxygen concentrator system includes one or more components that improve dissipation of heat formed during operation of the oxygen concentrator system.

Owner:INOVA LABS INC

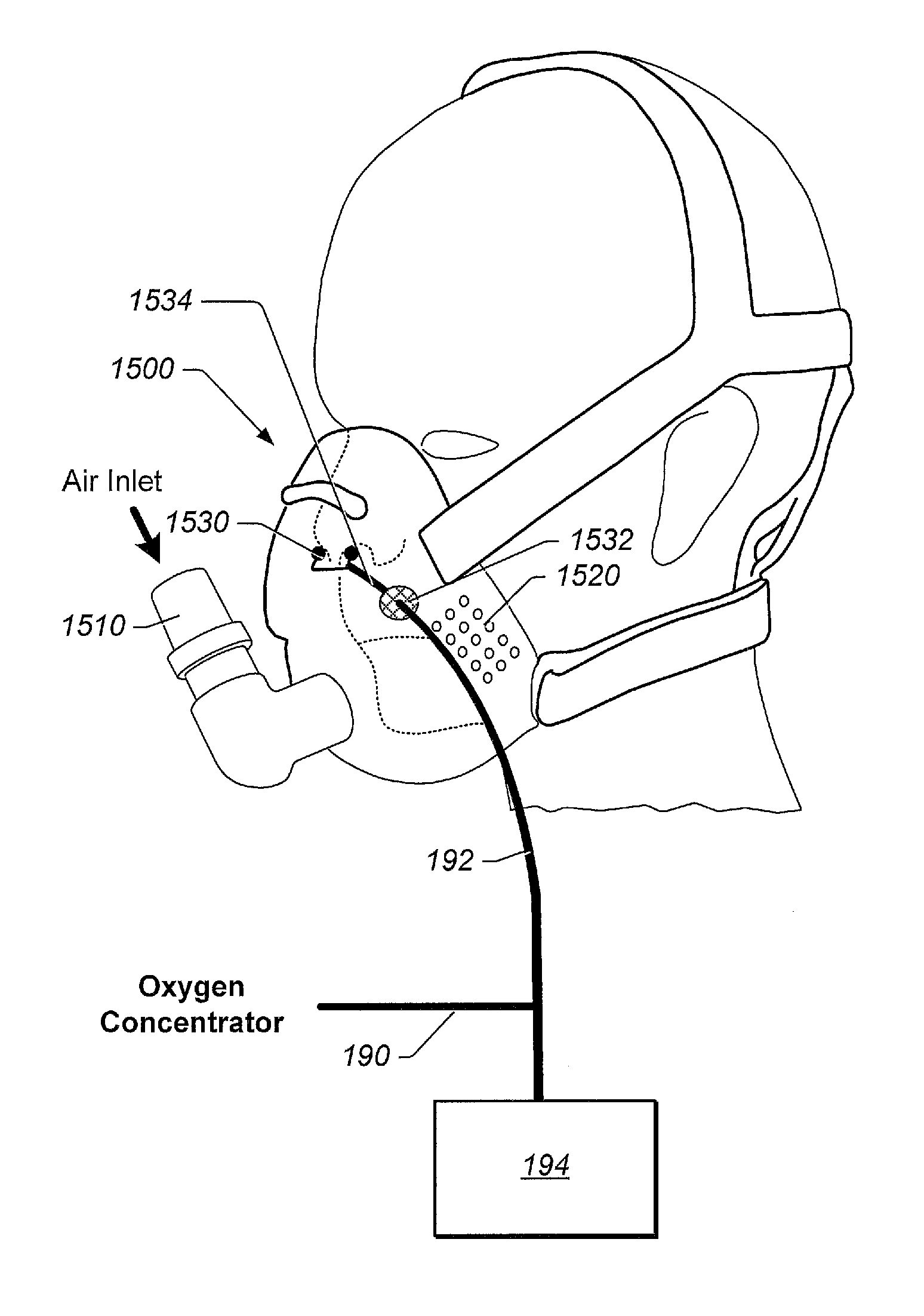

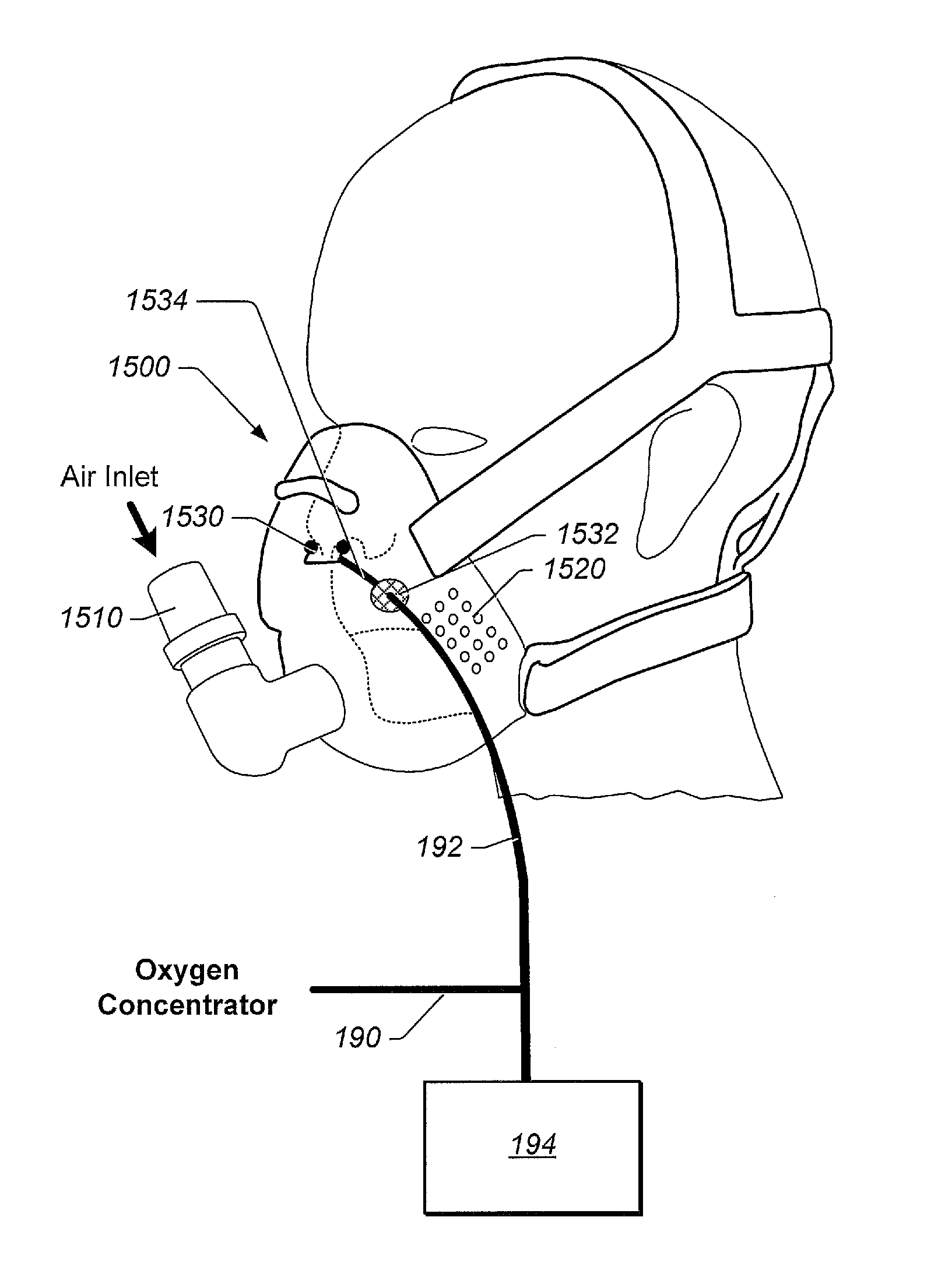

Oxygen concentrator system and methods for oral delivery of oxygen enriched gas

InactiveUS20120055475A1Speed up gas flowRespiratorsOxygen/ozone/oxide/hydroxideChemistryOxygen concentrator

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, an oxygen concentrator system may be used to provide oxygen enriched gas to a patient using a mouthpiece.

Owner:INOVA LABS INC

Methods and systems for providing oxygen enriched gas

InactiveUS20120055474A1Speed up gas flowRespiratorsOxygen/ozone/oxide/hydroxideInhalationEngineering

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, the delivery of oxygen enriched air by an oxygen concentrator system is controller based on an inhalation profile of a user of the oxygen concentrator system.

Owner:INOVA LABS INC

Substrate support system for reduced autodoping and backside deposition

ActiveUS7648579B2Reduce riskSimple, versatileLiquid surface applicatorsElectric discharge tubesSupporting systemEngineering

Owner:ASM IP HLDG BV

Positive pressure therapy systems and methods

InactiveUS20120055478A1Speed up gas flowGas treatmentOxygen/ozone/oxide/hydroxideIntensive care medicinePositive pressure therapy

Described herein are various embodiments of an oxygen concentrator system. In some embodiments, an oxygen concentrator system may be used to provide oxygen enriched gas to a patient undergoing positive pressure therapy.

Owner:INOVA LABS INC

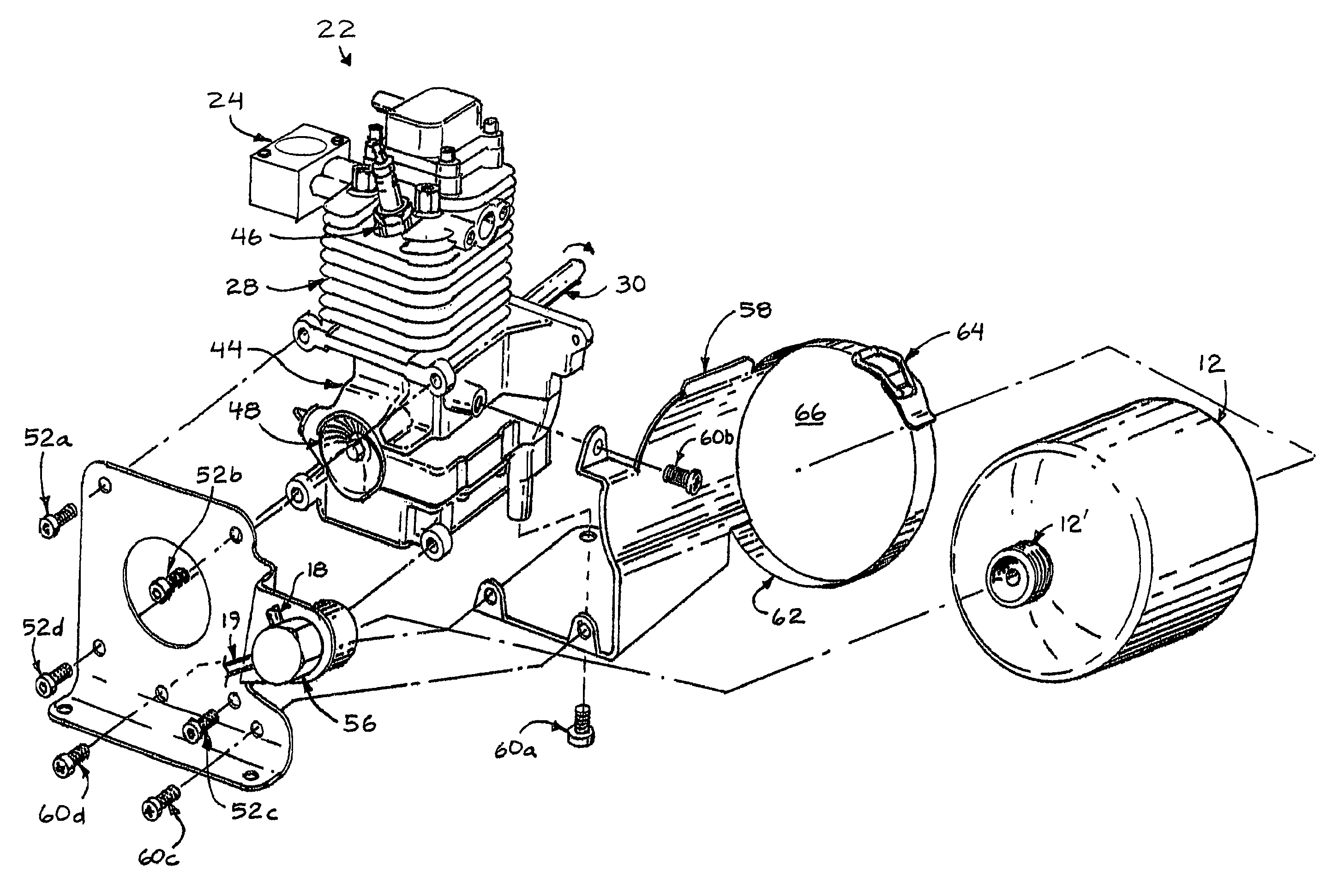

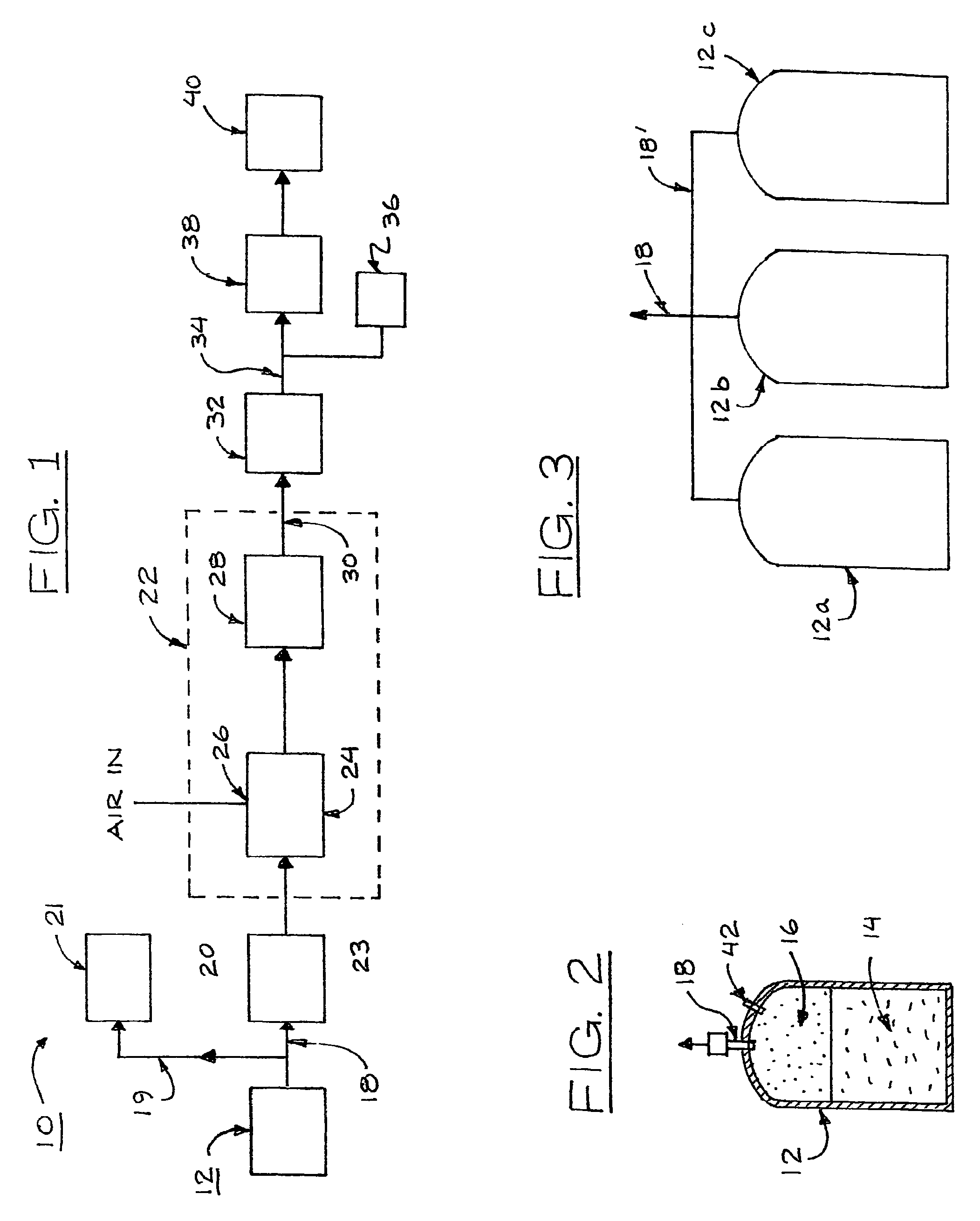

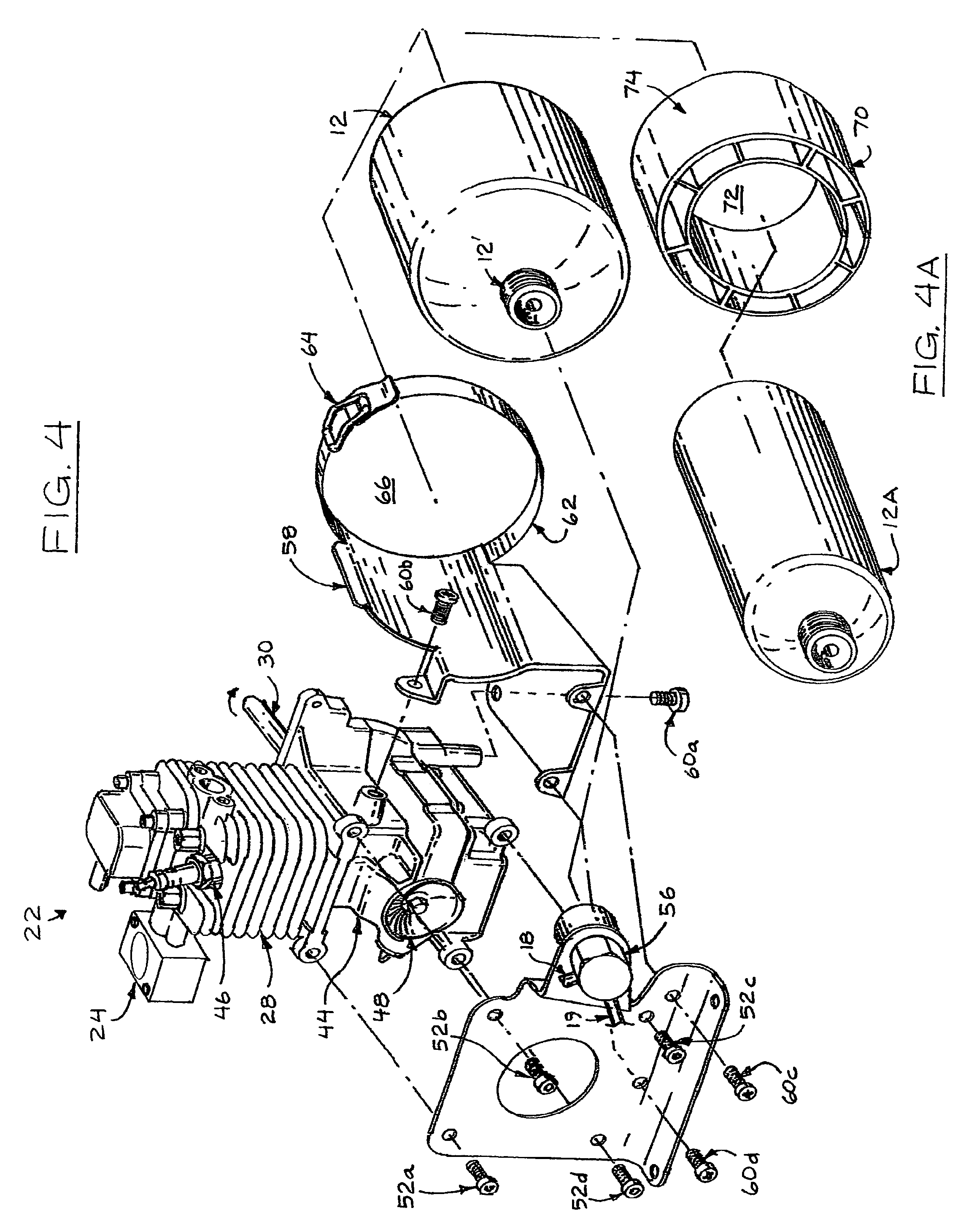

Portable gas powered internal combustion engine arrangement

InactiveUS7424886B1Maximizing gas flowAvoid flowCasingsMachine framesExternal combustion engineInternal combustion engine

A gas powered internal combustion engine in which the gas is provided from pressurized liquid gas in an LPG container and in which the LPG container is rigidly mounted adjacent to the internal combustion engine at a preselected angle to be in conductive heat transfer relationship to the internal combustion engine and in vibration receiving relationship to the internal combustion engine whereby the liquified gas in the LPG container is heated and the effective surface area thereof is increased.

Owner:LEHR IP LLC

Biological soil remediation agent and method for remediating soil

InactiveCN105618478AImprove the growing environmentEffective passivationContaminated soil reclamationSoil remediationBiology

The invention discloses a biological soil remediation agent which is prepared by mixing a solid passivator and a microbic solution according to the volume-weight ratio of 1:(15-30) (L / kg). The solid passivator comprises the following ingredients in percent by mass: 50-60 percent of clay carrier, 15-30 percent of diatomite, 10-15 percent of humic acid and 10-20 percent of charcoal. The microbic solution comprises a non-spore forming bacterium and streptomyces microflavus. The biological soil remediation agent can be used for remediating a soil ecosystem, improving the crop growth environment, effectively passivating heavy metal pollutants, such as lead, and reducing the availability for plants.

