Continuous drying equipment for cherry tree seeds

A technology for drying equipment and seeds, which is applied in the field of continuous drying equipment for cherry tree seeds, which can solve the problems of uneven drying and low drying efficiency, and achieve the effects of high drying efficiency, high production efficiency, and avoiding seed accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

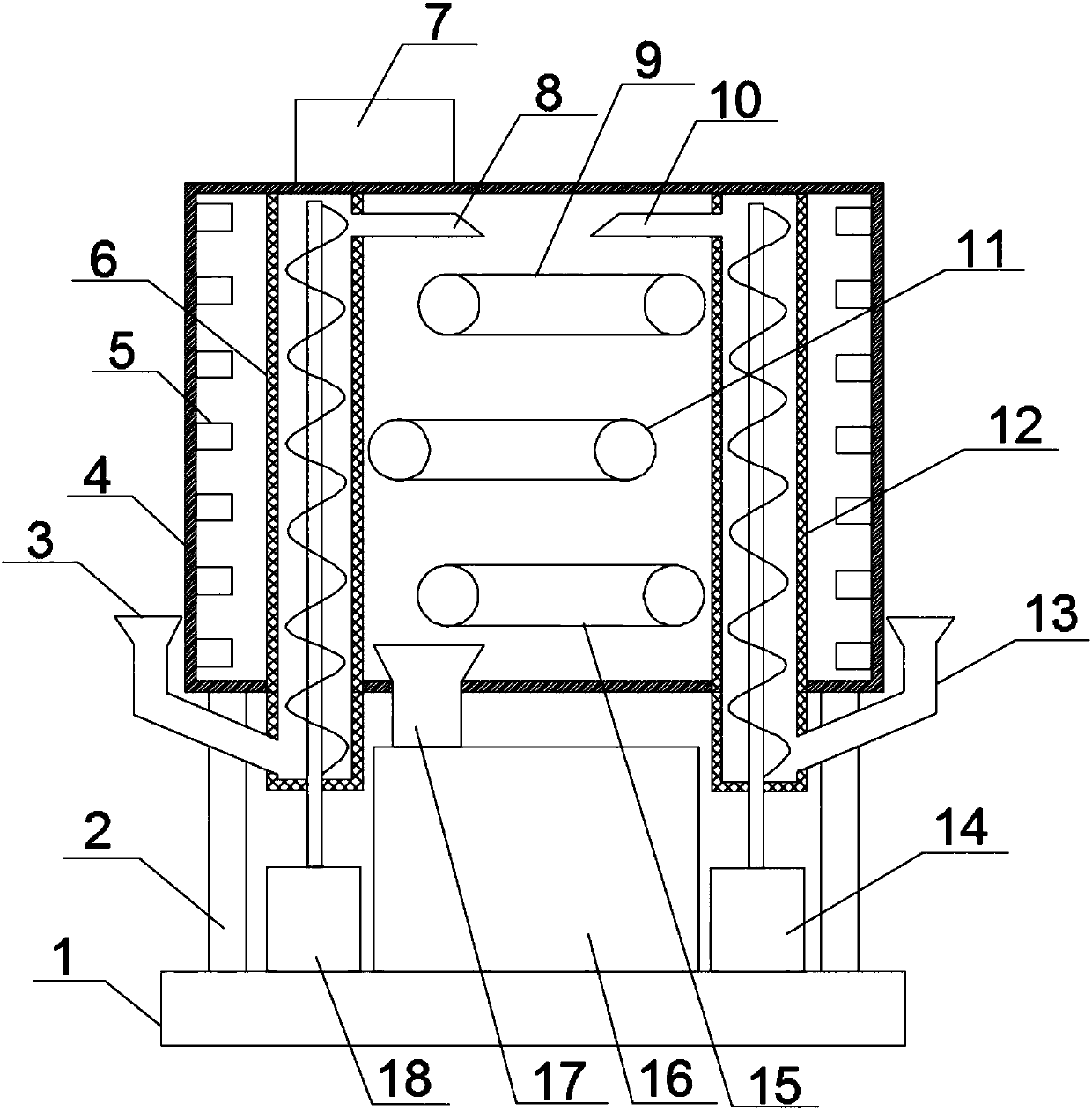

[0020] A continuous drying equipment for cherry tree seeds, comprising a box body 4, a first screw conveyor 6 and a second screw conveyor 12 are vertically arranged in the box body 4, the first screw conveyor 6 and the second screw conveyor The casings of the two screw conveyors 12 are all ventilation nets, and the tops of the first screw conveyor 6 and the second screw conveyor 12 are all fixed with the inner wall of the casing 4, and the bottom ends all stretch out from the casing 4. The first screw conveyor The lower end of 6 is provided with the first feed funnel 3 that communicates with the outside, and the lower end of the second screw conveyor 12 is provided with the second feed funnel 13 that communicates with the outside; , the middle conveyor belt 11 and the lower conveyor belt 15, the blanking end of the upper conveyor belt 9 is located above the middle conveyor belt 11, the blanking end of the middle conveyor belt 11 is positioned above the lower conveyor belt 15, a...

Embodiment 2

[0023] Based on Embodiment 1, the air outlet pipe 5 is spirally distributed along the side wall of the box body 4, which is conducive to uniform distribution of hot air in the box body 4, so that the seeds are heated evenly, and the uniformity of drying is further improved.

Embodiment 3

[0025] Based on Embodiment 1, a base 1 is provided under the box body 4 , and a support column 2 for supporting the box body 4 is fixed on the base 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com