Owner:NANJING GAIA BIOLOGICAL ENG CO LTD

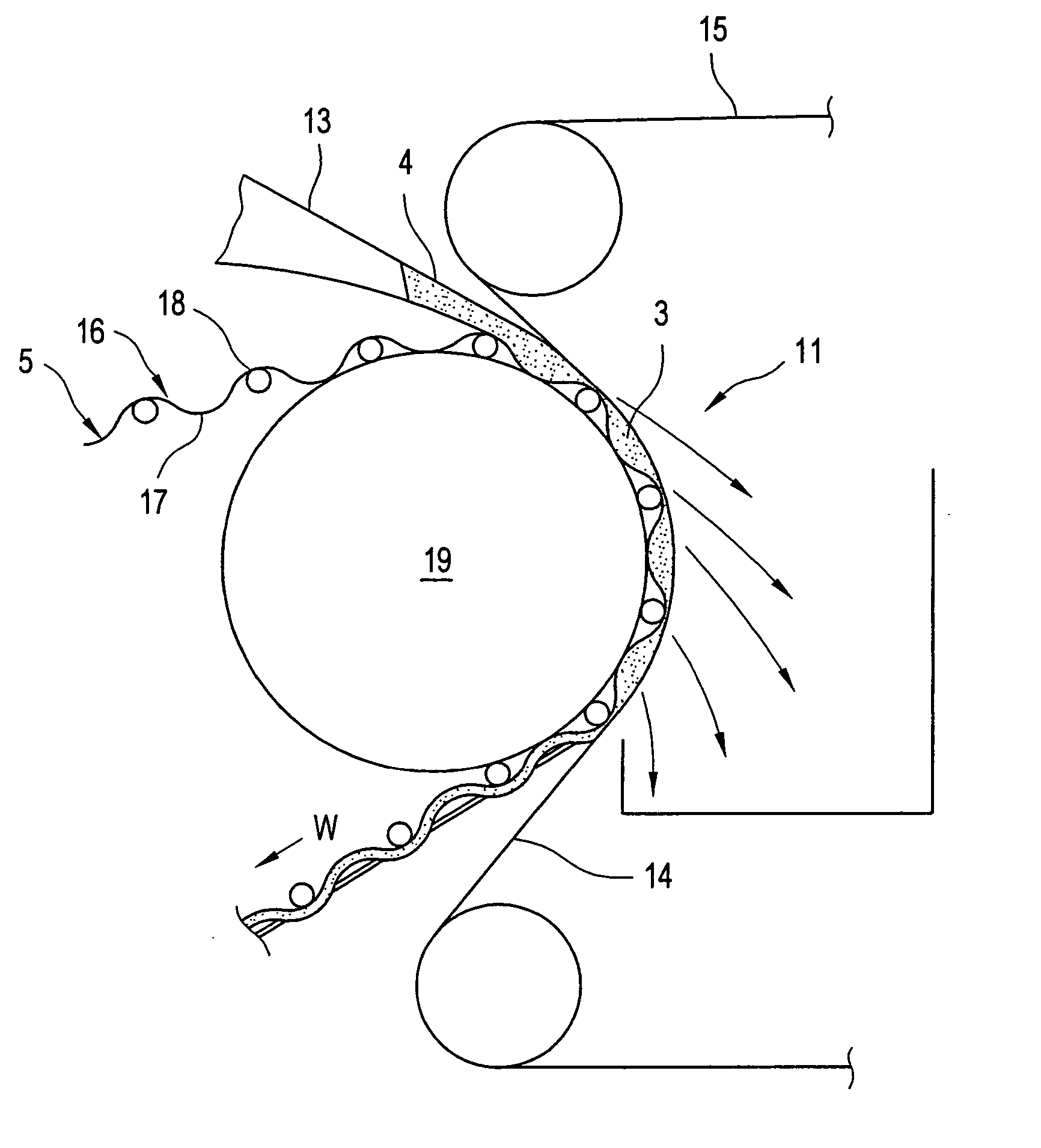

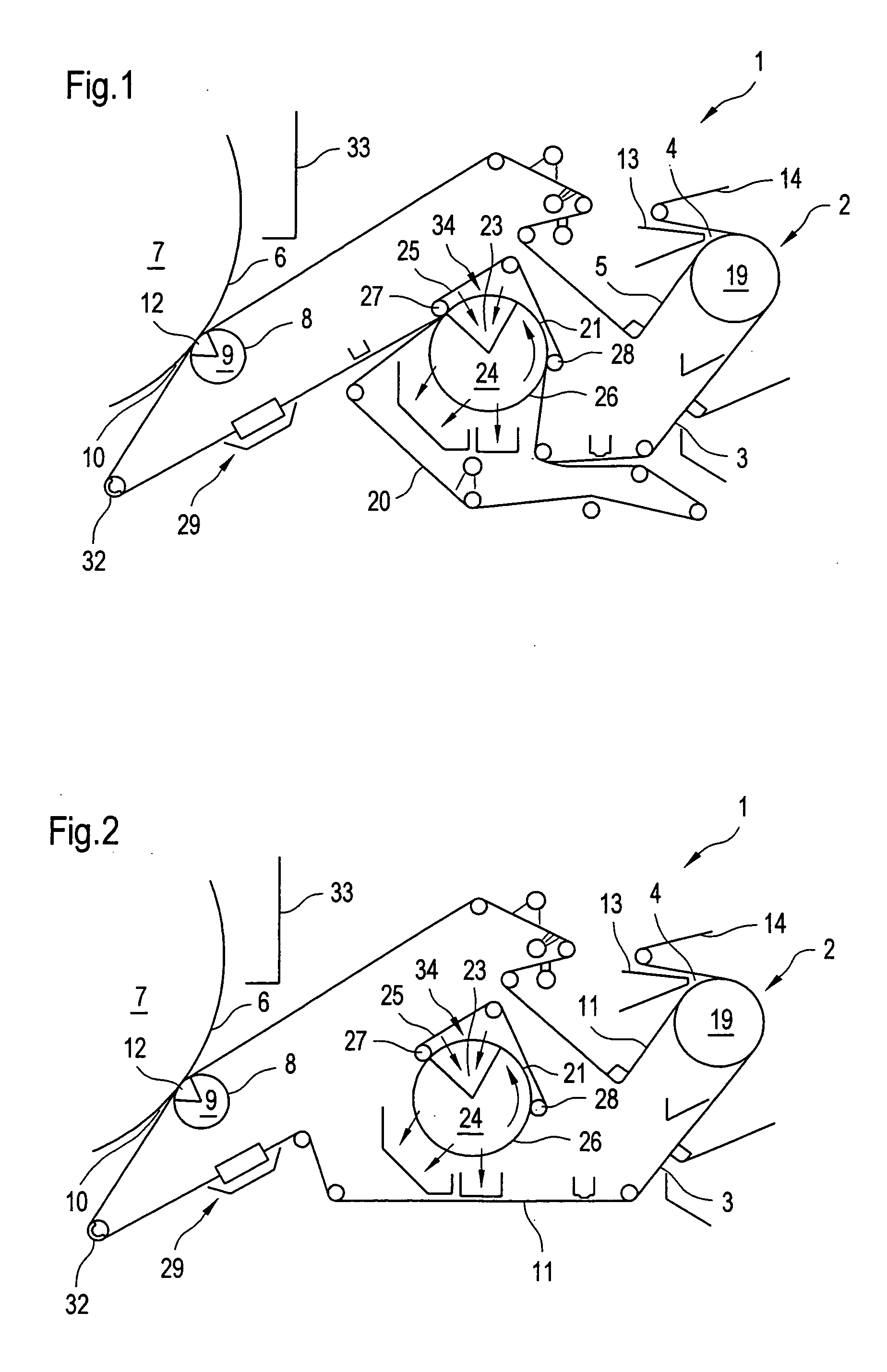

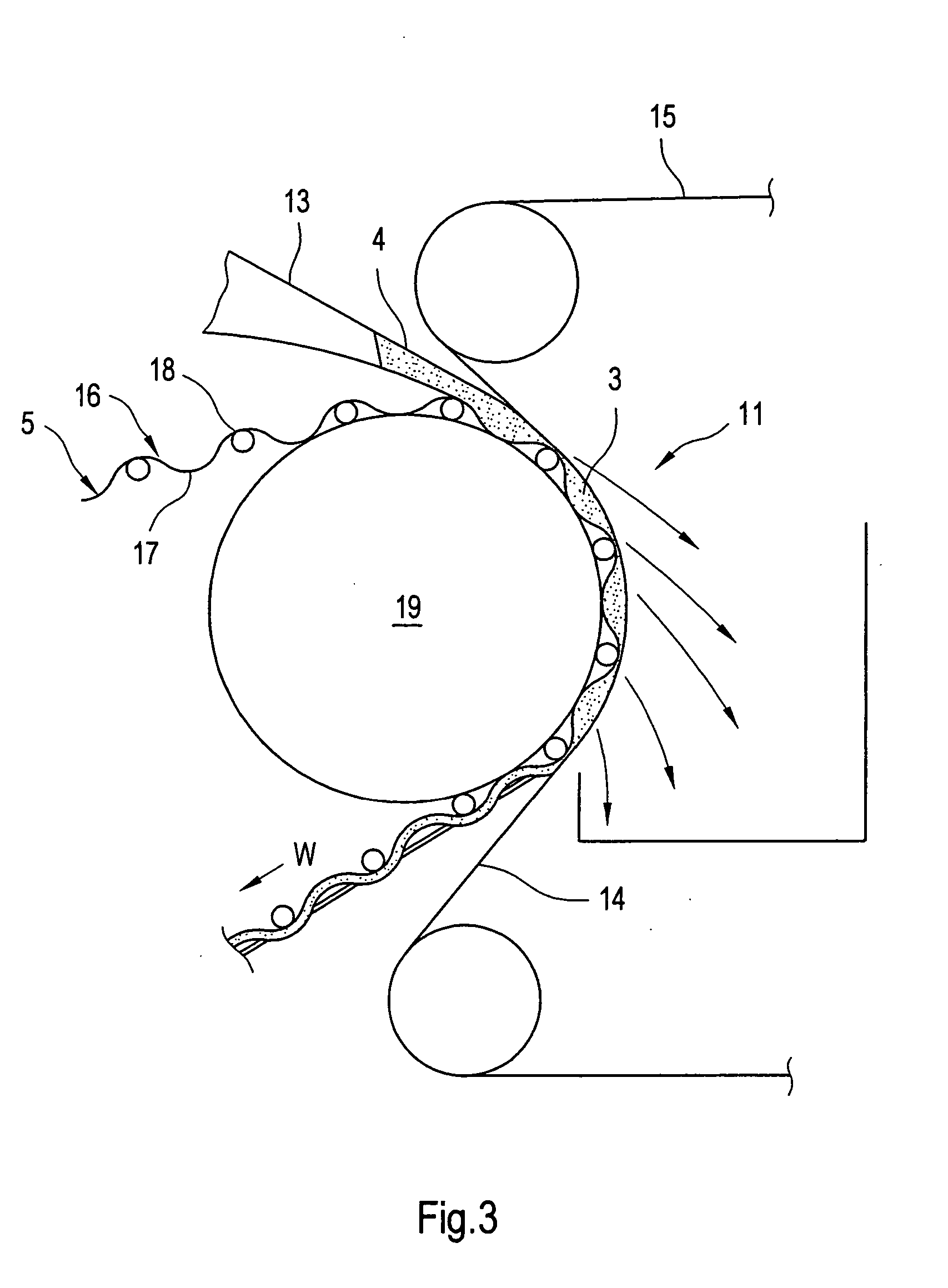

Machine for the production of tissue paper

InactiveUS20070029061A1Better dewateringSpeed up gas flowMachine wet endPress sectionTear resistanceTissue paper

This invention relates to a machine for the production of a tissue paper web with a forming section in which the tissue paper web is formed from a pulp suspension on a skin and with a nip which is formed between the cylindrical surface of a drying cylinder, in particular a Yankee drying cylinder, and a mating surface and through which the tissue paper web can be conveyed together with the skin. The configuration of the machine is variable such that, depending on the quality of the tissue paper to be produced, for example its absorbency or tear resistance, the skin is either a three-dimensionally structured skin, a structured mesh, a non-structured skin, or a felt, whereby the mating surface is formed by the cylindrical surface of a press roller which includes a suction zone and in which provision is made for bores communicating with the suction zone.

Owner:VOITH PATENT GMBH

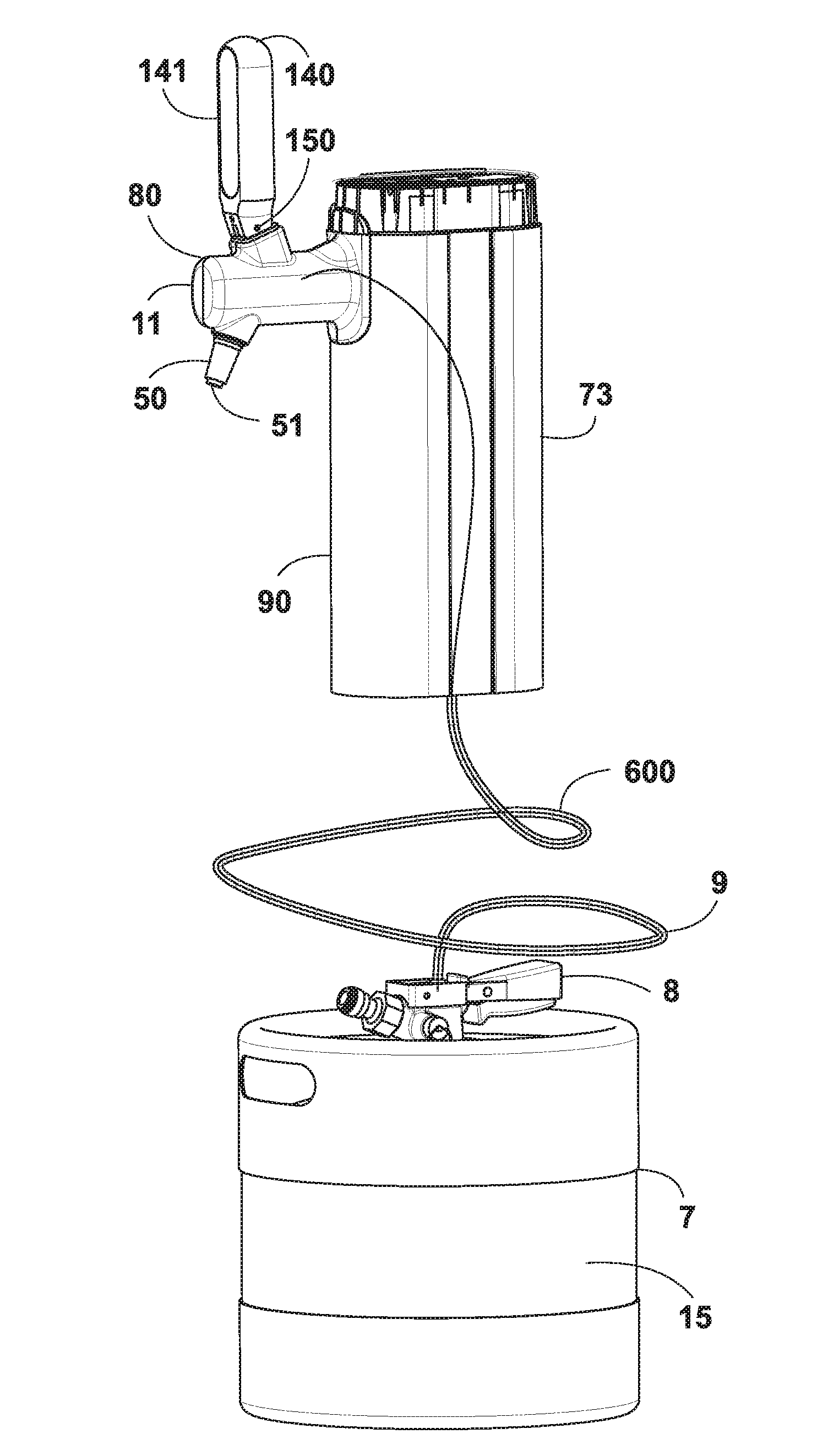

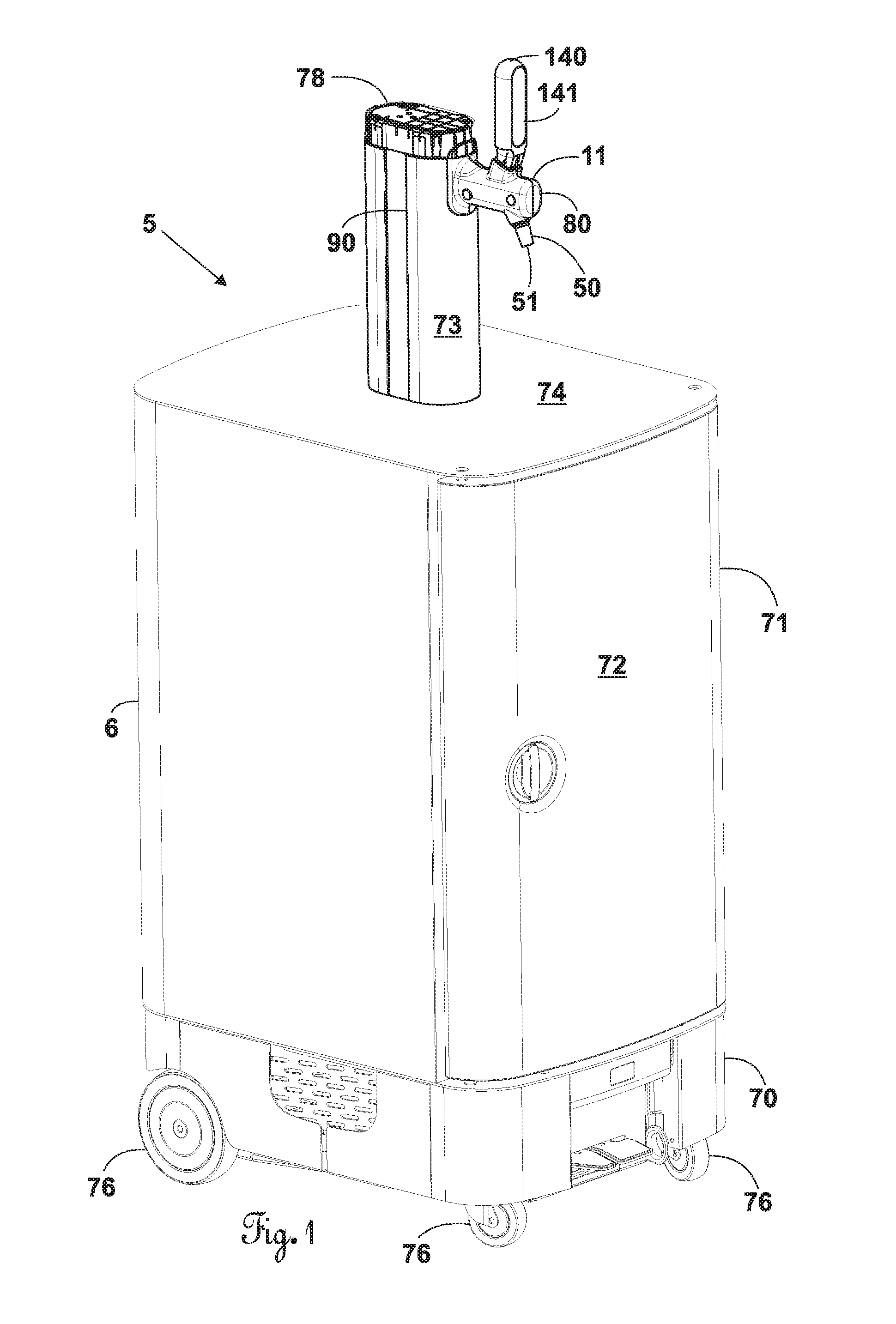

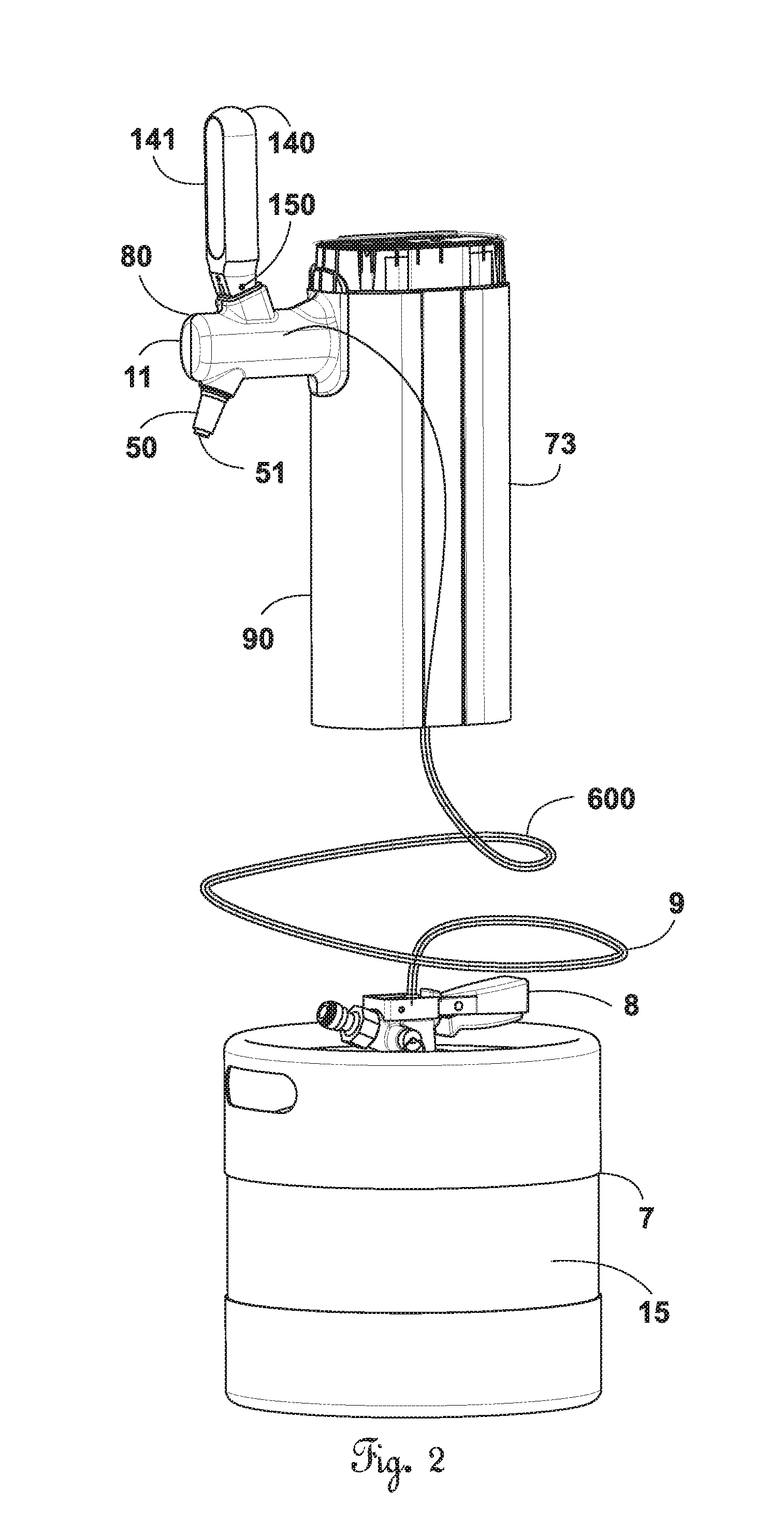

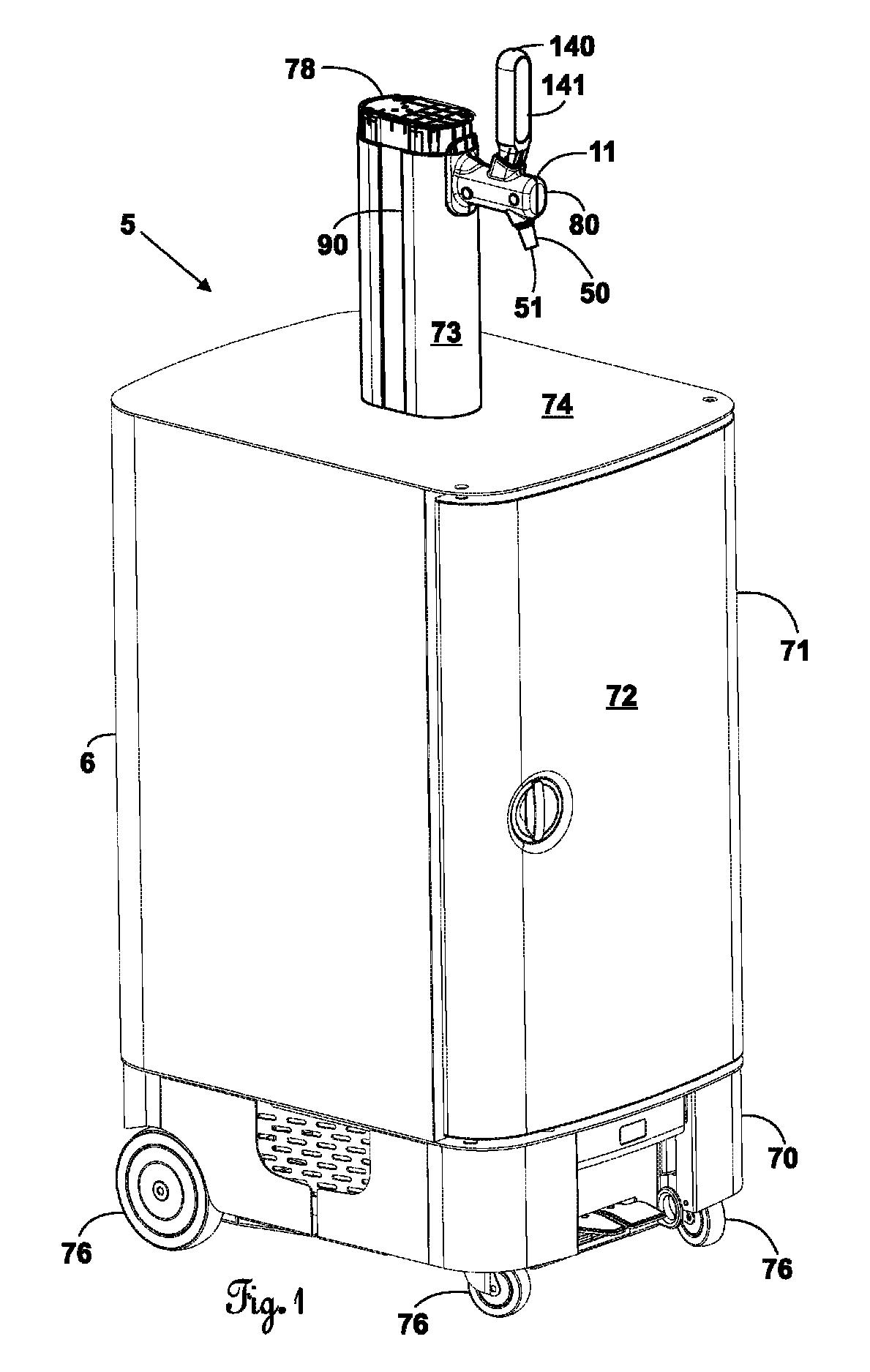

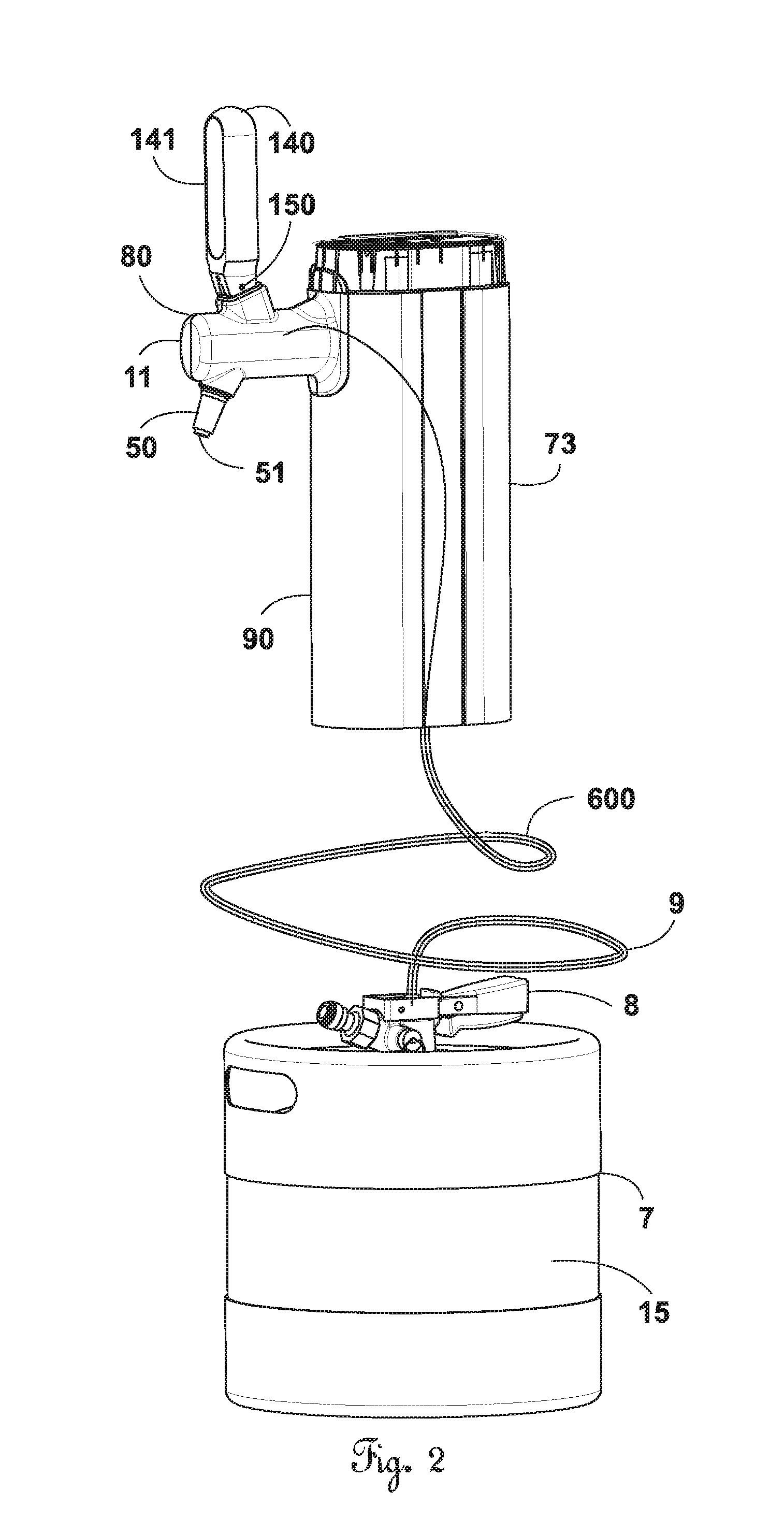

Creamy foam beer dispensing system

ActiveUS20120248139A1Easy to createSpeed up the flowOpening closed containersBottle/container closureTransport engineeringPlunger

A creamy foam beer dispensing system includes a coupler removably securable with a keg, a transportation tube, and a faucet having a handle coupled with a plunger communicating with the transportation tube. The handle is movable among a closed position, an open position, and a creamy foam position. In the closed position, the handle maintains the plunger squeezed against the transportation tube such that no beer flows from the faucet. In the open position, the handle lifts the plunger substantially, completely off the transportation tube such that beer flows smoothly from the faucet. In the creamy foam position, the handle lifts the plunger off the transportation tube a distance such that an aperture created in the transportation tube produces creamy foam flow from the faucet.

Owner:LANCER PARTNERSHIP

Device and method for absorbing water from gas

Owner:AIRWATERGREEN

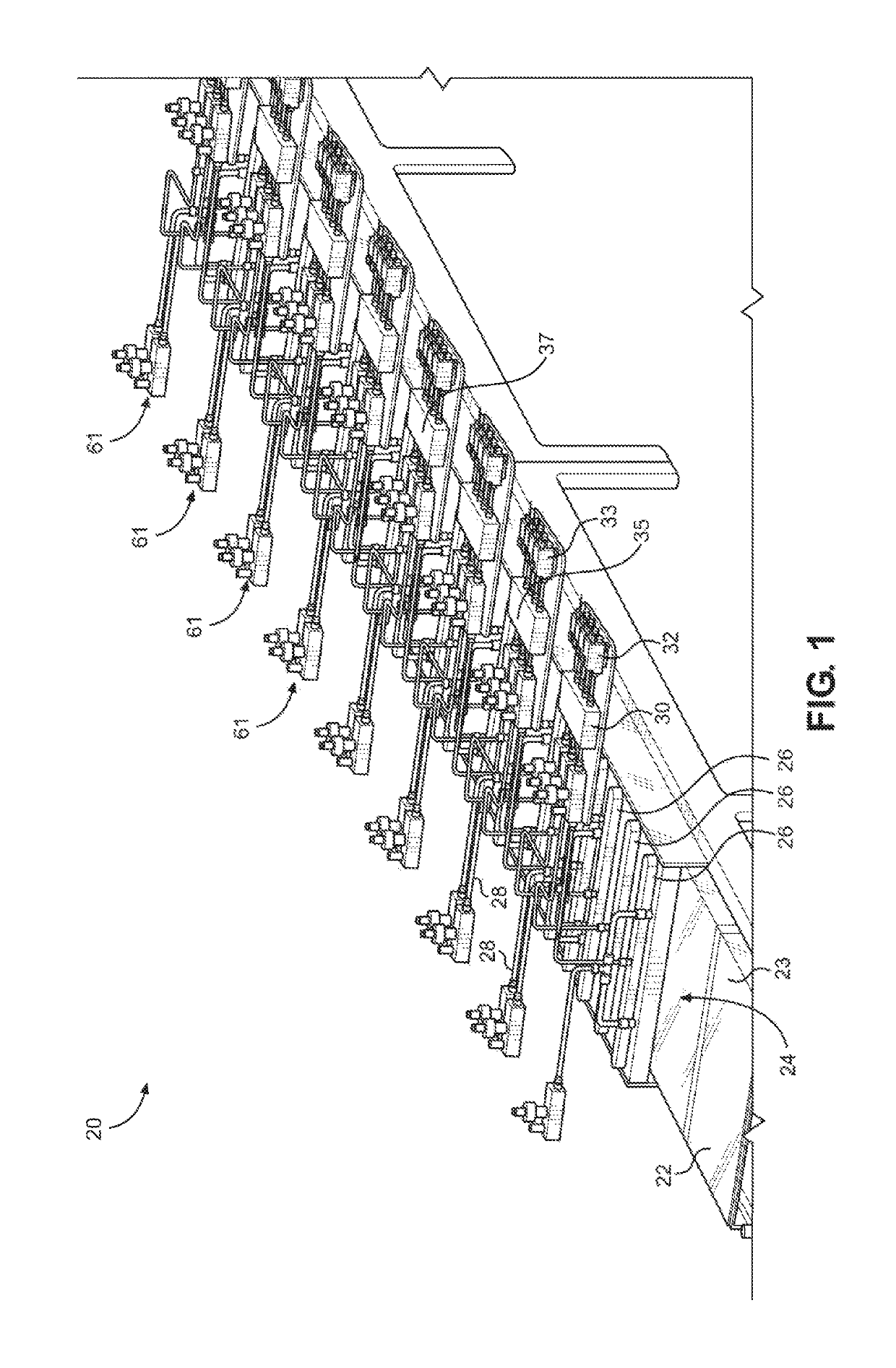

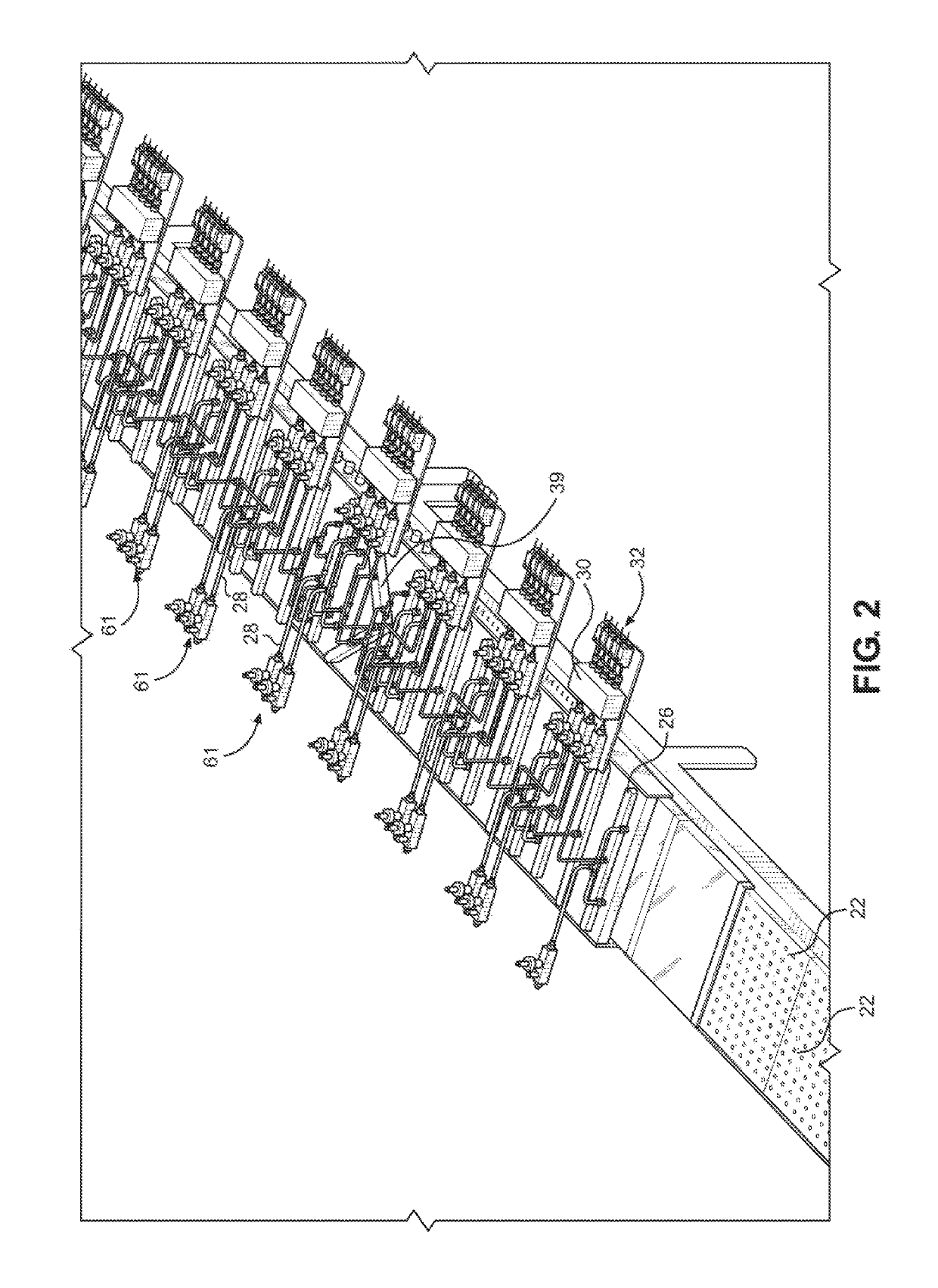

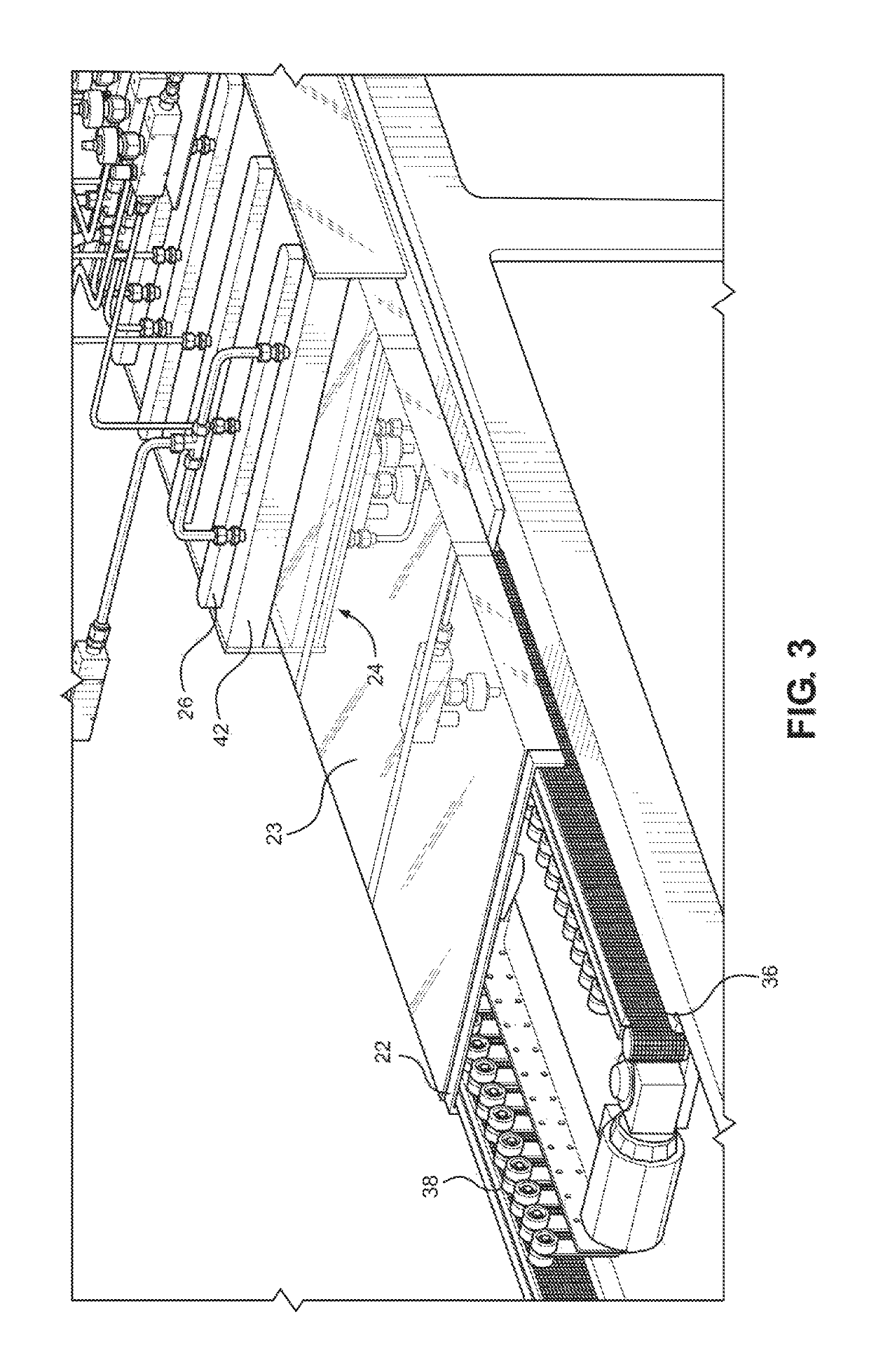

Modified Atmosphere Packaging Apparatus and Method With Automated Bag Production

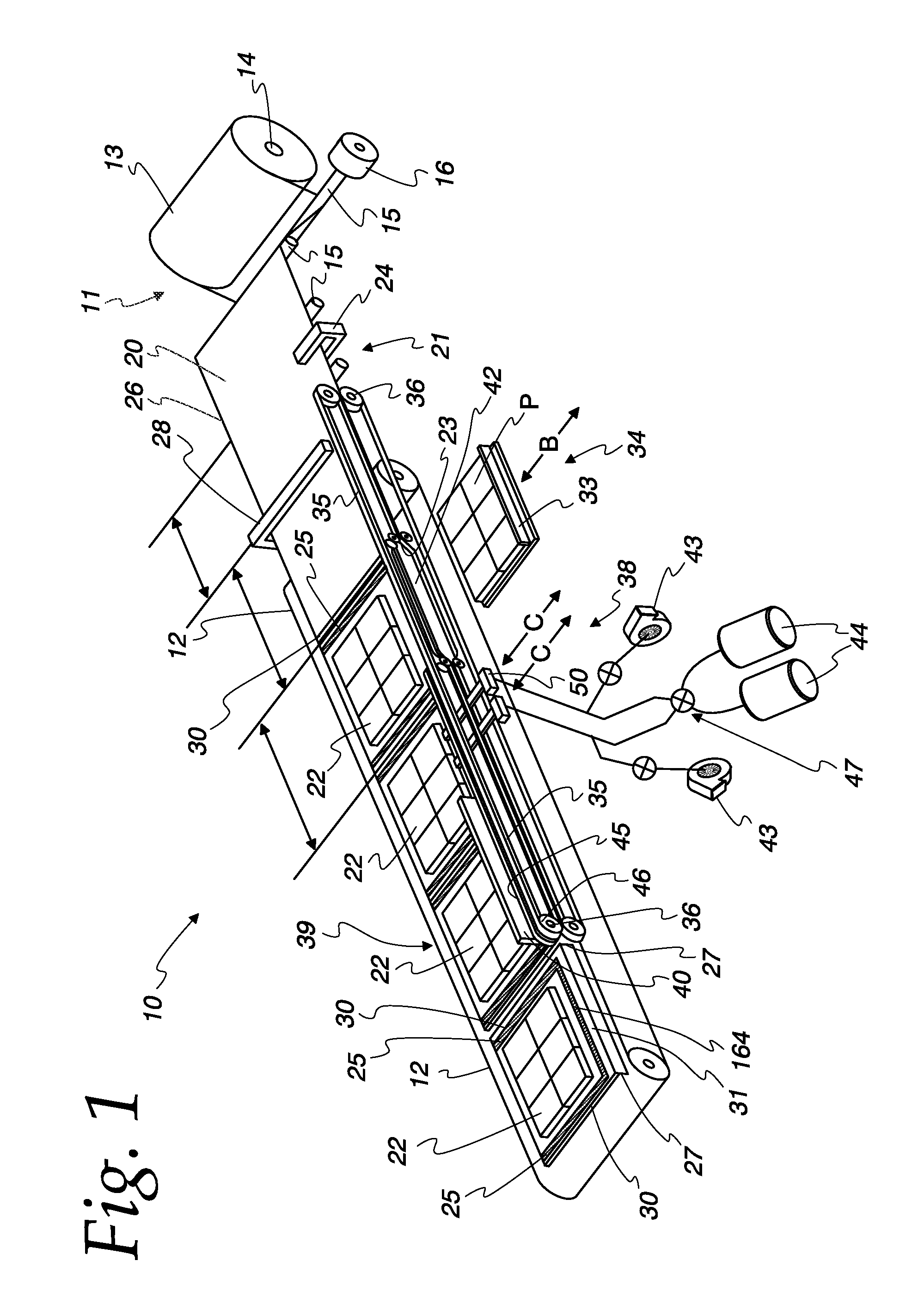

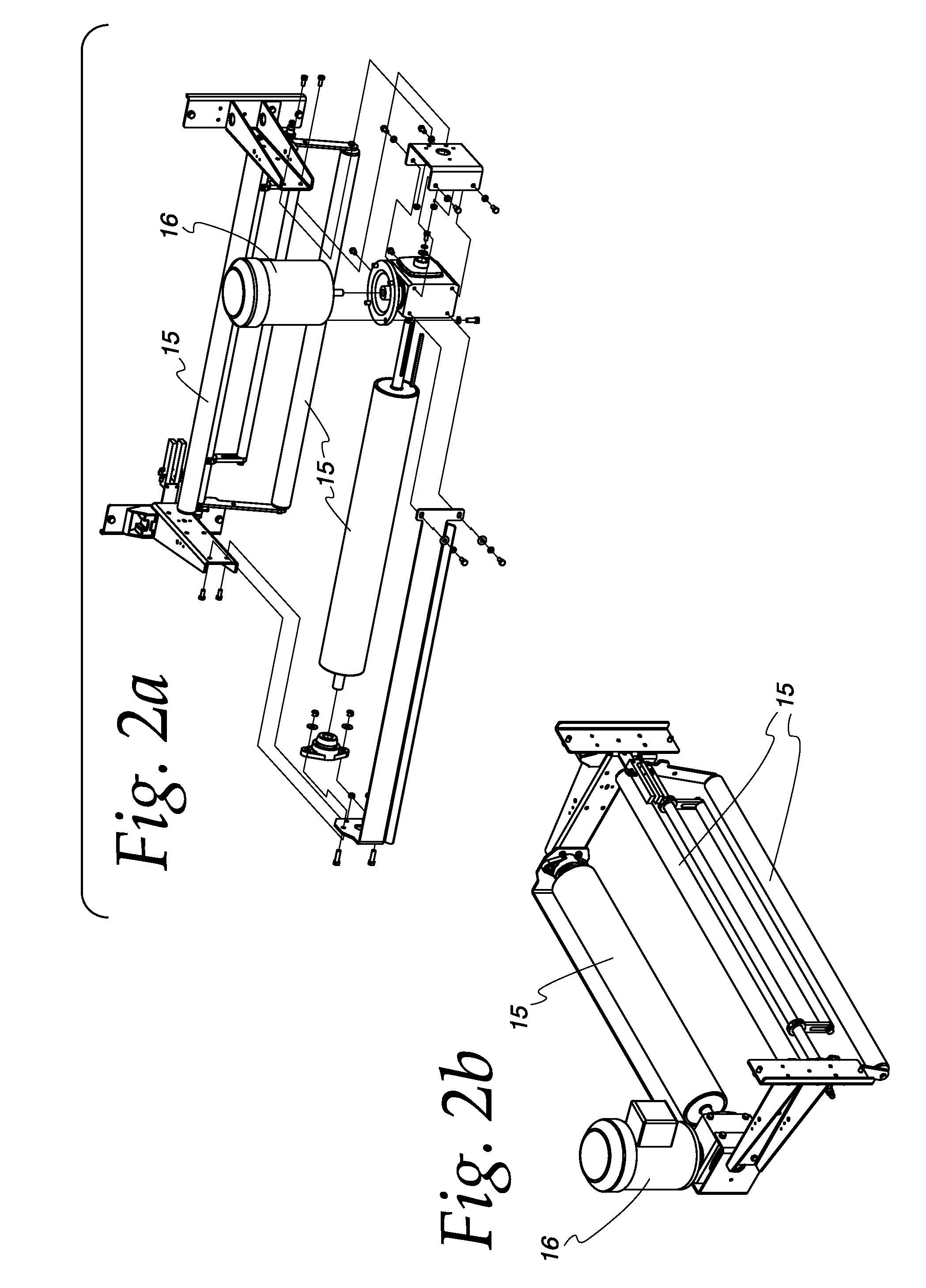

ActiveUS20140190125A1Easy to mountFacilitate advancingWrapping material feeding apparatusPackaging by pressurising/gasifyingModified atmosphereProduct gas

An automatic packaging apparatus is provided, having a conveyor, a continuous longitudinally folded web, cutting and sealing mechanisms for forming flexible pouches from the web. The apparatus also includes processing stations for loading the pouches, transferring fluids (typically gases) into and out of the pouches, and sealing the pouches. Various alternative methods and devices are provided for separating each sealed pouch from the web by either making a continuous cut across a connecting strip of web material downline of the processing stations or pre-perforating the connecting strip upline of the processing stations. When the connecting strip is pre-perforated, a sealed pouch of sufficient weight may be separated from the web passively by a takeaway conveyor, and a lighter sealed pouch may be separated from the web by a tear-off mechanism that grips and pulls the web.

Owner:CVP SYST LLC

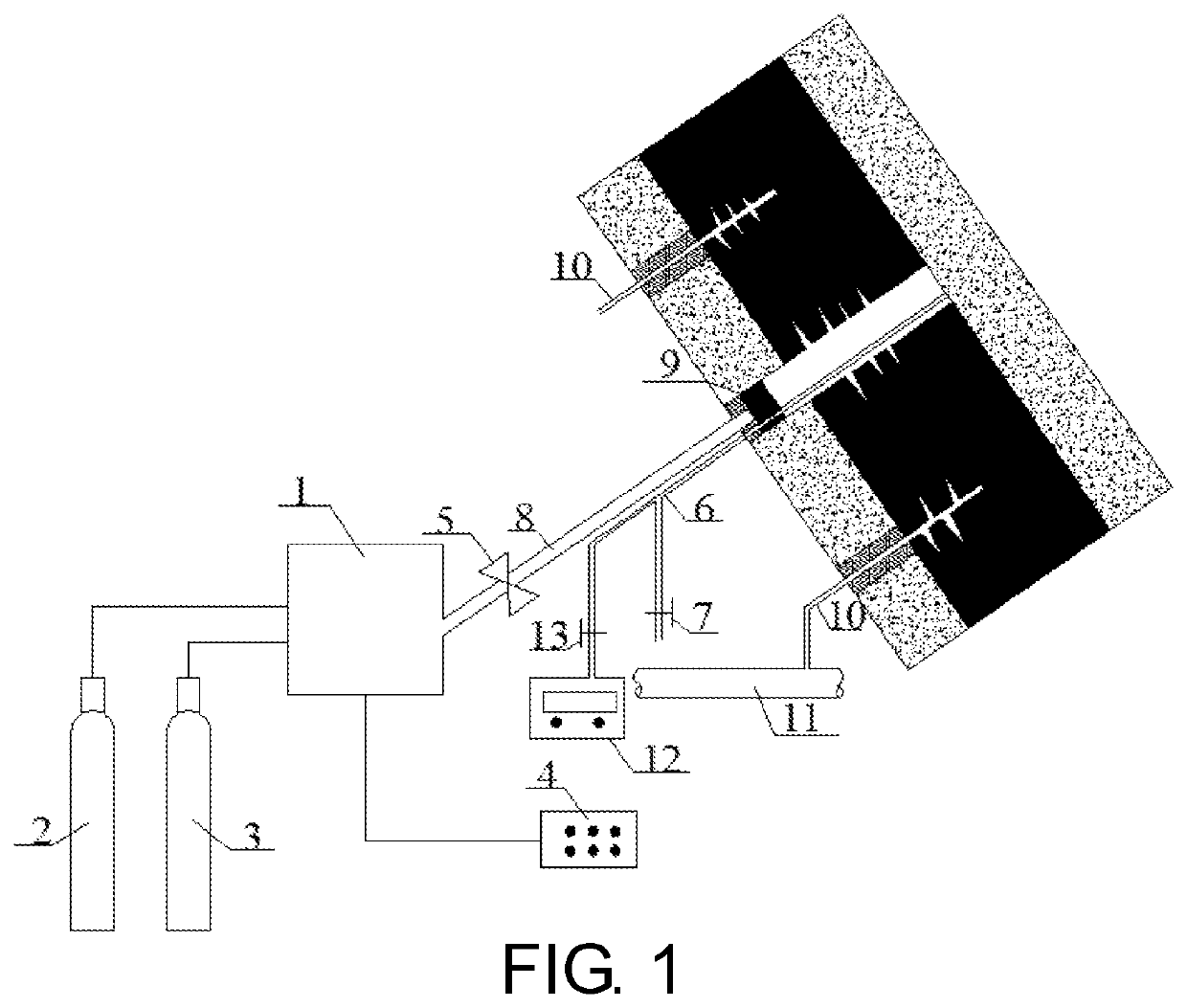

Multi-stage combustion impact wave coal mass cracking and heat injection alternating intensified gas extracting method

ActiveUS20200182033A1Easy to desorbSpeed up the flowFluid removalGas removalCombustion chamberThermodynamics

A multi-stage combustion impact wave coal mass cracking and heat injection alternating intensified gas extracting method is provided. A large amount of N2 or CO2 is injected into a drill hole by a heat injection and gas injection extracting pipe and by a high-pressure gas cylinder and a reducing valve, then a certain amount of methane and dry air are injected into a high-temperature and high-pressure combustion chamber by the high-pressure gas cylinder and the reducing valve, to be mixed and combusted to form high-temperature and high-pressure impact wave. High-temperature vapour is injected into the drill holes by the heat injection and gas injection extracting pipe to promote desorption of the coal masses.

Owner:CHINA UNIV OF MINING & TECH +1

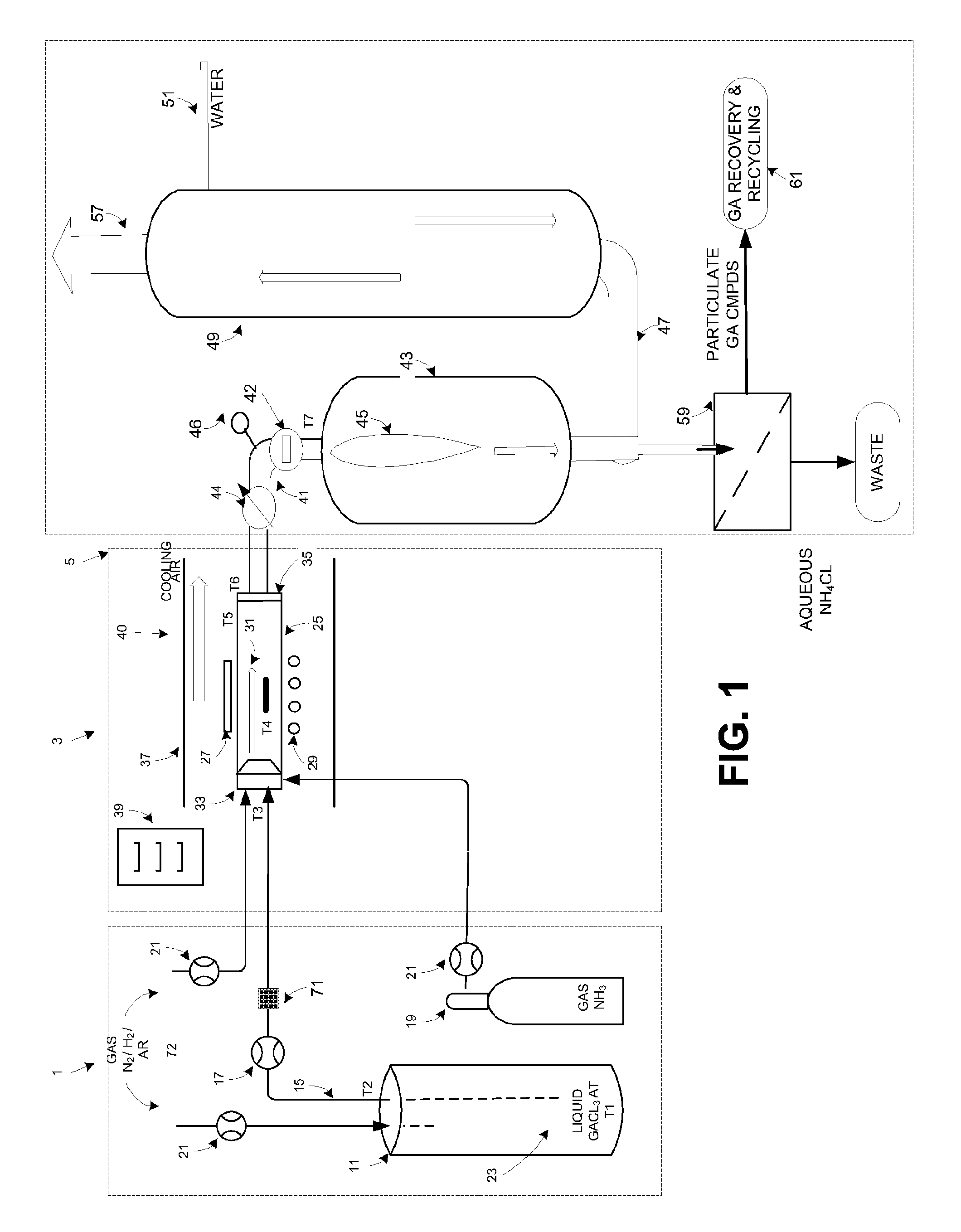

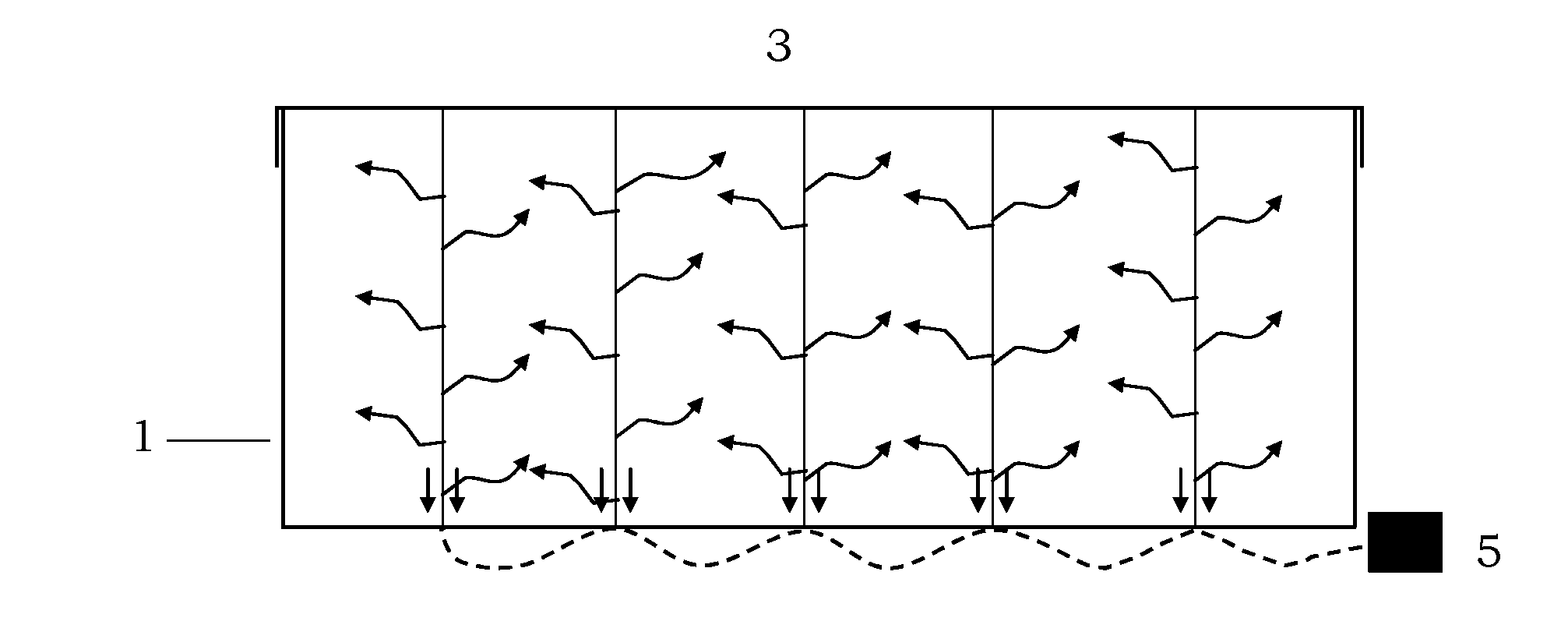

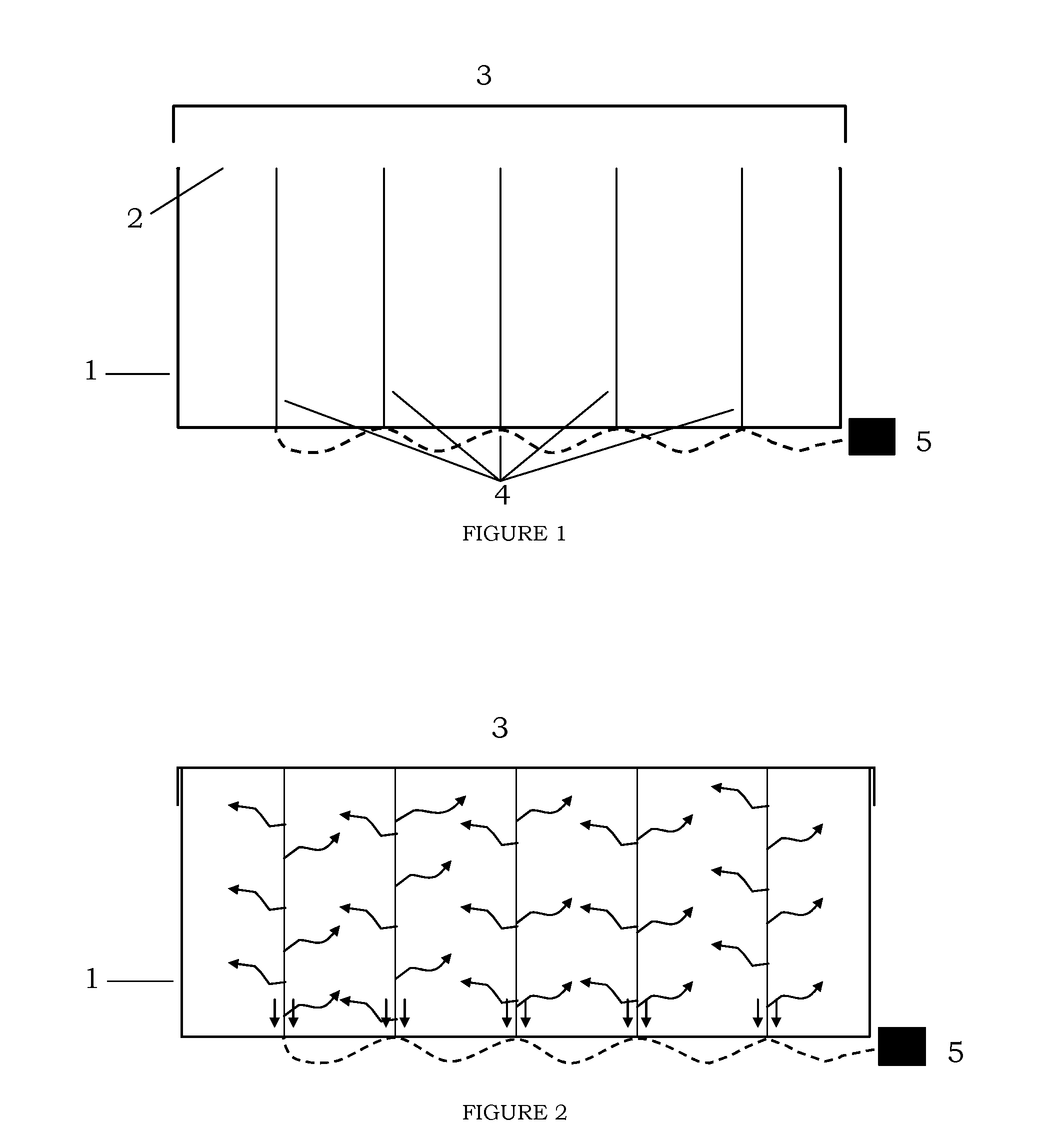

Apparatus for producing graphene and other 2D materials

ActiveUS10533264B1Low costHighly useful materialPolycrystalline material growthFrom chemically reactive gasesPhysical chemistryGraphite

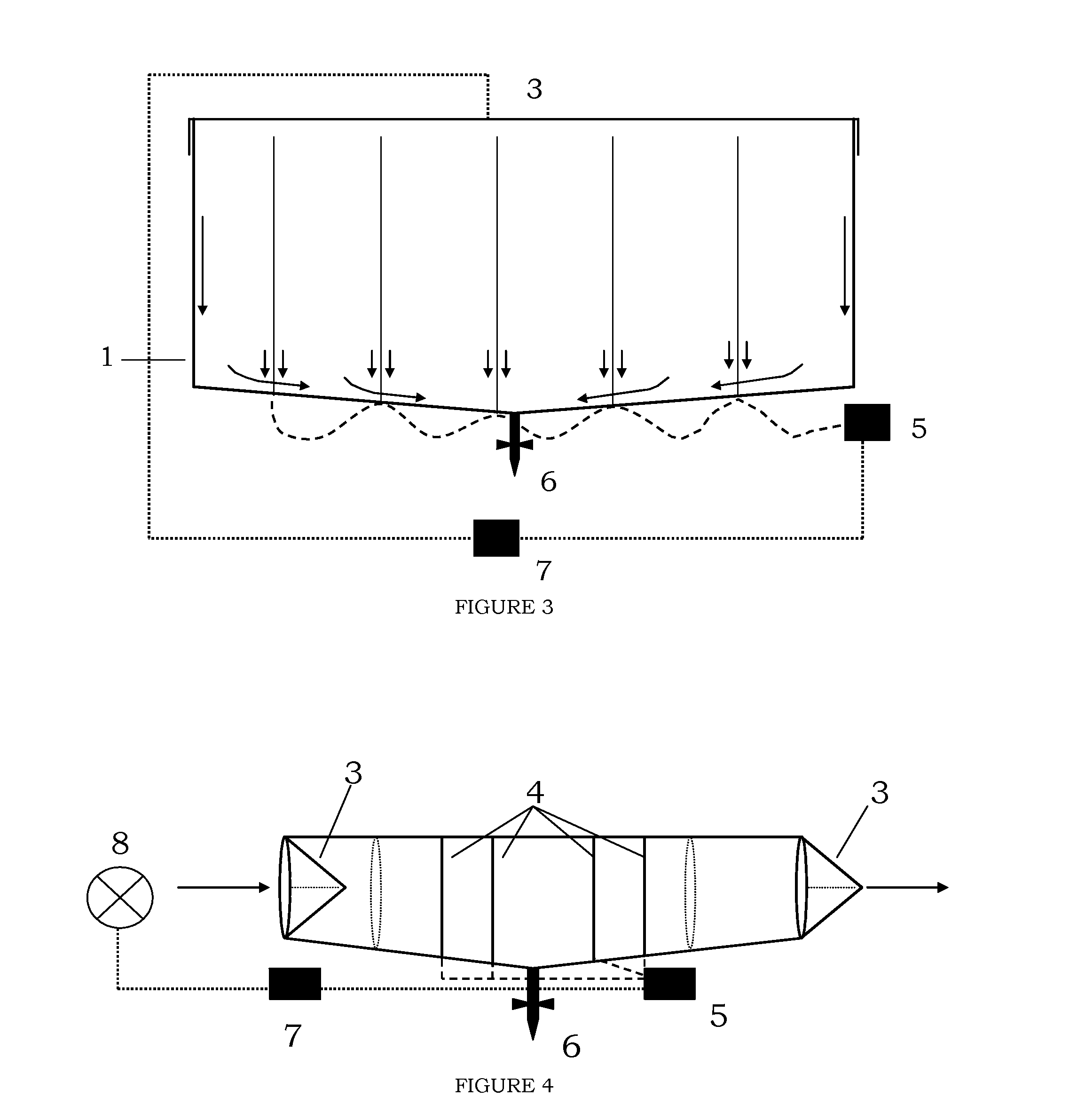

A 2D material such as graphene is produced on a forming sheet disposed on a carrier and exposed to a donor gas within a furnace. A first furnace surface is disposed immediately adjacent to and spaced apart from the forming sheet to define a volume. A purge gas is used to purge the volume of undesirable molecules, such as oxygen, and then a donor gas is introduced into the volume to supply an element or molecule necessary for the formation of a 2D material. Multiple carriers and forming sheets are moved in a train into the furnace during the presence of the donor gas, and each forming sheet is heated to a temperature sufficient to form 2D material on the sheet. The furnace is constructed of a nonreactive material, such as quartz, and the first furnace surface is provided by a quartz plate. Gas passageways and gas ports are formed in the quartz plate with the ports extending through the first furnace surface. The ports are disposed in patterns that facilitate the production of a smooth nonturbulent laminar flow of gas within the volume. As gases are introduced into the furnace, the gases are constrained but they escape and are collected by a surrounding gas chamber. Undesirable gases are purged and desirable gases are maintained in both the furnace and the gas chamber.

Owner:GENERAL GRAPHENE CORP

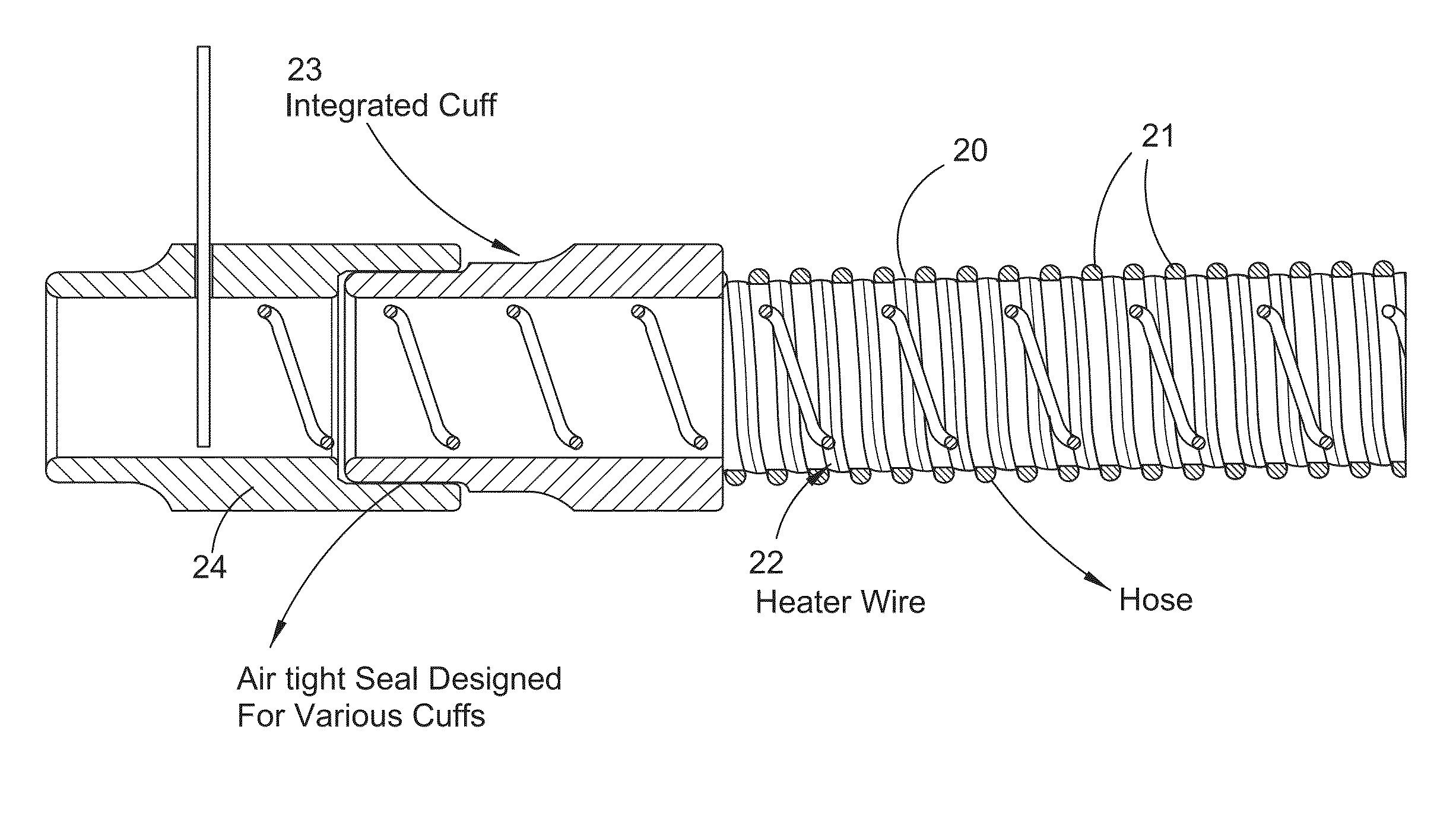

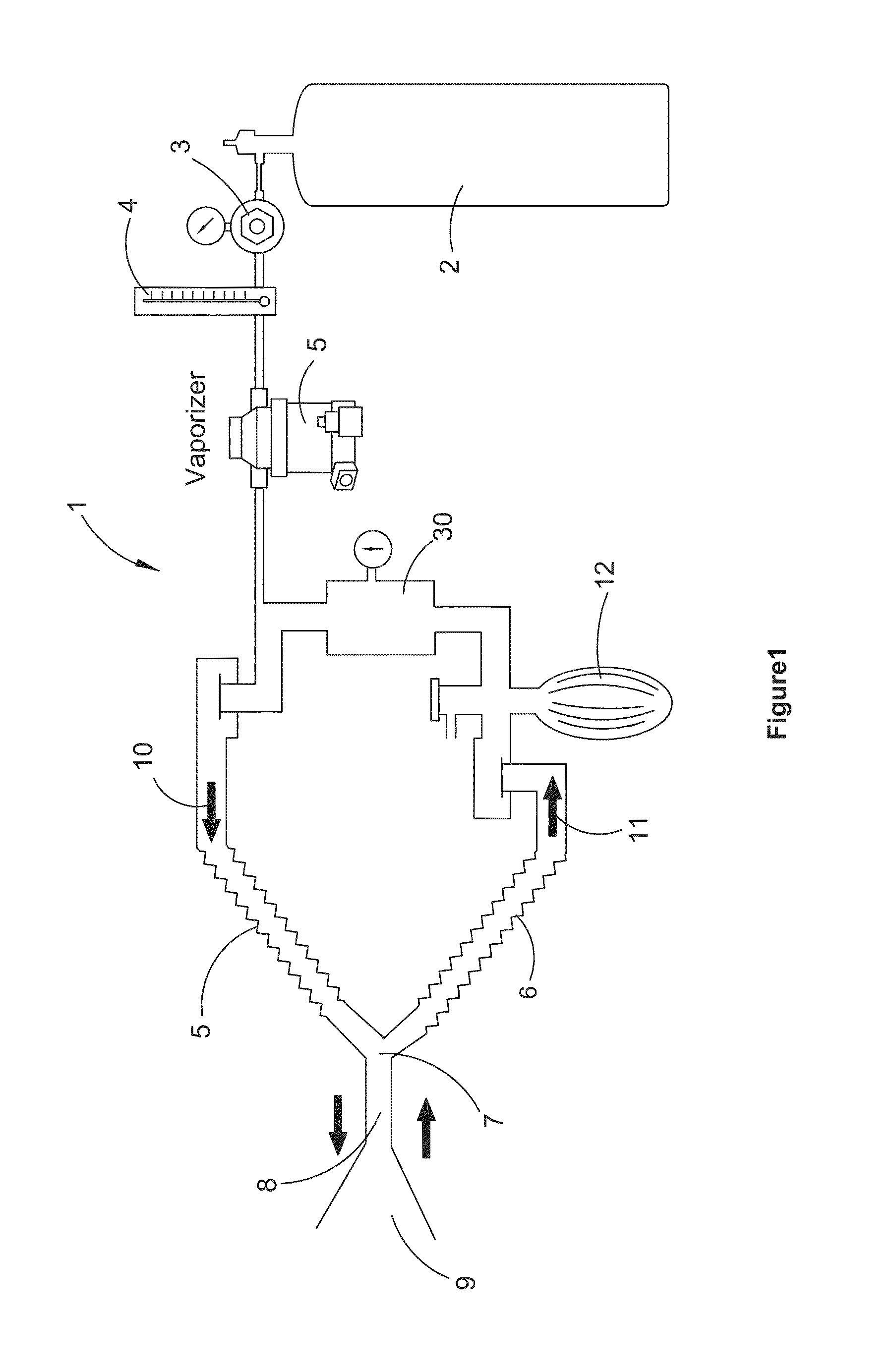

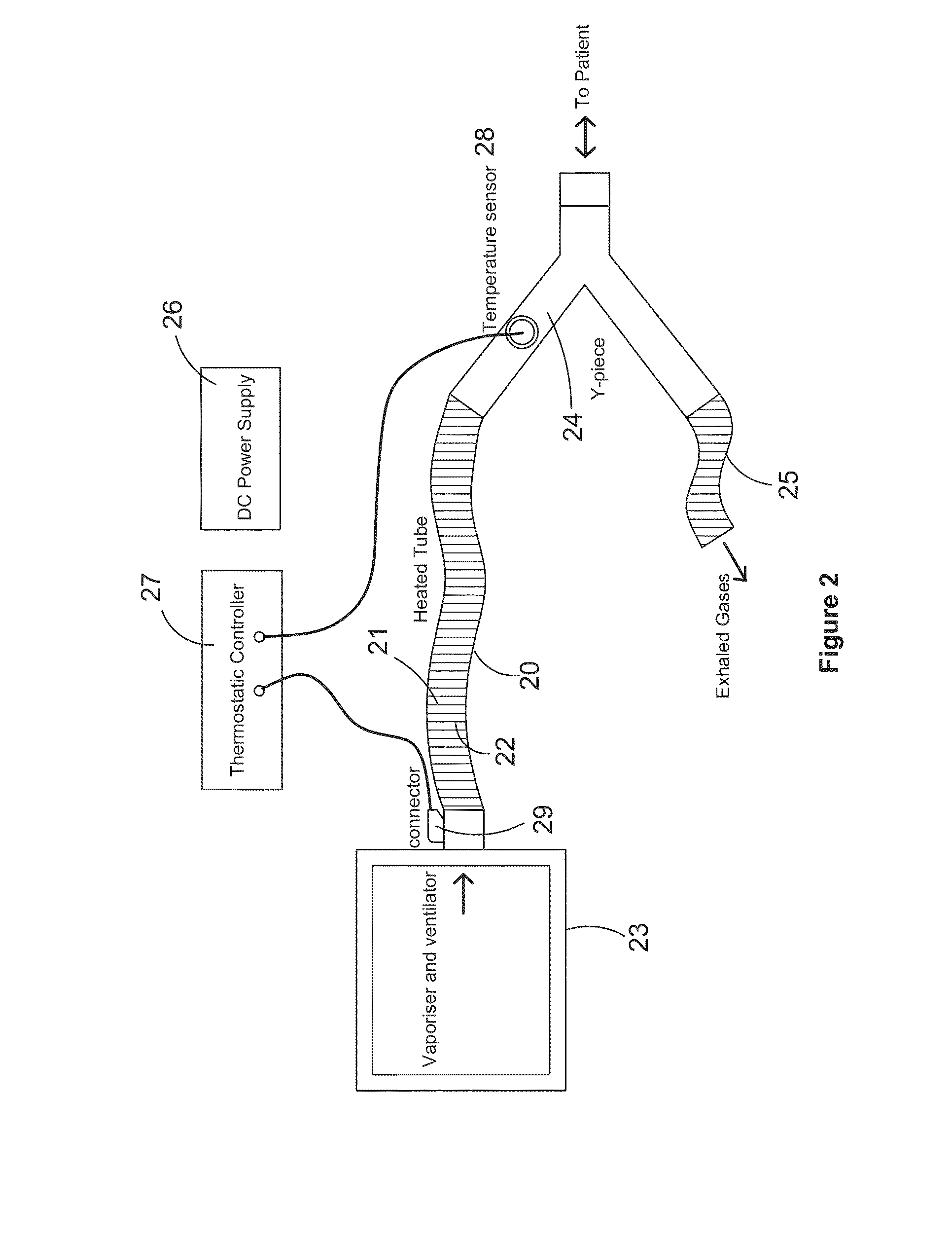

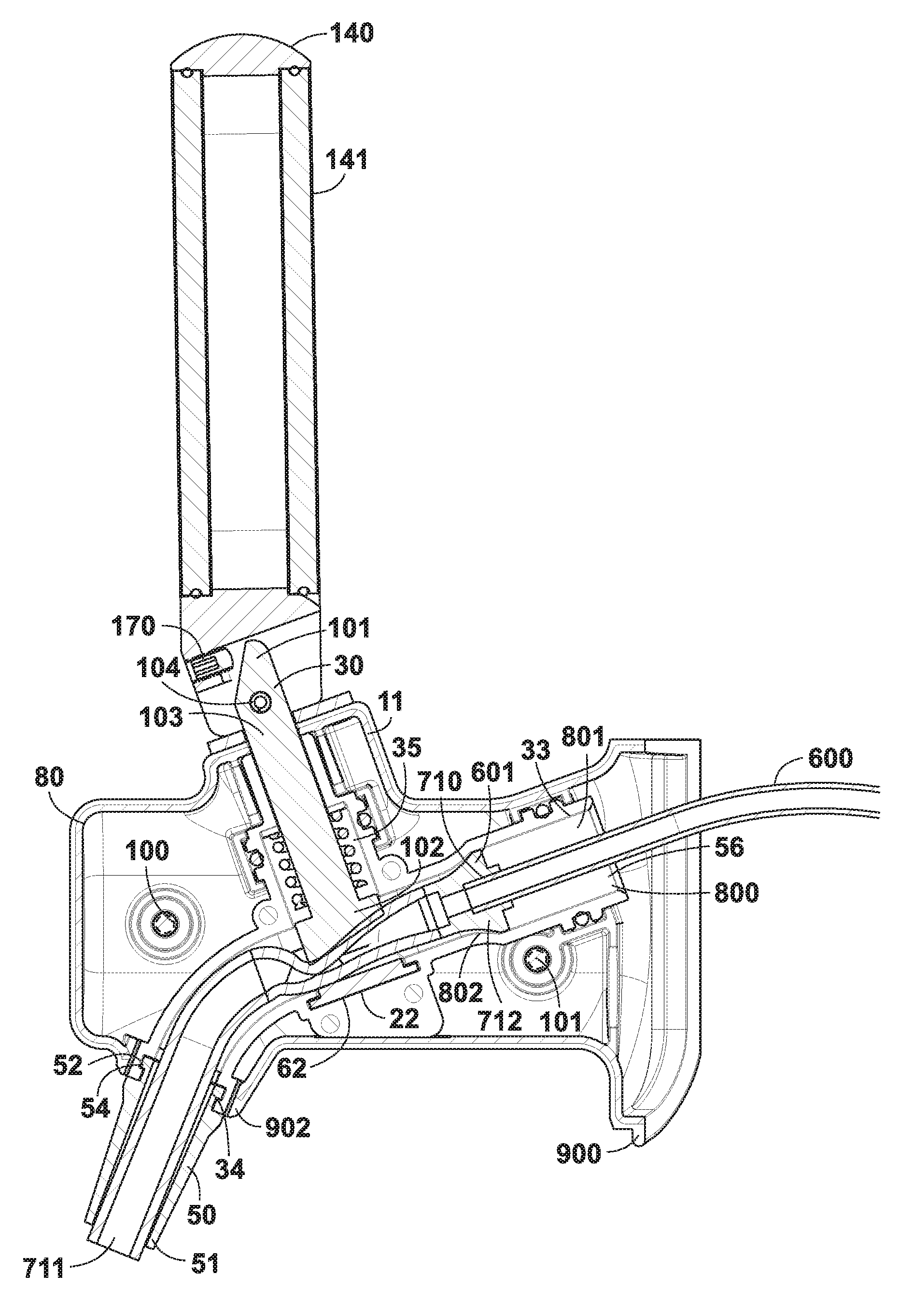

Apparatus and method for maintaining patient temperature during a procedure

ActiveUS20150020803A1Easy maintenanceMinimize dangerRespiratorsMedical devicesElectrical conductorIntensive care medicine

The present invention relates to an apparatus and method for maintaining patient temperature during an anaesthetic procedure. Patients, particularly small patients, can lose body temperature when undergoing surgery or other procedures where they are anaesthetised. The process of breathing the cool anaesthetic gas contributes to the temperature loss of the patient. An anaesthetic apparatus of the present invention is arranged to warm the gas being provided for the patient to breathe, to facilitate maintaining body temperature. An inspired limb of an anaesthetic circuit comprises tubing with a heating conductor for heating the inspired gas.

Owner:DUNLOP COLIN

Creamy foam beer dispensing system

ActiveUS8678247B2Easy to createSpeed up the flowOpening closed containersBottle/container closureEngineeringMechanical engineering

Owner:LANCER PARTNERSHIP

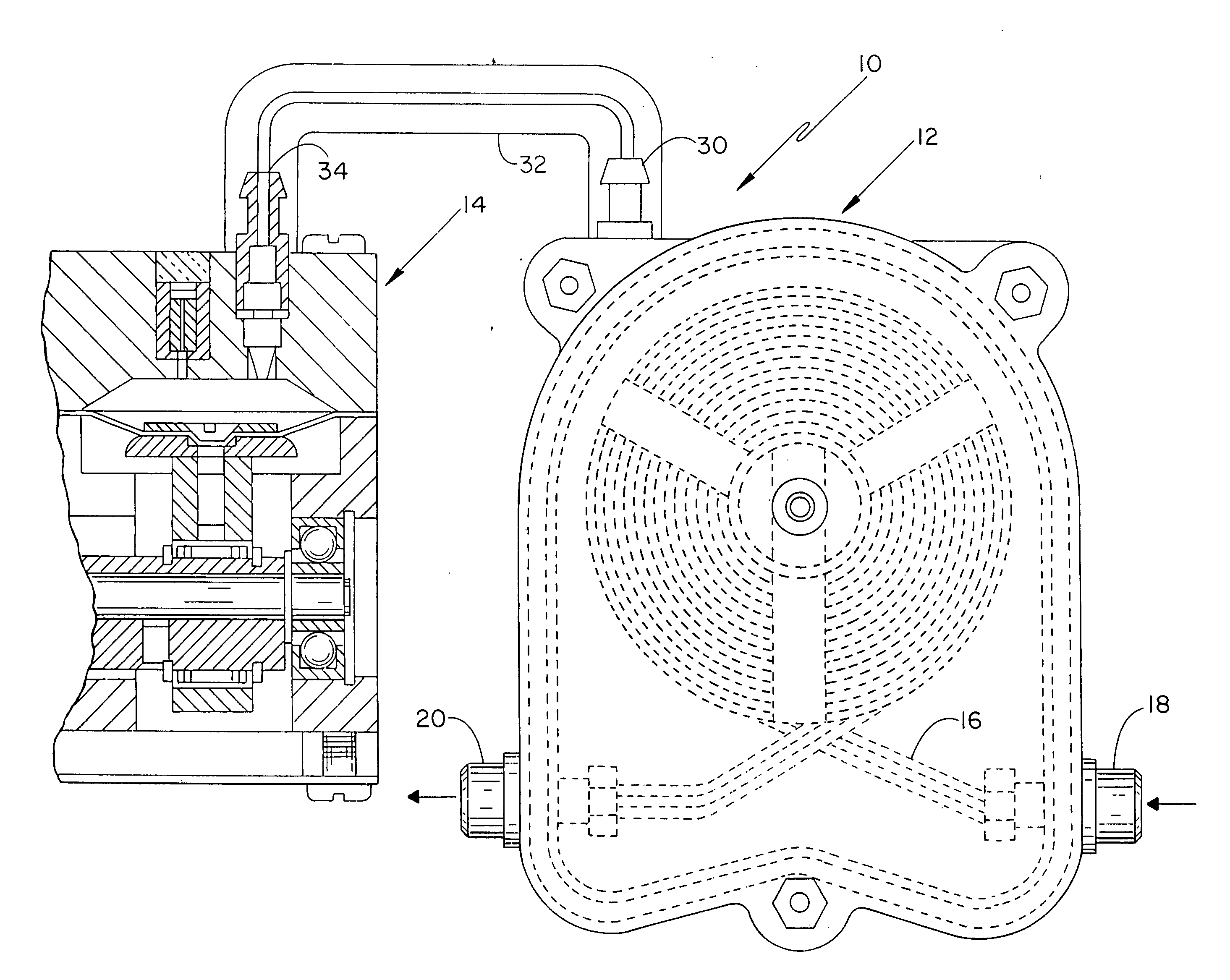

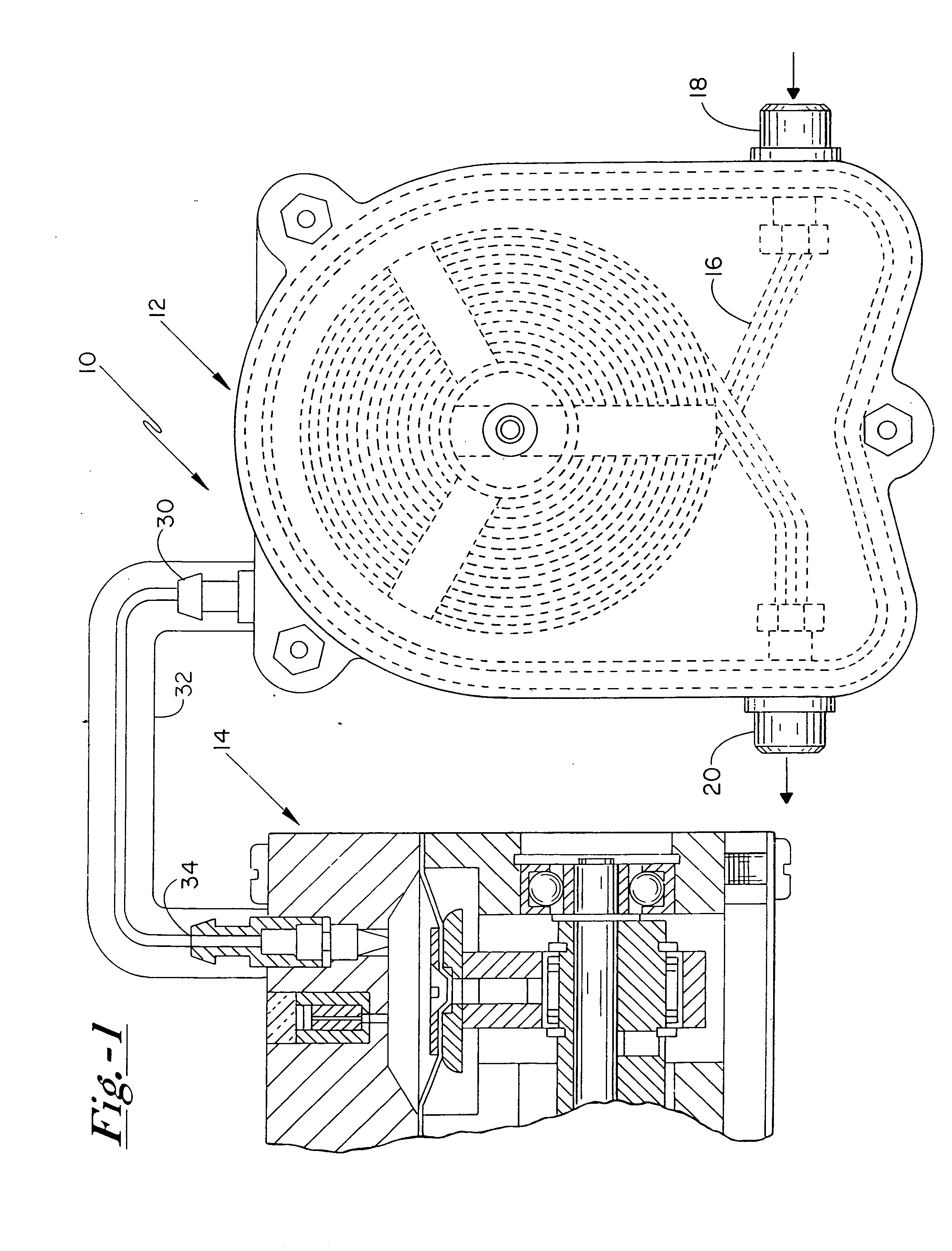

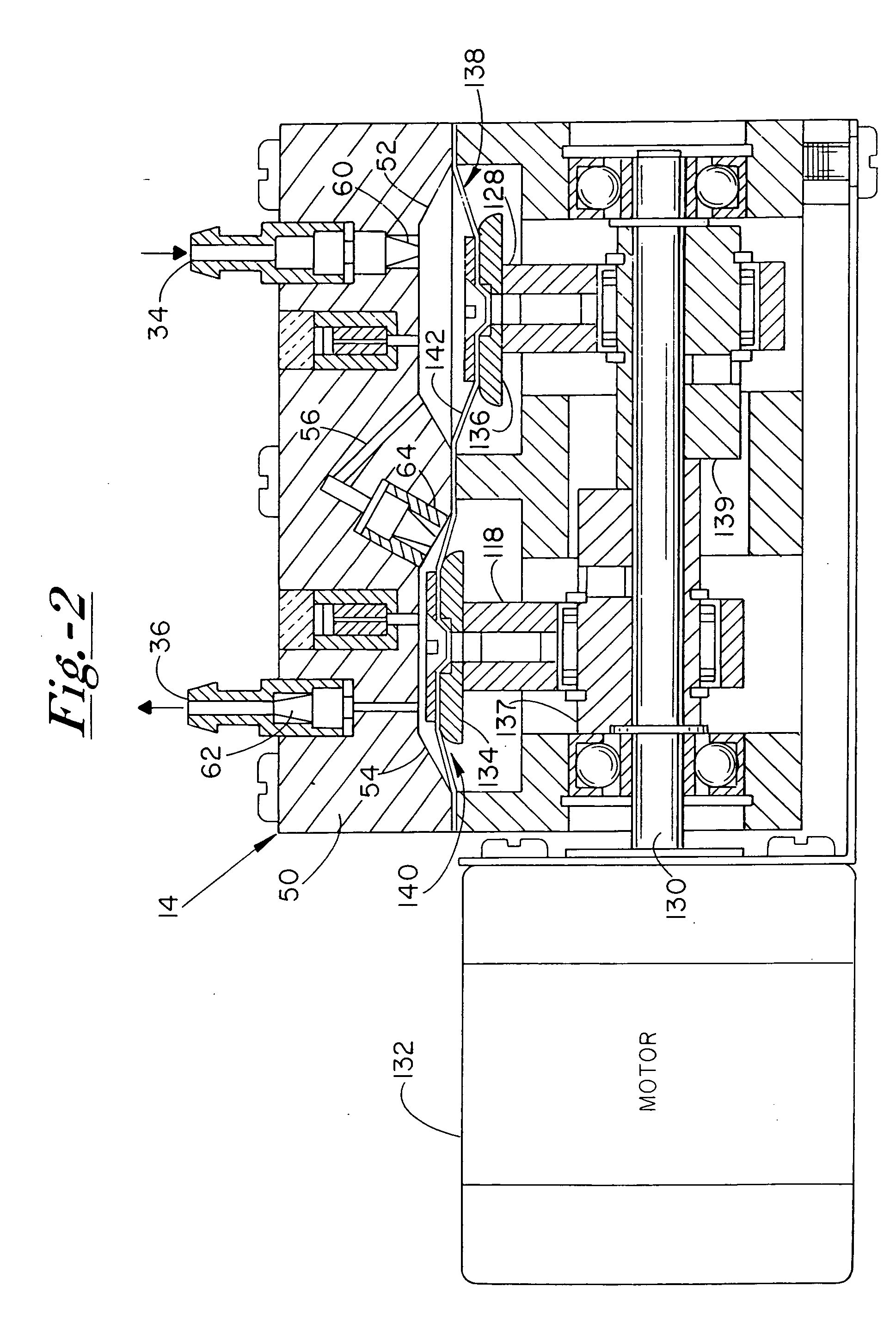

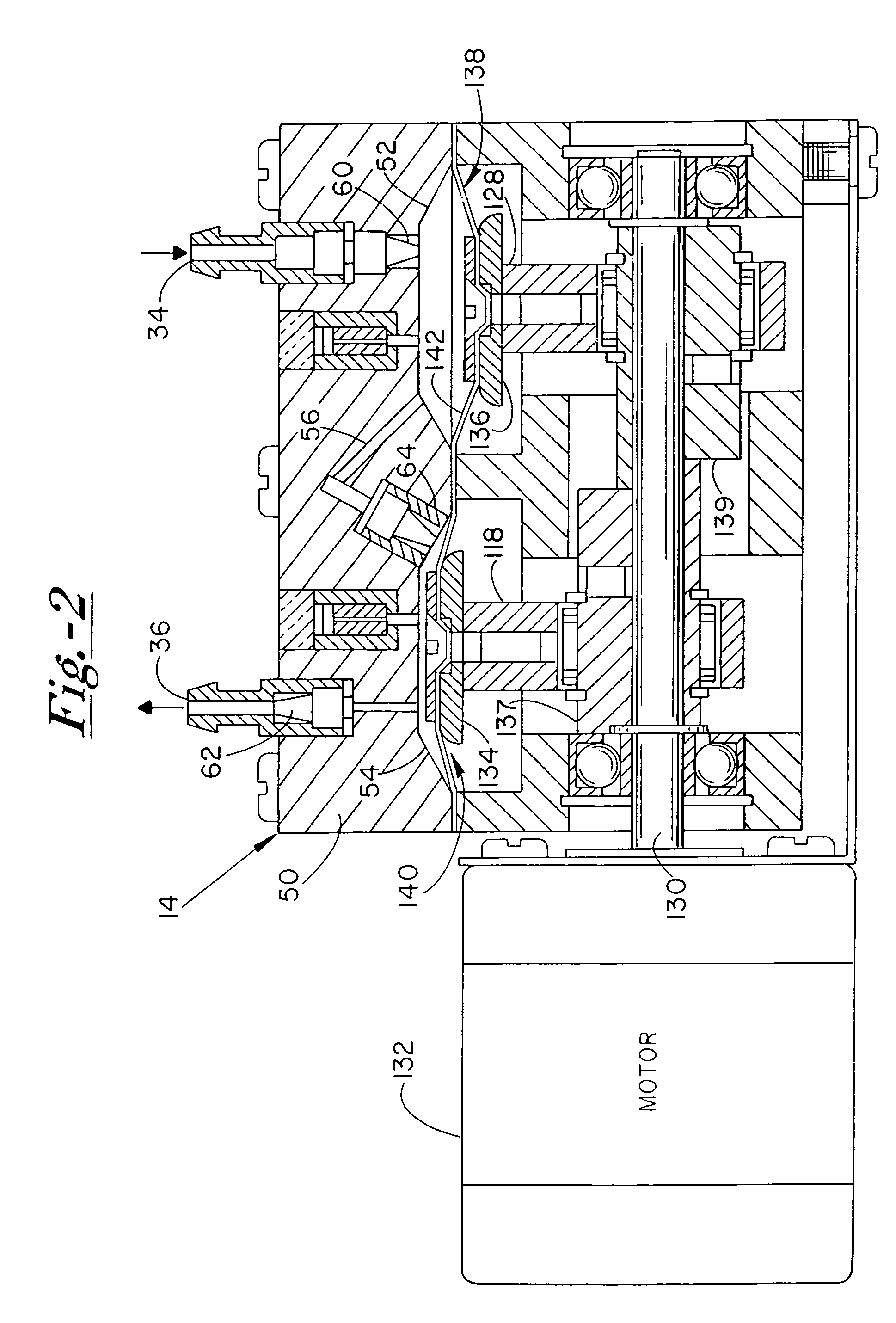

Capillary flow restrictor apparatus

ActiveUS20070261553A1Minimize the possibilityEasy to operateFlexible member pumpsLiquid degasification regulation/controlEngineeringSolvent

A pump for use in operably evacuating a chamber in a vacuum degassing apparatus includes one or more pumping cavities that are in fluid communication with the chamber, and a continuous vent channel that has an outlet disposed in fluid communication with a respective one of the one or more pumping cavities. The vent channel is configured to provide dilution gas flow into the pumping cavity of the pump at a rate sufficient to prevent solvent condensation in the pumping cavity during operation of the pump in liquid degassing applications.

Owner:IDEX HEALTH & SCI

Capillary flow restrictor apparatus

ActiveUS7399345B2Minimize the possibilityEasy to operateFlexible member pumpsLiquid degasification regulation/controlEngineeringSolvent

A pump for use in operably evacuating a chamber in a vacuum degassing apparatus includes one or more pumping cavities that are in fluid communication with the chamber, and a continuous vent channel that has an outlet disposed in fluid communication with a respective one of the one or more pumping cavities. The vent channel is configured to provide dilution gas flow into the pumping cavity of the pump at a rate sufficient to prevent solvent condensation in the pumping cavity during operation of the pump in liquid degassing applications.

Owner:IDEX HEALTH & SCI

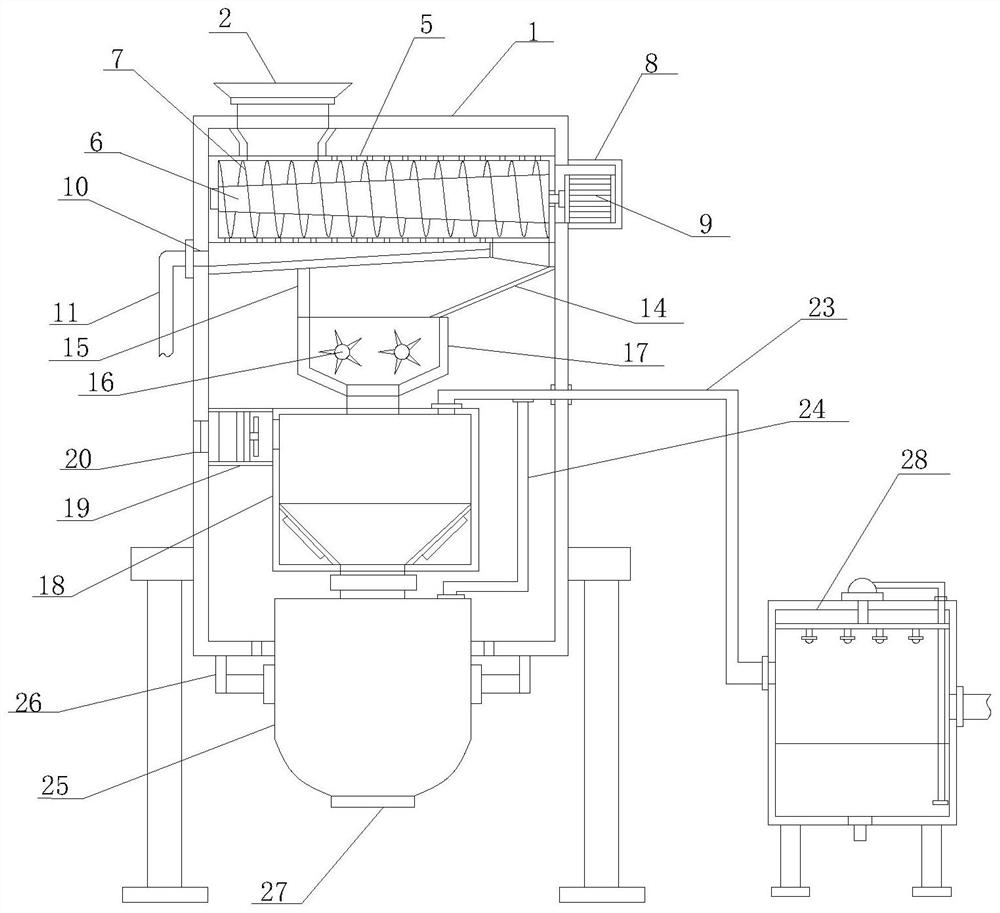

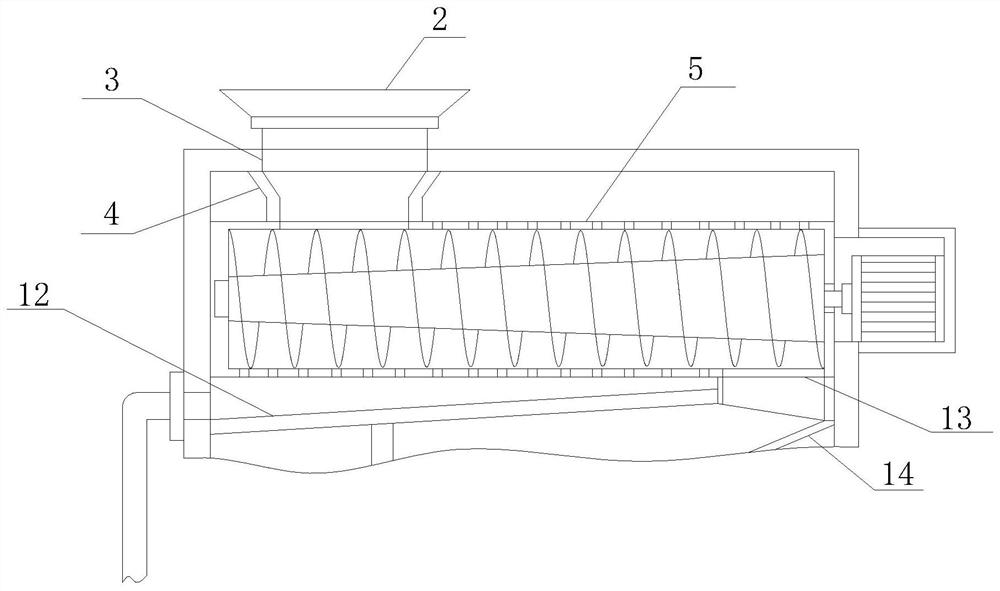

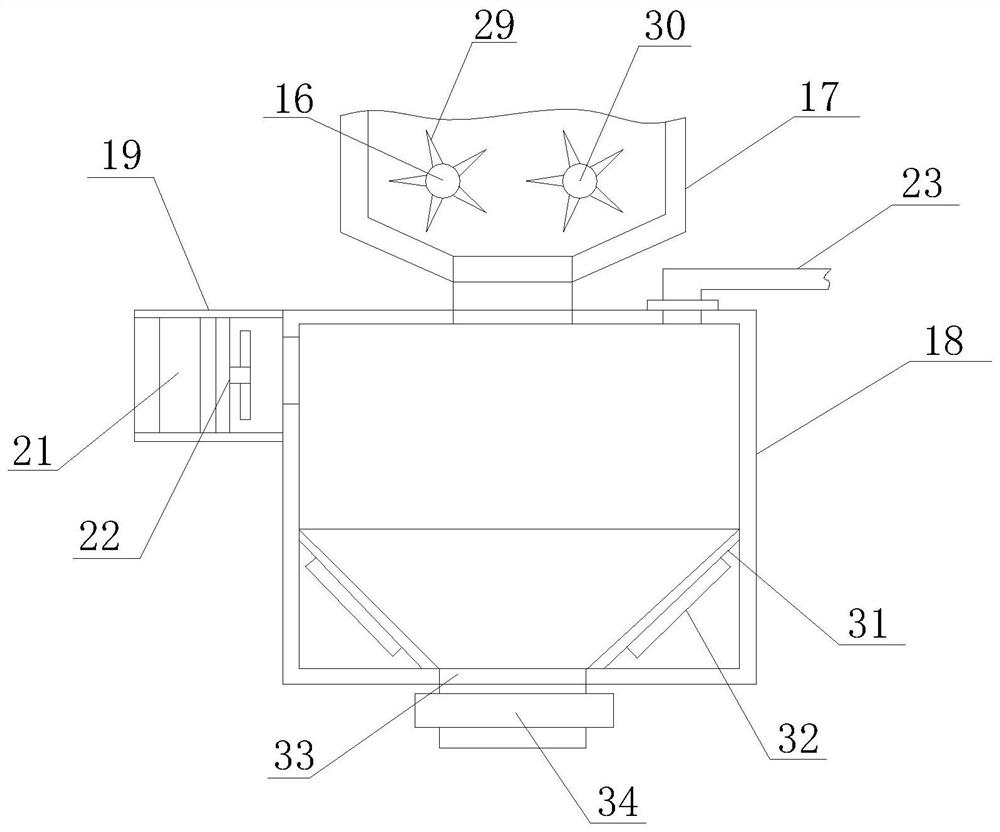

Garbage drying and pyrolyzing method

InactiveCN111853802AReduce moisture contentFast pyrolysisUsing liquid separation agentDrying solid materials without heatElectric machineDust control

The invention discloses a garbage drying and pyrolyzing method. The method comprises the following steps that pyrolytic garbage is poured into a feeding hopper, the garbage enters an extrusion cylinder, a driving motor is started to drive an extrusion rotating shaft to rotate, the garbage moves rightwards under the action of a spiral blade, the garbage is extruded through the inner wall of the extrusion cylinder to discharge water, sewage drips into a sewage tank and is discharged from a sewage outlet, and the garbage enters a crushing box from a first discharging opening; a crushing motor isstarted to drive a first crushing shaft and a second crushing shaft to rotate, crushing blades on the crushing shafts crush the garbage, and the crushed garbage enters a drying box; and a first heating plate, a second heating plate and a fan are started to dry the garbage in the drying box, generated gas enters a dust removal water tank from an exhaust pipe, an electric valve at the bottom of thedrying box is opened, and the dried garbage is discharged into a pyrolyzing furnace. According to the method, the moisture content in the garbage is greatly reduced, the pyrolysis speed of the garbagein the pyrolyzing furnace is increased, residues are reduced, and generated gas does not contain a large amount of incineration particles.

Owner:济南鸿泰华丰机械有限公司

Table

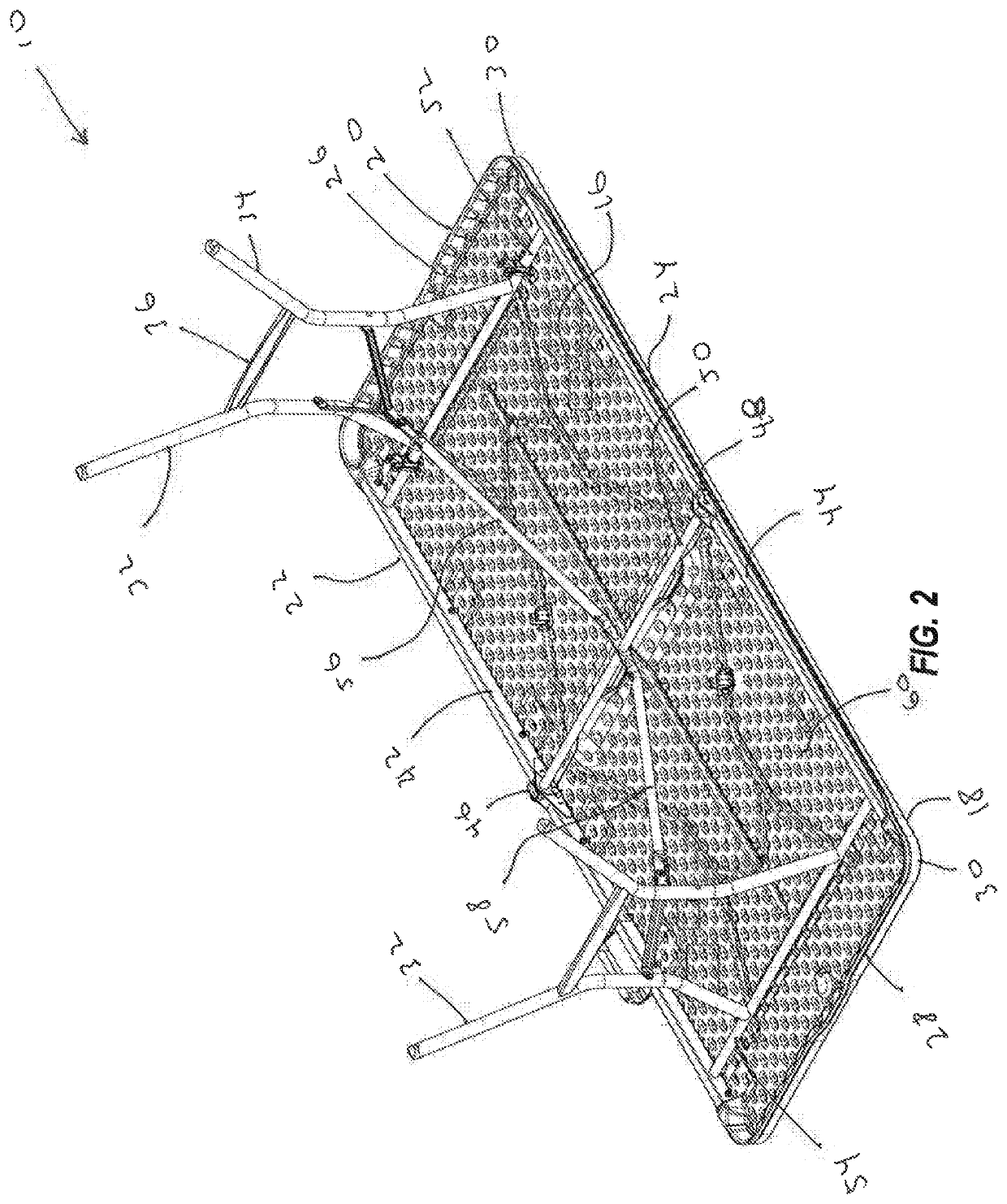

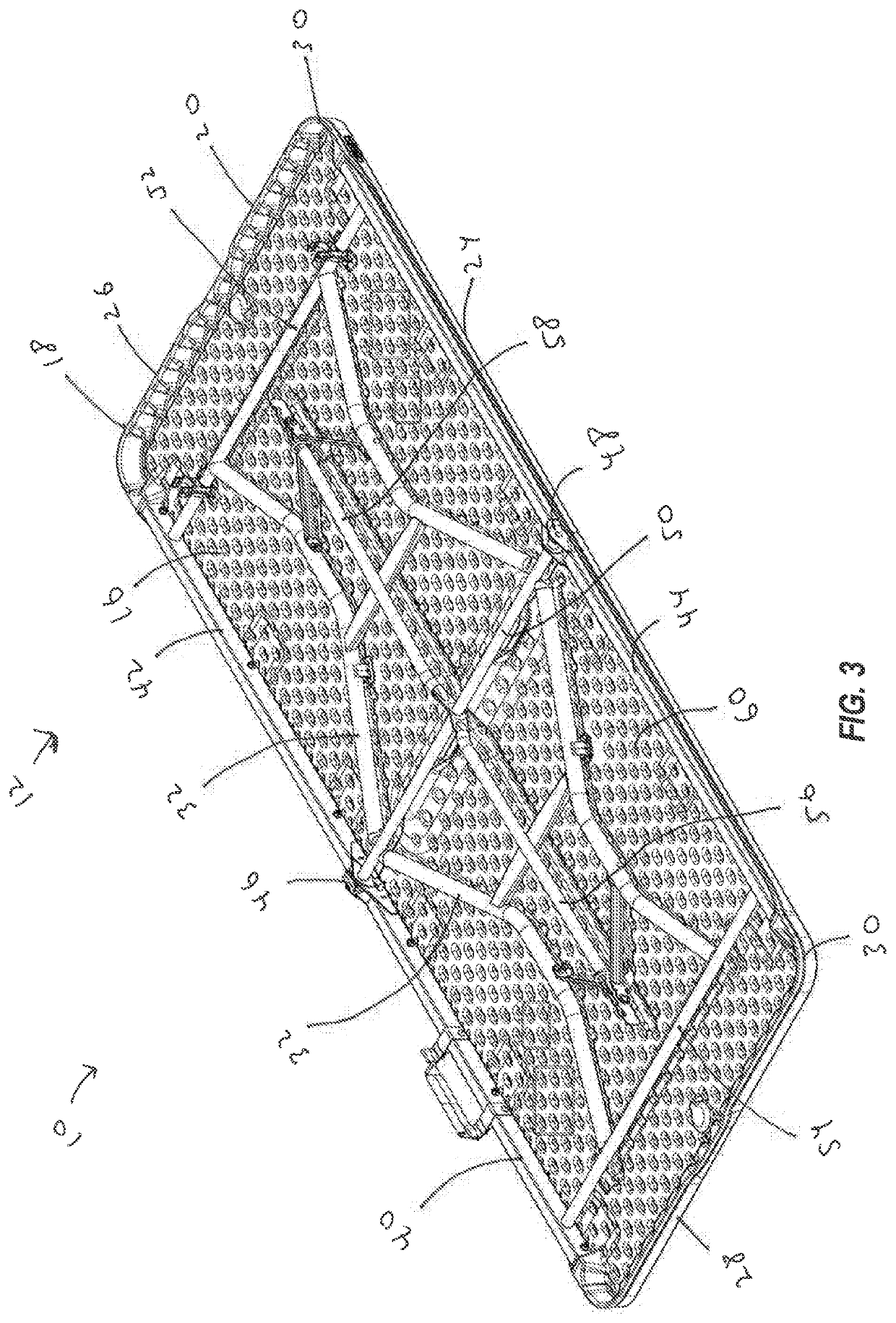

ActiveUS20200214440A1Enhanced strength and structural rigiditySpeed up gas flowFoldable tablesStowable tablesMechanical engineeringPhysics

Owner:LIFETIME PRODUCTS

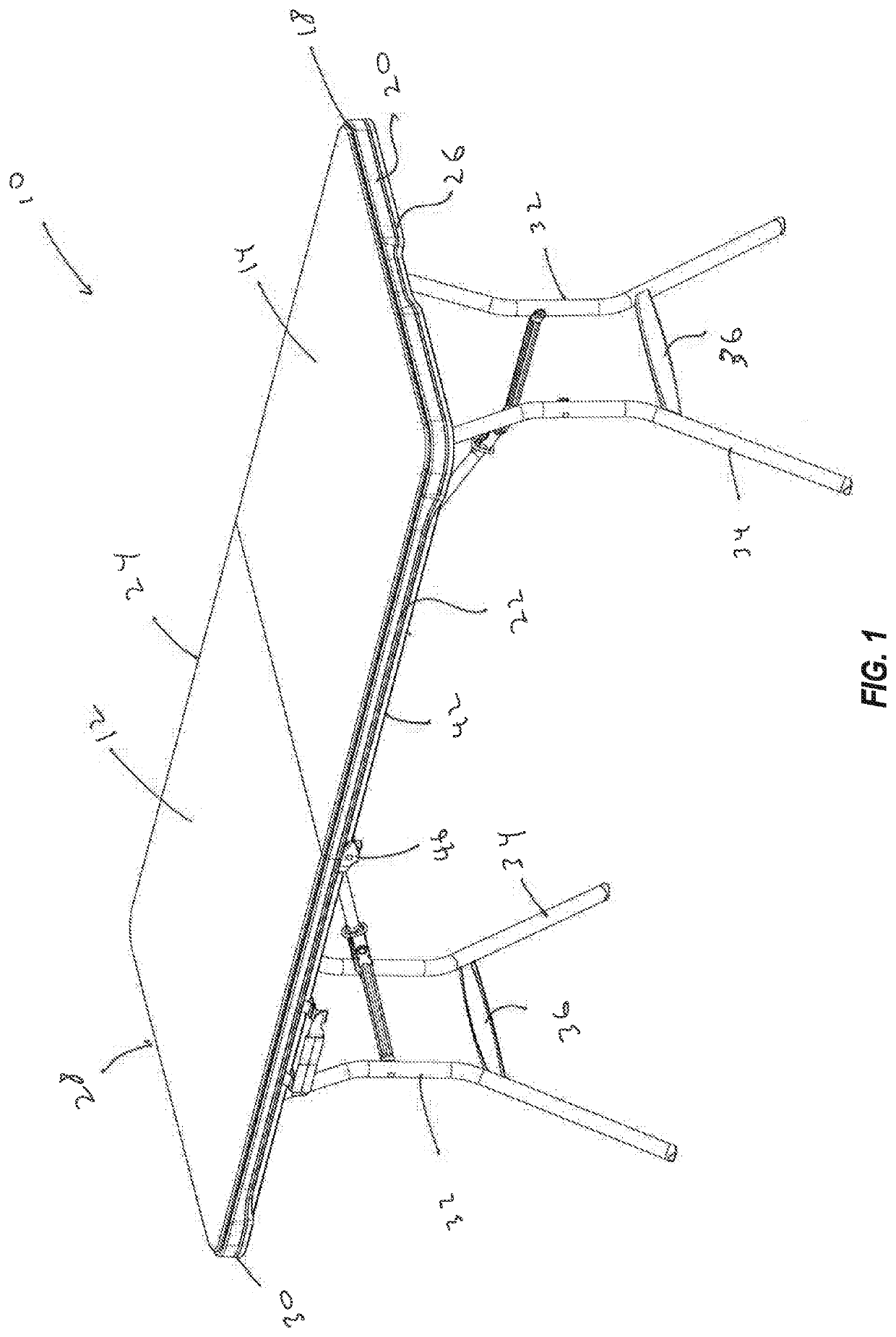

Modular gun silencer

InactiveUS20180058789A1Easy to assembleReduce manufacturing costMuzzle attachmentEngineeringProjectile

A modular silencer includes an outer tube and a plurality of chamber separators suspended through a tensile force within a bore of the outer tube and defining chambers between each pair of chamber separators in the silencer. An outer edge of the chamber separators is spaced apart from an inner surface of the tube to allow gas equalization between the chambers. A plurality of tube portions separate the chamber separators from each other and from the proximal and distal ends of the silencer assembly. The tube portions define a continuous center tube suspended in tension within the outer tube and through which the projectile travels. The tube portions have can have angled openings through which gas discharge exits into the chambers. Rotatable sleeves can be disposed over the tube portions to further disrupt gas flow and dissipate heat and sound. A carbon fiber sleeve can be disposed over the outer tube to inhibit burn injuries from contacting the silencer.

Owner:MAD MINUTE IP HOLDCO INC

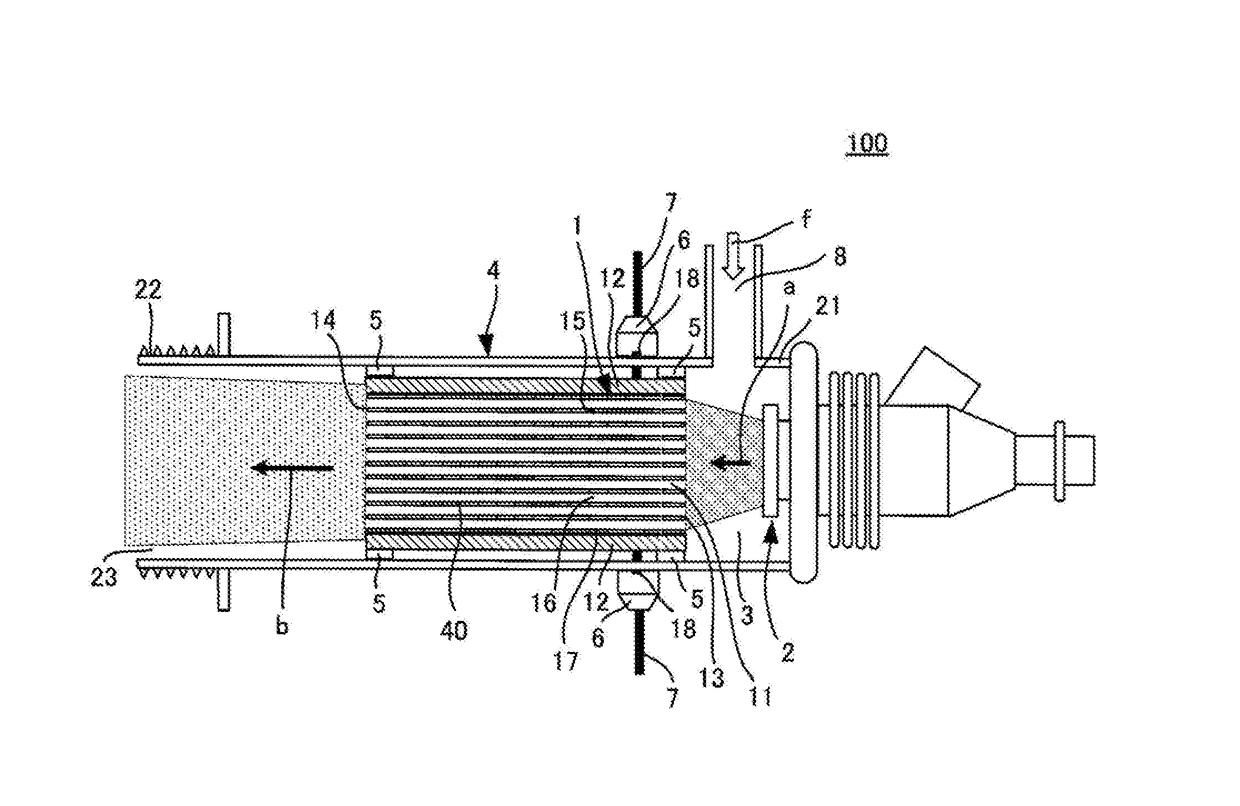

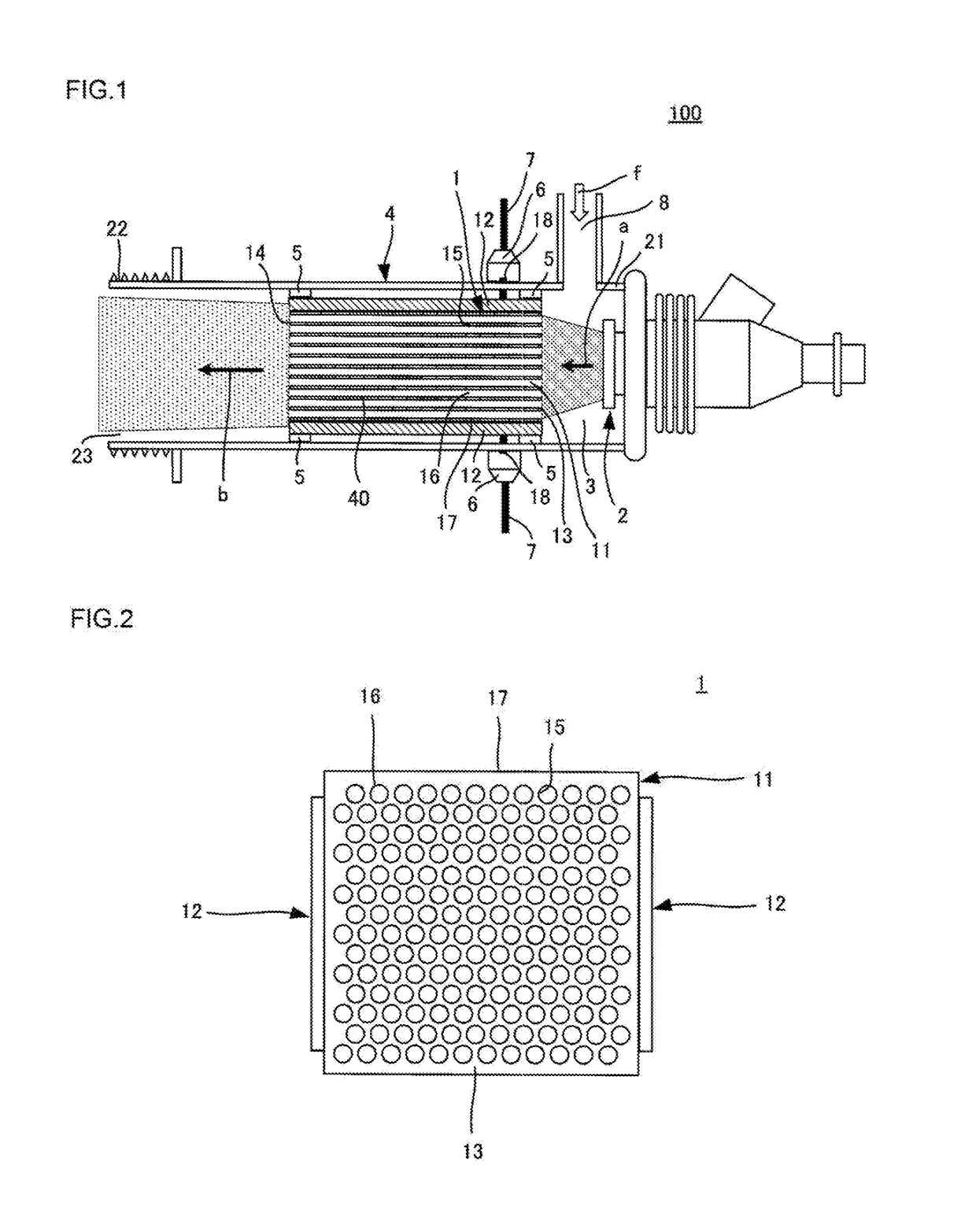

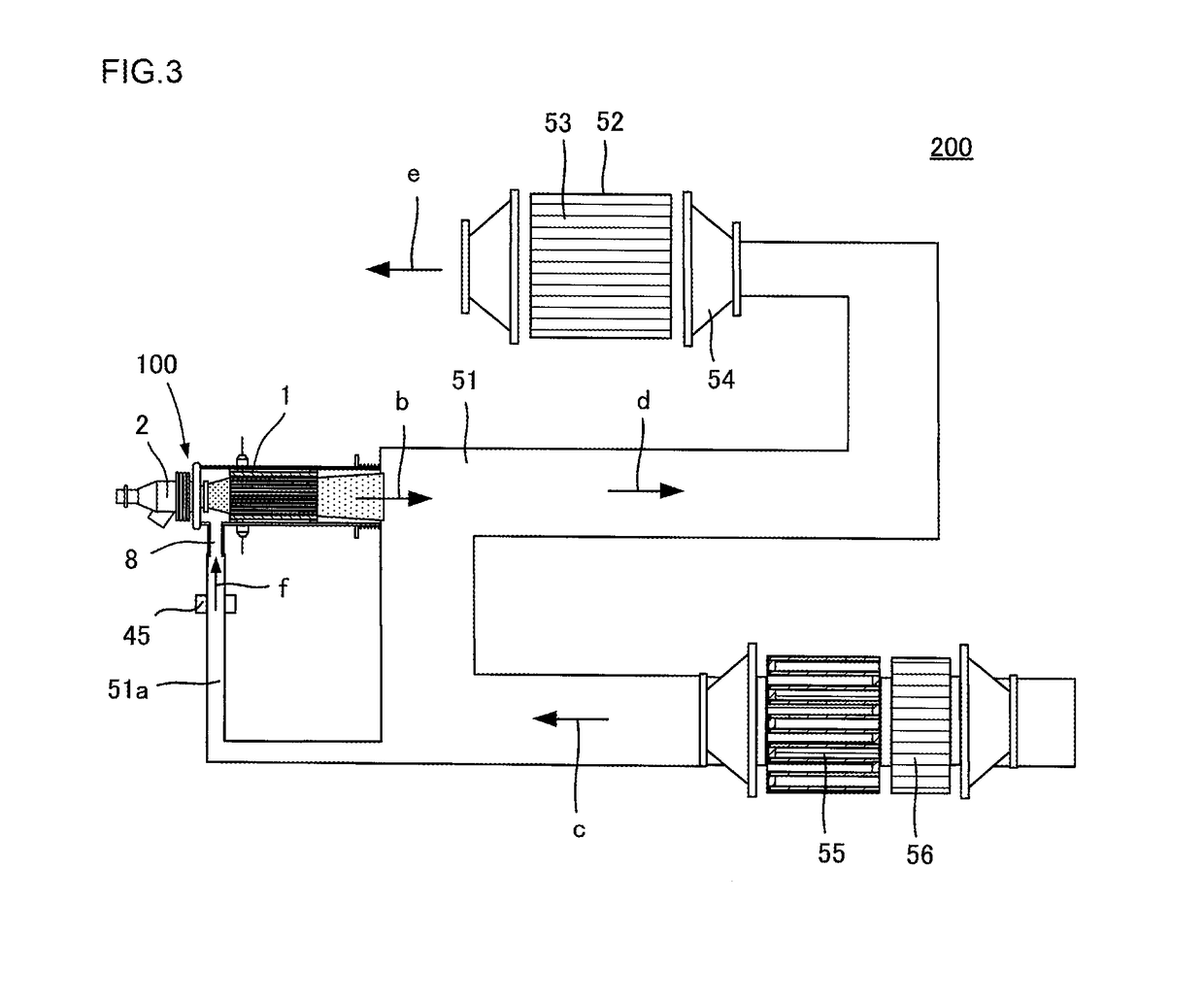

Reducing agent injection device and exhaust gas treatment method

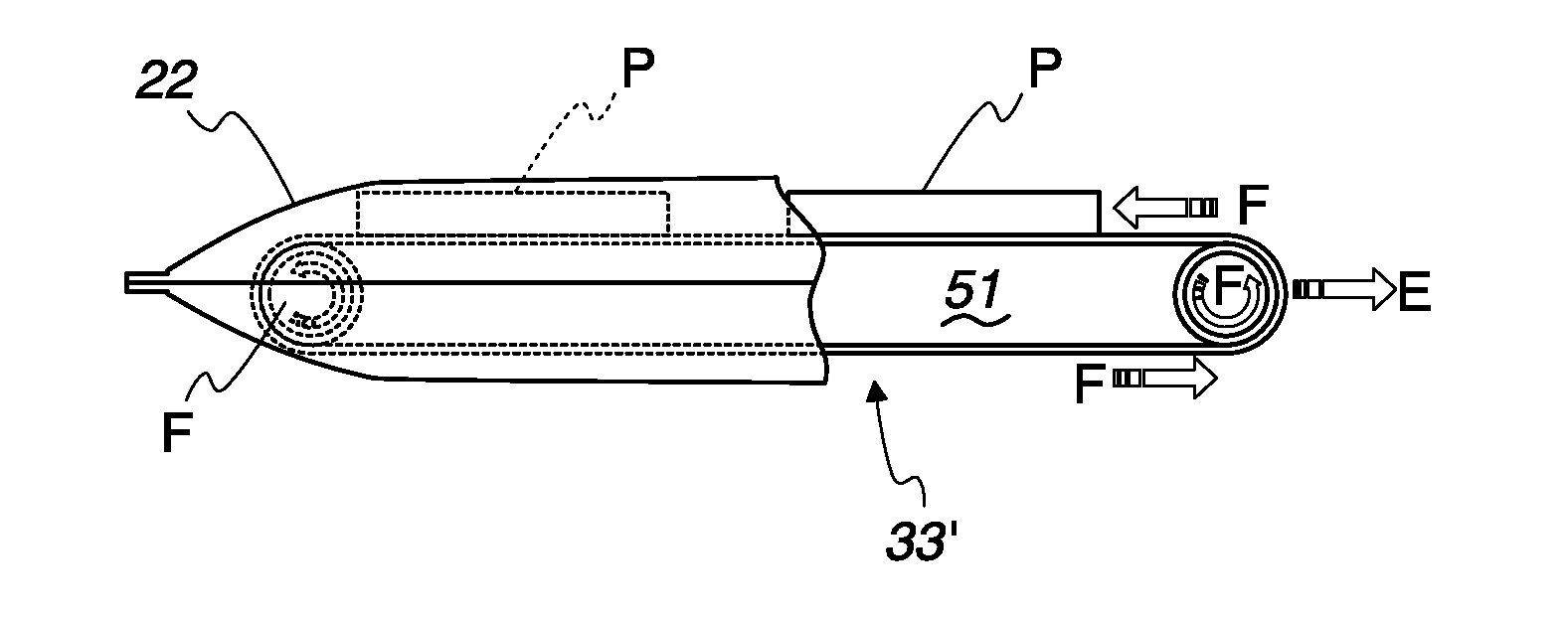

ActiveUS20170284258A1Speed up gas flowEasy to moveGas treatmentInternal combustion piston enginesExhaust gasHoneycomb structure

A reducing agent injection device includes a honeycomb structure and a urea spraying device spraying a urea water solution in mist form. In addition, the reducing agent injection device includes a carrier gas inlet that introduces carrier gas f between the urea spraying device and the honeycomb structure. The exhaust gas treatment method of the present invention supplies the urea water solution from the urea spraying device into the cells from the first end face of the honeycomb structure body to generate the ammonia, while introducing the carrier gas f from the carrier gas inlet, and injecting the ammonia to the outside to treat exhaust gas containing NOX.

Owner:NGK INSULATORS LTD

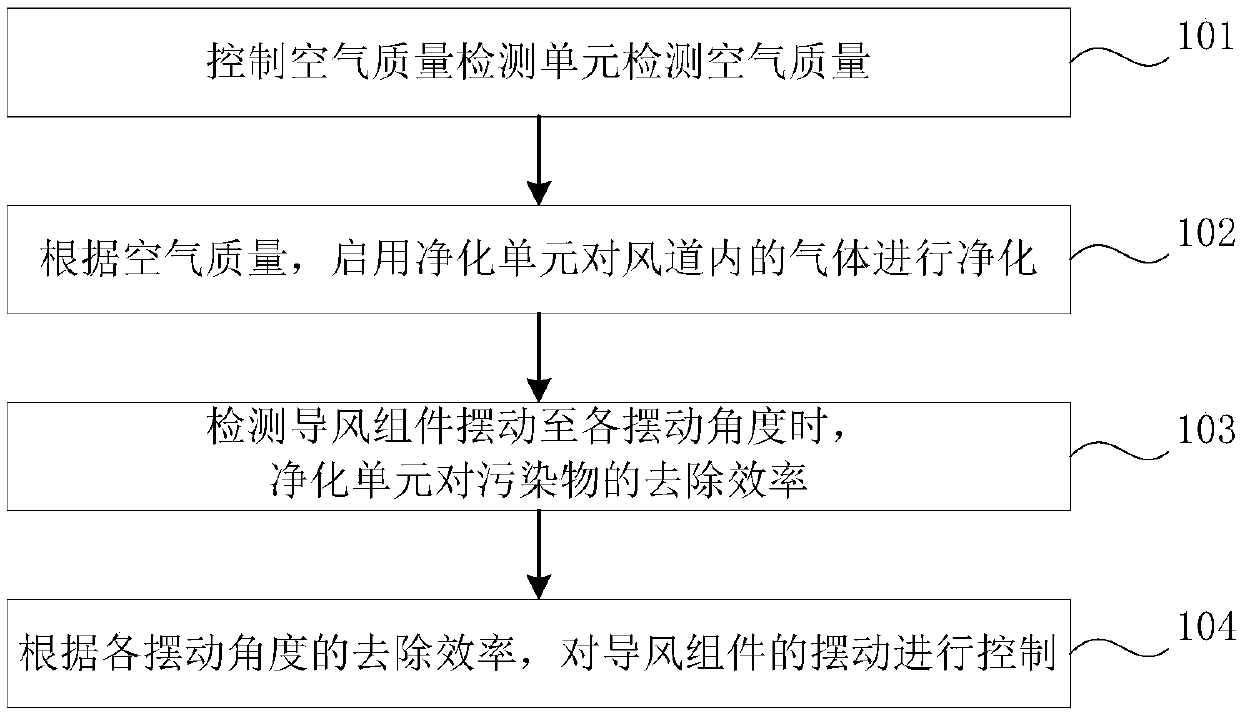

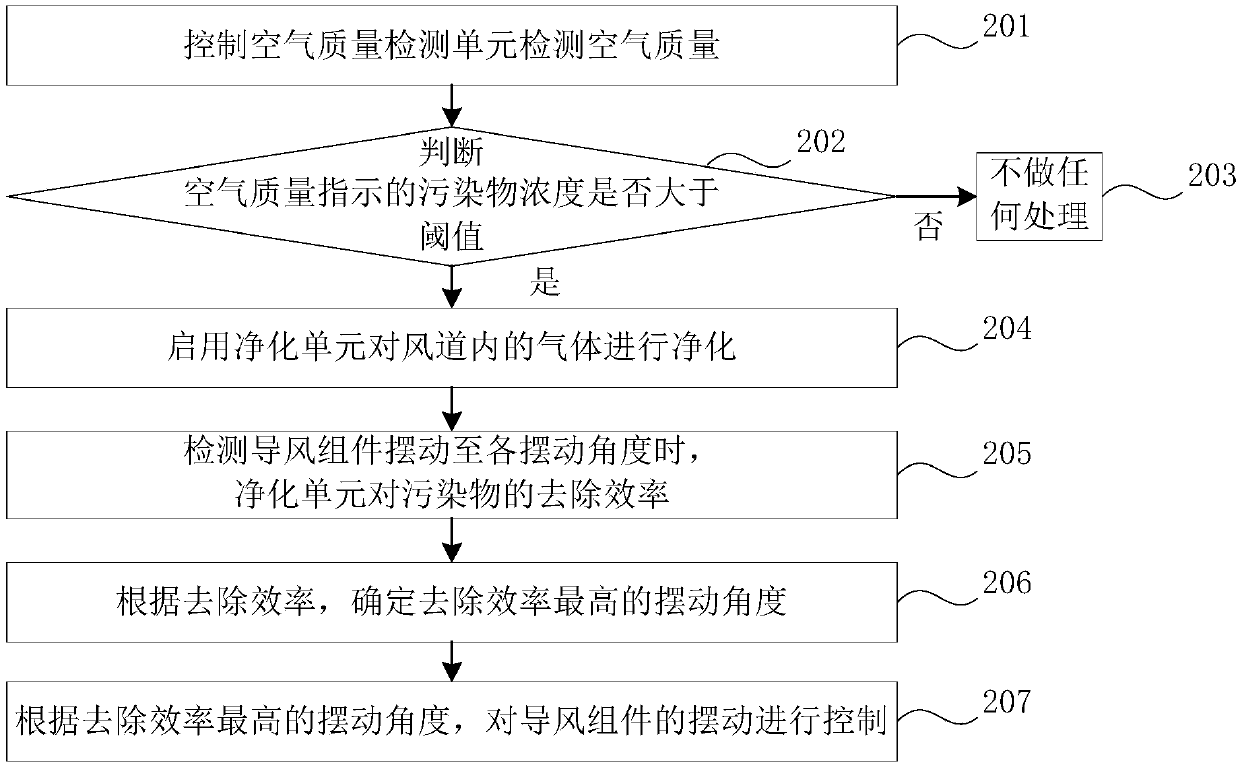

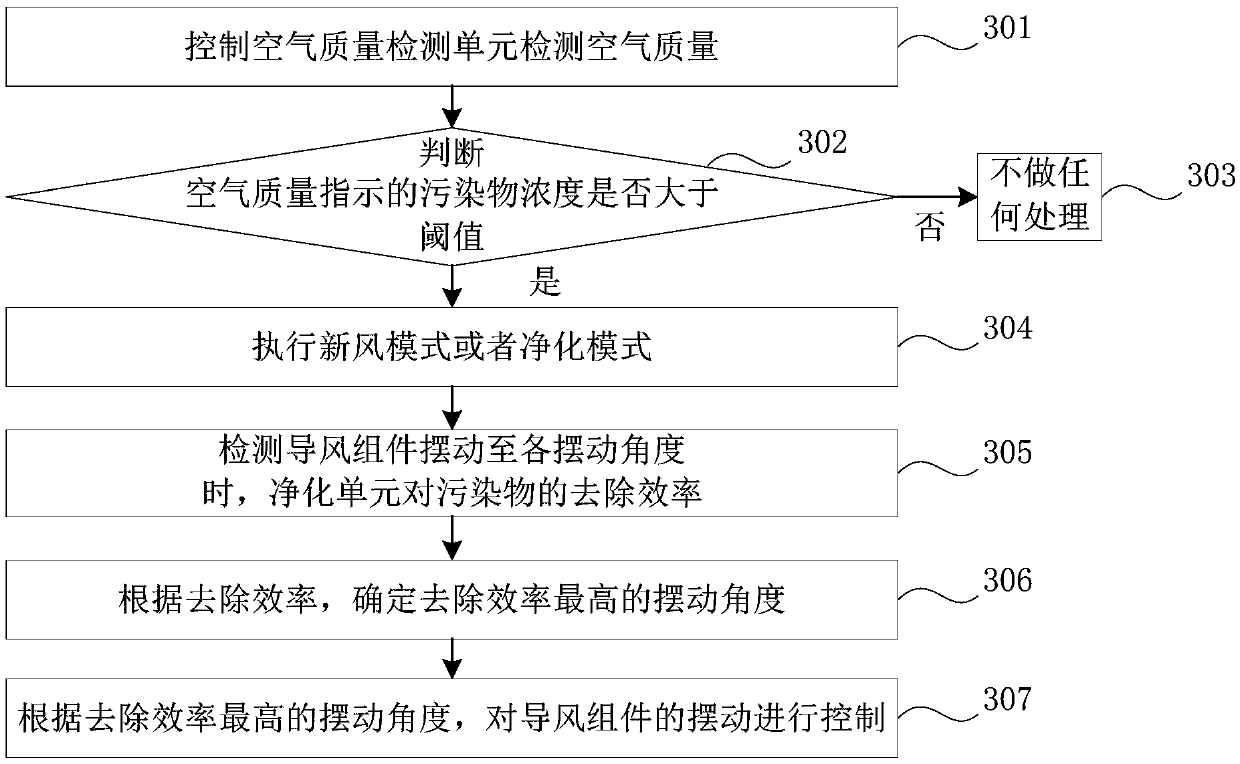

Air conditioning unit control method and device, and air conditioning unit

ActiveCN109668260AImprove removal efficiencyRemoval efficiency, finally, according to the removal efficiency improvement of each swing angleMechanical apparatusSpace heating and ventilation safety systemsAir conditioningIndustrial engineering

The application provides an air conditioning unit control method and device, and an air conditioning unit. An indoor unit of the air conditioning unit is provided with an air outlet which is providedwith an air guide component; and an air duct communicating with the air outlet is internally provided with a purification unit, and the indoor unit is further provided with an air quality detection unit internally. The method comprises the steps of controlling the air quality detection unit for detecting air quality; enabling the purification unit for purifying gas in the air duct according to theair quality; detecting the removal efficiency of contaminants by the purification unit when the air guide component is swung to each swing angle; and the swing of the air guide component is controlled according to the removal efficiency at each swing angle. According to the method, the removal efficiency of the contaminants can be improved, and the environmental comfort of space where the air conditioning unit is located is improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Power management systems and methods for use in an oxygen concentrator

Described herein are various embodiments of an oxygen concentrator system In some embodiment, an oxygen concentrator system includes improved charging and battery control circuits.

Owner:INOVA LABS INC

Air intake device for internal combustion engine

ActiveUS20180347522A1Speed up gas flowReduce flowInternal combustion piston enginesCylinder headsInternal combustion engineControl valves

An air intake device for an internal combustion engine of the present invention includes a water discharge passage extending from a bottom surface of a control valve housing part recessed in a housing passage forming part of an air intake passage to an air intake port. The water discharge passage is formed independently from the air intake passage, and includes: a water collection groove recessed in the bottom surface; a water discharge hole formed penetrating a cover of a valve control housing; and a water discharge hole penetrating a flange part of an insert inserted into the air intake port. The downstream end of the water discharge hole is connected to a space defined between an air intake port inner wall surface and an insert cylindrical part.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com